Professional Documents

Culture Documents

Project Report - D-Cut Bag

Project Report - D-Cut Bag

Uploaded by

rupeshcinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Report - D-Cut Bag

Project Report - D-Cut Bag

Uploaded by

rupeshcinCopyright:

Available Formats

KP Tech Machine (India) Pvt.Ltd.

KP TECH MACHINE (INDIA) PVT.LTD. is a part of KP TECH GROUP OF INDUSTRIES .Which is

pioneer in the field of designing, manufacturing and exporting of PP Nonwoven fabric bag

making machine, Printing machine, slitting machine etc. For the first time in India, KP Tech has

introduced latest digital ultrasonic welding technology for PP Nonwoven industry.

KP Tech having capability of producing machine for all kind of small, medium and large scale

machines for shopping bag, shoes bag, vest bag, zipper bag as well as box type bags of PP

Nonwoven fabric in various dimension ranging from very few centimeter to several meter.

Recently KP Tech have launched the most efficient and cost effective bag printing machine in 2

color and 4 color options which can print thousands of bags a day also capable for woven sack

bags rice bag, all kind of paper bags as well as cotton bags, polyester bags etc.

EMAIL:info@ktechnonwoven.com Website :www.ktechnonwoven.com

KP TECH MACHINE (INDIA) PVT.LTD.

K-209,Vishala Land mark, Above marigold restaurant,S.P.Ring Road,

Opp-Kathwada GIDC,Nikol,

Ahmedabad-382350

CELL NO: + 91 8980001011,

EMAIL : sales@ktechnonwoven.com

EMAIL : info@ktechnonwoven.com

Website : www.ktechnonwoven.com

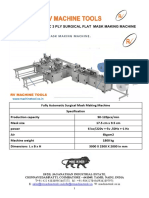

PROJECT REPORT FOR NON WOVEN FABRIC BAG MAKING MACHINE

MODEL NO :- KP-555

MACHINE PRODUCT D-CUT BAG T-SHIRT BAG

EMAIL: info@ktechnonwoven.com Website :www.ktechnonwoven.com

Features :-

This machine is adopts computer orientation, photocell tracking, operation by

man-machine interface touch. It’s adopts high wave band ultrasonic heat sealing

principle. It has functions like hem in bag orifice, punching, ultrasonic heat sealing,

cold cutting etc. It’s advanced machine for all kind of non-woven fabrics handle

shopping bag, shoes bag, haversack as 15-120 g.

TECHNICAL PARAMETER

Production speed 20-100 psc /min

Bag Length 100-800 mm (4 in to 32 in)

Bag Width 200-500mm (8in-22in)

Bag Thickness(GSM) 20-90 GSM

Power Supply 380v/220v

Total power 9 kw

Dimension 7900*1500*1800 mm

Working temp. <25°C

EMAIL: info@ktechnonwoven.com Website :www.ktechnonwoven.com

(1)Required space to keep non woven bag making machine.

→ Water and moisture proof shade

→ 10×40 square feet space for machine

Total space in loading Row material and finish Product 1000 square feet

→ RCC surface

(1) Required additional implement

→ Compressor : (2 HP)

→ Stabilizer : (12 KW)

(2) Required Workers

→ 3 (1 skilled and 2 unskilled)

(3) Raw Material

→ Non woven fabric Roll

EMAIL: info@ktechnonwoven.com Website :www.ktechnonwoven.com

Production Capacity and Cost of Production

1ST Method

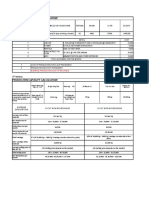

PRODUCTION CAPACITY CALCULATION

AVERAGE NO. OF BAGS THAT CAN BE MADE ON THE PER MIN 60 MIN 12 HR 25 DAYS

MACHINE

(based on a 12 hrs. working on a daily basis and 25 days

working / month) 60 3600 43200 10,80,000

COST OF PRODUCTION

S.NO DETAIL COST

1 SKILLED @ 9,000/MONTH AND 2 UNSKILLED @

1 LABOUR 4,000/MONTH 17,000

2 POWER TOTAL 9 KW POWER (PER MONTH) 8,500

3 RENTALS 1000 SQ FEET AREA 9,000

4 BANK INTREST ON LOAN 15 LACS @ 12% PER ANNUM 15,000

5 MISC ADMINISTRATION AND OTHER EXPENSES 18,000

TOTAL EXPENSES FOR THE MONTH 67,500

1 COST OF PRODUCTION TOTAL EXP PER MONTH 67,500

2 PRODUCTION CAPACITY PER MONTH 10,80,000

AVERAGE PRODUCTION COST OF EACH BAG 0.06

2ND Method

PRODUCTION CAPACITY CALCULATION

60

60 gsm Min 12Hr 25Days

Bag Ech bag per Per Per

60gsm fabric bag size 12” x 16 size Wt hr day MONTH

12×16bag

wt

12×16 14gr

AVERAGE (Kg) material processing ECH BAG WT.14 GRAM

Bag 1000gr/14gr

(based on a 12 hr working on a daily basis FOR 60 GSM

and 25 days working / month) 60 720

1kg=60bag Kg Kg 18,000 Kg

U-CUT NON WOVEN

EXPENSE DESCRIPTION

D-CUT NON WOVEN BAGS BAGS

Average cost of Row material 114 per Kg 114 per Kg

Per month cost of material 114 x 18,000 = 2052000 114.00 x 18,000 = 2052000

Production cost per month 67,500 67,500

Total expenses for one month with material 2119500 2119500

5 % of 18,000 Kg = 900 Kg (Wastage can also sale at 10% of 18000 kg 1800 Kg (wastage

Total wastage low price) can also sale at low price

After wastage ready material 17,100 Kg 16,200 Kg

145 (selling price depends on the

Average selling price of Bag per Kg 135 (Selling price depend on the market) market)

Total selling price 135 x 17,100 = 2308500 145 x 16200 = 2349000

Net Realization per month 2308500 -2119500 = 189000 2349000-2119500=229500

The above is approx. calculation as per our method. In different place the raw material cost comes differ then the

calculation will be changed accordingly.

,

Non-woven T-Shirt Punching machine

OR

U-CUT BAG PUNCHING MACHINE

TECHNICAL PARAMETER

. MODEL- KP-22

Push button & foot control switch

PP sheet and LR switch

Press machine with 2 H.P motor

Side adjustment

Speedy working

EMAIL: info@ktechnonwoven.com Website :www.ktechnonwoven.com

You might also like

- Project Profile On Tissue Paper ManufacturingDocument5 pagesProject Profile On Tissue Paper ManufacturingKamalam Cloudsoft100% (4)

- Business Plan For Hot Pepper BusinessDocument5 pagesBusiness Plan For Hot Pepper Businessoluwatobiloba esan100% (1)

- Paper Napkin Project ReportDocument5 pagesPaper Napkin Project ReportSantosh Kodere75% (4)

- Ipc SM 785sDocument3 pagesIpc SM 785sWandyy GonçalvesNo ratings yet

- Ncstudio V9 Programming Manual-R5.1Document102 pagesNcstudio V9 Programming Manual-R5.1beanib83No ratings yet

- Viral Press DocumentationDocument16 pagesViral Press DocumentationbizmaidaNo ratings yet

- Sikkim Manipal University ProjectDocument7 pagesSikkim Manipal University ProjectAnil Kumar SinghNo ratings yet

- GSMA - Global Mobile Trend 2017-2025 PDFDocument105 pagesGSMA - Global Mobile Trend 2017-2025 PDF123 mlmbNo ratings yet

- New Microsoft Excel WorksheetDocument1 pageNew Microsoft Excel WorksheetPranayNo ratings yet

- Eco Friendly Non Woven Mask Making Machine PDFDocument4 pagesEco Friendly Non Woven Mask Making Machine PDFJ MurugadasanNo ratings yet

- Fully Automatic Elastic Face Mask Machine PDFDocument4 pagesFully Automatic Elastic Face Mask Machine PDFGitanjali DubeyNo ratings yet

- KP Tech Machine (India) PVT - LTD: KP-1000 &1 Fully Automatic Non Woven Tie Face Mask MachineDocument4 pagesKP Tech Machine (India) PVT - LTD: KP-1000 &1 Fully Automatic Non Woven Tie Face Mask MachineRicardo PirelaNo ratings yet

- CHAPTER-III-2 (Draft)Document11 pagesCHAPTER-III-2 (Draft)Jenny PabualanNo ratings yet

- Project Report: 24/113/18/2A, LAXMINARAYANA NAGAR, IDA UPPAL, HYDERABAD-500039Document4 pagesProject Report: 24/113/18/2A, LAXMINARAYANA NAGAR, IDA UPPAL, HYDERABAD-500039avik chatterjeeNo ratings yet

- Sanitary PadDocument13 pagesSanitary PadSatpaul PathakNo ratings yet

- Software Infotech: (Computer Assemble and Service)Document3 pagesSoftware Infotech: (Computer Assemble and Service)suvarna rajeshNo ratings yet

- Planing MTG 2Document7 pagesPlaning MTG 2Ashraf AlamNo ratings yet

- Proforma Invoice-22th, July 2020Document5 pagesProforma Invoice-22th, July 2020Daniel Will Morales GuerreroNo ratings yet

- MV Enterprises: Project & Feasibility ReportDocument7 pagesMV Enterprises: Project & Feasibility ReportMaa LaxmiNo ratings yet

- Planing MTG 2Document7 pagesPlaning MTG 2Ashraf AlamNo ratings yet

- 3 Ply Flat Surgical Mask Making Machine. C A P-9 0 - 1 2 0 N o S / M I NDocument6 pages3 Ply Flat Surgical Mask Making Machine. C A P-9 0 - 1 2 0 N o S / M I NYaman MHNo ratings yet

- VSM Final Real 2Document16 pagesVSM Final Real 2Hasan WaqarNo ratings yet

- Elastic TapesDocument11 pagesElastic TapesVasantha Kumar.JNo ratings yet

- My ResearchDocument2 pagesMy ResearchnishantNo ratings yet

- Dry Oyster Mushroom Production B-PlanDocument14 pagesDry Oyster Mushroom Production B-PlanAmruta WadatkarNo ratings yet

- BlastDesign3 22305Document1 pageBlastDesign3 22305Reza KomarullohNo ratings yet

- Magramo Lusong CarpentryDocument3 pagesMagramo Lusong CarpentryRonnie ManaoNo ratings yet

- Machines Cost Rate (Bag/min) Rate (Bag/hr)Document5 pagesMachines Cost Rate (Bag/min) Rate (Bag/hr)Devang PrakashNo ratings yet

- Story of A GarmentDocument14 pagesStory of A GarmentArunraj ArumugamNo ratings yet

- Expenses Amount: Projected Profitability Statement For 90 ML Paper CupDocument1 pageExpenses Amount: Projected Profitability Statement For 90 ML Paper CupPrince SantoNo ratings yet

- Tisse Paper - Report - OrganizedDocument14 pagesTisse Paper - Report - Organizedsani_454296177No ratings yet

- Royal Cashew Nut FactoryDocument2 pagesRoyal Cashew Nut FactoryGarg AgamNo ratings yet

- Laundry CalculationsDocument2 pagesLaundry CalculationsJaffar AliNo ratings yet

- Sino Bangla Training ElementsDocument6 pagesSino Bangla Training ElementsShakil HassanNo ratings yet

- Agarbatti Making MachineDocument2 pagesAgarbatti Making Machineajay prasadNo ratings yet

- Quotation For Over Head Tank Repair 18FT Weight X 25FT LengthDocument1 pageQuotation For Over Head Tank Repair 18FT Weight X 25FT LengthAbdullahi AwwalNo ratings yet

- Detail For LoanDocument1 pageDetail For LoanlhiuahauNo ratings yet

- Agarbatti Making MachineDocument12 pagesAgarbatti Making Machinehussen seidNo ratings yet

- Rab dANA HIBAH Apbd 2019 DISETUJUIDocument4 pagesRab dANA HIBAH Apbd 2019 DISETUJUIAli SyahbanaNo ratings yet

- Scale Up Plan CuttingDocument9 pagesScale Up Plan CuttingbhadavNo ratings yet

- Woollen Mufflers Knitted: NtroductionDocument4 pagesWoollen Mufflers Knitted: NtroductionTaher BarwaniNo ratings yet

- Hot and Cold Lamination Machine ProjectReportDocument4 pagesHot and Cold Lamination Machine ProjectReportIndhu SharmaKSNo ratings yet

- Capacity Report FormatDocument9 pagesCapacity Report FormatsaimaNo ratings yet

- Project Profile On G. P. Bucket: Dcdi-Mzfpur - Dcmsme@gov - in WWW - Msmedimzfpur.bih - Nic.inDocument8 pagesProject Profile On G. P. Bucket: Dcdi-Mzfpur - Dcmsme@gov - in WWW - Msmedimzfpur.bih - Nic.inAMIT PRAJAPATINo ratings yet

- Roll To Roll Lamination Project ReportDocument3 pagesRoll To Roll Lamination Project ReportIndhu SharmaKSNo ratings yet

- Plastic CratesDocument9 pagesPlastic CratesfawwazNo ratings yet

- GOLDEN TERRY ProfileDocument15 pagesGOLDEN TERRY ProfileMuru GanNo ratings yet

- Fully Automatic Cashew Cutting MachineDocument11 pagesFully Automatic Cashew Cutting MachineLadrilleraNo ratings yet

- Unique PBAGDocument11 pagesUnique PBAGPurusotam TumulaNo ratings yet

- Vermihouse POWDocument4 pagesVermihouse POWMarlon Manaya GarriguesNo ratings yet

- Leatherbelt 140226061622 Phpapp01 PDFDocument9 pagesLeatherbelt 140226061622 Phpapp01 PDFshyguy30No ratings yet

- Adhesive Bopp Tape PDFDocument8 pagesAdhesive Bopp Tape PDFjitendrajain161050% (2)

- Compostable Bag Udyami - Org.inDocument24 pagesCompostable Bag Udyami - Org.inAndreea DeeaNo ratings yet

- UntitledDocument21 pagesUntitledRohan ChavanNo ratings yet

- BTL ActivityDocument12 pagesBTL ActivityManjunathNo ratings yet

- Full Automatic Incense Stick Making MachineDocument9 pagesFull Automatic Incense Stick Making Machineprince kumarNo ratings yet

- Venture Pearl Particulars 01.03.2023Document1 pageVenture Pearl Particulars 01.03.2023avishkar guptaNo ratings yet

- Project Work Cattle Shed QuoteDocument2 pagesProject Work Cattle Shed QuoteramakrishnaNo ratings yet

- Produk PT. KP E-Katalog (TM-PD-2021)Document64 pagesProduk PT. KP E-Katalog (TM-PD-2021)wawan1010No ratings yet

- Cash Flow V.1.4Document29 pagesCash Flow V.1.4sigit l.prabowoNo ratings yet

- Penawaran Paket Pekerjaan Back Walldrop Dan Neon Box Akrilik CoolpadDocument1 pagePenawaran Paket Pekerjaan Back Walldrop Dan Neon Box Akrilik CoolpadThe Killa CHNo ratings yet

- Understanding Plastics Recycling: Economic, Ecological, and Technical Aspects of Plastic Waste HandlingFrom EverandUnderstanding Plastics Recycling: Economic, Ecological, and Technical Aspects of Plastic Waste HandlingNo ratings yet

- How To Find An Applicant's UEI Within Grants - Gov - Grants - Gov Community BlogDocument3 pagesHow To Find An Applicant's UEI Within Grants - Gov - Grants - Gov Community BlogTuhin DeyNo ratings yet

- Ua 747Document9 pagesUa 747Noe Madrigal FriasNo ratings yet

- A Guide To Mpeg Fundamentals and Protocol Analysis: Updated With Qos/Qoe Diagnostics and TroubleshootingDocument108 pagesA Guide To Mpeg Fundamentals and Protocol Analysis: Updated With Qos/Qoe Diagnostics and Troubleshootinginfo gear4No ratings yet

- ds4200 DatasheetDocument30 pagesds4200 Datasheetehtisham1No ratings yet

- Blancco Corporate Presentation - Lenovo PDFDocument15 pagesBlancco Corporate Presentation - Lenovo PDFPaulSilvaNo ratings yet

- A10 DS Thunder TPSDocument13 pagesA10 DS Thunder TPSJimmy LiuNo ratings yet

- Cs-302: Software Engineering (Se)Document5 pagesCs-302: Software Engineering (Se)Saad GhouriNo ratings yet

- ODM Footer OptionsDocument5 pagesODM Footer OptionsBoleslaw KarczmarekNo ratings yet

- Cyber SecurityDocument34 pagesCyber SecurityShubhra ShahNo ratings yet

- Process Chain StepsDocument1 pageProcess Chain StepsJaguarNo ratings yet

- Robust Air Interface Signaling Feature Parameter DescriptionDocument23 pagesRobust Air Interface Signaling Feature Parameter DescriptionDominikus MadyaNo ratings yet

- Sursa Reglabila Cu Lm317Document8 pagesSursa Reglabila Cu Lm317Mr CrossplaneNo ratings yet

- Chapter2 - Part1 - SetDocument59 pagesChapter2 - Part1 - SetliasakinahNo ratings yet

- HomescapesDocument2 pagesHomescapesJohn LivingNo ratings yet

- Hyduino Automated Hydroponics With An Arduino PDFDocument12 pagesHyduino Automated Hydroponics With An Arduino PDFMarius DanilaNo ratings yet

- ADSL Modem:Router - PC World PDFDocument11 pagesADSL Modem:Router - PC World PDFAndrew BaranNo ratings yet

- Sindh Public Service Commission Thandi Sarak, Hyderabad: Shahroz Muhammad AkramDocument4 pagesSindh Public Service Commission Thandi Sarak, Hyderabad: Shahroz Muhammad AkramKhanNo ratings yet

- Two-Stage Least Squares (2SLS)Document7 pagesTwo-Stage Least Squares (2SLS)Mohimk MohammadNo ratings yet

- Submitted By: Batch 11Document35 pagesSubmitted By: Batch 11Amarnath ReddyNo ratings yet

- Project On - ORS: DevelopedDocument4 pagesProject On - ORS: DevelopedPallavNo ratings yet

- Lesson 01 - Introducing Windows 7Document35 pagesLesson 01 - Introducing Windows 7Z OureelNo ratings yet

- Ilsucatiirwy10: Santa Cruz SCR Santa Cruz SCR 113.60Document1 pageIlsucatiirwy10: Santa Cruz SCR Santa Cruz SCR 113.60Gui VecchiioNo ratings yet

- An8002 Program Isp Code in Ldrom en Rev1.00Document12 pagesAn8002 Program Isp Code in Ldrom en Rev1.00Charu SrivastavaNo ratings yet

- "Flexi" Sp3 - 3E: Security Control PanelDocument43 pages"Flexi" Sp3 - 3E: Security Control Panelcarlos lourencoNo ratings yet

- UIE Academic Unit-1: Bachelor of Engineering (CSE, CSE-IBM, IT) Engineering Graphics Using CAD MEP-117Document20 pagesUIE Academic Unit-1: Bachelor of Engineering (CSE, CSE-IBM, IT) Engineering Graphics Using CAD MEP-117Mukul RathoreNo ratings yet