Professional Documents

Culture Documents

I Electro Mechanical Equipments II STP Panel III Statutory Approval Charge

Uploaded by

SajeshKumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

I Electro Mechanical Equipments II STP Panel III Statutory Approval Charge

Uploaded by

SajeshKumarCopyright:

Available Formats

INSTAKART SERVICES PVT. LTD.

, HARINGHATA

Warehousing at Haringhata, West Bengal

SEWAGE TREATMENT PLANT (SEQUENTIAL

BATCH REACTOR TYPE, 420 KLD)

SUMMARY

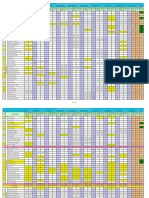

Sl.no. DESCRIPTION

i ELECTRO MECHANICAL EQUIPMENTS

ii STP PANEL

iii Statutory Approval Charge

Total without civil & GST

PTK Project Consultants LLP Page 1 of 11 Volume - III

INSTAKART SERVICES PVT. LTD., HARINGHATA

Warehousing at Haringhata, West Bengal

SEWAGE TREATMENT PLANT (SEQUENTIAL BATCH REACTOR TYPE, 420 KLD)

BILL OF QUANTITIES (BOQ)

Sl.

Description Unit QTY

No

I STP FOR CIVIL WORKS

Design, Engineering, and providing all equipment /machinery at site, installation

and commissioning of equipment's/ electrical/ piping inclusive of all types of

taxes and duties as described in specification.

The capacity of sewage treatment plant is 420 KLD (210 KLD X 2 streams)

All civil tanks both underground and above ground including excavation, Plain

cement concrete M10 grade,RCC wall / raft slab including necessary

reinforcement / shuttering sufficiently reinforced as per the design confirming to

latest IS code requirements with min. M25 grade concrete. The construction

should also include all necessary inserts for electro- mechanical work including

providing access provision from ground to bottom of tank, draining pits, pump

pits, etc. Appropriate water proofing to be made and water tightness to be tested

before back filling. Tank interiors shall be coated/cladded with suitable material LS 1.00

as approved. The tanks should have free board of required height (minimum

600 above ground level) and based on the process flow. All civil structures shall

be plastered and painted fully both internal and external all complete as

directed. The construction requirement stated above is not limited,but also any

additional requirement to be adopted to make the system functional.

RCC Plant room with necessary doors, windows, plastering painting etc.,

complete as directed by engineer in charge and all the open tanks shall be

closed by GI weld mesh with load of 75 kg/sqm including hand rail and

necessary guard/ fall protect railing. All colour scheme to match with other

structure inside the campus (Designing of all structures shall be as per relevant

IS code)

All civil / structural related design calculations and shop drawings to be

submitted for Consultant / client approval.

TOTA L - I

II ELECTRO-MECHANICAL EQUIPMENTS

1 Bar Screen

Supplying, installing, testing and commissioning of bar screen consisting of 1

No. of fine screen and 1 No. coarse shall be provided in front of the intake

works, so as to exclude the large sized particles with associated set of guide

angles in SS flat of 6.0 mm thick and 50 mm wide kept inclined at 45 degree to

the horizontal at 10mm c/c with one no. hand rack in GI. Bar rack fabricated

from SS-304 bars to the width of the screen chamber with a racking arm for

manual operation.

Size : 1000 x 900mm ( to suit the width of Bar screen chamber) Nos 2

2 Raw Sewage Transfer Pump

Supplying, installing, testing and commissioning of Raw Effluent transfer pumps

(Submersible type). The pump shall be coupled to the adequate HP. electrical

motor, as per technical specifications. The Pumps shall be with 2 Working + 1

Standby configuration.

Duty: 24 KLH @ 10 M head each (2W+1S) - For Module 1 & 2 Set 1

3 Coarse Bubble Diffuser

Supplying, installing, testing and commissioning of Disc type Coarse bubble

diffuser with 80mm dia × 800mm long to provide clog-free oxygen for

Equalization Tank , Sludge Holding Tank, Decant Tank and Treated Water Tank Nos 55

with PVC fitting, nylon rope braided hose with all accessories to make it

retrievable.

4 Fine Bubble Diffuser

Supplying, installing, testing and commissioning of Fine Bubble Diffuser with

90mm dia × 1000mmdia long with membrane from EDI, USA shall consists of

Nos 50

set of membranes, SS 304 clips PVC support pipe (10 kg/cm2 pressure rating),

PVC fitting, nylon rope braided hose with all accessories to make it retrievable.

PTK Project Consultants LLP Page 2 of 11 Volume - III

5 Air Blower

Supplying, installing, testing and commissioning of Twin Lobe design type air

blower complete with motors, pulleys, Rigid one piece CI casing and side plates,

silencer, base plate, Anti-friction bearings,. Rotary oil sealing having horizontal

configuration. approved make Twin lobe roots type Air Blower of adequate

capacity at 0.60 Kg/sq cm capacity of required head comprising of common

base frame, suction filter, suction silencer, non return, V belt, safety valve, belt

guard, drive and driven pulleys, pressure gauge, inter connection piping,

discharge silencer, anti vibration pads including required motor.

The blower shall be driven by a VFD drive, to regulate the air flow depending on

the Dissolved Oxygen in the aeration tank.

Air Blower for Equalization Tank, Decant Tank, Sludge Holding Tank, Soft

5.1 Water Tank, Treated Water Tank : 2 Nos ( 1 Working + 1 Standby ) Capacity : Set 1

300 cum/hr at 5000mm Wg.

Air Blower for SBR tank : 2 Nos ( 1 Working + 1 Standby ) Capacity : 230

5.2 cum/hr at 5000mm Wg. ( Note : When one SBR is under aeration, the other is

not)

For Module 1 & 2 Set 1

5.3 Acoustic Enclosure

Supply, installation testing and commissioning of acoustic enclosure, fabricated

out of 16 swg MS for a thickness of 100mm with rock wool insulation so as to

cut down the noise level to less than 65 dB when measured at a distance of 1m

away from the source. The enclosure shall be such sized so as to ensure that Nos 0

two blowers are housed in one enclosure. The enclosure shall be provided with

a suitable fan for the purpose of cooling. The vendor shall submit a GA drawing

and take approval from consultant prior to ordering the enclosure

6 Sludge transfer Pumps

Supplying, installing, testing and commissioning of sludge disposal pumps to

pump the sludge from aeration tank to sludge holding tank / sludge recirculation.

The pump shall be horizontal centrifugal non-clog pumps with vetted parts in CI

construction. The pump shall be coupled to the adequate H.P electrical motor,

mounted on a common base frame.

Duty: 18 KLH @ 10 M head each (1W+1S) - For Module 1 & 2 Set 1

7 Filter feed Pumps

Supplying, installing, testing and commissioning of filter feed pumps. The pump

shall be coupled to the adequate HP. electrical motor, mounted on a common

base frame as per technical specifications. The Pumps shall be (1 Working + 1

Standby) configuration.

Duty: 25 KLH @ 35 M head each (1W+1S) - For Module 1 & 2 Set 1

8 Chlorine Dosing System

Supplying, installation, testing and commissioning of on line automatic electronic

sodium hypo dosing unit with automatically operated dosing pump etc. The unit

shall comprise of the following

One no. Single molded HDPE cylindrical type chemical solution tank of 100 litres

a capacity having detachable lids with molded inserts for mounting of pump and

stirrer.

One no Electronic diaphragm type positive displacement pump of approved

make, for chemical dosing with plastic head. The electronic pump shall be

b

operated on 220V single phase supply and shall be mounted directly on the tank

top.

Capacity : 6 lph - For Module 1 & 2 Set 1

9 Pressure Sand filter

Supplying, installing, testing and commissioning approved make Multigrade /

Pressure Sand Filter with necessary accessories complete with Multiport Valve,

Pressure Gauge of 3" Dial one at the inlet and one at the outer of the Filter,

suitable supports for mounting pressure gauges, the filter shall be made of MS

Fabricated out of 6mm thick shell and 8mm Dish, confirming to (IS 2825 - U/F

Class) with two coats of Epoxy paint on the outside & inside. The cost of the

filter shall also include initial charge of under bed and multigrade (sand) filter

media to suit the requirements etc., complete as per standards.

Man Hole Size : 600mm dia minimum , Inspection Hole size : 300mm Dia

minimum

PTK Project Consultants LLP Page 3 of 11 Volume - III

Filter Diameter as per manufacturer's recommendation

Max. working pressure = 3.5kg/sqcm

Max flow rate = 25 cum/hr - For Module 1 & 2 Set 1

10 Activated Carbon Filter

Supplying, installing, testing and commissioning approved make Activated

Carbon Filter with necessary accessories complete with suitable Multiport /

Pneumatic Valve, Pressure Gauge of 3" Dial one at the inlet and one at the

outlet of the Filter, suitable supports for mounting pressure gauges, the filter

shall be made of MS Fabricated out of 6mm thick shell and 8mm Dish,

confirming to IS 2825 - U/F Class with two coats of Epoxy paint on the iniside

and outside . The cost of the filter shall also include initial charge of under bed

and activated carbon media ( IV 500) media to suit the requirements etc.,

complete as per standards.

Man Hole Size : 600mm dia minimum , Inspection Hole size : 300mm Dia

minimum

Filter Diameter as per manufacturer's recommendation

Max. working pressure = 3.5kg/sqcm

Max flow rate = 25 cum/hr - For Module 1 & 2 Set 1

11 Softener (for HVAC makeup)

Supplying, installing, testing and commissioning approved make Softener with

necessary accessories complete with suitable Multiport/ Pneumatic Valve,

Pressure Gauge of 3" Dial - one at the inlet and one at the outer of the Filter,

suitable supports for mounting pressure gauges, the filter shall be made of MS

Fabricated out of 6mm thick shell and 8mm Dish, confirming to IS 2825 - U/F

Class with two coats of Epoxy paint over two coats of zinc chromate primer on

outside and inside. The cost of the softener also include the cost of initial

charge of Resin media to suit the requirements etc., complete with necessary

brine tank, ejector assembly.

Quoted rate shall also include automatic brine preparation system with

mechanical agitator and FRP Brine Tank . The mechanical agitator provided

shall be with SS Shaft and stirrer arrangement.

Size as per manufacturer's recommendation

OBR : 200 cum

Feed Hardness < 600 ppm

Residual Hardness < 50 ppm

Resin Volume: As per manufacturer's recommendation

Max. working pressure = 3.5 kg / Sq cm

Max flow rate = 25 cum/hr No 0

12 Filter Press

Supplying, installation and commissioning of automatic hydraulic closing

mechanism filter press suitable for handling sludge, cast iron body grade FG

No 0

20, suitable no. of polypropylene plate of size 450 mm X 450 mm etc., complete.

Suitable for a plant capacity of 420 KLD

12a Centrifuge Basket Decanter (Alternative option for Filter Press)

Supplying, installation, testing and commissioning of centrifuge basket decanter

for sludge handling, inclusive of necessary poly dosing system, disposable

sludge handling trolley.

Flow rate = 4.5 cum/hr Set 1

13 Screw pump

Supplying, installing, testing and commissioning of screw pumps to pump

sewage from sludge holding tank to centrifuge basket decanter at uniform flow

rate. The pump shall be coupled to the adequate HP. Electrical motor, mounted

on a common base frame.

a Type : Helical screw pumps

Duty = 3 cum/hr at 60M head - For Module 1 & 2 Set 1

14 Decanter Mechanism

Supply, fixing, testing & Commissioning of PLC based moving decanter with

5mm thickness or as per recommendation from manufacturer, shall be installed

in reactor for decanted water extraction. Nos. 2

MOC of the decanter shall be SS-304 driven by geared motor of suitable power.

SBR cycle shall be auto controlled with continuous feedback level transmitter.

PTK Project Consultants LLP Page 4 of 11 Volume - III

15 Plant Piping

Plant Piping with UPVC Sch pipes with fittings and approved make valves,

gauges, instrumentation etc., for all plumbing lines and GI C Class pipeline with Lot 1

fittings for Blower Air Lines.

16 Flow Meter

Supply installation testing and commissioning of Magnetic Type Flow meter for

measuring the flow with totalizer

16.1 100 NB at the outlet of Raw Sewage Pump - for Module 1 & 2 No 1

16.2 65 NB at the outlet of Activated Carbon Filter - for Module 1 & 2 No 1

16.3 65 NB at the outlet of the Softener No 1

17 Sewage transfer pump (From external sewage collection sump to EQT).

Supply, installation, testing & commissioning of submersible cutter pumps,

connected to TEFC submersible motor for 415 + 10% volts, 3 phase, 50 cycles

A.C. power supply with mechanical seal, pump connector unit with rubber

diaphragm and bend, vertical discharge pipe, in built level controller with

operational mode as one pump working at low level, both pumps at high level

with a hooter alarm and cut off at dry level as determined. The pump shall be

provided with a lifting devise of pull chain/guide rail, 15 m cable etc. as per

requirement complete in all respects. (Pumps shall be installed in a set of two

pumps One working and One standby, with cascade operation). The cost for

electrical panel(indoor & Outdoor as specified below) shall also be inlcuded in

the quoted price

Electrical Starter panels complete with O/L Relay with Single phasing preventer

feature, earth leakage relay, ON-OFF and Trip Indicating lamps, interlocking,

level controller with operational mode as one pump working at low level, both

pumps at high level with a hooter alarm and cut off at dry level, cascade

operation, working / standby selection, etc. suitable for the motor H.P. as

specified below and with provision for remote P.B. on/off complete as required.

Set of accessories such as G.I headers for suction and discharge, control

valves, non return valves, pressure gauge, flow meters, inter connecting power

and control cabling etc. complete shall be included in the offer

(Pumps with grinder system and suitable to handle solids of minimum 50 mm

size with C.I. Body S.S. Shaft, CI Impeller with 15 mtr. Cable, double

mechanical seal).

a Flow Rate : 8.5 LPS (Indoor Panel) No 1

Head : 25m

Location : Inside the Sewage suction pit 03

1 working + 1 standby

TOTA L - II

III STP PANEL

Supply, erection, testing & commissioning of cubicle floor mounting type motor

control centre with copper busbar fabricated (Form 4b construction) in standard

sections, suitable for coupling at site comprising TPN busbar with busbar of

equal size in all phases with half the size of phases as neutral made out of 14

& 16 SWG sheet steel, reinforced angle iron frame work equipped with busbar

chambers and cable chambers. The bus fault level shall be designed as per

requirement and shall meet the statutory obligation of local CEIG, PCB

regulations and other authorities. The painting of the complete system shall be

powder coated or minimum 7 tank process with red oxide as base primer and

finished with enamel smoke grey/opaline green. The power control centre shall

comprise incoming and outgoing air circuit breakers & MCCB/fuse switches and

including all accessories like fuses, interlocks, etc. Vendor to be provide the

configuration of the Motor Control Centre showing the Incoming & Outgoing

Feeders, Control & Measuring devices, Starters, Tripping devices, Total feeders

with Loads for each feeders, etc

1 Lot 1

PTK Project Consultants LLP Page 5 of 11 Volume - III

1 Lot 1

STP Panel and PHE PLC Panel (Indoor type) with IP 54 ingress protection,

fabricated and lockable doors including the cost of interconnections, copper

crimping lugs, brass glands, bonding to earth and painting, suitable for use at

415 volts, 3 phase 4 wire 50 Hz system with 35KA rupturing capacity at 415

volts complete. The panel shall be suitable for complete auto and manual

operation of the plant with necessary instrumentation, auto valves, level

controller with necessary isolation valves and sensor. The panel shall also be

BMS compatible. Electrical Motor Control Centre shall be suitable for all

equipments connected to the STP with 3 Nos of spare feeders.The SLD and GA

drawing to be submitted for Consultant / client approval.Before fabrication the

panel.

STP Panel load -84 KW

PHE panel load -54 KW

PTK Project Consultants LLP Page 6 of 11 Volume - III

2 CABLES AND CABLE TERMINATIONS

Supplying, laying, testing and commissioning of approved make 1.1kV grade

armoured XLPE sheathed, copper conductor, FRLS power cables and Control

Cables. The cables shall be laid in cable tray / conduit. as required. Rate shall

include cost of G.I ladder/Perforated trays / MS conduit. Cables shall not be

procured based on BOQ. True measurements will be taken by the contractor

before ordering, based on drawings. The conductor to be of class II type,

insulation material XLPE, Inner sheath extruded ST2, Armouring round wire

armour for cables upto 10 sq.mm, outer sheath extruded ST2, temperature rise Lot 1

limit 90 Deg C, maximum permissible conductor temp. during short circuit 250

Deg C.

Quoted rate shall also consider - end terminations including supply of materials

such as lugs, solderless crimping type sockets, single compression cable

glands, necessary supports, taping, earthing of glands and local

Isolators/Starters/Push button stations etc.

3 INSTRUMENTATION

Supply, installation, testing & commissioning of auto monitoring system

consisting of the following digital instrumentation which can be integrated with

RS-485 incoming and output.

a. Dissolved Oxygen meter

Lot 1

b. Online TDS meter

c. pH meter

d. BOD analyzer

e. COD analyzer

TOTAL - III

Cost of obtaining statutory approvals (Item wise details of quoted cost to be

IV LOT 1

furnished by vendor)

TOTAL - IV

V ANNUAL MAINTENANCE CHARGE (AMC)

(i) Annual Maintenance Charge - 1st Year LS 1

(ii) Annual Maintenance Charge - 2nd Year LS 1

(iii) Annual Maintenance Charge - 3rd Year LS 1

Total V

PTK Project Consultants LLP Page 7 of 11 Volume - III

INSTAKART SERVICES PVT. LTD., HARINGHATA

Warehousing at Haringhata, West Bengal

SEWAGE TREATMENT PLANT (SEQUENTIAL BATCH REACTOR TYPE, 420 KLD)

LIST OF RECOMMENDED MAKES

SL. NO. DESCRIPTION MAKE

1 RAW SEWAGE TRANSFER PUMP GRUNDFOS / WILO

2 COARSE BUBBLE DIFFUSER SCOGEN / PROFLEX / EDI

3 FINE BUBBLE DIFFUSER SCOGEN / PROFLEX / EDI

4 AIR BLOWER KAY INTERNATIONAL / EVEREST

5 SLUDGE TRANSFER PUMP JOHNSON / KIRLOSKAR

6 FILTER FEED PUMP JOHNSON / KIRLOSKAR

7 CHLORINE DOSING SYSTEM EDOSE / ASIA LMI

8 MECHANICAL AGITATOR ANALA / FLOW LINE

9 FILTER PRESS HYDRO PRESS / CHALARI FOUNTAIN

10 CENTRIFUGE BASKET DECANTER ALPHA LAVEL / HILLER / APOLLO

ELECTRICALLY ACTUATED VALVE (FOR

11 SIEMENS / SDTORK

DECANTER MECHANISM)

12 UPVC PIPE SUPREME / ASHIRVAD / ASTRAL

13 GI 'C' CLASS PIPE TATA / JINDAL (HISSAR)

14 BRASS BALL VALVE ZOLOTO / LEADER / RB

15 BUTTERFLY VALVE AUDCO (ABOVE 2"), INTERVALVE (UPTO 2")

16 UV STABILIZER ALFA UV / HITECH

17 UF MEMBRANE MHT / HYFLUX / HYDRANAUTICS

18 UF PUMPS GRUNDFOS / CNP / WILO

19 VALVES FOR ULTRAFILTRATION AIRA / UFLOW

20 FLOW METER ASTER MAGFLOW / FOBE MARSHALL / TOSHNIWAL

CIVIL & STRUCTURAL WORKS

1 CEMENT ULTRATECH / ACC / ZUARI / BIRLA / DALMIA / AMBUJA

2 WHITE PORTLAND CEMENT BIRLA WHITE, JK WHITE

3 REINFORCEMENT BAR SAIL/ TATA STEEL/JINDAL/MONNET/ VIZAG / ESSAR/JSW

PAINTS DISTEMPER /ACRYLIC

4 BERGER PAINTS,ASIAN PANITS, ICI, NIPPON

EMULSION

5 WATER PROOFING CEMENT PAINT ASIAN PANITS, SNOWCEM INDIA LTD. BERGER PAINTS

6 SYNTHETIC ENAMEL PAINT BERGER PAINTS,ASIAN PANITS, ICI, NIPPON

7 VITRIFIED TILES RAK/JOHNSON/KAJARIA OR EQUIVALENT

8 HANDLES, DOOR CLOSER,LOCKS,ETC DORMA, DORSET OR EQUIVALENT

9 FLOAT GLASS SAINT GOBAIN, ASAHI OR EQUIVALENT

10 DOOR SHUTTER - STEEL DIAMOND/ SAKTHI HORMANN / GANDHI

HARDWARE /PATCH FITTINGS/

11 HETTICH, DORMA OR EQUIVALENT

FRICTION FITTINGS

12 ALUMINIUM SECTIONS JINDAL, BHARUKA,HINDALCO OR EQUIVALENT

13 WATER PROOFING FOSROC,SIKA, CICO, PENETRON , BASF OR EQUIVALENT

14 MEMBRANE WATER PROOFING ALCHIMICA OR NEOTRIC OR EQUIVALENT

15 INSULATION POLYNUM OR EQUIVALENT

UPVC PIPE & FITTINGS, PVC FITTING &

16 FINOLEX / TRUEBORE / PRINCE OR EQUIVALENT

FIXTURE

17 EPOXY COATING FOSROC / CIPY POLYURETHANE / JBA OR EQUIVALENT

18 SEALANT GE / DOWCONING / FOSROC / WACKER

19 EXPANSION JOINT, FILLER BOARD SUPREME INDUSTRIES OR EQUIVALENT

20 EXPANSION JOINT TREATMENT SIKA / FOSROC OR EQUIVALENT

21 PVC RUGS KGM ASSOCIATES OR EQUIVALENT

22 STAINLESS STEEL JINDAL/ SALEM

23 ALUMINIUM COMPOSITE PANEL DIBOND / ALUCOBOND OR EQUIVALENT

STEEL CASEMENTS, WINDOWS &

24 AGEW / ROYAL FAB / STEEL TECH/ DIANA OR EQUIVALENT

VENTILATOR

PRECONS / PRECAST CONCRETE PRODUCT COMPANY OR

25 SFRC MANHOLE COVER

EQUIVALENT

26 WELDING ELETRODE FASTENER ESAB / HYUNDAI

27 BOLTS & NUTS TVS / DEEPAK / POOJA FORGES OR EQUIVALENT

PTK Project Consultants LLP Page 8 of 11 Volume - III

COLD ROLLED SECTIONS- SHEET

28 ISPAT / JINDAL /UTTAM / SAIL / ESSAR

SOURCES

29 COLD ROLLED STEEL SECTIONS PENNAR / METCO / KIRBY OR EQUIVALENT

30 STRUCTURAL STEEL SAIL/ TISCO / JINDAL / JSW / RINL

31 ANCHOR BOLTS BRITE BAR/ HILTI

32 SHEETING - SOURCE TATA BLUESCOPE / JSW/ DONGBU / BHUSAN

SHEETING PROFILE SYSTEM - ROOF & BLUESCOPE / KIRBY / ZAMIL / INTERARCH / LLOYD,

33

CLADDING MULTICOLOUR & METCO OR EQUIVALENT

34 SHEETING FASTENER CORROSHIELD

35 POLYCARBONATE SHEETS SABIC - GE LEXAN / PALRAM

36 MS / GI PIPE TATA / JINDAL

37 MS HOLLOW SECTION TATA/ JINDAL/ APOLLO

38 CONCRETE ADMIXTURES SIKA / FOSROC / BASF

PTK Project Consultants LLP Page 9 of 11 Volume - III

INSTAKART SERVICES PVT. LTD., HARINGHATA

Warehousing at Haringhata, West Bengal

SEWAGE TREATMENT PLANT (SEQUENTIAL BATCH REACTOR TYPE, 420 KLD)

PREAMBLE

A GENERAL NOTES:

1 This BOQ is an indicative document and is to be used as a tendering aid only. The BOQ

does not constitute a warranty on quantity and item requirement as this Design & Build order.

2 Scope of work shall cover/include designing, supervising, supplying, installation, testing &

commissioning of STP (SBR technology - fully automatic with a central control panel fully

pre/site wired and with all power and control cables to all pumps and equipment including all

instrumentation, level sensor, other controls and weather proof cover/shed for motors &

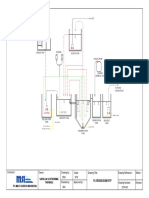

controller) for 420 KLD (210 KLD X 2 streams)

3 STP shall be based on activated sludge process (with air diffuser membrane system), SBR

type with 2 reactors in parallel with sewage handling capacity of 420 KLD (210 KLD X 2

streams)

4 The raw sewage comprises of sewage from entire building. The collection sump with bar

screen shall be a part of the STP.

5 The STP shall be designed as water retaining structures in RCC with RCC top structure and

M.S. epoxy coated, non-skid type, removable manholes covers including piping, valves,

necessary chemical dosing as required by the manufacturer's design.

6 All equipments, pipings, pumps, air blowers and electricals are to be housed in a plant room

including GI hot dipped puddle flange / insert, inlet, outlet, overflow, vents, MS covers, drain

channel with MS gratings etc.

7 Puddle flanges (including puddle flanges for treated water tank) shall be under vendor scope

and shall be GI hot dipped.

8 Offer should include cost of Mandatory spares & consumables etc required for 1st year

operation. In case AMC is also awarded to the bidder cost of these to be excluded.

9 Contractor shall ensure submission of detailed GA drawings (Plan, Section & Elevation),

Equipment GA, technical submittal, P & I diagram, schematic diagram for the above

mentioned components and additional components such as inserts, puddle flanges, vent

pipes etc. if so required for the complete automatic working of the STP and have it approved

by the Client / Consultants.

10 STP shall be designed based on the following incoming waste parameters.

Daily average flow: 420 KLD (210 KLD X 2 streams)

PH: 6.5 - 8.5

BOD5: 150 - 400 mg/l

Suspended Solids: 150 - 400 mg/l

COD: 300 - 800 mg/l

Total Nitrogen as N: Upto 40 mg/l

Total Phospate as P: Upto 10 mg/l

Oil & Grease: Upto 60 mg/l

E Coli: 106 - 108 MPN/100ml

11 Treated sewage outlet parameters:

Daily average flow: 420 KLD (210 KLD X 2 streams)

PH: 7.0 - 8.5

BOD5: Less than 20 mg/l

Suspended Solids: Less than 10 mg/l

COD: Less than 50 mg/l

Total Nitrogen as N: Upto 10 mg/l

Total Phospate as P: Upto 5 mg/l

Oil & Grease: Nil

E Coli: Nil

PTK Project Consultants LLP Page 10 of 11 Volume - III

12 Sewage treatment plant shall include design, supply, installation, testing & commissioning of

following items: Bar Screen Chamber / S.S. Screen having provision for lifting arrangement

etc. complete as required, Oil & Grease trap chamber of suitable size having inlet, outlet and

baffle walls, collection cum equalization tank. Provision for aeration to be kept to avoid any

smell problems and sedimentation, SBR tanks 2 Nos. SBR with 2 reactor system, fully

automatic system with diffused aeration system comprising of Air Blowers with VFD, Moving

decanter for water extruction. Sewage inlet, water decantation & aeration shall be automatic

and PLC controlled with the help of automatic valves or equipment arrangement. Chlorine

contact cum clear water tank with baffles for chlorine mixing and desired minimum volume,

aerobic sludge holding tank, Sludge thickener cum digestor with provision of air diffuser.

Necessary piping, valves & accessories for making the system complete shall also be

included.

13 Cost of following to be included in addition to components/factors mentioned in SCC and

other parts of BOQ:

A Four sets of Manuals for comprehensive Operation and Maintenance,

B Training of operators during commissioning and upto 3 months post commissioning

C Factory tests, if required by client

PTK Project Consultants LLP Page 11 of 11 Volume - III

You might also like

- 350 KLD Sbr-EstimationDocument10 pages350 KLD Sbr-EstimationPrashanth RamanNo ratings yet

- ECOLOGICS STANDARD PRICE LIST FOR ELECTROMECHANICAL EQUIPMENTDocument8 pagesECOLOGICS STANDARD PRICE LIST FOR ELECTROMECHANICAL EQUIPMENTEcologics IndiaNo ratings yet

- Techno-Commercial Offer 100 KLD STP, Betul Based On MBBR HybridDocument9 pagesTechno-Commercial Offer 100 KLD STP, Betul Based On MBBR HybridTech MongerNo ratings yet

- Diligent Etp 1000m3Document18 pagesDiligent Etp 1000m3Prabhakar DhamaleNo ratings yet

- 20 KLD STP Proposal Abha Shree Hotel at BetulDocument10 pages20 KLD STP Proposal Abha Shree Hotel at BetulTech MongerNo ratings yet

- 120KLD ETP - DharmikbhaiDocument7 pages120KLD ETP - DharmikbhaiM. D. RAMCHANDANINo ratings yet

- Techno-Commercial Offer 120KLD TM Based On SBR Technology, VrindavanDocument9 pagesTechno-Commercial Offer 120KLD TM Based On SBR Technology, VrindavanTech MongerNo ratings yet

- Techno-Commercial Offer 100 KLD TM Shiv Shakti Developers, Betul SiteDocument9 pagesTechno-Commercial Offer 100 KLD TM Shiv Shakti Developers, Betul SiteTech MongerNo ratings yet

- Techno-Commercial Offer For 150 KLD STP, Based Upon MBBR.Document9 pagesTechno-Commercial Offer For 150 KLD STP, Based Upon MBBR.Anshika RaiNo ratings yet

- 02.12.21 90m3hr Euroclean-DHV MaithonDocument16 pages02.12.21 90m3hr Euroclean-DHV MaithonSagnik DasNo ratings yet

- Techno-Commercial Offer For 600 KLD STP MBBRDocument9 pagesTechno-Commercial Offer For 600 KLD STP MBBRTech MongerNo ratings yet

- Vepl 5081 TC L 0516Document16 pagesVepl 5081 TC L 0516Nakclean Water SolutionsNo ratings yet

- Techno-Commercial Offer For 5 KLD ETP CUM 12 STP .Document10 pagesTechno-Commercial Offer For 5 KLD ETP CUM 12 STP .Anshika RaiNo ratings yet

- Prefabricated Effluent Treatment Plant ProposalDocument18 pagesPrefabricated Effluent Treatment Plant Proposalt m murshedNo ratings yet

- Design Basis: M/S Space Combine Kind Attn: Mr. Arun VishwakarmaDocument6 pagesDesign Basis: M/S Space Combine Kind Attn: Mr. Arun Vishwakarmabyajaytyagi2266No ratings yet

- Techno-Commercial Offer .For Krishna Hospital Cpacity of 100 KLD ETP Cum STPDocument9 pagesTechno-Commercial Offer .For Krishna Hospital Cpacity of 100 KLD ETP Cum STPAnshika RaiNo ratings yet

- Degasifier 18-02-2017 Sheet 1Document1 pageDegasifier 18-02-2017 Sheet 1Abu SuraisyNo ratings yet

- 04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFDocument8 pages04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFVic KeyNo ratings yet

- Effluent Treatment Plant Tech Report for LAIL Sugar MillDocument28 pagesEffluent Treatment Plant Tech Report for LAIL Sugar MillGarad MadhukarNo ratings yet

- 45 KLD STP PROPOSAL VRANDAVAN GREENS PDFDocument9 pages45 KLD STP PROPOSAL VRANDAVAN GREENS PDFTech MongerNo ratings yet

- Membrane Treatment Processes Offer Versatility and Physical Barrier for Contaminant RemovalDocument8 pagesMembrane Treatment Processes Offer Versatility and Physical Barrier for Contaminant RemovalbazediNo ratings yet

- GM Infinite 410kld FBBR Quote 26.08.16Document14 pagesGM Infinite 410kld FBBR Quote 26.08.16karthikeyanNo ratings yet

- 50 KLD Biological & Tertiary Treatment Plant - RLS FinalDocument19 pages50 KLD Biological & Tertiary Treatment Plant - RLS FinalkezaihrajNo ratings yet

- Techno Commercial Offer For 5 KLD Packaged Effluent Treatment PlantDocument11 pagesTechno Commercial Offer For 5 KLD Packaged Effluent Treatment PlantDogo ArgentinoNo ratings yet

- Handover Document - Yaden KatunayakeDocument39 pagesHandover Document - Yaden KatunayakeUTY ENGNo ratings yet

- GN Buildtech Private LTD: Proposal For, Supply& Installation of 10000 LPH Ro PlantDocument9 pagesGN Buildtech Private LTD: Proposal For, Supply& Installation of 10000 LPH Ro Plantgnbuildtech Pvt ltdNo ratings yet

- Supply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Document24 pagesSupply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Saif Ahmed Nabil100% (1)

- 2000 LPH Ro PlantDocument17 pages2000 LPH Ro PlantKamatchi NathanNo ratings yet

- WTE-ENDOM2021001505-R12-AS Cooling-SSF and DSDocument26 pagesWTE-ENDOM2021001505-R12-AS Cooling-SSF and DSDeepak Patil100% (1)

- 0.90 MLD MechanicalDocument8 pages0.90 MLD Mechanicalkiran raghukiranNo ratings yet

- FWD CALCULATION NOTESDocument10 pagesFWD CALCULATION NOTESMuhammad Ashraful ArifinNo ratings yet

- PFD FileDocument11 pagesPFD FileNaveen MahawarNo ratings yet

- 2000 LPDDocument5 pages2000 LPDACTS TECHNO SOLUTIONSNo ratings yet

- Bill of Quantities Sewage Treatment PlanDocument11 pagesBill of Quantities Sewage Treatment PlanMiguel ChanNo ratings yet

- ES0153-75320100-DBR-0001DM PlantDocument73 pagesES0153-75320100-DBR-0001DM Plantraaj bharath100% (1)

- Multiorganics 50 KLDDocument24 pagesMultiorganics 50 KLDArjun KrishnakumarNo ratings yet

- Techno-Commercial Offer 100 KLD TM Shiv Shakti Developers, Betul SiteDocument9 pagesTechno-Commercial Offer 100 KLD TM Shiv Shakti Developers, Betul SiteTech MongerNo ratings yet

- STP Design Report - IndiqubeDocument20 pagesSTP Design Report - IndiqubeRajkishore NayakNo ratings yet

- Bike Wash ETP OfferDocument11 pagesBike Wash ETP OfferMuhammadHanifaNo ratings yet

- Hydrochloric acid Regeneration of Cation Exchange Resin 225 HDocument8 pagesHydrochloric acid Regeneration of Cation Exchange Resin 225 HPravin BoteNo ratings yet

- Trehan STPDocument2 pagesTrehan STPsoma_sharadNo ratings yet

- 20 KLD STP - Offer - MBBRDocument10 pages20 KLD STP - Offer - MBBRHarish Kumar MahavarNo ratings yet

- 5011) QUOTATION FOR R O PLANT 4000 LPH FOR Multan Chemical (Faisalabad) 27-07-2015Document5 pages5011) QUOTATION FOR R O PLANT 4000 LPH FOR Multan Chemical (Faisalabad) 27-07-2015shahbaz shahNo ratings yet

- Operator - Book-StpDocument113 pagesOperator - Book-StpAce Dynamics India100% (1)

- 50 KLD STP BoqDocument104 pages50 KLD STP BoqAminur RahmanNo ratings yet

- Manual ENG - Kristal 600ER0820 V1.3b (221110)Document49 pagesManual ENG - Kristal 600ER0820 V1.3b (221110)merifie renegado67% (3)

- Presentation of WTPDocument75 pagesPresentation of WTPsiddhartha pandaNo ratings yet

- 40 KLD MBR QuoteDocument15 pages40 KLD MBR QuoteV Narasimha RajuNo ratings yet

- 20 KLD STP Upgreation PROPOSAL-GMCPLDocument7 pages20 KLD STP Upgreation PROPOSAL-GMCPLTech Monger100% (1)

- Techno Commercial Proposal For 50KLD STP For Bhakti EnterprisesDocument21 pagesTechno Commercial Proposal For 50KLD STP For Bhakti Enterprisesamol100% (1)

- Flint WTP O-M Manual With SOPs 553219 7Document83 pagesFlint WTP O-M Manual With SOPs 553219 7Omkar BharankarNo ratings yet

- Company ProfileDocument4 pagesCompany ProfileLOGIN ANIMONo ratings yet

- Sewage treatment plant membrane bioreactor flow sheetDocument13 pagesSewage treatment plant membrane bioreactor flow sheetyoucef tecNo ratings yet

- MBBR DesignDocument5 pagesMBBR Designsaurabh kushwahaNo ratings yet

- Annexure 16 - Tool For Design of Tube SettlerDocument1 pageAnnexure 16 - Tool For Design of Tube SettlerWikaz FiansyahNo ratings yet

- A3S Enviro Consultants - ProfileDocument7 pagesA3S Enviro Consultants - ProfileA3S Enviro Private LimitedNo ratings yet

- STP Drawing PDFDocument7 pagesSTP Drawing PDFRudi suhendroNo ratings yet

- Summary Report: RO System Flow DiagramDocument3 pagesSummary Report: RO System Flow Diagramjugal ranaNo ratings yet

- Mangalore PTA Project ISBL & OSBL Status and Path ForwardDocument21 pagesMangalore PTA Project ISBL & OSBL Status and Path ForwardSajeshKumarNo ratings yet

- Guard Pond: 08-Dec-14 JBF Petrochemicals LTD 1Document5 pagesGuard Pond: 08-Dec-14 JBF Petrochemicals LTD 1SajeshKumarNo ratings yet

- Internal PHE BOQ - R1Document7 pagesInternal PHE BOQ - R1SajeshKumarNo ratings yet

- Presentation For JBF-TP MGMT Meeting-Rev1 020216Document17 pagesPresentation For JBF-TP MGMT Meeting-Rev1 020216SajeshKumarNo ratings yet

- GCC EPC Vendor Status UpdateDocument5 pagesGCC EPC Vendor Status UpdateSajeshKumarNo ratings yet

- SCPL Phe BoqDocument120 pagesSCPL Phe BoqSajeshKumarNo ratings yet

- 1 Water Treatment Plant - 240 KLDDocument7 pages1 Water Treatment Plant - 240 KLDSajeshKumarNo ratings yet

- BILL OF QUANTITY For HSD Storage & Distribution SystemDocument6 pagesBILL OF QUANTITY For HSD Storage & Distribution SystemSajeshKumarNo ratings yet

- Flipkart, Kolkata-Concept Note On Hvac System-Rev p0Document24 pagesFlipkart, Kolkata-Concept Note On Hvac System-Rev p0SajeshKumarNo ratings yet

- Design of Ultra Filtration System: Sanjeev SrivastavaDocument33 pagesDesign of Ultra Filtration System: Sanjeev SrivastavaSajeshKumar0% (1)

- OSBL DPR Dated 16.01.2014Document9 pagesOSBL DPR Dated 16.01.2014SajeshKumarNo ratings yet

- Chapter 5Document219 pagesChapter 5AmySinghNo ratings yet

- Revised Boq For Office & Linlk Building R01 12.05.2021Document5 pagesRevised Boq For Office & Linlk Building R01 12.05.2021SajeshKumarNo ratings yet

- KitchenDocument39 pagesKitchenSajeshKumarNo ratings yet

- System Wise Piping Status 27042013Document3 pagesSystem Wise Piping Status 27042013SajeshKumarNo ratings yet

- Bill of Quantity (BOQ) - Part 2 Lift & Escalator Project Location - Haringhata, KolkataDocument3 pagesBill of Quantity (BOQ) - Part 2 Lift & Escalator Project Location - Haringhata, KolkataSajeshKumarNo ratings yet

- S.No. Description Action by Remarks 1 Safety To Be CompletedDocument6 pagesS.No. Description Action by Remarks 1 Safety To Be CompletedSajeshKumarNo ratings yet

- CGP Mech Comp Action PlanDocument16 pagesCGP Mech Comp Action PlanSajeshKumarNo ratings yet

- Primavera Schedule PDFDocument2 pagesPrimavera Schedule PDFSajeshKumarNo ratings yet

- CGP Progress 10Jan-16Jan2014Document38 pagesCGP Progress 10Jan-16Jan2014SajeshKumarNo ratings yet

- Pump TypesDocument2 pagesPump TypesAnonymous iQMKqMqqWNo ratings yet

- Primavera P6 Exercise WorksheetDocument35 pagesPrimavera P6 Exercise Worksheetdyeyson3095% (19)

- Microsoft Word - Primavera P6 Exercise Worksheet Rev 3.0 2013-10-23Document48 pagesMicrosoft Word - Primavera P6 Exercise Worksheet Rev 3.0 2013-10-23SajeshKumarNo ratings yet

- Pump TypesDocument2 pagesPump TypesAnonymous iQMKqMqqWNo ratings yet

- Primavera P6 PM Course MaterialDocument75 pagesPrimavera P6 PM Course Materialsunilas21840896% (27)

- Evaporator HandbookDocument68 pagesEvaporator Handbookche_abdo100% (3)

- Lab 1Document10 pagesLab 1SajeshKumarNo ratings yet

- Compressor PDFDocument3 pagesCompressor PDFSajeshKumarNo ratings yet

- Pump TypesDocument2 pagesPump TypesAnonymous iQMKqMqqWNo ratings yet

- AM007KNNDCH+AA+SUBMITTAL M4Way 12272017Document2 pagesAM007KNNDCH+AA+SUBMITTAL M4Way 12272017Gilberto Alfaro De la ONo ratings yet

- CSR 2016-17Document156 pagesCSR 2016-17ssdprojects RexNo ratings yet

- Rothoblaas en Membranes and Tapes 01 17Document220 pagesRothoblaas en Membranes and Tapes 01 17amazonfed2433No ratings yet

- Astm C-270 PDFDocument13 pagesAstm C-270 PDFGita Tawankz100% (2)

- Lifting Lug DesignDocument17 pagesLifting Lug Designguravdr100% (2)

- Investigatory Project On Prep of CementDocument9 pagesInvestigatory Project On Prep of CementKrish JaiswalNo ratings yet

- ASHRAE Report On Pre Cooling With Indirect Evaporative CoolingDocument8 pagesASHRAE Report On Pre Cooling With Indirect Evaporative CoolingAhmad Mahrous AboulsoudNo ratings yet

- Noreva Valve Cat - 2018 Online Download PDFDocument46 pagesNoreva Valve Cat - 2018 Online Download PDFSirvan HomaNo ratings yet

- Asce24 Highlights Dec2010Document5 pagesAsce24 Highlights Dec2010prg1000No ratings yet

- TANK 06 Test PackDocument12 pagesTANK 06 Test PackGomathyselvi100% (2)

- 29+635 - (32 Deg Skew)Document27 pages29+635 - (32 Deg Skew)Praveen CyssanNo ratings yet

- 6035 Riverview - Barn FlippedDocument3 pages6035 Riverview - Barn FlippedAlex Hdz GNo ratings yet

- Raychem Tubing Catalog 2009 PDFDocument205 pagesRaychem Tubing Catalog 2009 PDFlijojose1No ratings yet

- Slides - 4Document55 pagesSlides - 4Rahul PandeyNo ratings yet

- Stellite 12Document2 pagesStellite 12xy2zjgNo ratings yet

- AASHTO Guide Specifications For Design of Pedestrian Bridges 2009 (Draft)Document17 pagesAASHTO Guide Specifications For Design of Pedestrian Bridges 2009 (Draft)Laurence Arcon Banal0% (1)

- PT SLAB VERIFICATIONDocument6 pagesPT SLAB VERIFICATIONAashu chaudharyNo ratings yet

- Uflow Make Angle Seat ValveDocument3 pagesUflow Make Angle Seat ValveMurtaza BarwaniwalaNo ratings yet

- Part 5 Manufacturing 2023Document94 pagesPart 5 Manufacturing 2023Ilham AyuningNo ratings yet

- STRENGTH OF BASE BLOCK DURING ERECTIONDocument3 pagesSTRENGTH OF BASE BLOCK DURING ERECTIONShubham BhamareNo ratings yet

- Armor Rods: NomenclatureDocument8 pagesArmor Rods: NomenclatureArturo Tipacti QuijanoNo ratings yet

- Ceratherm 600-3: Radiant WarmersDocument4 pagesCeratherm 600-3: Radiant WarmersthsenNo ratings yet

- Centrifugal Pump Piping Design LayoutDocument21 pagesCentrifugal Pump Piping Design LayoutKavin KumarNo ratings yet

- Advantages of High Temperature MaterialsDocument20 pagesAdvantages of High Temperature MaterialsDeep MohantaNo ratings yet

- Branz BU578 Ventilation Drying Behind Wall CladdingsDocument8 pagesBranz BU578 Ventilation Drying Behind Wall CladdingsYanina MashkinaNo ratings yet

- Tool SectionDocument26 pagesTool Sectionswoo323No ratings yet

- ABG Green Retaining Wall GuideDocument24 pagesABG Green Retaining Wall GuideChris FindlayNo ratings yet

- 31 Samss 001Document38 pages31 Samss 001nadeem shaikh100% (1)

- General Requirements For Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and StripDocument26 pagesGeneral Requirements For Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and StripIlham Pane100% (1)

- 10 28 13 - Toilet Accessories PDFDocument6 pages10 28 13 - Toilet Accessories PDFmasoodaeNo ratings yet