Professional Documents

Culture Documents

Electroplating Work Instruction

Uploaded by

jeganOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electroplating Work Instruction

Uploaded by

jeganCopyright:

Available Formats

WORK INSTRUCTION TDP/WI/EPT/01

ISSUE: 01

ELECTRO PLATING DATE:17/11/09

1.0 INSTRUCTIONS

1.1 Ensure the proper electrical contacts of cathode and anode of respective vats.

1.2 Switch on the main power supply and exhuast.

1.3 Switch on the solution filter pump.

1.4 Swicth on the filtered air Blower.

1.5 Check the Code numbers, Shop order, Passed quantity, Required finish, Drawings.

Components to be plated as per spec specified in the components drawing.

1.6 Wire the fabricated components which are required to be plated in vats with the

help of sutiable copper wire.

1.7 Load the fabricated components for prescribe plating process as per process flow

chart. Record the details in control documents No. 1. Pack the passed quantity in

sutible packing paper with packng slip send to the concerned stores with passed

copy of Delivery ticket.

2.0 DOCUMENTS NEEDED

2.1 Components drawing, process layout, process specification, delivery ticket, process

flow chart, plant repair card.

3.0 AIDS NEEDED

3.1 Copper wire for wiring, wire cutter, polythylene bag, craft paper.

4.0 RECORDS

4.1 Incoming register, pink copy entry register, register for passed components.

5.0 PRECAUTION

5.1 Handle the components carefully, follow the safety precaution as per safety manual

while carrying components, chemical etc.

Revision 0 1 2 3 4 5

Date 1/1/2004 17/11/2009

Signature Designation Page 3/18

Prepared

AEE (F)

Checked M (PCB & F) TDP Division Bangalore

Approved CMR (PCB & F)

You might also like

- High Efficiency RF and Microwave Solid State Power AmplifiersFrom EverandHigh Efficiency RF and Microwave Solid State Power AmplifiersRating: 1 out of 5 stars1/5 (1)

- Data Sheet - Gen Protection PanelDocument3 pagesData Sheet - Gen Protection PanelArnold StevenNo ratings yet

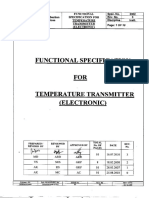

- FS 3302 - FS-Temperature Transmitter (Electronic)Document10 pagesFS 3302 - FS-Temperature Transmitter (Electronic)Binu ManiNo ratings yet

- Modern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantFrom EverandModern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantA. SherryRating: 4 out of 5 stars4/5 (5)

- Data Sheet - Gen Synchronising PanelDocument3 pagesData Sheet - Gen Synchronising PanelArnold StevenNo ratings yet

- Panasonic BGA IC Seminar 2013 - Resolder, Scule Si Cum Se Face PDFDocument45 pagesPanasonic BGA IC Seminar 2013 - Resolder, Scule Si Cum Se Face PDFCristea GabrielNo ratings yet

- Maintaining Electrical SystemsDocument32 pagesMaintaining Electrical Systemsdinie90100% (2)

- Cable Gland, Cable & Wire Installation ProcedureDocument14 pagesCable Gland, Cable & Wire Installation ProcedureIsaalexNo ratings yet

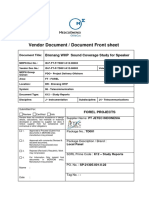

- Su Tu Trang Full Field Development Phase 1 Project: Vendor Front SheetDocument6 pagesSu Tu Trang Full Field Development Phase 1 Project: Vendor Front SheetRudolph RednoseNo ratings yet

- Sop For Electrical Positive IsolationDocument14 pagesSop For Electrical Positive IsolationKaushik PrakashNo ratings yet

- ELT-01-EP-TS-0003 - Specification For Piping Material - R1Document52 pagesELT-01-EP-TS-0003 - Specification For Piping Material - R1jorgekarlosprNo ratings yet

- Piping Specification for LNG Terminal ProjectDocument27 pagesPiping Specification for LNG Terminal ProjectjorgekarlosprNo ratings yet

- Flare Jide9Document17 pagesFlare Jide9samuel100% (3)

- Double Pipe and Multitube IP 6-2-1 Hairpin Heat Exchangers: Section 1 - GeneralDocument7 pagesDouble Pipe and Multitube IP 6-2-1 Hairpin Heat Exchangers: Section 1 - Generalhcsharma1967No ratings yet

- MTPL-OM-PPM-CL-003 - PPM Checklist For AFUDocument2 pagesMTPL-OM-PPM-CL-003 - PPM Checklist For AFUVeerendra YduvanshiNo ratings yet

- Vendor Document Cover SheetDocument75 pagesVendor Document Cover Sheetmujahed_muhammedNo ratings yet

- Iecex Kem 09.0034XDocument7 pagesIecex Kem 09.0034XFrancesco_CNo ratings yet

- (TW-P6-F14) - Testing Commissioning of Distribution Board, Feeder PilarsDocument3 pages(TW-P6-F14) - Testing Commissioning of Distribution Board, Feeder PilarsGlames WilliamsNo ratings yet

- 112-EP4-PE-IsS-0402 - Datasheet For Analyzer With ShelterDocument108 pages112-EP4-PE-IsS-0402 - Datasheet For Analyzer With Sheltercre1982100% (1)

- Proceso Cold RollingDocument7 pagesProceso Cold RollingFernando FiallosNo ratings yet

- MTPL-OM-PPM-CL-007 - PPM Checklist For TrackerDocument2 pagesMTPL-OM-PPM-CL-007 - PPM Checklist For TrackerVeerendra YduvanshiNo ratings yet

- 160KW 415V Induction MotorDocument2 pages160KW 415V Induction MotorManisha KharwarNo ratings yet

- PT 1968B MPD Parts ManualDocument28 pagesPT 1968B MPD Parts ManualBrandon CatronNo ratings yet

- Documentation Requirements for Liquid-Filled TransformersDocument2 pagesDocumentation Requirements for Liquid-Filled Transformersjavila21No ratings yet

- P01-E08 Rev 1 Jun 2001 Cold Springing and Expansion JointsDocument6 pagesP01-E08 Rev 1 Jun 2001 Cold Springing and Expansion Jointsjhunkujha11No ratings yet

- Agar Corporation Instruction Manual FORDocument77 pagesAgar Corporation Instruction Manual FORAnand SasidharanNo ratings yet

- 903240-001 EPZ Pump Manual Rev3Document34 pages903240-001 EPZ Pump Manual Rev3jaimesilva1972No ratings yet

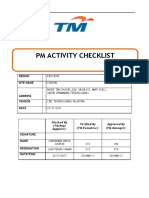

- PM Activity Checklist: Region Site NameDocument11 pagesPM Activity Checklist: Region Site NameJUNITA MUSLIHANo ratings yet

- 199-GST-0101-RevA - Electrical MV LV Transformers SpecificationDocument14 pages199-GST-0101-RevA - Electrical MV LV Transformers Specificationdhanny ma100% (1)

- Supplier - Turnover - DocumentationDocument4 pagesSupplier - Turnover - DocumentationBrian MarinNo ratings yet

- ECP200 BASE 2 / 4 User ManualDocument28 pagesECP200 BASE 2 / 4 User Manualroksandic.damirNo ratings yet

- Service Manual: Split Type Wall Mounted Air ConditionerDocument44 pagesService Manual: Split Type Wall Mounted Air ConditionerBane RadovicNo ratings yet

- BHA Equipment SelectionDocument152 pagesBHA Equipment SelectionKarim IsmailNo ratings yet

- E-003B Rev C2-MIPS Distribution BoardDocument2 pagesE-003B Rev C2-MIPS Distribution BoardMusab ShabbirNo ratings yet

- APH Maintenance ManualDocument11 pagesAPH Maintenance ManualGanesh EswaranNo ratings yet

- Nigeria LNG Limited Piping Components ProcedureDocument16 pagesNigeria LNG Limited Piping Components ProcedureMathias OnosemuodeNo ratings yet

- IOC/M&I/ELECT/E/18/2012 Electrical Motor Operated Valve Actuator & Master Station Rev.-0 Page 21 of 27Document6 pagesIOC/M&I/ELECT/E/18/2012 Electrical Motor Operated Valve Actuator & Master Station Rev.-0 Page 21 of 27Anonymous fLgaidVBhzNo ratings yet

- Equipment Manual: Product Functional Specifications and Installation ManualDocument21 pagesEquipment Manual: Product Functional Specifications and Installation ManualGee100% (1)

- On-Load Tap-Changers, Types UC and VUC With Motor-Drive Mechanisms, Type BUE/BULDocument28 pagesOn-Load Tap-Changers, Types UC and VUC With Motor-Drive Mechanisms, Type BUE/BULwinston11No ratings yet

- 4Z4TJDocument16 pages4Z4TJBimal Chutia100% (1)

- 7711-21B Change 1 PDFDocument20 pages7711-21B Change 1 PDFAkbar BaharuddinNo ratings yet

- Service Report - PMS of Line 2 Cooler Exhaust Fan and Raw Mill EP Fan - ACS600 VFDDocument8 pagesService Report - PMS of Line 2 Cooler Exhaust Fan and Raw Mill EP Fan - ACS600 VFDJunie V. TayrusNo ratings yet

- MARAFIQ Pipe Specification Rev 1Document17 pagesMARAFIQ Pipe Specification Rev 1jaseelNo ratings yet

- Make a Cheap Hot Air Soldering StationDocument4 pagesMake a Cheap Hot Air Soldering Stationkasiyo kasiyoNo ratings yet

- Ofc - 18T9918 - Sarviz 47Document9 pagesOfc - 18T9918 - Sarviz 47fm429vm7x2No ratings yet

- 06 Heat ExchangerDocument2 pages06 Heat ExchangerQaisar KhaiyamNo ratings yet

- SDS-01-M-01 Heavy Fuel Oil HeaterDocument2 pagesSDS-01-M-01 Heavy Fuel Oil HeaterAJAY1381No ratings yet

- E21-C Motor Operated ValveDocument2 pagesE21-C Motor Operated Valveyskushwah16No ratings yet

- Prosedure HEX & HPWJDocument131 pagesProsedure HEX & HPWJNaniura CreationNo ratings yet

- 3011i 3511iENSMRAODocument612 pages3011i 3511iENSMRAOiclaguna6No ratings yet

- Banggood IRF 530 PA Instructions V1.4Document16 pagesBanggood IRF 530 PA Instructions V1.4Jorge MarinNo ratings yet

- 2X500 MW Neyveli New Thermal Power Project (NNTPP) Neyveli, Tamilnadu, IndiaDocument4 pages2X500 MW Neyveli New Thermal Power Project (NNTPP) Neyveli, Tamilnadu, IndiaHiltonNo ratings yet

- Calling Tender Transformer To Rectify Isolator and Ball Valve LeakageDocument6 pagesCalling Tender Transformer To Rectify Isolator and Ball Valve LeakageLim ChsNo ratings yet

- Earth Electrode Pre-Commissioning Check SheetDocument1 pageEarth Electrode Pre-Commissioning Check SheetJITHIN KRISHNAN MNo ratings yet

- WHP Sound Coverage Study For SpeakerDocument23 pagesWHP Sound Coverage Study For Speakerselamet riantoNo ratings yet

- Electrical InstallationDocument13 pagesElectrical Installation'Low Kheng Seong'No ratings yet

- Etnstci/Etnstcilf Ice/sand Protected Tanks Installation ManualDocument14 pagesEtnstci/Etnstcilf Ice/sand Protected Tanks Installation ManualRafael ReisNo ratings yet

- Technical Specs for Instrument CablesDocument24 pagesTechnical Specs for Instrument CableskarimNo ratings yet

- Control Plan Form - AIAGDocument1 pageControl Plan Form - AIAGLauris ZapNo ratings yet

- Spectek Brightener 897 4Document1 pageSpectek Brightener 897 4jeganNo ratings yet

- Operating Conditions and Functions of Nickel Plating Solution ConstituentsDocument1 pageOperating Conditions and Functions of Nickel Plating Solution ConstituentsjeganNo ratings yet

- NickelElectroplatingSOP 7 3 2015Document15 pagesNickelElectroplatingSOP 7 3 2015jeganNo ratings yet

- Sample ProjectDocument4 pagesSample ProjectMukul Singh RathoreNo ratings yet

- Spectek Brightener 897 1Document1 pageSpectek Brightener 897 1jeganNo ratings yet

- Commissions Report DetailedDocument1 pageCommissions Report DetailedjeganNo ratings yet

- Atlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFDocument57 pagesAtlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFMikku KattaNo ratings yet

- Manual On Door and Window Details For Residrntial BuildingDocument59 pagesManual On Door and Window Details For Residrntial Buildingelhekary100% (5)

- Titanium and Titanium AlloysDocument24 pagesTitanium and Titanium AlloysGuilherme FranzoiNo ratings yet