Professional Documents

Culture Documents

Fire Terrace Booster Pump Specification

Uploaded by

Rajkishore NayakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Terrace Booster Pump Specification

Uploaded by

Rajkishore NayakCopyright:

Available Formats

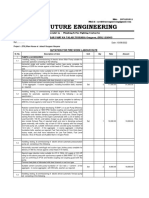

Part-II

RESERVE BANK OF INDIA

ESTATE DEPARTMENT

JAIPUR

Name of work : Fire fighting (Wet Riser) system at office building.

Bill of quantities

Item Description Qty Unit Rate Amount

No.

A FIRE HYDRANT SYSTEM

Electrical items

1 PUMP (Electrically Driven)

Supplying, installing, testing & commissioning

of electric driven, suitable for autometic

operation of horizontal single stage centrifugal

type synchoronous speed of 2900 rpm, TEFC

conforming to IP-55 & flexible coupling gaurd

mounted on a common structural base plate

with 150mm dia gun metal pressure gauges

with isolation cock and piping, suitable

vibration elimination pads of approved design

for pump foundation, motor to be suitable for

415 volts, 3 phase, 50 cycles AC.

a) Capacity 2280 LPM at 7 Kg/cm2 delivery 1 No. Each

pressure for Fire Hydrant Network.

b) Capacity 180 LPM at 7 Kg/cm2 (Jockey

Pump). 1 No. Each

c) 200mm dia water motor with gong with

drain piping, stopcock, complete in all

1 No. Each

respects.

2 Pumps (Diesel) Engine Driven

Supplying, installing, testing and

commissioning of horizontal single stage

centrifugal pumping set with CI volute and

bronze impeller with mechanical seals directly

coupled to automatic Diesel Engine complete

with all accessories like self starting by means

of Battery powered electric starter motor, oil

bath air cleaner, exhaust silencer etc.

complete in all respects. The engine & the

pump will be mounted on common base plate

on anti-vibration mountings.

Note: The rates quoted shall be inclusive of

filling of lubricants, quantities of which shall be

as per manufacturer's recommendations.

a) Capacity 2280 LPM at 7 Kg/Cm2 delivery

pressure for fire hydrant. 1 No. Each

3 Supplying, installing, testing & commissioning

of electric driven terrace pump suitable for

automatic operation of horizontal sigle stage

centrifugal type, sychoronous speed of 2900

rpm TEFC confirming to IP : 55 & Flexible

coupling & coupling guard mounted on

common bed plate of fabricated mild steel

channel or cast iron type as required.

a) Capacity 900 LPM at 3.5 Kg./Cm2

delivery pressure for fire hydrant

1 No. Each

network.

b) Capacity 450 LPM at 3.5 Kg./Cm2

delivery pressure for fire hydrant 1 No, Each

network.

4 Fire Pump Panel (Electrical)

Supplying, erecting, testing and

commissioning cubicle pattern electrical

control panel made of 14 SWG MS Sheet duly

painted with enamel paint Double door with IP

65 protection comprising of the following:

Incoming

1 No, 400Amps FP MCCB (35 KA)

Bus bars

1 Set 3 Phase, 4 wire busbar 500 Amps

Aluminium conductor, duly sleeved in PVC

colour coded sleeves.

Outgoings.

3 Nos 200 A TP MCCB withneutral link (25

KA)

3 Nos 63 A TP MCCB with neutral link (25 KA)

2 No. Star Delta starter with overload relay

suitable for 70 HP.

1 No. Dol starter with overload relay suitable

for 10 HP.

Metering

1 Set RYB phase indication lamps with toggle

suitable and protection fuses.

1 No. 0-500 volts, 96mm square with with

MCB.

1 No. 0-400 Amps Ammeter of 96mm square 1 Set Set

with Suitable CT's

1 No. 96sqmm energy meter with CT's

5 Cables

Supplying, laying, terminating aluminium

conductor, PVC insulated armoured cable on

necessary M.S. clamps and saddles on

walls/ceiling.

a) 3 x 95 Sq.mm PVC AA cable 60Rmt Rmt

alongwith 2x6 SWG GI wire.

b) 3 x 25 Sq.mm PVC AA cable 60Rmt Rmt

alongwith 2x8SWG GI wire.

c) 4 x 6 Sq.mm PVC AA cable alongwith 20Rmt Rmt

2x8 SWG GI wire

6 Cable Termination

Cutting, peeling, terminating and connecting

the cables with brass cable ground and

crimped aluminium lugs in respective

electrical panel and motor cable box.

a) 3 x 95 Sq.mm cable. 4 Nos. Each

b) 3x 25 Sq.mm cable. 2 Nos. Each

c) 4 x 6 Sq.mm cable. 2 Nos. Each

7 Cable Trays

Supplying & installing GI slotted cable trays

on walls fixing with necessary structural steel

members like Rods, Angles/Channels for

supporting the cable tray. The steel members

will be grouted in ceiling/walls with Dash

fasteners.

a) 40 x 100 x 40 x 2 mm 60 Rmt Rmt

8 Control Panel (Engine Driven Pump)

Supplying, erecting, testing and

commissioning cubicle pattern electrical

control panel (out door) made of 14 SWG MS

sheet duly painted with powder coated

comprising of the following:

a) 24 Volts 120 AH capacity battery set.

b) 15 Amps battery charger with Tricke

and boost facility.

c) 0-32 Volts votlmeter.

d) 0-15 Amps ammeter.

e) Auto-starting contactor with relay.

f) Auto/Manual selector switch with push 1 Set Set

button for manual start.

9 EARTHING

Earth Stations

a) Supplying the necessary materials and

making earth station with

600x600x6.3mm thk GI plate buried at

a level of 2.5m below ground encased

with atleast 15 cms. thk salt and

charcoal layer all round including

excavation of earth, back filling,

dressing and making 1:4:8 CC

manhole at ground level along with

2 Sets Set

300 x 300mm CI manhole cover,

funnel and 19 mm GI pipe for water

complete in all respects as per

IS:3043.

b) supplying & fixing 25x3 sqmm GI earth 50 Rmt Rmt

strip upto pump panel

10 Pressure Switch

Supplying, installing, testing and

commissioning 0 to 7 Kg/ cm2 ON/OFF

pressure switches in delivery line of pump

along with control wiring for auto starting and 1Set Set

auto stopping of hydrant and jockey pumps,

diesel pump. (Set of 3 pressure switches)

11 Oil Tank

Supplying, fixing and commissioning 500 ltrs.

capacity including first fill of 500 ltrs high

speed diesel oil in 16 SWG MS steel oil tank

with manhole cover, glass gauge, inlet and

outlet connections with gate valves, drain

plug, GI piping between tank and engine vent

pipe with wire mesh etc. duly painted and

mounted on suitable MS angle staging to

maintain gravity flow of oil.

1 Set Set

12 Exhaust piping

Supplying, erecting and commissioning

additional exhaust piping with heat resistance

Aluminium cladding insulation wrapped all

along the pipe including a cowl at the top with 10 Rmt Rmt

necessary MS clamps on walls/ceiling.

13 Supplying and fixing 1 x 20 Watt 240 V AC

supply Exit Sign Lamp Fixture with 6 V

battery, built-in charger and auto change over 12 Nos. Each

arrangement.

Civil items

14 Hose Cabinet (Internal)

Supplying, erecting, testing and

commissioning hose cabinet 900mm X

600mm X 250mm suitable for indoor

installation (on walls) made out of 16 SWG

MS sheet, glass fronted doors including

painting with two coat of scarlet red enamel 19Nos. Each

paint over a coat of metal primer etc

consisting of:

a) 2 Nos. 15 Mtrs. length 63 mm dia RRL

hose with gun metal couplings on

either end duly binded GI wires / rivets

etc as required.

b) 1 No. 63 mm dia instantaneous type

gun metal branch pipe and 16 mm dia

nozzle as per IS 903.

15 Supplying, erecting, testing and

commissioning 63mm dia oblique single

headed female instantaneous pattern gun

metal landing valve confirming to IS 5290

with blank cap and chain and gun metal

coupling, cast iron wheel etc complete as

directed. 19 Nos. Each

16 Supplying, erecting, testing and

commissioning 36.0 Mtr long 20 mm dia

Rubber hose reel with 6.35mm brass nozzle

and swinging bracket and 20 mm dia

Gunmetal ball valve with connection from riser

with 25mm dia butterfly valve (gun metal) & 19 Nos. Each

MS pipe etc complete as directed.

17 Hose Cabinet (External)

Supplying, erecting, testing and

commissioning hose cabinet 900mm X600mm

X 250mm suitable for outdoor installation

made out of 16 SWG MS sheet, glass fronted

door, sloping canopy on top (with 150 mm

extension on all sides) including painting with

two coat of scarlet red enamel paint over a

coat of metal primer etc. consisting of: 11Nos. Each

a) 2 Nos. 15 Mtrs. length 63 mm dia RRL

hose with couplings on either endduely

binded GI wires / rivets etc as

required.

b) 1 No. 63 mm dia instantaneous type

gun metal branch pipe and 16 mm dia

nozzle as per IS 903.

18 External Hydrant

Supplying, erecting testing & commissioning 11 Nos. Each

external hydrants consisting of:

a) 80 mm dia M.S. pipe (heavy quality) of

2.2 Mtr. length (1 Mtr. below ground &

1.2 mtr above ground).

b) 1 No. 63mm dia oblique female

instantaneous pattern gun metal

landing valve confirming to IS 5290

(Type-A) with blank cap and chain and

gun metal coupling, cast iron wheel etc

complete as directed.

c) Brick pedastal of 550mm above

ground and 230mm below ground

including 100mm thick 1:2:4 PCC at

the bottom.

19 Piping

ABOVE GROUND PIPING

Supplying, laying, fixing, testing and

commissioning heavy quality MS pipe

conforming to IS, including all necessary

pipe fittings like elbows, tees, flanges, tapers,

nuts, bolts, gaskets etc . The piping will be

provided with necessary steel brackets and

hardware for fixing on walls/slabs and with

cement concrete blocks as supports where

ever applicable Spacing between pipe

supports shall be 2.5 meter. Rate shall be

inclusive of making holes in RCC floor/wall

cutting the reinforcements etc. for taking pipe

and finishing the same after laying of the pipe.

The exposed piping shall be painted with

scarlet red enamel paint over two coats of

zinc chromate primer, including scaffolding,

working at all level etc. complete as directed.

a) 250 mm dia 15 Rmt Rmt

b) 200 mm dia 20 Rmt Rmt

c) 150 mm dia 550 Rmt Rmt

d) 100 mm dia 75 Rmt Rmt

e) 80 mm dia 25 Rmt Rmt

f) 65 mm dia 10 Rmt Rmt

g) 50 mm dia 5 Rmt Rmt

h) 40 mm dia 20 Rmt Rmt

i) 32 mm dia 10 Rmt Rmt

j) 25 mm dia 10 Rmt Rmt

20 BELOW GROUND PIPING

Supplying, laying, fixing, testing and

commissioning Heavy class MS pipe

conforming to IS including all necessary pipe

fittings including excavation of trenches at

approx. 1.0m depth including breaking

concrete/rcc floor, including cutting the

reinforcements and providing pedestals, back

filling of trench etc. complete in all respects

including making good as original surface with

PCC/RCC etc whereever applicable. The

exposed piping shall be painted with scarlet

red enamel paint. The pipes buried in ground

shall be painted with anticorrosive rubber

modified bituminous primer, two coats of hot

enamel paint and 4mm thick pypkote

including scaffolding, working at all level etc.

complete as directed.

a) 150 mm dia 125 Rmt Rmt

b) 100 mm dia 60 Rmt Rmt

c) 80 mm dia 175 Rmt Rmt

21 Providing and fixing GI heavy duty puddle

flange to sumps/RCC tanks,made up of GI

pipes threaded on both sides on MS Plate at

inner surface of tank. Inclusive of punchuring

the RCC tank for fixing GI puddle flange as re

finhisng as per standards complete as

required and as instructed by the Bank's

Engineer etc. complete.

a) 250 mm dia 2 Nos. Each

b) 100 mm dia 2 Nos. Each

c) 80 mm dia 2 Nos. Each

22 Piping Specials (Valves / Strainer)

Supplying, erecting, testing and

commissioning CI double flanged gate valves,

non return valves, 1.6mm thick SS stainers

with 3mm dia. holes, of following sizes

confirming to IS specifications with required

nuts, bolts, washers, gaskets etc, complete as

directed.

a) 250 mm dia. butterfly valve 2 Nos. Each

b) 200 mm dia. butterfly valve 2 Nos. Each

c) 150 mm dia. butterfly valve 11 Nos. Each

d) 150 mm dia. non-return valve 2 Nos. Each

(flanged)

e) 100mm dia. butterfly valve 8 Nos. Each

f) 100 mm dia. Gunmetal Non Return 2 Nos. Each

valve

g) 80mm dia. Gunmetal Gate valve 2 Nos. Each

h) 80mm dia. Gunmetal Non Return 1 No. Each

valve

i) 50mm dia. butterfly valve 2 Nos. Each

j) 200mm dia. strainer 2 Nos. Each

k) 100mm dia. strainer 1 No. Each

l) 100 mm dia. Air release valve 6 Nos. Each

23 Air Cushion Tank

Supplying, installing, testing and

commissioning 200mm dia. 8mm thick, 1 Mtr.

Long M.S. air cushion tank, at the top most

points of the system including all accessories,

such as one pressure gauge, 25mm dia gun

metal gate valve, Spring loaded air release

valve, etc complete as directed.

5 Set Set

24 Supplying, erecting, testing & commissioning

of :

a) Four way fire brigade inlet with 150mm 2 Nos. Each

dia sluice valve & non-return valve

complete in all respect. (Cast iron

body) as per detailed specifications.

b) Two way fire brigade inlet with 100mm 2 Nos. Each

dia sluice valve & non-return valve

complete in all respect. (Cast iron

body) as per detailed specifications.

25 Supplying, erecting, testing & commissioning

of suction coupling for fire brigade draw off

connection with 100mm dia GI pipe & foot

valve (pipe approx.6 mtr. Long). 1 Set Set

26 Supplying, erecting, testing & commissioning

of gun metal four way inlet for tank fillings with

all required accessories. 1 No. Each

27 Supplying, erecting, testing & commissioning

of double flanged vertical air vessel fabricated

from 10mm thick MS plate with dished ends

450mm dia & 2 mtr height common for fire &

jockey pumps complete with 3 pressure

switches to operate jockey, main & diesel

engine driven pumps at drop of pressures.

1 No. Each

28 Providing and laying non-pressure NP-2 class

(heavy duty) RCC pipes with collars jointed

with stiff mixture or cement mortar in the

proportion of 1:2 (1 cement : 2 fire sand )

including testing of joints etc. complete.

a) 200mm dia. RCC pipe 10 Rmt Rmt

b) 250mm dia. RCC pipe 60 Rmt Rmt

c) 300mm dia. RCC pipe 70 Rmt Rmt

29 Providing and placing on terrace `Sintex' or

any other approved brand Polyethylene water

storage tank with cover and suitable locking

arrangement and making necessary holes for

inlet, outlet and overflow pipes, fittings etc.

complete as directed.

a) For Main building 10000Ltr Ltr

b) For Annexe Building 5000Ltr Ltr

30 Providing and fixing drainage provision for the 2 Nos

Down comer with necessary 40mm dia pipe,

ball valve etc. as required, maximum length of

pipe shall be 6 Mtr.

31 Supplying the necessary materials and 6 Nos

constructing 1 Mtr x 1 Mtr x 1 Mtr brick

masonry valve chamber with 230 mm thick

brick wall in 1:3 cement sand mortar, 12 mm

thick plastering and providing 900 x 900 mm

CI cover.

Total of A

B Buy back : ( Rebate item) : Carefully LS LS

removing and taking away the following

materials including fixtures, clamps,

foundations etc

a) Approximate length of exposed 100mm

pipe=45 m

b) 12 Nos of double headed Hydrant valve

along with accessories.

c) 12 Nos Hose reel along with drum,

connecting pipe, nozzle, valves etc.

d) 17 Nos. MS hose box with brass branch

pipe nozzle, RRL of 30 m with couplings.

e) 2 Nos. Air release valves

f) 5 Nos-external Hydrant post with double

female adopter.

h) 3 Nos. MS hose box.

j) 10 Nos. Gates valves 100/200mm size

m) Fire brigade connection- 1No.s

d) Fire pump (28.4 LPS) with diesel engine

(kirloskar make) & battery charger etc..

Rate shall be inclusive of taking disposing

away the debris out of Bank’s premises.

Net amount

Rs.___________________________________________________

__________________________________________________Only

C The tenderers shall quote their charges for Total Per

comprehensive maintenance service System annum

(inclusive of all spares, consumables like

gland ropes to pumps, gasket on the piping

system, repair/replacement of pressure

gauges on the pumps / wet riser piping mains

etc. routine, preventive and breakdown

maintenance) of wet riser fire fighting system

including pumps and electrical gadgets which

will be applicable after the expiry of the

guarantee period of one year after

commissioning of the installations. Apart from

break down maintenance, the annual

maintenance contract includes deputing a

foreman /mechanic / service Engineer / once

in a month to check all the equipment's under

the supervision of Bank's staff & issuing a

certificate for satisfactory working. Annual

Maintenance should be as per the schedule

prescribed in the tender document page no.51

to 56 of Part-I. After first year of AMC after

one year of guarantee period, the remaining

year's AMC will be arrived as per page no 10

of Part-I.

Rs._______________________________________________________________________

__________________________________Only

Signature of the contractor with seal

You might also like

- Cg-010-457-Boq-Ff - 08.10.15Document33 pagesCg-010-457-Boq-Ff - 08.10.15Rajshekhar KategarNo ratings yet

- CA64 B3 D0 D 01Document48 pagesCA64 B3 D0 D 01kishor.kokateNo ratings yet

- Drilling of 1 No Bore Well at SRS, NDRI, Adugodi, Bangalore. SH:-Pdg. Pump SetsDocument5 pagesDrilling of 1 No Bore Well at SRS, NDRI, Adugodi, Bangalore. SH:-Pdg. Pump SetsRatnakar SeethiniNo ratings yet

- BOQ Fountain Water Body (1) .XLSXBDocument6 pagesBOQ Fountain Water Body (1) .XLSXBPrashant Singh Chauhan50% (4)

- Screenshot 2022-10-22 at 2.47.38 PMDocument3 pagesScreenshot 2022-10-22 at 2.47.38 PMARUN KUMARNo ratings yet

- RFQ - Hot WaterDocument8 pagesRFQ - Hot Waterrkpatel40No ratings yet

- Marathahalli Project - BlankDocument12 pagesMarathahalli Project - BlankSajad ManjadikkalNo ratings yet

- Fire Boq Global NoidaDocument9 pagesFire Boq Global NoidaPrasanth KumarNo ratings yet

- Electrical works bill of quantitiesDocument20 pagesElectrical works bill of quantitiesjobswithkumarNo ratings yet

- XPDocument9 pagesXPsureshn829100% (1)

- Schedule of QuantityDocument9 pagesSchedule of Quantityexecutive engineerNo ratings yet

- Kanchi - It - ParkDocument35 pagesKanchi - It - ParksparkCENo ratings yet

- TSP Work - Estimate - Template 330Document6 pagesTSP Work - Estimate - Template 330shivapannaleNo ratings yet

- PUBALI BANK LIMITED RENOVATION ELECTRICAL SCHEDULEDocument6 pagesPUBALI BANK LIMITED RENOVATION ELECTRICAL SCHEDULESaiful Hoque SohelNo ratings yet

- Revised de of Electric Fencing of Mansa JailDocument8 pagesRevised de of Electric Fencing of Mansa JailSumit gargNo ratings yet

- FSL Fire-Fighting Quotation New Future Engineers Saroj Kanta JenaDocument6 pagesFSL Fire-Fighting Quotation New Future Engineers Saroj Kanta JenaManish RaiNo ratings yet

- Fire Detection / Alarm and Fire Fighting Work at Proposed Group Housing Project Namely "NBCC Heights", Sec. 89, Pataudi Road, GurgaonDocument16 pagesFire Detection / Alarm and Fire Fighting Work at Proposed Group Housing Project Namely "NBCC Heights", Sec. 89, Pataudi Road, GurgaongbaludbNo ratings yet

- RFQ - Pumping SystemDocument6 pagesRFQ - Pumping Systemrkpatel40No ratings yet

- Fire Detection & Protection - ExcelDocument57 pagesFire Detection & Protection - ExcelMadhurima SenguptaNo ratings yet

- BOQDocument2 pagesBOQManish Goyal100% (1)

- SL Description of Work Unit Qty Rate Amount SCHEDULE C (Electrical Works)Document2 pagesSL Description of Work Unit Qty Rate Amount SCHEDULE C (Electrical Works)Basavaraj A GadigeppagolNo ratings yet

- STCL FF ServicingDocument13 pagesSTCL FF Servicingratnakar cpwdNo ratings yet

- 3.HYDRANT For TejgaonDocument6 pages3.HYDRANT For Tejgaonmujahid_islam85No ratings yet

- Project Estimation for Electrical Works at Sipradi TradingDocument27 pagesProject Estimation for Electrical Works at Sipradi TradingGaurab Rai Lama100% (2)

- ELECTRICAL SCOPEDocument11 pagesELECTRICAL SCOPESAMEERNo ratings yet

- Amendment in Bill of Quantities (Boq) : Paithan Mega Food Park Pvt. Ltd. at Paithan (MH)Document12 pagesAmendment in Bill of Quantities (Boq) : Paithan Mega Food Park Pvt. Ltd. at Paithan (MH)Karthick MahadevanNo ratings yet

- La Royal LaborDocument7 pagesLa Royal LaborDEVSHILPI ARCHITECTSNo ratings yet

- UGD Scope of Works - TPGDocument4 pagesUGD Scope of Works - TPGjuliyet strucNo ratings yet

- RFQ - Swimming PoolDocument4 pagesRFQ - Swimming Poolrkpatel40No ratings yet

- Providing Lift EstimateDocument11 pagesProviding Lift EstimateTapan MishraNo ratings yet

- Fire Fighting BOQDocument32 pagesFire Fighting BOQdesign.aquafireprotectionNo ratings yet

- 132KV Sub StationDocument11 pages132KV Sub StationMurali MohanNo ratings yet

- 33 KV Outdoor Type Current Transformer TSDocument6 pages33 KV Outdoor Type Current Transformer TSSandip AhireNo ratings yet

- Fire Fighting Works Bill of QuantityDocument341 pagesFire Fighting Works Bill of QuantityMuhammad Afzal100% (1)

- Uipl FPS Boq T1Document11 pagesUipl FPS Boq T1Sashikumar NarayanakurupNo ratings yet

- La Royal SupplyDocument7 pagesLa Royal SupplyDEVSHILPI ARCHITECTSNo ratings yet

- Annexure 1 PDFDocument2 pagesAnnexure 1 PDFDevi DeepkumarNo ratings yet

- Civil Works For Data Center Sr. N0. Item Description Units QtyDocument13 pagesCivil Works For Data Center Sr. N0. Item Description Units QtyGypsum ChennaiNo ratings yet

- DATE: 30-01-15 Project: Aspire International Shool Services: Electrical Systems Price Summary Sr. No. Description Amount Amount in Words HT WorkDocument53 pagesDATE: 30-01-15 Project: Aspire International Shool Services: Electrical Systems Price Summary Sr. No. Description Amount Amount in Words HT WorkaniketNo ratings yet

- Boq Elect - Bpo at CoimbatureDocument9 pagesBoq Elect - Bpo at CoimbatureBenadict JoshuaNo ratings yet

- FIRE HYDRANT SYSTEMDocument4 pagesFIRE HYDRANT SYSTEMJoshua Gnanaraj100% (1)

- Electric Fencing bill of MalerkotlaDocument14 pagesElectric Fencing bill of MalerkotlaSumit gargNo ratings yet

- 33/11kV Outdoor Potential Transformers and Control Panels SpecificationDocument30 pages33/11kV Outdoor Potential Transformers and Control Panels SpecificationSandip AhireNo ratings yet

- Electrical Work: Normal Item 350.00 Normal Item 360.00Document43 pagesElectrical Work: Normal Item 350.00 Normal Item 360.00sreyashanand3011No ratings yet

- DG Sets Installation and Commissioning ProjectDocument3 pagesDG Sets Installation and Commissioning ProjectSHRIYA POWERNo ratings yet

- Tuty Court Genset ESTIMATES NewDocument42 pagesTuty Court Genset ESTIMATES NewRajaDurai RamakrishnanNo ratings yet

- Bill of Quantity: Name of Work:-Fire Hydrant SystemDocument2 pagesBill of Quantity: Name of Work:-Fire Hydrant Systempramod tiwariNo ratings yet

- Financial Bid - Electrical - DO PathanamthittaDocument4 pagesFinancial Bid - Electrical - DO PathanamthittaHarendra SinghNo ratings yet

- WiringDocument8 pagesWiringANKIT KUMAR RAJNo ratings yet

- Fire Fighting Installation System: Bill of QuantitiesDocument24 pagesFire Fighting Installation System: Bill of QuantitiesIqram Meon100% (1)

- 1 Electrical N/A: Group Item No. Item Code (If Any)Document9 pages1 Electrical N/A: Group Item No. Item Code (If Any)ApexBD01No ratings yet

- FInal Unpriced BO Breakup - 15.06.23Document14 pagesFInal Unpriced BO Breakup - 15.06.23Nikhil sharmaNo ratings yet

- WTP BOQ FOR SCINDIA SCHOOLDocument35 pagesWTP BOQ FOR SCINDIA SCHOOLsupportNo ratings yet

- BOQ Pack 4Document36 pagesBOQ Pack 4Prachi DongreNo ratings yet

- Jyothi Final EstimateDocument10 pagesJyothi Final Estimateakhil joshyNo ratings yet

- Technical Specifcation of Electrical MaterialsDocument53 pagesTechnical Specifcation of Electrical MaterialsAnonymous sAmJfcVNo ratings yet

- I Electro Mechanical Equipments II STP Panel III Statutory Approval ChargeDocument11 pagesI Electro Mechanical Equipments II STP Panel III Statutory Approval ChargeSajeshKumarNo ratings yet

- 30HP Inlinebooster Indira NagarDocument12 pages30HP Inlinebooster Indira Nagarsuprajag919No ratings yet

- Galsi RRIDocument56 pagesGalsi RRISourendra KaranNo ratings yet

- Air Blower - HSRDocument1 pageAir Blower - HSRRajkishore NayakNo ratings yet

- Fire - B - PRO - BDocument24 pagesFire - B - PRO - BRajkishore NayakNo ratings yet

- Basement Sump Pit CalculationDocument12 pagesBasement Sump Pit CalculationRajkishore NayakNo ratings yet

- ECO - B - PRO - BDocument2 pagesECO - B - PRO - BRajkishore NayakNo ratings yet

- Interview QuestionsDocument3 pagesInterview QuestionsRajkishore NayakNo ratings yet

- Booster PumpDocument2 pagesBooster PumpNghiaNo ratings yet

- Domestic Water Sizing CalculationDocument5 pagesDomestic Water Sizing CalculationNghiaNo ratings yet

- Elite Hydraulic Calculation SampleDocument12 pagesElite Hydraulic Calculation SampleSam Choi100% (2)

- Jain Plumbing SWR Upvc Pipe FittingsDocument6 pagesJain Plumbing SWR Upvc Pipe FittingsKrishan PandyaNo ratings yet

- Pex Design Manual PDFDocument95 pagesPex Design Manual PDFBipin Tom ThomasNo ratings yet

- Victaulic Cs Spec To 24 In.Document10 pagesVictaulic Cs Spec To 24 In.Luis HernandezNo ratings yet

- Product Catalog: Drilling & CompletionsDocument45 pagesProduct Catalog: Drilling & CompletionsjohangomezruizNo ratings yet

- Helpful HintsDocument40 pagesHelpful HintsIvan LizarazoNo ratings yet

- FMDS0798Document7 pagesFMDS0798hbcbmwtuningNo ratings yet

- ITT 8100 Yatay Bölünebilir GövdeliDocument2 pagesITT 8100 Yatay Bölünebilir GövdeliOscar CruzNo ratings yet

- 38 H Gyrasphere Crusher ManualDocument26 pages38 H Gyrasphere Crusher ManualCarl Richter100% (1)

- Method of Statement For Under-Ground and Above-Ground Piping InstallationDocument10 pagesMethod of Statement For Under-Ground and Above-Ground Piping Installationamr100% (1)

- PF1000 Series Checkball Piston Pumps: Pressures To 10 000 PsiDocument7 pagesPF1000 Series Checkball Piston Pumps: Pressures To 10 000 PsiRodo RequenaNo ratings yet

- Technical Requirements For Plumbing Works in Buildings eDocument118 pagesTechnical Requirements For Plumbing Works in Buildings eclementmwwong6387No ratings yet

- General Installation Practices: Section EDocument26 pagesGeneral Installation Practices: Section EMohsen ArabifardNo ratings yet

- Foote-Jones 8000 Series Gear Reducer ManualDocument20 pagesFoote-Jones 8000 Series Gear Reducer ManualbwelzNo ratings yet

- Bradco 625 Trencher ManualDocument107 pagesBradco 625 Trencher ManualAnonymous zSpR5jUdNo ratings yet

- NPCIL Tube Fitting SpecificationsDocument22 pagesNPCIL Tube Fitting Specificationssumant.c.singh1694100% (1)

- Product List Onetouch PDFDocument5 pagesProduct List Onetouch PDFGouse BujjiNo ratings yet

- Analyser Mounting Solutions PDFDocument40 pagesAnalyser Mounting Solutions PDFBo Cu BinNo ratings yet

- W5Q - Stainless SteelDocument6 pagesW5Q - Stainless SteelHuy NguyễnNo ratings yet

- Ball Bearings and Sleeve Bearings for Conveyor RollersDocument3 pagesBall Bearings and Sleeve Bearings for Conveyor RollersMehran KhNo ratings yet

- Astm D3034Document10 pagesAstm D3034Hernando Andrés Ramírez GilNo ratings yet

- Lobatse Master Plan BOQ-Option 2Document23 pagesLobatse Master Plan BOQ-Option 2Robins MsowoyaNo ratings yet

- Pressure drop calculation for vapor pipelineDocument5 pagesPressure drop calculation for vapor pipelineBaskar KannaiahNo ratings yet

- Dixon Sanitary Fittings CompleteDocument252 pagesDixon Sanitary Fittings CompleteLufti Nurhartanto SmansapatiNo ratings yet

- Fisher DFA Variable Geometry Desuperheater: Scope of ManualDocument12 pagesFisher DFA Variable Geometry Desuperheater: Scope of ManualWADENo ratings yet

- Lawton Online Brochure 2016Document44 pagesLawton Online Brochure 20163obaydoofNo ratings yet

- BASIC PLUMBING SKILLSDocument1 pageBASIC PLUMBING SKILLSFREDERICK DELA CRUZNo ratings yet

- MTO #6 Fase VII, Accesorios de Instrumentacion PDFDocument3 pagesMTO #6 Fase VII, Accesorios de Instrumentacion PDFdavidseins2009No ratings yet

- Instalacion de PlomeriaDocument20 pagesInstalacion de Plomeriagota_lluviaNo ratings yet

- Plumbing ReviewerDocument28 pagesPlumbing ReviewerPrincess Diana Arrojado0% (1)

- Technical Standards & Specifications Including Safety Standards For City or Local Natural Gas Distributions NetworksDocument91 pagesTechnical Standards & Specifications Including Safety Standards For City or Local Natural Gas Distributions Networkspravesh sharma80% (5)