Professional Documents

Culture Documents

HAZARDS-Pneumatic Test PDF

HAZARDS-Pneumatic Test PDF

Uploaded by

AlienshowOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HAZARDS-Pneumatic Test PDF

HAZARDS-Pneumatic Test PDF

Uploaded by

AlienshowCopyright:

Available Formats

HAZARDS & SAFETY CONCERNS DURING PNEUMATIC TESTING OF PRESSURE PLANTS

Introduction

Chemical Plant Equipments like Pressure Vessels, Heat Exchangers, Columns, Pipe Lines etc. need

to be tested for leak tightness at various stages like completion of fabrication, before commissioning

and at regular intervals during plant operation to ensure adherence to Statutory regulations and Safe

operation. Normally employed methods of testing are Hydrostatic and Pneumatic tests in addition to

rarely used test like “Helium Test” etc.

Pneumatic test is widely used to achieve minimum down time and economy and convenience of

testing as compared to hydrostatic tests. It is also useful to detect very fine leak paths which may not

be found in Hydrostatic Test. However it is not as safe as hydrostatic tests for reasons enumerated

below.

Hazards involved in Pneumatic testing.

It is well known fact that as water cannot be compressed (Boyles law), the energy stored in a vessel

under hydrostatic pressure is very very less as compared to that of vessel under same pressure with

Air. This stored potential Energy gets converted to kinetic energy at the time of rupture and that is

what makes pneumatic test very dangerous.

What is pneumatic test? Is it permitted by codes?

It is an alternative method of pressure test in lieu of Hydrostatic test, allowed by codes at certain

conditions, by using air or any other gas as test media.

It is mostly recommended only for equipments already tested and proved safe by hydrostatic

pressure test.

Preferably done only for low pressure applications & vessels having low volumetric capacity.

Pneumatic Test pressure is always less compared to hydrostatic test pressure. ( as per ASME

Sec. VIII Div. 1 pneumatic test pressure is 1.1 times of design pressure where as hydrostatic test

pressure is 1.3 times of design pressure)

Leakages are identified by soap water application on weld joints and not by observing the

pressure gauge.

What are the risks involved with pneumatic test ?

Air / gas used for pneumatic test is compressible to large extent and has very high potential

energy stored when compressed.

Any minor leak path can lead to a rupture and blast within no time releasing total energy with an

impact of sudden explosion.

Time gap between identifying a leakage and failure is very small making it almost impossible to

take remedial action.

Damages associated with failure are uncontrollable and huge.

Why Hydrostatic test is safer as compared to Pneumatic Test ?

Water or liquid used for pressure test are not compressible compared to air or gases.

Energy stored is very less.

Small leak will reduce gauge pressure immediately which does not happen when Air is the test

medium.

It has less potential energy hence damages are mostly limited to near by area.

There is a possibility that you can take remedial action once minor leakages are noticed before

total failure occurs.

Leakages are easy to detect incase of hydrostatic test

A GENERAL COMPARISON OF HYDROSTATIC TEST Vs. PNEUMATIC TEST.

Hydrostatic Test Pneumatic Test

Test pressure normally 30 % above the Test pressure normally 10 % above the

Design pressure (Refer ASME Sec. VIII Div. 1 Design pressure (Refer ASME Sec. VIII

UG 99.) Div. 1 UG 100)

Recommended for high pressure applications Recommended for only low pressure

applications.

Test media used is not compressible by Test media is compressible by pressure

pressure application application

Energy stored per unit volume of water under Energy stored per unit volume of

pressure is very negligible. compressed air is very high

Recommended to prove the strength of Recommended mainly for leak test on

equipment equipments which have already proved

their strength by Hydrostatic test.

Needs thorough cleaning after test to Easy to clean after testing.

eliminate moisture especially for services

which are reactive to moisture / fluids

Normally water is used as medium of test Air, Nitrogen, Argon etc. used for

pneumatic test

Pressure Relief valves are recommended to Pressure relief valves are must during

control sudden increase in pressure during test to ensure no over pressurisation

testing.

Needs less safety distance to cordon off from Needs large area to be cordoned off

man entry during test period during testing as accidental release of

pressure travels long distance due to

high energy stored.

Chances of equipment failures are less Chances of equipment / test apparatus

failures are high

Weight of equipment with test medium as Weight of equipment with test medium

water is high hence special attention should as air is comparatively less

be given to floor and supporting

arrangements.

Needs verification and examination of joints Needs very careful and specific

and connections before testing checking of weld joints thoroughly

before testing (Refer ASME Sec. VIII

Div. 1, UW – 50)

Test media can be reused and transferred to Test media can not be transferred or

other place after testing. reused after testing.

Skilled and semi skilled personnel can carry Needs involvement of senior

out test. experienced staff to monitor test.

Recommended where large volumes are to be If pipe lines are tested should be done

tested at same time ( example pipe lines ) with small segmental lengths at a time.

Damages due to failures are less compared to Damages due to failure in testing are

failures in pneumatic testing very huge and extensive.

Is a regular practice and safe procedure and Needs special attention and safety

can be followed in any work site precautions.

A WELL WRITTEN DOWN PROCEDURE IS MUST FOR BOTH BEFORE CONDUCTING TEST

Some Case Studies of wrong practices adopted in Industry, its consequences and

recommended procedures.

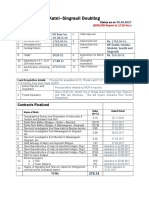

Sr. Practice Consequences Recommendation

No.

In a Fabrication Shop, During The pressure went too Test Pressure should

1. Hydrostatic test of a Pressure Vessel, high, bolting of one be achieved only with

when pump was not capable of manway sheared, man water. No air should

generating the required pressure, gas way cover flew away, and be left in the vessel or

cylinder was used to boost the pressure hit the Inspector who died should be used to

which could not be controlled. on the spot. increase hydrostatic

pressure. Pressure

Relief arrangement

should be provided

2. In a large petrochemical plant, a 3.5m There was considerable For small pressure, U

dia. vertical storage tank with flat top & damage to other tube Monometer

having manway and few nozzles on top installation however, no should be used instead

cover was to be tested with a very small human lives were lost. of pressure gauges.

air pressure to check some instruments. Take more care to

By some error, the pressure increased ensure no over

and as result, the whole top cover pressure is possible.

sheared from the shell and flew away Use certified safety

like a projectile and fell around 130 relief valve as

meters away additional safety.

3. From a dairy plant, one used condenser The condenser burst in the A used equipment

was sent for repairs, The fabrication shop seriously injuring should first be tested

shop carried out pneumatic test in place number of workers. Few only with water. After

of Hydraulic test for shell side to detect equipments in the shop that a pneumatic test at

tube to tube sheet leakage. were also damaged due to reduced pressure may

explosion. be taken if necessary.

4 A freak incident happened in Brazil

during pneumatic testing of piping

connected to an atmospheric

Tank. Pipe line was not fully

isolated from tank although there

was a valve in between, but not

closed and blanked fully, allowing

air to enter the tank which

uprooted the tank and the tank

was thrown on top of near by plant

building as shown in the actual

picture.

AUTHOR

Naveenraj.T.R. is a Mechanical Engineer working with Chempro

Inspections Pvt. Ltd. as Senior Manager (QA/QC) . He has got 22 years

of experience out of which 18 years in Third Party Inspection of plant

equipments and Machineries. Chempro carries out inspection for various

National and International clients in India, China, Europe, Africa, Korea

Etc. Chempro is an approved competent authority to carry out inspection

and certification as per Statutory rules under The Chief Controller of

Explosives and The Directorate of Industrial Safety and Health.

You might also like

- Basic Scaffolding Questions AnswersDocument11 pagesBasic Scaffolding Questions AnswersSomu Mahadevan89% (28)

- 896mk3 Manuale ITADocument114 pages896mk3 Manuale ITAblonde60100% (1)

- Principles of Cable Sizing CalculationsDocument5 pagesPrinciples of Cable Sizing CalculationsDuong BuiNo ratings yet

- Air Leak TestingDocument5 pagesAir Leak Testingkusdiyanta67% (3)

- 27 - MS - Leak Test Rev 1Document9 pages27 - MS - Leak Test Rev 1rajum465100% (2)

- Pages From Model Code of Safe Practice Part 21 Sample PagesDocument10 pagesPages From Model Code of Safe Practice Part 21 Sample Pageshazopman0% (2)

- Weekly Industrial Training Report Mohd Izzat - Week 1Document3 pagesWeekly Industrial Training Report Mohd Izzat - Week 1Izzat FakhriNo ratings yet

- Leak Test PDFDocument48 pagesLeak Test PDFdaniel oliveira100% (1)

- Pressure Test - Hydrostatic and Pneumatic Test RequirementsDocument6 pagesPressure Test - Hydrostatic and Pneumatic Test RequirementslorenzoNo ratings yet

- Hydro Vs PneumaticDocument4 pagesHydro Vs PneumaticAnonymous rYZyQQot55No ratings yet

- Hydrotest Procedure For Piping SystemsDocument6 pagesHydrotest Procedure For Piping Systemscatherine100% (1)

- TESTINGDocument7 pagesTESTINGSoner Kulte100% (1)

- Hydro Testing Pressure VesselDocument5 pagesHydro Testing Pressure VesselAkansha Sharma100% (1)

- Adyxen Leak Detection TechniquesDocument14 pagesAdyxen Leak Detection TechniquesSavij_ChouhanNo ratings yet

- Pneumatic Testing ProcedureDocument4 pagesPneumatic Testing ProcedureEddie TaiNo ratings yet

- 30 Mainline Hydrotesting 111Document25 pages30 Mainline Hydrotesting 111rexNo ratings yet

- Helium Leak TestDocument8 pagesHelium Leak TestHiren Panchal50% (2)

- Helium Leak TestingDocument21 pagesHelium Leak TestingSaut Maruli Tua Samosir100% (1)

- 090 G - Pressure and Leak Testing SafetyDocument2 pages090 G - Pressure and Leak Testing SafetyParth Patel100% (1)

- Pneumatic TestDocument3 pagesPneumatic Testpuneethkumarr100% (1)

- QPR0120 Leak Testing Proc.Document3 pagesQPR0120 Leak Testing Proc.ZackTeeKeatTeongNo ratings yet

- AB-522 Standard Pneumatic Test Procedure RequirementsDocument13 pagesAB-522 Standard Pneumatic Test Procedure Requirementskysuco100% (1)

- Hydrostatic Test ProcedureDocument7 pagesHydrostatic Test Procedurelaleye_olumideNo ratings yet

- TCW Tube CleaningDocument56 pagesTCW Tube CleaningMarcela Vargas GomezNo ratings yet

- Field Hydrotest Manual UndergroundDocument8 pagesField Hydrotest Manual UndergroundPhuoc PhuNo ratings yet

- Case Studies in Pre Inspection: CleaningDocument4 pagesCase Studies in Pre Inspection: CleaningSamtron610No ratings yet

- Inspection of Double Tube Sheet Exch - Presentation1Document37 pagesInspection of Double Tube Sheet Exch - Presentation1Asad Bin Ala QatariNo ratings yet

- Ab-522 Standard Pneumatic Test Procedure Requirements PDFDocument17 pagesAb-522 Standard Pneumatic Test Procedure Requirements PDFMarizta Perdani PutriNo ratings yet

- Leak Test MethodDocument5 pagesLeak Test Methodmohamed100% (1)

- Astm E1003 - 95 R00Document3 pagesAstm E1003 - 95 R00aan_09100% (1)

- AB-522 Standard Pneumatic Test Procedure RequirementsDocument16 pagesAB-522 Standard Pneumatic Test Procedure RequirementsShank HackerNo ratings yet

- Boiler Hydrostatic TestingDocument2 pagesBoiler Hydrostatic Testingbonginkosi mathunjwaNo ratings yet

- Leak Test Procedure For SubDocument5 pagesLeak Test Procedure For Subpallav chatterjeeNo ratings yet

- CPP-NA2-PM-PLN-0015 Procedure For Hydrostatic TestingDocument18 pagesCPP-NA2-PM-PLN-0015 Procedure For Hydrostatic TestingAdil Ijaz100% (1)

- The Pressure Testing of DI CI and PVC Pipe - Upload - 27!10!16Document4 pagesThe Pressure Testing of DI CI and PVC Pipe - Upload - 27!10!16Rushan Lakdimuthu100% (1)

- Leak Rate CalculationDocument1 pageLeak Rate Calculationtenjoe_38No ratings yet

- Hydrotest ProcedureDocument12 pagesHydrotest Procedurealex_feryando42100% (1)

- Pressure Testing Code Requirements PDFDocument26 pagesPressure Testing Code Requirements PDFriysall100% (1)

- Factors Contributing To Foarming Crude OilDocument11 pagesFactors Contributing To Foarming Crude OilSang Duong Van100% (1)

- P3-PTP-001 R0 Piping Pressure Test ProceduresDocument8 pagesP3-PTP-001 R0 Piping Pressure Test ProceduresHengNo ratings yet

- Pnumatic TestDocument27 pagesPnumatic TestV_Santhanakrishnan100% (1)

- Procedure Pneumatic TestDocument4 pagesProcedure Pneumatic TestSalman Khan100% (1)

- IENCSEPRO0007-2 - General Leak Test Procedure PDFDocument9 pagesIENCSEPRO0007-2 - General Leak Test Procedure PDFCatalinNo ratings yet

- PR-P-003 (1) .Piping Cleaning Flushing, Hydro Test & Drying Procedure (Rev.a)Document27 pagesPR-P-003 (1) .Piping Cleaning Flushing, Hydro Test & Drying Procedure (Rev.a)naseema183% (6)

- Boiler Cleaning+Procedure+Rev+00Document10 pagesBoiler Cleaning+Procedure+Rev+00Govarthanan Gopalan100% (1)

- Hydro-Testing of Pressure Equipment: Presented By: Sheikh M Naeem Action Item: 404881 Incident Report #: 2004-IR-931941Document10 pagesHydro-Testing of Pressure Equipment: Presented By: Sheikh M Naeem Action Item: 404881 Incident Report #: 2004-IR-931941JamalAhmedNo ratings yet

- Proof Pressure Test Leak Detection Test PDFDocument2 pagesProof Pressure Test Leak Detection Test PDFDan Nicole DadivasNo ratings yet

- Leak Testing Basic Principles - Background Information of Leaks and Leak Testing From TQCDocument3 pagesLeak Testing Basic Principles - Background Information of Leaks and Leak Testing From TQCMirza Safeer Ahmad100% (1)

- Snoop Leak Test LiquidDocument6 pagesSnoop Leak Test Liquidaldi_crisNo ratings yet

- Flushing ProcedureDocument4 pagesFlushing ProcedureSarif IslamNo ratings yet

- Leak Test and VacuumDocument2 pagesLeak Test and VacuumLinh TruongNo ratings yet

- Pressure Testing (Hydrostatic Pneumatic) Safety GuidelinesDocument7 pagesPressure Testing (Hydrostatic Pneumatic) Safety GuidelinesSuleyman HaliciogluNo ratings yet

- Hydrostatic Test and Pneumatic Test of Piping Systems-Hydrotest Vs Pneumatic Test With PDFDocument15 pagesHydrostatic Test and Pneumatic Test of Piping Systems-Hydrotest Vs Pneumatic Test With PDFYudha Andrie Sasi ZenNo ratings yet

- Hydrotest Vs Pneumatic TestDocument5 pagesHydrotest Vs Pneumatic TestMidhun K Chandrabose100% (1)

- Hydrotest and Pneumatic Test of Piping Systems-Hydrotest Vs Pneumatic Test With PDFDocument16 pagesHydrotest and Pneumatic Test of Piping Systems-Hydrotest Vs Pneumatic Test With PDFGunawanNo ratings yet

- Pressure Tests of Piping Systems-Hydrotest Vs Pneumatic TestDocument4 pagesPressure Tests of Piping Systems-Hydrotest Vs Pneumatic TestRakesh RanjanNo ratings yet

- Pressure Tests of Piping SystemsDocument14 pagesPressure Tests of Piping SystemsharishcsharmaNo ratings yet

- Hydrotest and Pneumatic Test of Piping Systems-Hydrotest Vs Pneumatic TestDocument11 pagesHydrotest and Pneumatic Test of Piping Systems-Hydrotest Vs Pneumatic TestAzher ANo ratings yet

- Pressure & Leak TestingDocument18 pagesPressure & Leak TestingBilly KurniawanNo ratings yet

- NDT Pressure TestingDocument23 pagesNDT Pressure TestingRamu Nallathambi100% (2)

- Vakve Pressure TestingDocument11 pagesVakve Pressure TestingShubhajit ChakrabortyNo ratings yet

- EQUIPMENT - Testing ProceduresDocument7 pagesEQUIPMENT - Testing ProceduresGon FloNo ratings yet

- Pressure Tests of Piping Systems-Hydrotest Vs Pneumatic TestDocument19 pagesPressure Tests of Piping Systems-Hydrotest Vs Pneumatic Testsin67438No ratings yet

- Pneumatic TestDocument6 pagesPneumatic TestSubbarayan SaravanakumarNo ratings yet

- Pressure Test System To Demonstrate Integrity: by Anil Kumar SaxenaDocument47 pagesPressure Test System To Demonstrate Integrity: by Anil Kumar SaxenaThe Engineers EDGE, Coimbatore100% (3)

- Abb PDFDocument9 pagesAbb PDFhazopmanNo ratings yet

- SC 15Tw: Scanjet Tank Cleaning EquipmentDocument1 pageSC 15Tw: Scanjet Tank Cleaning EquipmenthazopmanNo ratings yet

- Safety and Health Topics - Hydrogen Sulfide - Evaluating and Controlling ExposureDocument3 pagesSafety and Health Topics - Hydrogen Sulfide - Evaluating and Controlling ExposurehazopmanNo ratings yet

- ProcedureDocument1 pageProcedurehazopmanNo ratings yet

- Faset: Review of Significant Changes To EN 1263-2 2002Document1 pageFaset: Review of Significant Changes To EN 1263-2 2002hazopmanNo ratings yet

- Avoid Outrigger FailureDocument1 pageAvoid Outrigger FailurehazopmanNo ratings yet

- Bucket Truck Safety-PioneerDocument4 pagesBucket Truck Safety-PioneerhazopmanNo ratings yet

- InControl 1 2013 enDocument12 pagesInControl 1 2013 enhazopmanNo ratings yet

- Honeywell Sensors and Switches in Mobile - Cranes - 009586-2-En - LowresDocument2 pagesHoneywell Sensors and Switches in Mobile - Cranes - 009586-2-En - LowreshazopmanNo ratings yet

- Shiploader Rev2 27may2010Document24 pagesShiploader Rev2 27may2010hazopmanNo ratings yet

- Safety Alert177Document1 pageSafety Alert177hazopmanNo ratings yet

- 1926.1400 Convenient Pocket CardsDocument6 pages1926.1400 Convenient Pocket CardshazopmanNo ratings yet

- MSHA Regulation EZcomplianceDocument12 pagesMSHA Regulation EZcompliancehazopmanNo ratings yet

- Ten Points For Safe LiftDocument8 pagesTen Points For Safe LifthazopmanNo ratings yet

- Safety & Maintenance Inspection - Stellar Cranes Daily V0810.1Document1 pageSafety & Maintenance Inspection - Stellar Cranes Daily V0810.1hazopmanNo ratings yet

- PDF 01 ControlsDocument6 pagesPDF 01 ControlshazopmanNo ratings yet

- Rollover Hangtag LaserresDocument2 pagesRollover Hangtag LaserreshazopmanNo ratings yet

- Forklift ChecklistDocument4 pagesForklift ChecklisthazopmanNo ratings yet

- Methods of Approximation and Determination of Human Vulnerability For Offshore Major Accident Hazard AssessmentDocument55 pagesMethods of Approximation and Determination of Human Vulnerability For Offshore Major Accident Hazard AssessmenthazopmanNo ratings yet

- z.2. Sertifikat + Materi Seminar Internasional Usm 2022 (Lengkap)Document6 pagesz.2. Sertifikat + Materi Seminar Internasional Usm 2022 (Lengkap)Sutarno -No ratings yet

- VGA To RGB Sync-On-Green AdapterDocument3 pagesVGA To RGB Sync-On-Green AdapterKrista TranNo ratings yet

- Siemens - FMR FlyerDocument8 pagesSiemens - FMR FlyerAnonymous ZrP5LqNo ratings yet

- CATALOG - GABRIEL - MODELOS HD-Catalog-2019Document344 pagesCATALOG - GABRIEL - MODELOS HD-Catalog-2019WERNER SILVA ALVAREZNo ratings yet

- Service Manual - Lid45w13n (7312d)Document37 pagesService Manual - Lid45w13n (7312d)jupecas matosinhosNo ratings yet

- Thevenin and Norton Equivalent Circuits: ECE 205 Prof. Ali KeyhaniDocument5 pagesThevenin and Norton Equivalent Circuits: ECE 205 Prof. Ali Keyhaniumar khan0% (1)

- Construction Methods and TechniquesDocument23 pagesConstruction Methods and TechniquesTEODORO AMATOSA JR.No ratings yet

- Smartform QuestionDocument14 pagesSmartform QuestionrohanNo ratings yet

- TQM-Literature Review by Ahire Et Al 1995Document30 pagesTQM-Literature Review by Ahire Et Al 1995bizhanj100% (1)

- Cooling Water Treatment For Industrial UseDocument56 pagesCooling Water Treatment For Industrial UseChakravarthy Bharath100% (3)

- Thermal Conductivity and Stability of Paraffin Wax With Various Nanoparticles Without RevisionDocument30 pagesThermal Conductivity and Stability of Paraffin Wax With Various Nanoparticles Without Revisionvahit06No ratings yet

- Chemical Engineering Science: Ishara Dedunu Kamalanathan, Peter James MartinDocument11 pagesChemical Engineering Science: Ishara Dedunu Kamalanathan, Peter James MartinarulrajasiNo ratings yet

- 02whole PDFDocument352 pages02whole PDFganga_chNo ratings yet

- Section 1: Introduction To Isdn, Atm and Broadband TransmissionDocument27 pagesSection 1: Introduction To Isdn, Atm and Broadband TransmissiondgrsriNo ratings yet

- Technical Seminar ReportDocument17 pagesTechnical Seminar ReportBasavaraj M Patil0% (1)

- Closed Loop Speed and Position Control of DC MotorsDocument7 pagesClosed Loop Speed and Position Control of DC Motorslizhi0007No ratings yet

- MMM-A-132B Federal Spec For Adhesives Heat Resistant Airframe Structural Metal To MetalDocument29 pagesMMM-A-132B Federal Spec For Adhesives Heat Resistant Airframe Structural Metal To Metalbman0051401No ratings yet

- Status Report For EDW RB For Katni-Singrauli 5th Sept 2017 1709 Hours CORRECTED Monthly PositionDocument4 pagesStatus Report For EDW RB For Katni-Singrauli 5th Sept 2017 1709 Hours CORRECTED Monthly PositionmchkppNo ratings yet

- Blender 3D by Example - Sample ChapterDocument21 pagesBlender 3D by Example - Sample ChapterPackt Publishing33% (3)

- l3070 e 0Document128 pagesl3070 e 0Riki NurzamanNo ratings yet

- Capacitive and Inductive Proximity SensorsDocument16 pagesCapacitive and Inductive Proximity Sensorsislamooov100% (1)

- My Resume Updated ...Document4 pagesMy Resume Updated ...ClydeGutierrezNo ratings yet

- RXV2700Document173 pagesRXV2700Евгений ЗахаровNo ratings yet

- AIRBUS Aditive ManufacturingDocument75 pagesAIRBUS Aditive ManufacturingХардип ЗинтаNo ratings yet

- Distance Learning Programme: Pre-Medical: Leader Test Series / Joint Package CourseDocument60 pagesDistance Learning Programme: Pre-Medical: Leader Test Series / Joint Package CourseSaket DubeyNo ratings yet

- Workshop Practice Series 37 DividingDocument53 pagesWorkshop Practice Series 37 DividingJilpLmNo ratings yet

- Fracture Toughness - Wikipedia, The Free EncyclopediaDocument8 pagesFracture Toughness - Wikipedia, The Free EncyclopediaAshokNo ratings yet