Professional Documents

Culture Documents

2 National Certification Examination 2005 FOR: Energy Auditors Model Test Series - 1

2 National Certification Examination 2005 FOR: Energy Auditors Model Test Series - 1

Uploaded by

Shahedabanu AghadiCopyright:

Available Formats

You might also like

- ICE All ExercisesDocument10 pagesICE All ExercisesB Ninh100% (1)

- Ejercicios Motores.Document10 pagesEjercicios Motores.Daniel Armas100% (1)

- 144 BDocument14 pages144 BJoshi DhvanitNo ratings yet

- Analysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantFrom EverandAnalysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantNo ratings yet

- TOTAL Angola Block 17 Pazflor Fields Development ProjectDocument26 pagesTOTAL Angola Block 17 Pazflor Fields Development ProjectYangNo ratings yet

- Check List Valve PDFDocument2 pagesCheck List Valve PDFikan100% (1)

- Paper 4A SolutionDocument10 pagesPaper 4A SolutionSHAMSIK2002No ratings yet

- ICE RevisionDocument4 pagesICE RevisionjehadyamNo ratings yet

- BeeDocument20 pagesBeeAnudeep ChittluriNo ratings yet

- ME 416 (ME 4) Internal Combustion Engine Practice ProblemsDocument3 pagesME 416 (ME 4) Internal Combustion Engine Practice ProblemsMark MagdaleNo ratings yet

- Paper 4 - Set A Key 14 National Certification Examination FOR Energy Auditors - August, 2013Document14 pagesPaper 4 - Set A Key 14 National Certification Examination FOR Energy Auditors - August, 2013Muthiah Chidambaram MuthiahNo ratings yet

- Paper-4 SetB Key Final 8may2009Document10 pagesPaper-4 SetB Key Final 8may2009chkk.ramakumarNo ratings yet

- Me8493 Te Rejinpaul Iq Am19 PDFDocument2 pagesMe8493 Te Rejinpaul Iq Am19 PDFAngelinNo ratings yet

- Shantanu DasDocument10 pagesShantanu DasarunkdevassyNo ratings yet

- Paper-4 SetA Key Final 8may2009Document10 pagesPaper-4 SetA Key Final 8may2009SHAMSIK2002No ratings yet

- SQ - 4.1 - Boiler (Table Format)Document11 pagesSQ - 4.1 - Boiler (Table Format)Gajanan JagtapNo ratings yet

- YgDocument2 pagesYgVincent Martinez0% (1)

- PROJECT. (Final) ME3CDocument1 pagePROJECT. (Final) ME3CJoesun LizardoNo ratings yet

- Home Exercises - AllDocument6 pagesHome Exercises - AllRajithaSomathilakeNo ratings yet

- MEREV 2 Assessment 3Document1 pageMEREV 2 Assessment 3Mark David MoradasNo ratings yet

- Unit I: Gas Power CyclesDocument78 pagesUnit I: Gas Power CyclesBalaji DsNo ratings yet

- Assignment 1 MEPPEDocument5 pagesAssignment 1 MEPPEFrancis Paulo CruzNo ratings yet

- Numerical Problems: Power Plant Equipment (Electrical IV/I)Document3 pagesNumerical Problems: Power Plant Equipment (Electrical IV/I)Rishav niroulaNo ratings yet

- Thermal and Nuclear Power Plant Assignment QuestionsDocument3 pagesThermal and Nuclear Power Plant Assignment QuestionsAshok KumarNo ratings yet

- At AssignmentDocument3 pagesAt AssignmentYogesh PatilNo ratings yet

- ME FinalDocument81 pagesME FinalAnkit DahiyaNo ratings yet

- Gas Turbines Tutorial Part 1 of 2Document4 pagesGas Turbines Tutorial Part 1 of 2Gulain MayomboNo ratings yet

- ME6404 Thermal EngineeringDocument21 pagesME6404 Thermal EngineeringAnonymous mRBbdopMKfNo ratings yet

- ME482 M3 Ktunotes - inDocument15 pagesME482 M3 Ktunotes - inTHIAGARAJAN ANo ratings yet

- Duration: 2 Hrs. Max. Marks: 100Document4 pagesDuration: 2 Hrs. Max. Marks: 100AshutoshBhattNo ratings yet

- Assignment 2 MEC451 HampaskacaDocument2 pagesAssignment 2 MEC451 HampaskacahampaskacaNo ratings yet

- Final Practice-ProblemsDocument4 pagesFinal Practice-ProblemsMhd Donde Al HajNo ratings yet

- Thermal Engineering QP AuDocument14 pagesThermal Engineering QP AusaisenthNo ratings yet

- 4 3 CogenerationDocument10 pages4 3 CogenerationJayvin RossNo ratings yet

- Fallsem2013-14 Cp0084 Asgn03 Assignment3Document2 pagesFallsem2013-14 Cp0084 Asgn03 Assignment3Agnibh PrakashNo ratings yet

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDocument12 pagesEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshNo ratings yet

- SY - Thermal Engineering - JAN 2019Document3 pagesSY - Thermal Engineering - JAN 2019Paras kapoorNo ratings yet

- Paper 4SetA 24nov2009 KeyDocument8 pagesPaper 4SetA 24nov2009 KeySHAMSIK2002No ratings yet

- Mce320 Tutorial KitDocument20 pagesMce320 Tutorial KitxentrixxNo ratings yet

- Assignment2 - 110006 - Elements of Mechenical EngineeringDocument6 pagesAssignment2 - 110006 - Elements of Mechenical EngineeringSaniya Jumani0% (1)

- Chapter 8 Van NessDocument76 pagesChapter 8 Van NessConrad MonterolaNo ratings yet

- ICE Assignment 15032017 035808AMDocument5 pagesICE Assignment 15032017 035808AMGerlan Madrid MingoNo ratings yet

- Ormat Technologies Inc. - Ormat Energy Converters Proven Power From Cement Plant Waste Heat - 2013-05-09Document7 pagesOrmat Technologies Inc. - Ormat Energy Converters Proven Power From Cement Plant Waste Heat - 2013-05-09Kiran VeerubhotlaNo ratings yet

- Universiti Teknologi Mara Final Examination: Confidential EM/APR 2007/KJM451Document10 pagesUniversiti Teknologi Mara Final Examination: Confidential EM/APR 2007/KJM451Diraf AlipNo ratings yet

- Local Media1133470422700059155Document6 pagesLocal Media1133470422700059155Billy JhunNo ratings yet

- Fluid Mechanics QuestionsDocument3 pagesFluid Mechanics QuestionsWaleed UsmanNo ratings yet

- Sheet 1Document3 pagesSheet 1saad ElsheikhNo ratings yet

- Tutorial AssignmentDocument5 pagesTutorial AssignmentAnup ChauhanNo ratings yet

- 4.9 HVAC SystemDocument5 pages4.9 HVAC Systembsunanda01No ratings yet

- Me8595 Iq R17Document2 pagesMe8595 Iq R17Narayanan SubramanianNo ratings yet

- Final Exam ENGI 2800 - Engineering Thermodynamics IDocument2 pagesFinal Exam ENGI 2800 - Engineering Thermodynamics Iياسر سعيد عبادي البحريNo ratings yet

- Mechanical Engineering Department: Refrigeration & Air Conditioning (ME 434)Document3 pagesMechanical Engineering Department: Refrigeration & Air Conditioning (ME 434)Ahmed SabryNo ratings yet

- Cog en Era Ti OnDocument12 pagesCog en Era Ti OnMayank DubeyNo ratings yet

- National Certification Examination 2008 FOR Energy AuditorsDocument10 pagesNational Certification Examination 2008 FOR Energy AuditorsMukesh KumarNo ratings yet

- Tutorials 1-4Document6 pagesTutorials 1-4KrishnaNo ratings yet

- Nhom 10 - Chuong 4Document10 pagesNhom 10 - Chuong 4Alfie StacyNo ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- How To Scale-Up: M Miix Xiin NG G P Prro Occe Es Ss Se Es S Iin NDocument9 pagesHow To Scale-Up: M Miix Xiin NG G P Prro Occe Es Ss Se Es S Iin NOdst Ovac100% (1)

- What Is MineralDocument18 pagesWhat Is MineralImee TiloNo ratings yet

- The Mole Concept-Set A Power Point 2020Document23 pagesThe Mole Concept-Set A Power Point 2020Muyatwa LiksNo ratings yet

- Borjatherm - FolletoDocument12 pagesBorjatherm - FolletoEduardo DíezNo ratings yet

- Mark Scheme (Results) January 2008: GCE Chemistry (6246) Paper 1ADocument8 pagesMark Scheme (Results) January 2008: GCE Chemistry (6246) Paper 1Anahian_aziz9050No ratings yet

- Shiva Prasad BhatDocument160 pagesShiva Prasad BhatrambhadesiNo ratings yet

- Flopamfa 920 SepDocument9 pagesFlopamfa 920 SepAgung Ariefat LubisNo ratings yet

- Study Material: Free Master Class SeriesDocument34 pagesStudy Material: Free Master Class SeriesKshitij ChandraNo ratings yet

- Self-Emulsifying Drug Delivery Systems (SEDDS) For Improved Oral Delivery of Lipophilic DrugsDocument10 pagesSelf-Emulsifying Drug Delivery Systems (SEDDS) For Improved Oral Delivery of Lipophilic DrugsAna KovačevićNo ratings yet

- Pollution Status and Trends in Water Quality of The Shitalakhya and Balu RiversDocument19 pagesPollution Status and Trends in Water Quality of The Shitalakhya and Balu RiversZisan AhmedNo ratings yet

- GTC Isomalk Technologies For Light Naphtha IsomerizationDocument29 pagesGTC Isomalk Technologies For Light Naphtha IsomerizationToni ĐạtNo ratings yet

- Charge-Directed Conjugate Addition Reactions of SilylatedDocument8 pagesCharge-Directed Conjugate Addition Reactions of SilylatedJonathan MendozaNo ratings yet

- Bohler Colour ChartDocument1 pageBohler Colour Chartscooba84No ratings yet

- Development, Applications and Investigations of Self-Compacting ConcreteDocument3 pagesDevelopment, Applications and Investigations of Self-Compacting ConcreteAnonymous 9iK0i8h0dPNo ratings yet

- Design of Sewage Treatment Plants-1Document20 pagesDesign of Sewage Treatment Plants-1Jishnu JayarajNo ratings yet

- Water Quality For Supercritical Units Steag FormatDocument40 pagesWater Quality For Supercritical Units Steag FormatAmit MukherjeeNo ratings yet

- B135M-10 Standard Specification For Seamless Brass Tube (Metric)Document6 pagesB135M-10 Standard Specification For Seamless Brass Tube (Metric)Salma FarooqNo ratings yet

- Module 5Document39 pagesModule 5Yasmine ShafaNo ratings yet

- Azolla TenderDocument4 pagesAzolla TenderprashantkothariNo ratings yet

- RHIZOSPHERE Project WorkDocument22 pagesRHIZOSPHERE Project WorkAniekeme GabrielNo ratings yet

- AN-nir065Document4 pagesAN-nir065Mihaly JNo ratings yet

- Isodon Rugosus As Potential Source of Phyto-Pharmacological Agents: A ReviewDocument7 pagesIsodon Rugosus As Potential Source of Phyto-Pharmacological Agents: A ReviewMuhammad Muneeb AhmadNo ratings yet

- Safety GramDocument4 pagesSafety GramsjmpakNo ratings yet

- Catalogo CimaDocument6 pagesCatalogo Cimazetta08No ratings yet

- CHEM F313: Instrumental Methods of Analysis: UV-Vis Spectrometry (Contd.)Document17 pagesCHEM F313: Instrumental Methods of Analysis: UV-Vis Spectrometry (Contd.)AYUSH SHARMANo ratings yet

- 9701 s10 QP 41Document20 pages9701 s10 QP 41Hubbak KhanNo ratings yet

- PB PHT 1Document32 pagesPB PHT 1Gabriel Caicedo RussyNo ratings yet

- Measurement of Corrosion Potentials of Aluminum Alloys: Standard Test Method ForDocument4 pagesMeasurement of Corrosion Potentials of Aluminum Alloys: Standard Test Method ForNav Talukdar100% (1)

2 National Certification Examination 2005 FOR: Energy Auditors Model Test Series - 1

2 National Certification Examination 2005 FOR: Energy Auditors Model Test Series - 1

Uploaded by

Shahedabanu AghadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 National Certification Examination 2005 FOR: Energy Auditors Model Test Series - 1

2 National Certification Examination 2005 FOR: Energy Auditors Model Test Series - 1

Uploaded by

Shahedabanu AghadiCopyright:

Available Formats

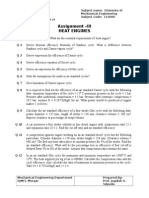

2nd NATIONAL CERTIFICATION EXAMINATION 2005

FOR

ENERGY AUDITORS

MODEL TEST SERIES –1

Paper – 4: Energy Performance Assessment for Equipment and Utility Systems

Duration: 2 HRS

Max. Marks: 100

General instructions:

o Please check that this question paper contains 16 questions

o The question paper is divided into three sections

o All questions in all three sections are compulsory

o All parts of a question should be answered at one place

o Open Book Examination

Section – I: Short Questions

Marks: 10 x 1 = 10

(i) Answer all Ten questions

(ii) Each question carries One mark

1 How boiler rated capacity is specified?

2 What are the components of surface heat loss in the furnaces and its dependent

factors affecting loss?

3 How Efficiency and Power Factor varies in motors with VSD Drives.

4 What are the three reasons for poor fan performance in the field?

5 How do you determine system resistance for a pump?

6 What are the measuring instruments required for a compressed air delivery test by

nozzle method ?

7 A refrigeration plant operating at 600 T is consuming 564 kW of compressor power.

Find out the kW/ton, COP and EER

8 What is Lamp Circuit Efficacy?

9 What is the capacity factor of wind turbine.

Paper 4/ Series 1 Dr. Ambedkar Institute of Productivity, NPC-Chennai. Page 1 of 4

10 Name four type of wastage due to poorhouse keeping?

Section - II: Long Questions

Marks: 2 x 5 = 10

(i) Answer all Two questions

(ii) Each question carries Five marks

1 Compare the advantage of biogas generation over the direct burning of 25 kg

biomass?

2 What are the Factors Affecting Furnace Performance ?

Section - III: Numerical Questions

Marks: 4 x 20 = 80

(i) Answer all Four questions

(ii) Each question carries Twenty marks

1 A Boiler Efficiency trial was conducted in an Furnace Oil fired process boiler during

Energy Audit Study and the following data were collected.

Boiler Data :

Boiler Rated Capacity = 10 TPH (F&A 100oC)

Rated Boiler Efficiency = 84%

Actual steam generation pressure = 7 kg/cm2 (g) Saturated

Feed water Temperature = 45oC

Fuel Oil Data :

Furnace Oil Consumption = 600 litre per hour

GCV of Oil = 10200 Kcal/kg

Specific gravity of oil = 0.92

% Carbon = 84%

% Hydrogen = 12%

% Sulphur = 3%

% Oxygen = Nil

% Nitrogen = 1%

Flue Gas Data :

% O2 in Flue Gas = 5.5% by volume

CO = Nil

Flue Gas Temperature = 240oC

Specific Heat of Flue Gas = 0.24

Moisture at Ambient air = 0.03 kg/kg of air

Paper 4/ Series 1 Dr. Ambedkar Institute of Productivity, NPC-Chennai. Page 2 of 4

Ambient air temperature = 40oC

Determine the boiler efficiency by indirect method by assuming 2% boiler surface

heat loss. Also find out the fuel oil saving in litre per hour, if efficiency of boiler was

improved to Rated efficiency.

2 A process plant requires 28 tonnes of steam per hour. The power requirement is 2250

kW. The plant operates for 8000 hours per annum.

Steam is generated at 2 bar in a coal fired boiler with an efficiency of 75% The feed

water temperature is 80OC. The calorific value of coal is 4000 kcal/kg. The cost of

coal is Rs.2000/tonne.

Power is drawn from the grid at Rs. 4/kWh. The contract demand is 3000 kVA and the

company is charged for 100 % of the contract demand at Rs. 300/kVA.

The company is planning for a back pressure cogeneration plant using the same coal

with the following parameters. The power and steam demand were fully met by the

cogeneration plant.

Boiler generation pressure - 18 bar, 310OC

Boiler efficiency - 81 %

A contract demand of 1000 kVA with the grid was kept for emergency purpose.

Investment required - Rs. 20 crores

Generated power = 2250 kW

Find out the IRR over a project life cycle of 6 years.

3 A centrifugal pump at base of cooling tower pumps 120 m3/hr at pressure 2.1 kg/cm2.

The cooling tower range was measured to be 4 oC. What is the power input at the

motor? (Efficiency of pump is 65% and motor efficiency is 82%).

Pump is throttled such that cooling tower range was 6oC. What is the new flow rate

under throttled conditions? (Pressure drop across the throttle valve is 0.5 kg/cm2).

If instead of throttling, the existing impeller is replaced with a new impeller at a cost

of Rs.25000/- find the operating point and differential savings vis-à-vis throttling case

considering 8760 operating hours and unit cost of Rs.4/- (assume pump efficiency of

63% and motor efficiency of 82%)

4 In an air conditioning system, the air flow rate is 80,000 m3/hr at a density of 1.2

kg/m3.. The inlet and outlet enthalpies of air at Air Handling Unit is 105 kJ/kg and 79

kJ/kg. The COP of the system is 3.82. It is proposed to replace it with a vapour

absorption system at a cost of Rs. 50 lacs with an annual maintenance cost of Rs.4

lacs.. The steam consumption will be 4.5 kg/hr/TR. The steam is to be generated by a

coal fired boiler with an evaporation ratio of 4.5. The energy electrical energy cost is

Rs.4 per kWh and the system operates for 8000 hrs per annum. The cost of coal is

Paper 4/ Series 1 Dr. Ambedkar Institute of Productivity, NPC-Chennai. Page 3 of 4

Rs.2000/tonne. Find out the payback period for the investment.

Paper 4/ Series 1 Dr. Ambedkar Institute of Productivity, NPC-Chennai. Page 4 of 4

You might also like

- ICE All ExercisesDocument10 pagesICE All ExercisesB Ninh100% (1)

- Ejercicios Motores.Document10 pagesEjercicios Motores.Daniel Armas100% (1)

- 144 BDocument14 pages144 BJoshi DhvanitNo ratings yet

- Analysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantFrom EverandAnalysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantNo ratings yet

- TOTAL Angola Block 17 Pazflor Fields Development ProjectDocument26 pagesTOTAL Angola Block 17 Pazflor Fields Development ProjectYangNo ratings yet

- Check List Valve PDFDocument2 pagesCheck List Valve PDFikan100% (1)

- Paper 4A SolutionDocument10 pagesPaper 4A SolutionSHAMSIK2002No ratings yet

- ICE RevisionDocument4 pagesICE RevisionjehadyamNo ratings yet

- BeeDocument20 pagesBeeAnudeep ChittluriNo ratings yet

- ME 416 (ME 4) Internal Combustion Engine Practice ProblemsDocument3 pagesME 416 (ME 4) Internal Combustion Engine Practice ProblemsMark MagdaleNo ratings yet

- Paper 4 - Set A Key 14 National Certification Examination FOR Energy Auditors - August, 2013Document14 pagesPaper 4 - Set A Key 14 National Certification Examination FOR Energy Auditors - August, 2013Muthiah Chidambaram MuthiahNo ratings yet

- Paper-4 SetB Key Final 8may2009Document10 pagesPaper-4 SetB Key Final 8may2009chkk.ramakumarNo ratings yet

- Me8493 Te Rejinpaul Iq Am19 PDFDocument2 pagesMe8493 Te Rejinpaul Iq Am19 PDFAngelinNo ratings yet

- Shantanu DasDocument10 pagesShantanu DasarunkdevassyNo ratings yet

- Paper-4 SetA Key Final 8may2009Document10 pagesPaper-4 SetA Key Final 8may2009SHAMSIK2002No ratings yet

- SQ - 4.1 - Boiler (Table Format)Document11 pagesSQ - 4.1 - Boiler (Table Format)Gajanan JagtapNo ratings yet

- YgDocument2 pagesYgVincent Martinez0% (1)

- PROJECT. (Final) ME3CDocument1 pagePROJECT. (Final) ME3CJoesun LizardoNo ratings yet

- Home Exercises - AllDocument6 pagesHome Exercises - AllRajithaSomathilakeNo ratings yet

- MEREV 2 Assessment 3Document1 pageMEREV 2 Assessment 3Mark David MoradasNo ratings yet

- Unit I: Gas Power CyclesDocument78 pagesUnit I: Gas Power CyclesBalaji DsNo ratings yet

- Assignment 1 MEPPEDocument5 pagesAssignment 1 MEPPEFrancis Paulo CruzNo ratings yet

- Numerical Problems: Power Plant Equipment (Electrical IV/I)Document3 pagesNumerical Problems: Power Plant Equipment (Electrical IV/I)Rishav niroulaNo ratings yet

- Thermal and Nuclear Power Plant Assignment QuestionsDocument3 pagesThermal and Nuclear Power Plant Assignment QuestionsAshok KumarNo ratings yet

- At AssignmentDocument3 pagesAt AssignmentYogesh PatilNo ratings yet

- ME FinalDocument81 pagesME FinalAnkit DahiyaNo ratings yet

- Gas Turbines Tutorial Part 1 of 2Document4 pagesGas Turbines Tutorial Part 1 of 2Gulain MayomboNo ratings yet

- ME6404 Thermal EngineeringDocument21 pagesME6404 Thermal EngineeringAnonymous mRBbdopMKfNo ratings yet

- ME482 M3 Ktunotes - inDocument15 pagesME482 M3 Ktunotes - inTHIAGARAJAN ANo ratings yet

- Duration: 2 Hrs. Max. Marks: 100Document4 pagesDuration: 2 Hrs. Max. Marks: 100AshutoshBhattNo ratings yet

- Assignment 2 MEC451 HampaskacaDocument2 pagesAssignment 2 MEC451 HampaskacahampaskacaNo ratings yet

- Final Practice-ProblemsDocument4 pagesFinal Practice-ProblemsMhd Donde Al HajNo ratings yet

- Thermal Engineering QP AuDocument14 pagesThermal Engineering QP AusaisenthNo ratings yet

- 4 3 CogenerationDocument10 pages4 3 CogenerationJayvin RossNo ratings yet

- Fallsem2013-14 Cp0084 Asgn03 Assignment3Document2 pagesFallsem2013-14 Cp0084 Asgn03 Assignment3Agnibh PrakashNo ratings yet

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDocument12 pagesEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshNo ratings yet

- SY - Thermal Engineering - JAN 2019Document3 pagesSY - Thermal Engineering - JAN 2019Paras kapoorNo ratings yet

- Paper 4SetA 24nov2009 KeyDocument8 pagesPaper 4SetA 24nov2009 KeySHAMSIK2002No ratings yet

- Mce320 Tutorial KitDocument20 pagesMce320 Tutorial KitxentrixxNo ratings yet

- Assignment2 - 110006 - Elements of Mechenical EngineeringDocument6 pagesAssignment2 - 110006 - Elements of Mechenical EngineeringSaniya Jumani0% (1)

- Chapter 8 Van NessDocument76 pagesChapter 8 Van NessConrad MonterolaNo ratings yet

- ICE Assignment 15032017 035808AMDocument5 pagesICE Assignment 15032017 035808AMGerlan Madrid MingoNo ratings yet

- Ormat Technologies Inc. - Ormat Energy Converters Proven Power From Cement Plant Waste Heat - 2013-05-09Document7 pagesOrmat Technologies Inc. - Ormat Energy Converters Proven Power From Cement Plant Waste Heat - 2013-05-09Kiran VeerubhotlaNo ratings yet

- Universiti Teknologi Mara Final Examination: Confidential EM/APR 2007/KJM451Document10 pagesUniversiti Teknologi Mara Final Examination: Confidential EM/APR 2007/KJM451Diraf AlipNo ratings yet

- Local Media1133470422700059155Document6 pagesLocal Media1133470422700059155Billy JhunNo ratings yet

- Fluid Mechanics QuestionsDocument3 pagesFluid Mechanics QuestionsWaleed UsmanNo ratings yet

- Sheet 1Document3 pagesSheet 1saad ElsheikhNo ratings yet

- Tutorial AssignmentDocument5 pagesTutorial AssignmentAnup ChauhanNo ratings yet

- 4.9 HVAC SystemDocument5 pages4.9 HVAC Systembsunanda01No ratings yet

- Me8595 Iq R17Document2 pagesMe8595 Iq R17Narayanan SubramanianNo ratings yet

- Final Exam ENGI 2800 - Engineering Thermodynamics IDocument2 pagesFinal Exam ENGI 2800 - Engineering Thermodynamics Iياسر سعيد عبادي البحريNo ratings yet

- Mechanical Engineering Department: Refrigeration & Air Conditioning (ME 434)Document3 pagesMechanical Engineering Department: Refrigeration & Air Conditioning (ME 434)Ahmed SabryNo ratings yet

- Cog en Era Ti OnDocument12 pagesCog en Era Ti OnMayank DubeyNo ratings yet

- National Certification Examination 2008 FOR Energy AuditorsDocument10 pagesNational Certification Examination 2008 FOR Energy AuditorsMukesh KumarNo ratings yet

- Tutorials 1-4Document6 pagesTutorials 1-4KrishnaNo ratings yet

- Nhom 10 - Chuong 4Document10 pagesNhom 10 - Chuong 4Alfie StacyNo ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- How To Scale-Up: M Miix Xiin NG G P Prro Occe Es Ss Se Es S Iin NDocument9 pagesHow To Scale-Up: M Miix Xiin NG G P Prro Occe Es Ss Se Es S Iin NOdst Ovac100% (1)

- What Is MineralDocument18 pagesWhat Is MineralImee TiloNo ratings yet

- The Mole Concept-Set A Power Point 2020Document23 pagesThe Mole Concept-Set A Power Point 2020Muyatwa LiksNo ratings yet

- Borjatherm - FolletoDocument12 pagesBorjatherm - FolletoEduardo DíezNo ratings yet

- Mark Scheme (Results) January 2008: GCE Chemistry (6246) Paper 1ADocument8 pagesMark Scheme (Results) January 2008: GCE Chemistry (6246) Paper 1Anahian_aziz9050No ratings yet

- Shiva Prasad BhatDocument160 pagesShiva Prasad BhatrambhadesiNo ratings yet

- Flopamfa 920 SepDocument9 pagesFlopamfa 920 SepAgung Ariefat LubisNo ratings yet

- Study Material: Free Master Class SeriesDocument34 pagesStudy Material: Free Master Class SeriesKshitij ChandraNo ratings yet

- Self-Emulsifying Drug Delivery Systems (SEDDS) For Improved Oral Delivery of Lipophilic DrugsDocument10 pagesSelf-Emulsifying Drug Delivery Systems (SEDDS) For Improved Oral Delivery of Lipophilic DrugsAna KovačevićNo ratings yet

- Pollution Status and Trends in Water Quality of The Shitalakhya and Balu RiversDocument19 pagesPollution Status and Trends in Water Quality of The Shitalakhya and Balu RiversZisan AhmedNo ratings yet

- GTC Isomalk Technologies For Light Naphtha IsomerizationDocument29 pagesGTC Isomalk Technologies For Light Naphtha IsomerizationToni ĐạtNo ratings yet

- Charge-Directed Conjugate Addition Reactions of SilylatedDocument8 pagesCharge-Directed Conjugate Addition Reactions of SilylatedJonathan MendozaNo ratings yet

- Bohler Colour ChartDocument1 pageBohler Colour Chartscooba84No ratings yet

- Development, Applications and Investigations of Self-Compacting ConcreteDocument3 pagesDevelopment, Applications and Investigations of Self-Compacting ConcreteAnonymous 9iK0i8h0dPNo ratings yet

- Design of Sewage Treatment Plants-1Document20 pagesDesign of Sewage Treatment Plants-1Jishnu JayarajNo ratings yet

- Water Quality For Supercritical Units Steag FormatDocument40 pagesWater Quality For Supercritical Units Steag FormatAmit MukherjeeNo ratings yet

- B135M-10 Standard Specification For Seamless Brass Tube (Metric)Document6 pagesB135M-10 Standard Specification For Seamless Brass Tube (Metric)Salma FarooqNo ratings yet

- Module 5Document39 pagesModule 5Yasmine ShafaNo ratings yet

- Azolla TenderDocument4 pagesAzolla TenderprashantkothariNo ratings yet

- RHIZOSPHERE Project WorkDocument22 pagesRHIZOSPHERE Project WorkAniekeme GabrielNo ratings yet

- AN-nir065Document4 pagesAN-nir065Mihaly JNo ratings yet

- Isodon Rugosus As Potential Source of Phyto-Pharmacological Agents: A ReviewDocument7 pagesIsodon Rugosus As Potential Source of Phyto-Pharmacological Agents: A ReviewMuhammad Muneeb AhmadNo ratings yet

- Safety GramDocument4 pagesSafety GramsjmpakNo ratings yet

- Catalogo CimaDocument6 pagesCatalogo Cimazetta08No ratings yet

- CHEM F313: Instrumental Methods of Analysis: UV-Vis Spectrometry (Contd.)Document17 pagesCHEM F313: Instrumental Methods of Analysis: UV-Vis Spectrometry (Contd.)AYUSH SHARMANo ratings yet

- 9701 s10 QP 41Document20 pages9701 s10 QP 41Hubbak KhanNo ratings yet

- PB PHT 1Document32 pagesPB PHT 1Gabriel Caicedo RussyNo ratings yet

- Measurement of Corrosion Potentials of Aluminum Alloys: Standard Test Method ForDocument4 pagesMeasurement of Corrosion Potentials of Aluminum Alloys: Standard Test Method ForNav Talukdar100% (1)