Professional Documents

Culture Documents

Flange #: Plant: ID Code: Nomenclature: Flange Calculation According To EN 1591-1:2001 + A1:2009

Flange #: Plant: ID Code: Nomenclature: Flange Calculation According To EN 1591-1:2001 + A1:2009

Uploaded by

benssjOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flange #: Plant: ID Code: Nomenclature: Flange Calculation According To EN 1591-1:2001 + A1:2009

Flange #: Plant: ID Code: Nomenclature: Flange Calculation According To EN 1591-1:2001 + A1:2009

Uploaded by

benssjCopyright:

Available Formats

LJC s.a.r.l. date: 14.05.

2014

4 et 6, rue de Bièvre - BP 40046 calculated: -

92163 ANTONY Cedex checked: -

FRANCE revision: -

flange #: -

plant: -

ID code: -

nomenclature: -

Flange calculation according to EN 1591-1:2001 + A1:2009

test condition: 20 °C 44 bar

load condition 1: 206 °C 18 bar

load condition 2: 210 °C 26 bar

bolts: G41400 1Cr-1/5Mo (A193 B7)

16 x M20 (EN ISO 4014)

gasket: MPR® GASKET 'SP' PETRO 4,0mm

363 x 323 x 4,5 mm (2 pieces)

tightening device: torque wrench = wrench with measuring of torque

(only)

recommended assembly presetting: 400 Nm 0,229 mm 1988 kN

min. required assembly presetting: 245 Nm 0,140 mm 1217 kN

max. allowable assembly presetting: 419 Nm 0,239 mm 2080 kN

max. load ratio bolts: 0,88 (assembly)

max. load ratio flange 1: 0,96 (assembly)

max. load ratio flange 2: 0,96 (assembly)

max. load ratio gasket: 0,33 (assembly)

compliance of min. required gasket stress: 1,00 (assembly)

remarks:

To model the flange with tube plate as practical as possible, the depth of the recesses has been

reduced so that the seals are in the main power circuit. To model the grip length and the thermal

expansion of the tube plate correctly, the height of the tube sheet has been taken into account by

expansion sleeves. Reducing the clamping length of the changes in the recesses is balanced with

the sleeve length.

calculated checked checked customer checked third-party

division amtec amtec

name - -

date 14.05.2014 14.05.2014

signature

TEMES fl.cal (Ver: 7.01) Page 1 print date: 20.05.2014

LJC s.a.r.l. date: 14.05.2014

4 et 6, rue de Bièvre - BP 40046 calculated: -

92163 ANTONY Cedex checked: -

FRANCE revision: -

flange #: -

plant: -

ID code: -

nomenclature: -

Flange calculation according to EN 1591-1:2001 + A1:2009

input values

loads

assembly test cond. load cond.1 load cond.2

temperature T 20 20 206 210 °C

internal pressure p 0 4,4 1,8 2,6 MPa

additional forces according EN 1092-1

external axial force FA 0 0 174 174 kN

external bending moment MA 0 0 0 0 kNm

remarks on loads For all components the same temperature is applied. Covering

additional loads according to DIN EN 1092-1 considered.

geometry

flange 1

type weld-neck flange

hub conical hub

code -

nominal pressure / nominal size -

blind hole no

outer diameter flange d4 440,00 mm

bolt circle diameter d3 398,00 mm

inner diameter flange d0 303,80 mm

diameter of bolt hole d5 22,00 mm

thickness of flange ring bF 35,00 mm

thickness of wall eS 10,00 mm

wall thickness at thick end of hub e2 18,00 mm

lenght of conical hub lH 32,00 mm

type of raised faces type F - recess

code DIN 2633

nominal pressure / nominal size PN16/DN50

height of raised face f1 0,00 mm

depth of recess f3 3,00 mm

outer diameter raised face d1 440,00 mm

outer diameter recess Y 366,00 mm

remarks on flange 1

flange 2

type weld-neck flange

hub conical hub

code -

nominal pressure / nominal size -

blind hole no

outer diameter flange d4 440,00 mm

bolt circle diameter d3 398,00 mm

inner diameter flange d0 303,80 mm

diameter of bolt hole d5 22,00 mm

thickness of flange ring bF 35,00 mm

thickness of wall eS 10,00 mm

wall thickness at thick end of hub e2 18,00 mm

lenght of conical hub lH 32,00 mm

type of raised faces type F - recess

TEMES fl.cal (Ver: 7.01) Page 2 print date: 20.05.2014

LJC s.a.r.l. date: 14.05.2014

4 et 6, rue de Bièvre - BP 40046 calculated: -

92163 ANTONY Cedex checked: -

FRANCE revision: -

flange #: -

plant: -

ID code: -

nomenclature: -

Flange calculation according to EN 1591-1:2001 + A1:2009

code EN 1092-1 (2008)

nominal pressure / nominal size PN16/DN50

height of raised face f1 0,00 mm

depth of recess f3 3,00 mm

outer diameter raised face d1 440,00 mm

outer diameter recess Y 366,00 mm

remarks on flange 2

bolts

type of bolts screw

code EN ISO 4014

thread M20

pitch pt 2,50 mm

nominal diameter dB0 20,00 mm

basic pitch diameter dB2 18,38 mm

effekive diameter dBe 17,65 mm

number of bolts nB 16 -

clamping length lb 102,00 mm

diameter internal bolt di 0,00 mm

remarks on bolts

gasket

type of gasket Metal jacketed gasket with layers

quantity of gaskets 2,00

inner diameter inner ring dG0 323,00 mm

inner diameter gasket dG1 323,00 mm

outer diameter gasket dG2 363,00 mm

outer diameter centerring ring dG3 363,00 mm

gasket thickness eG 4,50 mm

rubber lining 0,00 mm

remarks on gasket

extension sleeve

inner diameter di 22,00 mm

outer diameter da 44,00 mm

length h 29,00 mm

remarks on extension sleeve Into account the level of the tube plate by extension sleeves.

materials

material flange

material name/number AF 42 (C22 1.0402)

code EN 10083-2 (1996-10)

form of manufacture Aciers pour trempe et revenu

austenitic no

cast no

assembly test cond. load cond.1 load cond.2

temperature T F1 20 20 206 210 °C

strength parameter Rp0,2T 245 245 204 202 MPa

strength parameter Rp1,0T MPa

strength parameter RmT 440 440 403 401 MPa

TEMES fl.cal (Ver: 7.01) Page 3 print date: 20.05.2014

LJC s.a.r.l. date: 14.05.2014

4 et 6, rue de Bièvre - BP 40046 calculated: -

92163 ANTONY Cedex checked: -

FRANCE revision: -

flange #: -

plant: -

ID code: -

nomenclature: -

Flange calculation according to EN 1591-1:2001 + A1:2009

modulus of elasticity EF 206000 206000 189490 189150 MPa

thermal expansion coefficient F

1,11E-05 1,11E-05 1,21E-05 1,22E-05 K -1

minimum rupture elongation A 19 %

determination of nominal design stress according to EN 13445

nominal design stress fF 233,3 233,3 136,0 134,7 MPa

covering nominal design stress fE 233,3 233,3 136,0 134,7 MPa

remarks on flange 1

material of bolts

material name/number G41400 1Cr-1/5Mo (A193 B7)

code Section II/Part D (06/11)

form of manufacture Aciers pour éléments de fixation d ≤64 mm

austenitic no

cast no

assembly test cond. load cond.1 load cond.2

temperature TB 20 20 206 210 °C

strength parameter Rp0,2T 724 724 724 648 MPa

strength parameter Rp1,0T MPa

strength parameter RmT 862 862 862 862 MPa

modulus of elasticity EB 204000 204000 204000 195800 MPa

thermal expansion coefficient B

1,15E-05 1,15E-05 1,15E-05 1,25E-05 K -1

minimum rupture elongation A 14 %

determination of nominal design stress according to Rp0,2/SB

safety coefficient SB 1,05 1,05 1,5 1,5 -

nominal design stress fB 689,5 689,5 482,7 432,0 MPa

remarks on bolts

material of extension sleeve

material name/number AF 42 (C22 1.0402)

code EN 10083-2 (1996-10)

form of manufacture Aciers pour trempe et revenu

austenitic no

cast no

assembly test cond. load cond.1 load cond.2

temperature TD 20 20 206 210 °C

strength parameter Rp0,2T 245 245 204 202 MPa

strength parameter Rp1,0T MPa

strength parameter RmT 440 440 403 401 MPa

modulus of elasticity ED 206000 206000 189490 189150 MPa

thermal expansion coefficient D

1,11E-05 1,11E-05 1,21E-05 1,22E-05 K -1

minimum rupture elongation A 19 %

determination of nominal design stress according to EN 13445

nominal design stress fD 233,3 233,3 136,0 134,7 MPa

remarks on extension sleeve Expansion sleeves material such as pipe plate.

gasket characteristics

gasket manufacturer LJC

gasket marking MPR® GASKET 'SP' PETRO 4,0mm

material Graphit

scope 40 bar - L 0.01

assembly test cond. load cond.1 load cond.2

temperature TG 20 20 206 210 °C

TEMES fl.cal (Ver: 7.01) Page 4 print date: 20.05.2014

LJC s.a.r.l. date: 14.05.2014

4 et 6, rue de Bièvre - BP 40046 calculated: -

92163 ANTONY Cedex checked: -

FRANCE revision: -

flange #: -

plant: -

ID code: -

nomenclature: -

Flange calculation according to EN 1591-1:2001 + A1:2009

minimum gasket stress Q SMIN 86 15 15 15 MPa

max. gasket stress Q SMAX 300 300 300 300 MPa

modulus of elasticity EG 1952 1952 2241 2248 MPa

creep relaxation factor PQR 0,99 0,99 0,92 0,92 -

thermal expansion coefficient G

1,00E-05 1,00E-05 1,00E-05 1,00E-05 K -1

numerical constant of a gasket type c1 0,00 -

remarks on gasket characteristics

tightening device

nomenclature torque wrench = wrench with measuring of torque (only)

scatter of bolt force 1+

0,160 -

scatter of bolt force 1-

0,160 -

neglection of torsion moment no

number of re-assemblies NR 1 -

thread friction coefficient t

0,120 -

friction factor connecting surface n

0,120 -

remarks on tightening procedure

TEMES fl.cal (Ver: 7.01) Page 5 print date: 20.05.2014

LJC s.a.r.l. date: 14.05.2014

4 et 6, rue de Bièvre - BP 40046 calculated: -

92163 ANTONY Cedex checked: -

FRANCE revision: -

flange #: -

plant: -

ID code: -

nomenclature: -

Flange calculation according to EN 1591-1:2001 + A1:2009

calculation results

check of validity

flange 1

ratio width/heigth of flange ok

uniformity of gasket stress not ok

flange 2

ratio width/heigth of flange ok

uniformity of gasket stress not ok

effective gasket geometry

effective gasket diameter dGe 343,00 mm

effective gasket width bGe 20,00 mm

effective gasket area AGe 21551,33 mm 2

flexibilities

axial flexibility modulus of bolts XB 2,92E-02 1/mm

rotational flexibility modulus of flange 1 ZF 3,16E-05 1/mm 3

rotational flexibility modulus of flange 2 ZF 3,16E-05 1/mm 3

axial flexibility modulus of gasket XG 2,09E-04 1/mm

loads

assembly test cond. load cond.1 load cond.2

pressure force FQ 0 407 166 240 kN

axial force (addition bending moment) F R+ 0 0 174 174 kN

axial force (subtraction bending moment) F R- 0 0 174 174 kN

axial thermal expansion U 0,000 0,000 -0,008 0,010 mm

axial compliance

assembly test cond. load cond.1 load cond.2

axial compliance related to

gasket force YG 4,57E-07 4,57E-07 4,61E-07 4,67E-07 mm/N

pressure force YQ 4,87E-07 4,87E-07 5,17E-07 5,23E-07 mm/N

resulting additional force YR 4,36E-07 4,36E-07 4,62E-07 4,68E-07 mm/N

minimum forces

assembly test cond. load cond.1 load cond.2

minimum gasket force F Greq 1843 323 323 323 kN

internal forces in assembly

minimum assembly gasket force F Gdel 875 kN

required gasket force F G0req 1843 kN

required bolt force F B0req 1842 kN

gasket force (several assemblies) F G0d 875 kN

min. required assembly presetting

minimum assembly bolt force F B0min 1217 kN

corresponding bolt elongation l min 0,140 mm

corresponding torque Mmin 245 Nm

TEMES fl.cal (Ver: 7.01) Page 6 print date: 20.05.2014

LJC s.a.r.l. date: 14.05.2014

4 et 6, rue de Bièvre - BP 40046 calculated: -

92163 ANTONY Cedex checked: -

FRANCE revision: -

flange #: -

plant: -

ID code: -

nomenclature: -

Flange calculation according to EN 1591-1:2001 + A1:2009

max. allowable assembly presetting

max. allowable assembly bolt force F B0max 2080 kN

max. allowable bolt elongation l max 0,239 mm

max. allowable torque Mmax 419 Nm

definition of assembly bolt force

chosen assembly bolt force F B0nom 1988 kN

corresponding bolt elongation l nom 0,229 mm

corresponding torque Mnom 400 Nm

internal forces in subsequent condition

assembly test cond. load cond.1 load cond.2

gasket force FG 2127 433 454 323 kN

bolt force FB 2127 840 794 738 kN

gasket stress Q 86 20 21 15 MPa

internal forces in subsequent conditions resulting from FB0nom (only informative)

assembly test cond. load cond.1 load cond.2

gasket force F Gmin 1848 1397 1342 1199 kN

F Gnom 1988 1535 1468 1324 kN

F Gmax 2127 1672 1595 1449 kN

bolt force F Bmin 1848 1804 1682 1613 kN

F Bnom 1988 1941 1809 1739 kN

F Bmax 2127 2079 1936 1864 kN

gasket stress Q min 86,0 64,8 62,3 55,6 MPa

Q nom 92 71 68 61 MPa

Q max 99 78 74 67 MPa

check of thightness criteria

assembly test cond. load cond.1 load cond.2

compliance of min. required gasket stress Q min >Q smin ok ok ok ok

check of admissibility of the load ratio

assembly test cond. load cond.1 load cond.2

bolts

allowable load ration B all

1,00 1,00 1,00 1,00

load ratio B

0,88 0,31 0,42 0,44

ok ok ok ok

flange 1

allowable load ration F all

1,00 1,00 1,00 1,00

load ratio F

0,96 0,43 0,73 0,71

ok ok ok ok

flange 2

allowable load ration F all

1,00 1,00 1,00 1,00

load ratio F

0,96 0,43 0,73 0,71

ok ok ok ok

gasket

allowable load ration G all

1,00 1,00 1,00 1,00

TEMES fl.cal (Ver: 7.01) Page 7 print date: 20.05.2014

LJC s.a.r.l. date: 14.05.2014

4 et 6, rue de Bièvre - BP 40046 calculated: -

92163 ANTONY Cedex checked: -

FRANCE revision: -

flange #: -

plant: -

ID code: -

nomenclature: -

Flange calculation according to EN 1591-1:2001 + A1:2009

load ratio G

0,33 0,07 0,07 0,05

ok ok ok ok

flange rotation

flange 1 assembly test cond. load cond.1 load cond.2

min. flange rotation Fmin

0,42 0,47 0,46 0,46 °

max. flange rotation Fmax

0,49 0,54 0,53 0,52 °

flange 2 assembly test cond. load cond.1 load cond.2

min. flange rotation Fmin

0,42 0,47 0,46 0,46 °

max. flange rotation Fmax

0,49 0,54 0,53 0,52 °

TEMES fl.cal (Ver: 7.01) Page 8 print date: 20.05.2014

LJC s.a.r.l. date: 14.05.2014

4 et 6, rue de Bièvre - BP 40046 calculated: -

92163 ANTONY Cedex checked: -

FRANCE revision: -

flange #: -

plant: -

ID code: -

nomenclature: -

Flange calculation according to EN 1591-1:2001 + A1:2009

detailed calculation results

calculation parameters

flange parameters

flange 1 flange 2

pitch between bolts pB 78,15 78,15 mm

eff. diameter of bolt hole d5e 11,67 11,67 mm

eff. bolt circle diameter d3e 394,89 394,89 mm

cross-section area of flange ring AF 2290,20 2290,20 mm 2

cross-section area of loose flange ring AL 0,00 0,00 mm 2

eff. width of flange ring bF 56,43 56,43 mm

eff. diameter of flange ring dF 371,90 371,90 mm

eff. thickness of flange ring eF 33,63 33,63 mm

equ. wall thickness for flexibility eE 13,90 13,90 mm

intermediate variable 1,800 1,800 -

mean diameter shell dE 317,70 317,70 mm

lever arm correction hP 8,06 8,06 mm

lever arm hG 25,95 25,95 mm

lever arm hH 38,59 38,59 mm

lever arm hL 0,00 0,00 mm

intermediate variable 0,288 0,288 -

intermediate variable 1,087 1,087 -

intermediate variable 0,000 0,000 -

correction factor cF 0,191 0,191 -

lever arm correction hS 12,29 12,29 mm

lever arm correction hT 16,88 16,88 mm

lever arm correction hQ 12,56 12,56 mm

lever arm correction hR -1,84 -1,84 mm

correction factor kQ 0,850 0,850 -

correction factor kR -0,150 -0,150 -

rotational flexibility modulus of flange ZF 3,16E-05 3,16E-05 1/mm 3

rotational flexibility modulus of flange ZL 0,00E+00 0,00E+00 1/mm 3

bolt parameters

eff. cross-section area AB 3916,70 mm 2

axial flexibility modulus XB 2,92E-02 1/mm

gasket parameters

theoretical gasket width bGt 20,00 mm

theoretical mean gasket diameter dGt 343,00 mm

theoretical gasket area AGt 21551,33 mm 2

gasket force for calculation of width F G0 1987,61 kN

interim gasket width bGi 20,00 mm

Effective gasket width bGe 20,00 mm

Effective mean gasket diameter dGe 343,00 mm

Effective gasket area AGe 21551,33 mm 2

axial flexibility modulus XG 2,09E-04 1/mm

internal forces

loads assembly test cond. load cond.1 load cond.2

axial fluid-pressure force FQ 0 407 166 240 kN

axial force (addition bending moment) F R+ 0 0 174 174 kN

TEMES fl.cal (Ver: 7.01) Page 9 print date: 20.05.2014

LJC s.a.r.l. date: 14.05.2014

4 et 6, rue de Bièvre - BP 40046 calculated: -

92163 ANTONY Cedex checked: -

FRANCE revision: -

flange #: -

plant: -

ID code: -

nomenclature: -

Flange calculation according to EN 1591-1:2001 + A1:2009

axial force (subtraction bending moment) F R- 0 0 174 174 kN

differential axial expansion U 0,000 0,000 -0,008 0,010 mm

compliance of the joint assembly test cond. load cond.1 load cond.2

axial compliance related to FG YG 4,57E-07 4,57E-07 4,61E-07 4,67E-07 mm/N

axial compliance related to FQ YQ 4,87E-07 4,87E-07 5,17E-07 5,23E-07 mm/N

axial compliance related to FR YR 4,36E-07 4,36E-07 4,62E-07 4,68E-07 mm/N

minimum forces necessary for the gasket assembly test cond. load cond.1 load cond.2

min. gasket force in assembly F G0min 1842,64 kN

min. gasket force in sub. conditions F GImin 323,27 323,27 323,27 kN

internal forces in assembly condition assembly test cond. load cond.1 load cond.2

min. gasket force for sub. Conditions F Gdel 874,90 kN

min. gasket force for all conditions F G0req 1842,64 kN

min. bolt force for all conditions F B0req 1842,33 kN

scatter for global load above nom. value e+ 0,070 -

scatter for global load above nom. value e- 0,070 -

nominal bolt force F B0nom 1217,00 kN

check of min. bolt force FB0req ok -

max. bolt force F B0max 1302,19 kN

max. gasket force F G0max 2080,00 kN

internal forces in subsequent condition assembly test cond. load cond.1 load cond.2

max. gasket force F G0d 874,90 kN

accumulation of plastic deformation no -

checking the admissibility of the load ratio

general flange 1 flange 2

reduced max. allowable load ratio 1,00 1,00 -

intermediate variable 1,45 1,45 -

bolts assembly test cond. load cond.1 load cond.2

twisting moment applied to bolt shank Mt, B 221,96 Nm

plastic torsion modulus IB 1440,57 mm 3

bolt load ratio B

0,88 0,31 0,42 0,44 -

gasket assembly test cond. load cond.1 load cond.2

gasket load ratio G

0,33 0,07 0,07 0,05 -

flange 1 assembly test cond. load cond.1 load cond.2

equ. wall thickness for load limit eD 16,56 mm

intermediate variable Q

0 0,180955 0,126989 0,185198 -

intermediate variable R

0 0 0,077425 0,078173 -

intermediate variable cM 1,153256 1,135505 1,134236 1,122273 -

correction factor (jS=-1) cS 0,785398 0,889574 0,823925 0,855154 -

correction factor (jS=1) cS 0,785398 0,676392 0,73513 0,698369 -

intermediate variable jM 1 1 1 1 -

intermediate variable kM 1 1 1 1 -

particular value opt

1 1 1 1 -

particular value 0

0 -0,053093 -0,037259 -0,054338 -

particular value max

0,425819 0,33902 0,371296 0,341766 -

particular value min

-0,425819 -0,502773 -0,469786 -0,492656 -

TEMES fl.cal (Ver: 7.01) Page 10 print date: 20.05.2014

LJC s.a.r.l. date: 14.05.2014

4 et 6, rue de Bièvre - BP 40046 calculated: -

92163 ANTONY Cedex checked: -

FRANCE revision: -

flange #: -

plant: -

ID code: -

nomenclature: -

Flange calculation according to EN 1591-1:2001 + A1:2009

particular value Z

0,425819 0,33902 0,371296 0,341766 -

resistance of flange WF 5,75E+07 5,47E+07 3,24E+07 3,15E+07 Nmm

flange load ratio F

0,96 0,43 0,73 0,71 -

flange 2 assembly test cond. load cond.1 load cond.2

equ. wall thickness for load limit eD 16,56 mm

intermediate variable Q

0 0,180955 0,126989 0,185198 -

intermediate variable R

0 0 0,077425 0,078173 -

intermediate variable cM 1,153256 1,135505 1,134236 1,122273 -

correction factor (jS=-1) cS 0,785398 0,889574 0,823925 0,855154 -

correction factor (jS=1) cS 0,785398 0,676392 0,73513 0,698369 -

intermediate variable jM 1 1 1 1 -

intermediate variable kM 1 1 1 1 -

particular value opt

1 1 1 1 -

particular value 0

0 -0,053093 -0,037259 -0,054338 -

particular value max

0,425819 0,33902 0,371296 0,341766 -

particular value min

-0,425819 -0,502773 -0,469786 -0,492656 -

particular value Z

0,425819 0,33902 0,371296 0,341766 -

resistance of flange WF 5,75E+07 5,47E+07 3,24E+07 3,15E+07 Nmm

flange load ratio F

0,96 0,43 0,73 0,71 -

TEMES fl.cal (Ver: 7.01) Page 11 print date: 20.05.2014

You might also like

- Torque BoltDocument1 pageTorque Boltmuchamad yasin0% (1)

- Radiation Safety TrainingDocument222 pagesRadiation Safety Traininghendra100% (2)

- PHE SelectionsDocument67 pagesPHE SelectionsSelva Kumar Selva KumarNo ratings yet

- Origin of The UniverseDocument44 pagesOrigin of The UniverseLuis PazNo ratings yet

- Conveyor Systems and Equipment11Document6 pagesConveyor Systems and Equipment11benssjNo ratings yet

- Hoist CapacityDocument10 pagesHoist CapacityDheeraj ThakurNo ratings yet

- 2A?Djkhkcu: Insulation & LiningsDocument4 pages2A?Djkhkcu: Insulation & LiningsbenssjNo ratings yet

- Level 3 Assessment As Per API 579-1ASME FFS-1 For Pressure Vessel General Metal Loss by Using FEA TechniquesDocument21 pagesLevel 3 Assessment As Per API 579-1ASME FFS-1 For Pressure Vessel General Metal Loss by Using FEA TechniquesKingston RivingtonNo ratings yet

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- MDESIGN Bolt, VDI 2230 (Coupling - Bolt - CalDocument6 pagesMDESIGN Bolt, VDI 2230 (Coupling - Bolt - CalSridhar Tholasingam100% (1)

- WPS - 0601 00112 01 PDFDocument1 pageWPS - 0601 00112 01 PDFAnonymous zzMwR2aNNo ratings yet

- HE Header E535Document91 pagesHE Header E535rizal mubarokNo ratings yet

- Electrostatic - Separation by SandeepDocument10 pagesElectrostatic - Separation by SandeepSandeep GummallaNo ratings yet

- Kelvion Plate Heat Exchanger: Thermal Data For: NT100X CDL-10Document2 pagesKelvion Plate Heat Exchanger: Thermal Data For: NT100X CDL-10JafarNo ratings yet

- HE Can Warmer 3150313-173 English VersionDocument2 pagesHE Can Warmer 3150313-173 English Versiongrantday2000No ratings yet

- Pall Flange 3 - June 2020Document15 pagesPall Flange 3 - June 2020גרבר פליקסNo ratings yet

- Dockweiler BPE SpecDocument1 pageDockweiler BPE SpecRey LieNo ratings yet

- Datasheet NovarotorDocument3 pagesDatasheet NovarotorSalimNo ratings yet

- DP Flange Transmitter (Arita)Document6 pagesDP Flange Transmitter (Arita)Diki Permana SNo ratings yet

- PD MeterDocument2 pagesPD MeterjrrrrrrrrrrrNo ratings yet

- TECHNICAL DATASHEET FOR - For Supply of Amine - Plate & Frame ExchangerDocument4 pagesTECHNICAL DATASHEET FOR - For Supply of Amine - Plate & Frame Exchangerdilip matalNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1004-1AB41-7AA4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1004-1AB41-7AA4-ZOmair FarooqNo ratings yet

- Phe Spec For HR 81 91Document2 pagesPhe Spec For HR 81 91JafarNo ratings yet

- Specs T11 24Kl SSZ DepotransDocument4 pagesSpecs T11 24Kl SSZ DepotransGUSTAVONo ratings yet

- Volute Pumps Sihi: SupernovaDocument10 pagesVolute Pumps Sihi: SupernovaLuis Fernando collazosNo ratings yet

- 1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enDocument1 page1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enavinash mathurNo ratings yet

- FD TC BERMO COPOLIMERO 3943 X ÁGUA Rev01Document2 pagesFD TC BERMO COPOLIMERO 3943 X ÁGUA Rev01Guilherme ZanotelliNo ratings yet

- Data SheetDocument5 pagesData SheetRah KhanNo ratings yet

- Sizing PSV-201 301 401 501 601 701 Glycol CASE R0Document5 pagesSizing PSV-201 301 401 501 601 701 Glycol CASE R0XxavierNo ratings yet

- BoM Old ShanghaiDocument1 pageBoM Old ShanghaiMuhammad IrsyadNo ratings yet

- General: AP-A203169A Technical Specification Rev.00Document4 pagesGeneral: AP-A203169A Technical Specification Rev.00Honesto BautistaNo ratings yet

- FT Pompe KSB Etanorm 080-065-200 - enDocument5 pagesFT Pompe KSB Etanorm 080-065-200 - enSecundar UtilizatorNo ratings yet

- Volute Casing Pumps: SupernovaDocument9 pagesVolute Casing Pumps: SupernovaP. Ernesto C. GutierrezNo ratings yet

- LPDA Technical DatabookDocument5 pagesLPDA Technical DatabookTAUFIQ ARIEF NUGRAHANo ratings yet

- SYT 01aDocument6 pagesSYT 01aEfril dilen franciscoNo ratings yet

- CPP 540 Technical DairyDocument58 pagesCPP 540 Technical DairySiddhant SatpathyNo ratings yet

- CORONA P 423/424: Multi-Jet Meter - Wet RunnerDocument5 pagesCORONA P 423/424: Multi-Jet Meter - Wet RunnerDhanushka RathnasooriyaNo ratings yet

- CORONA P 423/424: Multi-Jet Meter - Wet RunnerDocument5 pagesCORONA P 423/424: Multi-Jet Meter - Wet RunnerDhanushka RathnasooriyaNo ratings yet

- CRN - 45 3 - A F G V HQQVDocument2 pagesCRN - 45 3 - A F G V HQQVWendyNo ratings yet

- InputDocument5 pagesInputTrần Văn NhânNo ratings yet

- Input Echo, Tubesheet Number 1, Description: Fixed TS ST - Out Shell DataDocument14 pagesInput Echo, Tubesheet Number 1, Description: Fixed TS ST - Out Shell Datajiroj12669No ratings yet

- Qty. Description NB 65-160/173 DF2BBAQE: Company Name: Created By: Phone: DateDocument5 pagesQty. Description NB 65-160/173 DF2BBAQE: Company Name: Created By: Phone: DatePriyanka KumariNo ratings yet

- 1LE1003 1DA43 4AB4 Datasheet enDocument1 page1LE1003 1DA43 4AB4 Datasheet enElio TavaresNo ratings yet

- Parametros de SoldaduraDocument17 pagesParametros de SoldaduraBenjamin Alvarez MedinaNo ratings yet

- 22-792-STD-37-DS-08-C Unidad Manejadora de AireDocument3 pages22-792-STD-37-DS-08-C Unidad Manejadora de AireMEGASL420No ratings yet

- U NT U NV U B: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023 REV: 2Document14 pagesU NT U NV U B: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023 REV: 2Anh KyNo ratings yet

- Melegvíz TartályokDocument5 pagesMelegvíz TartályokKovács TamásNo ratings yet

- Fe-103, Fe-104 8''Document2 pagesFe-103, Fe-104 8''Vikram JitNo ratings yet

- Input Echo, Tubesheet Number 1, Description: Fixed TS Test Shell DataDocument14 pagesInput Echo, Tubesheet Number 1, Description: Fixed TS Test Shell Datajiroj12669No ratings yet

- No.1 Dare Addendu) /I (Cryil: Memo - O No. - Wbphed Control ValvesDocument1 pageNo.1 Dare Addendu) /I (Cryil: Memo - O No. - Wbphed Control ValvesID SkechtNo ratings yet

- Company Name: Created By: Phone: Date:: Qty. Description NK 80-200/195 AA2F2KESBQQESW1Document8 pagesCompany Name: Created By: Phone: Date:: Qty. Description NK 80-200/195 AA2F2KESBQQESW1SantoshNo ratings yet

- Grundfos PumpDocument8 pagesGrundfos PumpSmile ForeverNo ratings yet

- ANG 23-0616 METALINOXGROUP Several PHE FMA v1Document7 pagesANG 23-0616 METALINOXGROUP Several PHE FMA v1Alexis PradoNo ratings yet

- Liquid Turbine Flow Meter: Subject To Change Without NoticeDocument27 pagesLiquid Turbine Flow Meter: Subject To Change Without Noticenew587No ratings yet

- Dual Fuel Genset - Heat Recovery-1-2Document2 pagesDual Fuel Genset - Heat Recovery-1-2Ab Sami100% (1)

- B 202 TW 042 - 201105 00406 - EnglishDocument1 pageB 202 TW 042 - 201105 00406 - EnglishNavid DavaniNo ratings yet

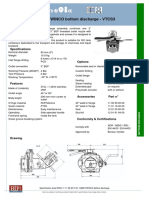

- 3'' (ND80) TWINCO Bottom Discharge - VTCS3: SpecificationsDocument2 pages3'' (ND80) TWINCO Bottom Discharge - VTCS3: Specificationsyounes1980No ratings yet

- r6 ETN 065-040-250-GG (GP)Document8 pagesr6 ETN 065-040-250-GG (GP)ashar jafferyNo ratings yet

- WFI Plant Cooling Water Exchanger PHEDocument2 pagesWFI Plant Cooling Water Exchanger PHEdaniyalahmad119No ratings yet

- Inline Pump 35 MDocument10 pagesInline Pump 35 Mbipan rawatNo ratings yet

- Grundfos Pumps CR18Document2 pagesGrundfos Pumps CR18Wil MolinaNo ratings yet

- GEV 001 OVENS - 2017 - TECNOEKA (ENU) TecnoekaDocument29 pagesGEV 001 OVENS - 2017 - TECNOEKA (ENU) TecnoekaIlyaNo ratings yet

- BombasDocument6 pagesBombaschu42No ratings yet

- NK 50-200-210 - 98318043 - Genoa PlasticDocument4 pagesNK 50-200-210 - 98318043 - Genoa PlasticSajidNo ratings yet

- 1MB1511-1BB29-0AA4-Z M1Y+Q02+Y54 Datasheet enDocument1 page1MB1511-1BB29-0AA4-Z M1Y+Q02+Y54 Datasheet enJoe GrosirNo ratings yet

- Torrent: Frame Assembly & Service Parts ReferenceDocument3 pagesTorrent: Frame Assembly & Service Parts ReferencebenssjNo ratings yet

- MDG 12 Guide For The Construction of Friction WindersDocument23 pagesMDG 12 Guide For The Construction of Friction WindersbenssjNo ratings yet

- Ansys Act App 7t Trajectory: Draws 3D Path (Trajectory) of Points (Vertices or Nodes)Document24 pagesAnsys Act App 7t Trajectory: Draws 3D Path (Trajectory) of Points (Vertices or Nodes)benssjNo ratings yet

- Prediction of Wheel WearDocument20 pagesPrediction of Wheel Wearbenssj100% (1)

- Shevtsov - 2008 TrainDocument218 pagesShevtsov - 2008 TrainbenssjNo ratings yet

- Chapter 1: Static Connections: Repair Advisors A DivisionDocument12 pagesChapter 1: Static Connections: Repair Advisors A DivisionbenssjNo ratings yet

- Høgskolen I Narvik - Sivilingeniørutdanningen Eksamen Og Løsningsforslag I Faget Ste 6243 Moderne MaterialerDocument7 pagesHøgskolen I Narvik - Sivilingeniørutdanningen Eksamen Og Løsningsforslag I Faget Ste 6243 Moderne MaterialerbenssjNo ratings yet

- Precipitation Hardening LabDocument5 pagesPrecipitation Hardening LabbenssjNo ratings yet

- 'Cheat Sheet' PDFDocument5 pages'Cheat Sheet' PDFbenssjNo ratings yet

- The Scalar ProductDocument9 pagesThe Scalar ProductKing EverestNo ratings yet

- mth108 MCQ For Practice PDFDocument2 pagesmth108 MCQ For Practice PDFGowtham Chandrasekar100% (1)

- Pkumar DiffractionDocument76 pagesPkumar DiffractionSouradeep GuptaNo ratings yet

- Basics Concepts of Radiation PhysicsDocument45 pagesBasics Concepts of Radiation PhysicsgloriamarisNo ratings yet

- I. Introductory Concept: SHS-Physical Science (Intermolecular Forces)Document10 pagesI. Introductory Concept: SHS-Physical Science (Intermolecular Forces)Jane182004No ratings yet

- 4400 Series Displacement TransducersDocument4 pages4400 Series Displacement TransducersasimovvNo ratings yet

- Metallurgical Failure Analysis: by DR - Yahya WaqadDocument130 pagesMetallurgical Failure Analysis: by DR - Yahya WaqadYahya Faiez WaqqadNo ratings yet

- CBSE Class 12 Chemistry-Alcohol, Phenol & Ether PDFDocument10 pagesCBSE Class 12 Chemistry-Alcohol, Phenol & Ether PDFVaishnavi DurbadeNo ratings yet

- Pharmaceutical Emulsions: Iqra Zulfiqar (R#33)Document51 pagesPharmaceutical Emulsions: Iqra Zulfiqar (R#33)MalekLeeNo ratings yet

- Ch10 Test File-PhotosynthesisDocument40 pagesCh10 Test File-PhotosynthesisAnonymous 9xheGVRM1No ratings yet

- Experiment 1: Change of Standard Gibbs Free Energy For The Decomposition of Sodium Hydrogen CarbonateDocument12 pagesExperiment 1: Change of Standard Gibbs Free Energy For The Decomposition of Sodium Hydrogen CarbonatenotmeNo ratings yet

- Dualnature CasebasedDocument4 pagesDualnature CasebasedDisha RawatNo ratings yet

- SGUJ0001Document3 pagesSGUJ0001Anonymous sAtHIZyNo ratings yet

- Grade 8 Science TQDocument2 pagesGrade 8 Science TQAngel DPNo ratings yet

- CAMPUS® Datasheet: Akulon® F130-C1 - PA6 DSM Engineering PlasticsDocument3 pagesCAMPUS® Datasheet: Akulon® F130-C1 - PA6 DSM Engineering Plasticsthehoang12310No ratings yet

- Signal Representation & Analysis and Digital CommunicationDocument221 pagesSignal Representation & Analysis and Digital Communicationgaurav_juneja_4100% (1)

- Examples of KlinkenbergDocument9 pagesExamples of KlinkenbergAbdullah OmerNo ratings yet

- Lesson-Guide-G9 - Q2 M1 Chemistry On Template Final PDFDocument26 pagesLesson-Guide-G9 - Q2 M1 Chemistry On Template Final PDFIAN PAULO G. CARAANNo ratings yet

- Fluxes Used in SAWDocument21 pagesFluxes Used in SAWTrushar ParmarNo ratings yet

- The International System of Units, Fundamental Constants, and Conversion FactorsDocument4 pagesThe International System of Units, Fundamental Constants, and Conversion FactorsSaravanapriya KarthikNo ratings yet

- CE 241 Materials ScienceDocument18 pagesCE 241 Materials SciencePepe Mag-aboNo ratings yet

- VorticityDocument9 pagesVorticitySwej ShahNo ratings yet

- Lecture 8 HydrogenDocument85 pagesLecture 8 HydrogenshengNo ratings yet

- PhysicsBowl 2013 SDocument7 pagesPhysicsBowl 2013 SicemeteorNo ratings yet

- Science 10: Melcs - Based Learning Activity SheetDocument4 pagesScience 10: Melcs - Based Learning Activity SheetTrisha Aizel BioNo ratings yet

- Glencoe Chapter 23 MagnetismDocument30 pagesGlencoe Chapter 23 MagnetismdioNo ratings yet