Professional Documents

Culture Documents

1 1.1 Induced Draft Type Twin Cell Cooling Tower

Uploaded by

iampatel566Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 1.1 Induced Draft Type Twin Cell Cooling Tower

Uploaded by

iampatel566Copyright:

Available Formats

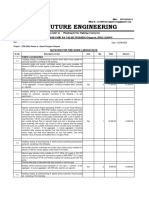

BILL OF QUANTITY

Name of work:- Replacement of 500 TR twin cell type cooling tower along with other associated works at ACMS AC

plant, IIT Kanpur.

Name of Agency:-

Description Qty. Unit Rate Amount

1 COOLING TOWERS

1.1 Induced Draft Type Twin Cell Cooling Tower

Supply of Twin cell, FRP type cooling tower shall be suitable for 500 TR

(250 TR each cell), with induced draft counter flow cooling tower of

rectangular / square shape with fan, TEFC, IE-03/ IE5 motor with

protection class of IP65,with direct drive set mechanism with FRP axial

fan assembly with SS304 hub, all SS bolts & nuts, CTI-136 certified PVC

fills, drain, over flow, quick fills, float valve, equalizer line connection,

0.001% drift rate drift eliminators (Eurovent certified), hot water

distribution system, FRP basin minimum 6 mm thickness and min. 5

mm thick body panel etc as per the specifications. The cooling tower

fan shall be suitable for operation on 415±10% Volts, 50 Hz, 3 Phase

AC power supply. The FRP panels shall be factory fabricated. Each cell

Heat rejection capacity should be minimum 37, 50,000 BTUs/hr.

Cooling towers shall be CTI standard 201 certified. The FRP panels and

casing shall be minimum 5 mm thick using unsaturated polyester resin

with UV protected gel coat. The tower fills & drift eliminator shall be

UV protected high efficiency low clog uPVC virgin PVC type. The

microcellular polyurethane based vibration isolators is also included in

the scope of cooling towers. The rate includes all the MS GI supporting

structure ,base frames I beam/C Channel, angles and channels for

successful commissioning of the cooling tower as per specification.

a. Max. wet bulb temperature : 83 F (28.3C)

b. Temperature of water

entering cooling tower : 100 F (37.7 C)

c. Temperature of water

leaving cooling tower : 90 F (32.2 C)

d. Water flow rate per tower : 1600 USGPM

e. Minimum efficiency of motors : 90%

Twin cell cooling towers as described above. 1 No 0.00

2 CONDENSER WATER PIPING

2.1 Supplying & laying , testing & commissioning mild steel 'C' class pipe of

size as mentioned below on exposed surface / underground including

connection with existing condenser water line, chiller, pump,

fabrication of bends, tees, reducers, shoe, support ( brick masonry

block & wooden support for underground / MS angle- clamp & wooden

support for exposed surface ) along with priming coat of steel primer as

per standard specification.

Note:-The Pipes of sizes 150 mm & below shall be M.S.

‘C’class as per IS : 1239 and pipes size above 150 mm shall be heavy

class of thickness min. 7mm as per IS: 3589

a 250 mm 12 Rmt. 0.00

b 200 mm 12 Rmt. 0.00

c 150 mm 5 Rmt. 0.00

d 100 mm 3 Rmt. 0.00

f 50 mm 2 Rmt. 0.00

2.2 Supplying and fixing of butterfly valves cast iron body with SS 304 disc

& PN-16 rating of size 200 mm to 400 mm gear type with removable

hand lever and below 200 mm hand lever operated including nut, bolt,

flanges, gasket duly painted with synthetic enamel paint as per

specification complete as reqd. make Honeywell or its equivalent.

a 250 mm 2 Nos 0.00

b 200 mm 2 Nos 0.00

c 100 mm 1 Nos 0.00

d 50 mm 1 Nos 0.00

3 Electrical Works

3.1 Supply, laying, affecting connections and Testing of the following

sizes of 1.1 KV armoured XLPE insulated aluminium/ copper conductor

cables. Cables shall be inclusive of all clamps, saddles, screws, cable

identification tags, cable terminal joints including terminal lugs,

insulating tapes, affecting terminal connections to the

equipment as per the specifications and as required.

a 4C x 16 Sqmm cable (Copper) 10 Mtr. 0.00

3.2

Supplying and laying 25 mm X 5 mm G.I strip at 0.50 meter below

ground as strip earth electrode, including connection/ terminating with

G.I. nut, bolt, spring, washer etc. as required. (Jointing shall be done by 60 Mtr. 0.00

overlapping and with 2 sets of G.I. nut bolt & spring washer spaced at

50 mm).

4 Civil work

4.1

Brick work with common burnt clay F.P.S. (non modular) bricks of class

designation 7.5 in superstructure above plinth level up to floor V level 3 Cum. 0.00

in all shapes and sizes in, Cement mortar 1:4 (1 cement : 4 coarse sand)

4.2 Repairs of cooling tower foundation with plaster of thickness 12 mm to

20 mm in patches of area 2.5 sq.meters and under, including cutting

the patch in proper shape, raking out joints and preparing and

plastering the surface of the walls complete, including disposal of

rubbish to the dumping ground, all complete as per direction of 6 Sqm. 0.00

Engineer in- Charge. 14.1.1 With cement mortar 1:4 (1 cement : 4

Coarse sand)

Sub Total 0.00

5 Buy-back of twin cell cooling tower

5.1 Buy-BACK of twin cell cooling tower with 2 nos. 10 HP motor including

Cutting and dismantling of existing cooling tower including dismantling

of each parts of tower removing of all pipe connections, fills , panel, GI

support etc. and depositing waste material at designated location. 1 Set 0.00

Total 0.00

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- BoqDocument3 pagesBoqKailas NimbalkarNo ratings yet

- Bill of QuantityDocument4 pagesBill of Quantityeng-ashraf abdullahNo ratings yet

- CA64 B3 D0 D 01Document48 pagesCA64 B3 D0 D 01kishor.kokateNo ratings yet

- RFQ - Swimming PoolDocument4 pagesRFQ - Swimming Poolrkpatel40No ratings yet

- Fire Hydrant SystemDocument4 pagesFire Hydrant SystemJoshua Gnanaraj100% (1)

- FSL Fire-Fighting Quotation New Future Engineers Saroj Kanta JenaDocument6 pagesFSL Fire-Fighting Quotation New Future Engineers Saroj Kanta JenaManish RaiNo ratings yet

- La Royal LaborDocument7 pagesLa Royal LaborDEVSHILPI ARCHITECTSNo ratings yet

- BOQ For Hot Water System L T Boys Girls Hostel Project 22 (1) .02.06Document24 pagesBOQ For Hot Water System L T Boys Girls Hostel Project 22 (1) .02.06manjunath hrNo ratings yet

- Estimation For Store RoomDocument17 pagesEstimation For Store RoompviccuNo ratings yet

- Annexure 1 PDFDocument2 pagesAnnexure 1 PDFDevi DeepkumarNo ratings yet

- Fire Fighting Works: S.No. Description Unit Qty 1.0 Fire Hydrant SystemDocument7 pagesFire Fighting Works: S.No. Description Unit Qty 1.0 Fire Hydrant SystemRakesh Karan SinghNo ratings yet

- Bore WellDocument3 pagesBore WelltubaiNo ratings yet

- Schedule of QuantityDocument9 pagesSchedule of Quantityexecutive engineerNo ratings yet

- SL - No Description Qty Unit Supply Basic Tax%Document10 pagesSL - No Description Qty Unit Supply Basic Tax%ratnakar cpwd100% (1)

- Boq Comparative ChartDocument13 pagesBoq Comparative ChartMulayam YadavNo ratings yet

- 2a Annexure - II-IMTECH-NEW ITEMS Draft-16.01.2016Document12 pages2a Annexure - II-IMTECH-NEW ITEMS Draft-16.01.2016Amit SinghNo ratings yet

- BoqDocument3 pagesBoqaerorockNo ratings yet

- Electrical Work: Normal Item 350.00 Normal Item 360.00Document43 pagesElectrical Work: Normal Item 350.00 Normal Item 360.00sreyashanand3011No ratings yet

- Ghazipur VRV VoltasDocument8 pagesGhazipur VRV VoltasFluidus EngineeringNo ratings yet

- Electrical BOQDocument22 pagesElectrical BOQSAI ASSOCIATENo ratings yet

- Fire Detection & Protection - ExcelDocument57 pagesFire Detection & Protection - ExcelMadhurima SenguptaNo ratings yet

- Lift Estimate (1) (1) NewDocument11 pagesLift Estimate (1) (1) NewTapan MishraNo ratings yet

- Fire Fighting System For M/S RTRC, Manesar: Description Qty. Make Fire Hydrant System Sr. No. Rate/ Unit AmountDocument6 pagesFire Fighting System For M/S RTRC, Manesar: Description Qty. Make Fire Hydrant System Sr. No. Rate/ Unit AmountJASPAUL KalraNo ratings yet

- Estimation Name of Work: Construction of Toilets For Logistic and VigilanceDocument12 pagesEstimation Name of Work: Construction of Toilets For Logistic and Vigilancepviccu100% (1)

- Fire Fighting BOQDocument32 pagesFire Fighting BOQdesign.aquafireprotectionNo ratings yet

- Hec Boq SubconDocument25 pagesHec Boq SubconSHRIYA POWERNo ratings yet

- DK Z DK Uke % Xzke Ia%&: Phed BSR 2019 2.1.1Document5 pagesDK Z DK Uke % Xzke Ia%&: Phed BSR 2019 2.1.1Sunita SainiNo ratings yet

- La Royal SupplyDocument7 pagesLa Royal SupplyDEVSHILPI ARCHITECTSNo ratings yet

- S.No. Description of Item No. L (M) B (M) D/H Quantity Unit Rate AmountDocument3 pagesS.No. Description of Item No. L (M) B (M) D/H Quantity Unit Rate Amountshivshankar kushwahaNo ratings yet

- Hidco Affordable Housing FIRE BOQ - (Internal & External) 04.05.2021Document23 pagesHidco Affordable Housing FIRE BOQ - (Internal & External) 04.05.2021UTTAL RAYNo ratings yet

- iwCmY6WPaXBR - BOQ RABAI 220KV FINALDocument11 pagesiwCmY6WPaXBR - BOQ RABAI 220KV FINALkajale.shrikantNo ratings yet

- Spec - ACODocument5 pagesSpec - ACOReza MohebbiNo ratings yet

- Proforma of SchedulesDocument13 pagesProforma of SchedulesAmit SharmaNo ratings yet

- 3 - 4 Part B Revised Price Bid Boq For Air ConditioningDocument4 pages3 - 4 Part B Revised Price Bid Boq For Air Conditioningkishore vpNo ratings yet

- Fire Terrace Booster Pump SpecificationDocument11 pagesFire Terrace Booster Pump SpecificationRajkishore NayakNo ratings yet

- 191120221906-Price BidDocument3 pages191120221906-Price Bidsatish goreNo ratings yet

- Sample BOQ Central HVACDocument7 pagesSample BOQ Central HVACbookjaman92% (12)

- Electric Fencing Bill of MalerkotlaDocument14 pagesElectric Fencing Bill of MalerkotlaSumit gargNo ratings yet

- PE RT PIPE KavitaDocument11 pagesPE RT PIPE KavitaaasifNo ratings yet

- Estimate For Providing Electrification of A.J.K. Thana Bulding Block & Distt-MungeliDocument10 pagesEstimate For Providing Electrification of A.J.K. Thana Bulding Block & Distt-MungeliMahendra panditNo ratings yet

- Khandala - Pipe - Line - Work - Phase 1 PDFDocument23 pagesKhandala - Pipe - Line - Work - Phase 1 PDFborkarsd007No ratings yet

- Enquiry - Cable Tray - APL TowerDocument4 pagesEnquiry - Cable Tray - APL Towerrkpatel40No ratings yet

- Chapter - E12: Requirements of Auxiliary Items Aluminium Tubular ConductorDocument10 pagesChapter - E12: Requirements of Auxiliary Items Aluminium Tubular ConductorvenkateshbitraNo ratings yet

- QT - DI - Electrical BOQ Purulia Warehouse - RAW FILE - 19-20 - 21-10-2019Document4 pagesQT - DI - Electrical BOQ Purulia Warehouse - RAW FILE - 19-20 - 21-10-2019aiplNo ratings yet

- Fire Fighting Bill ValueDocument341 pagesFire Fighting Bill ValueMuhammad Afzal100% (1)

- ItemrateCPWDSCHEDULE1Document3 pagesItemrateCPWDSCHEDULE1sreyashanand3011No ratings yet

- Extra Items Penur PatkulDocument4 pagesExtra Items Penur PatkulSìmply Rayees VakilNo ratings yet

- BOQ Fire DetailDocument7 pagesBOQ Fire DetailDaudMuhammadNo ratings yet

- TABLE1Document1 pageTABLE1Suhail EhtishamNo ratings yet

- SCDA Building Electrical Assesment As Per Work Order.Document5 pagesSCDA Building Electrical Assesment As Per Work Order.sourendra prasad karanNo ratings yet

- T 003 Part IV BOQ UGR External ConnectivityDocument4 pagesT 003 Part IV BOQ UGR External ConnectivitydineshkashniaNo ratings yet

- Schedule of Quantities: (QTY. - 01no. - LAB BUILDING)Document7 pagesSchedule of Quantities: (QTY. - 01no. - LAB BUILDING)deathesNo ratings yet

- MES BoQDocument28 pagesMES BoQRam ChavanNo ratings yet

- Sr. No. Description of Item Qty. UNIT Rate Amount A Pumps: IITM at Madras Bill of Quantities For Pumps DATE: 04.07.16Document2 pagesSr. No. Description of Item Qty. UNIT Rate Amount A Pumps: IITM at Madras Bill of Quantities For Pumps DATE: 04.07.16sanjay khatriNo ratings yet

- Sl. No. Description of Item Unit QTY Amount 1.00 WTP & Pump Room WorksDocument9 pagesSl. No. Description of Item Unit QTY Amount 1.00 WTP & Pump Room WorksMohteshim MalikNo ratings yet

- Detailed Estimate (Electrical Work)Document5 pagesDetailed Estimate (Electrical Work)ruchita vishnoiNo ratings yet

- P.D. 1096 National Building Code of The PhilippinesDocument12 pagesP.D. 1096 National Building Code of The Philippineshobi jungNo ratings yet

- Fence Requirements Resident IDocument16 pagesFence Requirements Resident IRama Krishna PasupulettiNo ratings yet

- Birla Navya Avik 2Document40 pagesBirla Navya Avik 2nxq4syygzwNo ratings yet

- M3 Cantrail Inner AssemblyDocument16 pagesM3 Cantrail Inner AssemblyDongTaNo ratings yet

- Eurocode Conference 2023 Mandara Eurocode 9Document25 pagesEurocode Conference 2023 Mandara Eurocode 9Rodolfo BlanchiettiNo ratings yet

- m3 C-Pillar ReinforcementDocument29 pagesm3 C-Pillar ReinforcementWilliam SouzaNo ratings yet

- BOQ ALOR (Submitted) FinalDocument23 pagesBOQ ALOR (Submitted) FinalDaffaBahirNo ratings yet

- Improvement of The Dhaka (Katchpur) - Sylhet National Highway (N2) Into A 4-Lane Highway With Service Lane On Both SidesDocument22 pagesImprovement of The Dhaka (Katchpur) - Sylhet National Highway (N2) Into A 4-Lane Highway With Service Lane On Both SidesAdvut TonmoyNo ratings yet

- Pds - Floor Hardener NMDocument2 pagesPds - Floor Hardener NMkasivisanadhNo ratings yet

- Vernacular Assignment 2Document63 pagesVernacular Assignment 2Jayanth PonnaMNo ratings yet

- Bba Certificate hrt4 rt2Document8 pagesBba Certificate hrt4 rt2belu diazNo ratings yet

- Fabrication of PlasticDocument1 pageFabrication of PlasticAllan SsemujjuNo ratings yet

- EIM Tools and EquipmentDocument15 pagesEIM Tools and EquipmentRegine Proel Macaranas0% (1)

- Compressed Air Uses Compressed Air UsesDocument757 pagesCompressed Air Uses Compressed Air UsesAVCB RÁPIDONo ratings yet

- Dinding Panel Beton Pas. Batu Dinding SayapDocument4 pagesDinding Panel Beton Pas. Batu Dinding SayapNarnoNo ratings yet

- Res SpecificationDocument3 pagesRes SpecificationHeri SetyantoNo ratings yet

- SLM 3 Carpentry 9 4th QuarterDocument12 pagesSLM 3 Carpentry 9 4th QuarterDanielNo ratings yet

- Usatbu123 UtilitiesDocument110 pagesUsatbu123 UtilitiesDisenyo LokalNo ratings yet

- 2 Construction WorkDocument53 pages2 Construction WorkShuvam AdhikariNo ratings yet

- Module 4 Construction Methods and EquipmentDocument35 pagesModule 4 Construction Methods and EquipmentOkita SoujiNo ratings yet

- Allegiant Stadium Team BDocument52 pagesAllegiant Stadium Team BOgedengbe oluwapelumiNo ratings yet

- Burland (2017) Rescuing The Leaning Tower of PisaDocument101 pagesBurland (2017) Rescuing The Leaning Tower of PisaJoeNo ratings yet

- Complete The Email With The Words From The BoxDocument1 pageComplete The Email With The Words From The BoxAnna SokalaNo ratings yet

- Tekasil Neutral Profi enDocument2 pagesTekasil Neutral Profi enEzeval GráficaNo ratings yet

- Block Work CalculationDocument2 pagesBlock Work Calculationtruth finderNo ratings yet

- Carport UniversalDocument19 pagesCarport UniversalRobert BNo ratings yet

- S.No Item No. Description of Item Unit Rate (RS.) Quantity Amount (RS.) Reference For Rate Schedule A - Excavation, Tunnel 1Document29 pagesS.No Item No. Description of Item Unit Rate (RS.) Quantity Amount (RS.) Reference For Rate Schedule A - Excavation, Tunnel 1George K GeorgeNo ratings yet

- Lab Notes 1 - ME Workshop Theory and PracticeDocument6 pagesLab Notes 1 - ME Workshop Theory and PracticeJane AndaNo ratings yet

- AppendixeDocument9 pagesAppendixeSriNo ratings yet

- Furniture of Yesterday and Today (1937)Document68 pagesFurniture of Yesterday and Today (1937)gmand68No ratings yet