Professional Documents

Culture Documents

No.1 Dare Addendu) /I (Cryil: Memo - O No. - Wbphed Control Valves

Uploaded by

ID Skecht0 ratings0% found this document useful (0 votes)

3 views1 pageOriginal Title

637975551308594490

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pageNo.1 Dare Addendu) /I (Cryil: Memo - O No. - Wbphed Control Valves

Uploaded by

ID SkechtCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Memo No.

1 L\2g 8o/ft I \3 Dare I q-f lz'[ 2 -o 2't

If

ADDENDU]\I NO. - 2

WBPHED SCHEDULE OF RATES (CryIL WORKS), JULY,2O19

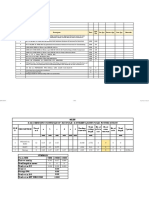

SOR OF PP-RC PIPES AND FLOW CONTROL VALVES

Item

Description of item Unit Rate (Rs.)

No.

L Providing and fixing 3 layer PP-R (Poly propylene Random copolymer) pipes

confirming to lS:15801 UV stabilized & anti - microbial fusion welded, having

thermal stability for hot & cold water supply, including all PP - R plain & brass

threaded polypropylene random fittings, including trenching, refilling & testing of

joints complete as per direction of Engineer-in-Charge.

A) External work (Class - SDR7.4 / PN16)

a)20mm dia OD mtr 117.00

b) 25mm dia OD mtr 151.00

c) 32mm dia OD mtr 20s.00

d)40mm dia OD mtr 295.00

B) External work (Class - 5DR11 / PN10)

a)50mm dia OD mtr 409.00

b) 63mm dia OD mtr 480.00

c)75mm dia OD mtr 672.4O

d)90mm dia OD mtr 942.OO

e) 110mm dia OD mtr 1349.00

f)160mm dia OD mtr 3660.00

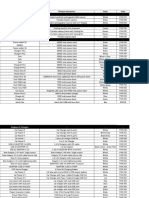

) Supply of tamper proof Flow Control Valve (FCV) cum Non Return Valve (NRV),

made with solid steel bar (hexagonal and round) body & SS ball for float option,

materials grade of Stainless Steel finished with CNC machining of size not less

than 71 mm with connection size: 15mm Dia BSP thread, design and working in

float principle (as per CPHEEO manual) including cost of materials, manufacturing,

Loading, unloading, transit insurance and transportation.

Manufactures must proride tfrira party inspection report from PHE authorised

Laboratory.

Materials grade of stainless steel made with SS316

a) 5 LPM discharge @ 0.5 bar pressure. Each 157 00

b) 1-0 LPM discharge @ 0.5 bar pressure. Each 166.00

& Ch ngineer

Planning Circle-|, PHE Dte. Planning & WQM, PHE Dte,

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Not For Print, Copy and Edit: Enclosure - FDocument16 pagesNot For Print, Copy and Edit: Enclosure - FMahfuzur RahmanNo ratings yet

- Hidco Affordable Housing FIRE BOQ - (Internal & External) 04.05.2021Document23 pagesHidco Affordable Housing FIRE BOQ - (Internal & External) 04.05.2021UTTAL RAYNo ratings yet

- Mechanical BOQ As SentDocument3 pagesMechanical BOQ As SentPoojaashish TripathiNo ratings yet

- FIRE FIGHTING WORKS (Hydrant System With Wet Riser) N.no: Description of Works QuantityDocument11 pagesFIRE FIGHTING WORKS (Hydrant System With Wet Riser) N.no: Description of Works QuantityHunkNo ratings yet

- Mechanical BOQ and EstimateDocument4 pagesMechanical BOQ and EstimatePoojaashish TripathiNo ratings yet

- Sr. No. Description of Item Qty. UNIT Rate Amount A Pumps: IITM at Madras Bill of Quantities For Pumps DATE: 04.07.16Document2 pagesSr. No. Description of Item Qty. UNIT Rate Amount A Pumps: IITM at Madras Bill of Quantities For Pumps DATE: 04.07.16sanjay khatriNo ratings yet

- Earthing Deatils For DumadDocument9 pagesEarthing Deatils For DumadNisith SahooNo ratings yet

- Isolated Footing DesignDocument11 pagesIsolated Footing DesignPadmanabh Shridhar DesaiNo ratings yet

- SI Beam Singlyrc oDocument4 pagesSI Beam Singlyrc oRenvil PedernalNo ratings yet

- Hvac - Kpma 05.07.2021Document1 pageHvac - Kpma 05.07.2021varunthalariNo ratings yet

- Dokumen - Tips - Boq For Fire Fighting Installation Works of Boqpdfof Electrical HydrantDocument24 pagesDokumen - Tips - Boq For Fire Fighting Installation Works of Boqpdfof Electrical HydrantJona Mae LapitanNo ratings yet

- SBU URB PlatformDocument6 pagesSBU URB PlatformMusaab MohamedNo ratings yet

- Proposed Niper Campus at Guwahati, Assam. Girls Hostel (2 Blocks)Document3 pagesProposed Niper Campus at Guwahati, Assam. Girls Hostel (2 Blocks)kiran raghukiranNo ratings yet

- Foreign Part A: Fire Suppression System S/N Description Unit Foam Proportioning Unit Vertical Bladder Type Ul ListedDocument6 pagesForeign Part A: Fire Suppression System S/N Description Unit Foam Proportioning Unit Vertical Bladder Type Ul ListedNakoraNo ratings yet

- Bill of QuantityDocument4 pagesBill of Quantityeng-ashraf abdullahNo ratings yet

- CA64 B3 D0 D 01Document48 pagesCA64 B3 D0 D 01kishor.kokateNo ratings yet

- Design Manual Is-800 Chapter 7Document120 pagesDesign Manual Is-800 Chapter 7Vivek Kumar GopeNo ratings yet

- RCC DesignDocument39 pagesRCC DesignMariappan .PNo ratings yet

- RFQ - Swimming PoolDocument4 pagesRFQ - Swimming Poolrkpatel40No ratings yet

- Pipeline Coatings PDFDocument29 pagesPipeline Coatings PDFAsimNo ratings yet

- By Abutayeb: F1 1500mm 1500mm 200mm 12# @170C/C 12# @170C/C 50mm 1 12# @170C/C 1500mmDocument22 pagesBy Abutayeb: F1 1500mm 1500mm 200mm 12# @170C/C 12# @170C/C 50mm 1 12# @170C/C 1500mmjohnny0% (1)

- Revised de of Electric Fencing of Mansa JailDocument8 pagesRevised de of Electric Fencing of Mansa JailSumit gargNo ratings yet

- Tank Shell Calculation: Mechanical Calculations According To en 14015Document5 pagesTank Shell Calculation: Mechanical Calculations According To en 14015paeg651250% (4)

- Template Plumbing Sanitary Works 1Document17 pagesTemplate Plumbing Sanitary Works 1Carlo MangalindanNo ratings yet

- 2Document31 pages2koko srihandokoNo ratings yet

- Deck Slab Design John Newhook Gamil Tadros: Please, If You Find A Mistake Send The Info To: Gamil TadrosDocument53 pagesDeck Slab Design John Newhook Gamil Tadros: Please, If You Find A Mistake Send The Info To: Gamil TadrosKaustubh JadhavNo ratings yet

- Streetlight Pole BoqDocument3 pagesStreetlight Pole BoqNitin kambleNo ratings yet

- Sewage Pump XFP 80C-150EDocument2 pagesSewage Pump XFP 80C-150EJose CastroNo ratings yet

- Fire Hydrant SystemDocument4 pagesFire Hydrant SystemJoshua Gnanaraj100% (1)

- General Abstract Estimate For Providing Augmentation To Pws Scheme at Degoan (V) of Armoor (M)Document6 pagesGeneral Abstract Estimate For Providing Augmentation To Pws Scheme at Degoan (V) of Armoor (M)dee balkondaNo ratings yet

- Electrical BOQDocument100 pagesElectrical BOQPrakashNo ratings yet

- SRB DesignDocument3 pagesSRB DesignRam LangheNo ratings yet

- Exide New BoqDocument7 pagesExide New Boqkishor veheleNo ratings yet

- T Proc Notices Notices 040 K Notice Doc 35289 253020834Document8 pagesT Proc Notices Notices 040 K Notice Doc 35289 253020834billy chrisNo ratings yet

- Ghan22 JMRDocument1 pageGhan22 JMRAshok KumarNo ratings yet

- Central HeatingDocument4 pagesCentral HeatingDanish NowshariNo ratings yet

- Proposed Niper Campus at Guwahati, Assam. Admin BlockDocument7 pagesProposed Niper Campus at Guwahati, Assam. Admin Blockkiran raghukiranNo ratings yet

- SKUM Medium Expansion Foam MRM - FDS14322 0214 LRDocument2 pagesSKUM Medium Expansion Foam MRM - FDS14322 0214 LRValentin A.No ratings yet

- 1 1.1 Induced Draft Type Twin Cell Cooling TowerDocument2 pages1 1.1 Induced Draft Type Twin Cell Cooling Toweriampatel566No ratings yet

- Item No. Particulars of Item Unit Quantity Rate in Fig. Rate in Words Amount (Nu) Earth WorkDocument5 pagesItem No. Particulars of Item Unit Quantity Rate in Fig. Rate in Words Amount (Nu) Earth WorkGautham GautiNo ratings yet

- Bzdawka Composite Column Calculation ExamplesDocument62 pagesBzdawka Composite Column Calculation Examplesjust meNo ratings yet

- Strip Footing Design: 4141 KN 2645 KN 1489 KN 2185 KN 2617 KNDocument13 pagesStrip Footing Design: 4141 KN 2645 KN 1489 KN 2185 KN 2617 KNkushaljp8989No ratings yet

- Scope of Work & MTO Compressor To H1Document4 pagesScope of Work & MTO Compressor To H1khalid ahmedNo ratings yet

- Design Data Sheet For Air ReceiverDocument3 pagesDesign Data Sheet For Air ReceivergksakthiNo ratings yet

- Parametros de SoldaduraDocument17 pagesParametros de SoldaduraBenjamin Alvarez MedinaNo ratings yet

- THG Hooks Forged Hooks Catalogue Sheet PDFDocument5 pagesTHG Hooks Forged Hooks Catalogue Sheet PDFjhonNo ratings yet

- THG Hooks Forged Hooks Catalogue SheetDocument5 pagesTHG Hooks Forged Hooks Catalogue SheetjhonNo ratings yet

- Abs Submersible Sewage Pump XFP 80C - 151e (GB)Document2 pagesAbs Submersible Sewage Pump XFP 80C - 151e (GB)Ashraf Gomah Mohamed ElshamandyNo ratings yet

- Final BOQ and Annexure - Fire Fighting - 00Document7 pagesFinal BOQ and Annexure - Fire Fighting - 00Anonymous x7ue2F4iNo ratings yet

- Input Echo, Tubesheet Number 1, Description: Fixed TS ST - Out Shell DataDocument14 pagesInput Echo, Tubesheet Number 1, Description: Fixed TS ST - Out Shell Datajiroj12669No ratings yet

- ICoTA Canada 2010 PresentationDocument33 pagesICoTA Canada 2010 PresentationMahesh sinhaNo ratings yet

- S.No Description Unit QtyDocument3 pagesS.No Description Unit QtySunilNo ratings yet

- Comparison Sheet Final FFTG Laundry - BOQ - Eros Hotel 240519Document9 pagesComparison Sheet Final FFTG Laundry - BOQ - Eros Hotel 240519Raja KrsNo ratings yet

- Ghazipur VRV VoltasDocument8 pagesGhazipur VRV VoltasFluidus EngineeringNo ratings yet

- Sandvik SAF 2304: Duplex Stainless SteelDocument8 pagesSandvik SAF 2304: Duplex Stainless SteelmattiaNo ratings yet

- BOQ 20 - Danish PDFDocument4 pagesBOQ 20 - Danish PDFDanish Nowshari100% (1)

- 37 PDFDocument14 pages37 PDFID SkechtNo ratings yet

- Gopal Chatterje Road Floor Beam & Slab Reinforcement CalculationDocument14 pagesGopal Chatterje Road Floor Beam & Slab Reinforcement CalculationID SkechtNo ratings yet

- B) 150 MM Dia: Ainn Ben@alDocument1 pageB) 150 MM Dia: Ainn Ben@alID SkechtNo ratings yet

- Cement Rate - Rs 517 - 42-2 PDFDocument5 pagesCement Rate - Rs 517 - 42-2 PDFID SkechtNo ratings yet

- Assignment 4 SuspensionDocument3 pagesAssignment 4 SuspensionAdam LuqmanNo ratings yet

- Dealer GST Price SheetDocument18 pagesDealer GST Price SheetRajesh SongirkarNo ratings yet

- GSM TP's Hybrid SystemDocument15 pagesGSM TP's Hybrid SystemChristian StrømmeNo ratings yet

- GDocument2 pagesGmahmod alrousanNo ratings yet

- MS-Installation 11Kv Switch Gear at Lusail-CP1Document6 pagesMS-Installation 11Kv Switch Gear at Lusail-CP1Tayab Ansari100% (2)

- 8A978BPDocument12 pages8A978BPMelvin TejedaNo ratings yet

- MPC 4500 Katalog Czesci PDFDocument220 pagesMPC 4500 Katalog Czesci PDFKrzysztof DanelczykNo ratings yet

- Written Test 1 - SolutionDocument3 pagesWritten Test 1 - SolutionNajwa LolyPopNo ratings yet

- P 4740100 InstallDocument13 pagesP 4740100 InstallAshraf Adel Nashed ZakiNo ratings yet

- Computer Architecture From Microprocessors To Supercomputers The Oxford Series in Electrical and Computer Engineering PDF-1Document3 pagesComputer Architecture From Microprocessors To Supercomputers The Oxford Series in Electrical and Computer Engineering PDF-1kartikNo ratings yet

- Honda Goldwing GL1000 Bates Saddlebag Mounting InstructionsDocument1 pageHonda Goldwing GL1000 Bates Saddlebag Mounting Instructionsjcoltar73No ratings yet

- NCERT Books For Class 10 Science Chapter 13 Magnetic Effects of Electric CurrentDocument25 pagesNCERT Books For Class 10 Science Chapter 13 Magnetic Effects of Electric CurrentVanitha raoNo ratings yet

- Theory2021-22-IC5I - IAU Teaching PlanDocument2 pagesTheory2021-22-IC5I - IAU Teaching Planrashmi patilNo ratings yet

- Amos - Lubricator RiserDocument13 pagesAmos - Lubricator RisersambhajiNo ratings yet

- Diode 1NDocument57 pagesDiode 1Nalexandru255No ratings yet

- Technical Specification For 11 KV Packaged SubstationDocument271 pagesTechnical Specification For 11 KV Packaged SubstationPeter pan100% (1)

- Tunorma Transformer11Document1 pageTunorma Transformer11aliNo ratings yet

- SAMSUNG UA32EH4003R, UA39EH5003R Chassis U74H, U74GDocument59 pagesSAMSUNG UA32EH4003R, UA39EH5003R Chassis U74H, U74Gprem raj100% (2)

- Ground Control 3.0 (5th Wheel) 4 Point and 6 Point: Service ManualDocument28 pagesGround Control 3.0 (5th Wheel) 4 Point and 6 Point: Service ManualyankeestylzeNo ratings yet

- Best Performance For Mid-Range Cylinders and Tools: Shown: PEJ-1401BDocument4 pagesBest Performance For Mid-Range Cylinders and Tools: Shown: PEJ-1401BGleynder IraricaNo ratings yet

- Method Statement FF Piping System Pipes - DotxDocument9 pagesMethod Statement FF Piping System Pipes - DotxBader ShrbajiNo ratings yet

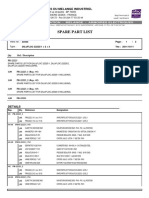

- DSA 2011 01967 - Spare Parts ListDocument2 pagesDSA 2011 01967 - Spare Parts ListMehedi HasanNo ratings yet

- Instalation Manual FratelliDocument25 pagesInstalation Manual FratelliIon Aniel Barbu100% (1)

- Xrhs385 MDDocument32 pagesXrhs385 MDanacer55No ratings yet

- Solar Grass CutterDocument22 pagesSolar Grass CutterPrathik AkkapallyNo ratings yet

- Automatic Railway Gate Control System Using Arduino Uno PresentationDocument20 pagesAutomatic Railway Gate Control System Using Arduino Uno PresentationRio Martin100% (1)

- Honda 9.9 - BABJDocument137 pagesHonda 9.9 - BABJCraig Smith67% (3)

- PLC 2Document31 pagesPLC 2Biniam HaddisNo ratings yet

- B1 RC18 User GuideDocument20 pagesB1 RC18 User Guideharold_anilloNo ratings yet

- 4CX250M PDFDocument3 pages4CX250M PDFucnopNo ratings yet