Professional Documents

Culture Documents

Specifications of PCM - HX

Uploaded by

SivaramSubramanian0 ratings0% found this document useful (0 votes)

34 views2 pagesPCM Heat exchanger system

Original Title

Specifications of Pcm_hx

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPCM Heat exchanger system

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

34 views2 pagesSpecifications of PCM - HX

Uploaded by

SivaramSubramanianPCM Heat exchanger system

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

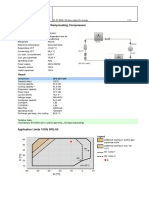

SPECIFICATIONS OF PCM HEAT EXCHANGER

Fig 1: PCM Heat exchanger operation Schematic

Working

The Liquid Circulation Unit (LCU) circulates the coolant, Ethylene Glycol and Water

Mixture (65:35) through the heat load at 12 lpm flow rate. Hot coolant is sent to PCM heat

exchanger, which contains Phase change material, for dissipating the heat absorbed from the

heat load.

Phase Change Material (PCM) Requirements

a. Type of Phase change material to be used in BHE can be selected by Vendor.

b. The PCM material should be of airborne standard.

Property or Characteristic Requirement

Type Solid - Liquid

Latent Heat (kJ/kg) > 280 KJ/Kg

Corrosivity Non-Corrosive

Thermal cycles > 1000

Density Variation Low

Thermal Conductivity High

Specifications of PCM HX

Sl. no. Description Specification

1 Heat Load 2000 W

Ethylene Glycol & Water Mixture

2 Coolant used

(65:35)

3 Coolant Volume Flow rate 12 LPM

Coolant operating temp at heat load inlet

4 < 50 °C

in PCM Heat Exchanger mode

5 Coolant operating temperature range -40 °C to +85 °C

6 Storage Temperature -55 °C to +85 °C

8 Operating Pressure 5 Bar

9 Coolant capacity in circuit 2.5 Litres

10 Mechanical Dimensions (LxWxH, Ref Fig 2) 750mmX75mmX65mm

Operation time to be achieved with

11 > 5 Minutes

PCM heat exchanger

13 Weight of the Unit (Including PCM) <6 Kgs

Fig 2: PCM HX CONCEPT

You might also like

- LK65CZ1Document9 pagesLK65CZ1hobolghaniNo ratings yet

- Methanol Recovery Calculation 31-12-2023 R1Document1 pageMethanol Recovery Calculation 31-12-2023 R1Preetpal SinghNo ratings yet

- Energy Consumption Breakdown of An Industrial Plant Is Given Below: Measured Data For Existing Chiller SystemsDocument2 pagesEnergy Consumption Breakdown of An Industrial Plant Is Given Below: Measured Data For Existing Chiller SystemsMeriem NguirNo ratings yet

- LC111CY: Compressor Technical SpecificationDocument8 pagesLC111CY: Compressor Technical SpecificationEsiNo ratings yet

- LS Absorption ChillersDocument8 pagesLS Absorption ChillersMuhammad Amin Uddin100% (1)

- LC126CY: Compressor Technical SpecificationDocument8 pagesLC126CY: Compressor Technical SpecificationEsiNo ratings yet

- Experiment 1: TheoryDocument2 pagesExperiment 1: TheoryMUSKAN PRNNo ratings yet

- Selection: Semi-Hermetic Reciprocating Compressors: Input ValuesDocument1 pageSelection: Semi-Hermetic Reciprocating Compressors: Input ValuesYutt WattNo ratings yet

- HSN7471-75 R449A t0 - 15 TC 45Document2 pagesHSN7471-75 R449A t0 - 15 TC 45KritsdaNo ratings yet

- CH-01 30RBM360 Air Cooled Liquid Chiller Selection PDFDocument2 pagesCH-01 30RBM360 Air Cooled Liquid Chiller Selection PDFBilguun BurenjargalNo ratings yet

- CH126P Lec 8 - Ch9Document20 pagesCH126P Lec 8 - Ch9kumiristineNo ratings yet

- Skikda Training CDU (Goal Content)Document26 pagesSkikda Training CDU (Goal Content)Mohamed OuichaouiNo ratings yet

- JM Dryers Air Tropical PCM 60hz C913E BRO USDocument12 pagesJM Dryers Air Tropical PCM 60hz C913E BRO USDeny PranowojatiNo ratings yet

- 6 Refrigeration Cycles EditedDocument31 pages6 Refrigeration Cycles EditederioNo ratings yet

- Circulation Heater SelectionDocument3 pagesCirculation Heater SelectionWaqasNo ratings yet

- Sample Question Paper ME 604ADocument11 pagesSample Question Paper ME 604Amumtaz alamNo ratings yet

- Process Simulation Cases Flash SeparationDocument23 pagesProcess Simulation Cases Flash Separationahmed atwaNo ratings yet

- LM72CZ V01Document8 pagesLM72CZ V01hobolghaniNo ratings yet

- Simulation An OptimizationDocument28 pagesSimulation An Optimizationalmoanna97100% (1)

- Simple (Ideal) Vapor Compression Refrigeration Cycle ProblemsDocument3 pagesSimple (Ideal) Vapor Compression Refrigeration Cycle Problemssajawal hassanNo ratings yet

- K390BZ1 CompressedDocument9 pagesK390BZ1 CompressedRefrigeración PinNo ratings yet

- Improving Performance of Vapour Compression Refrigeration System by Using PCM in EvaporatorDocument4 pagesImproving Performance of Vapour Compression Refrigeration System by Using PCM in EvaporatorFawaz IqbalNo ratings yet

- Partner in Renewable Energy SystemsDocument34 pagesPartner in Renewable Energy Systemstan0314100% (1)

- Mec 351 - Chapter 1Document42 pagesMec 351 - Chapter 1Azib Azamuddin Juri100% (1)

- Slides Lec 9 HVAC and Refrigeration System PDFDocument28 pagesSlides Lec 9 HVAC and Refrigeration System PDFAhmed JavedNo ratings yet

- 30XB1100@46Document1 page30XB1100@46Mohammed EmamNo ratings yet

- EN 317 - Sanidhya Anad - All Parts CombinedDocument22 pagesEN 317 - Sanidhya Anad - All Parts CombinedAtharva ChodankarNo ratings yet

- Compresor 14HP R600a 110V Baja LU118XY1 DonperDocument8 pagesCompresor 14HP R600a 110V Baja LU118XY1 Donperdanielbarbosagoncalv100% (1)

- Selectie ChillerDocument4 pagesSelectie ChillerPopescu Mircea IulianNo ratings yet

- High Performance Chiller Plant in Green - Low Flow FinalDocument25 pagesHigh Performance Chiller Plant in Green - Low Flow Finalsatyamech1_395565923No ratings yet

- Refrigeration Systems Lecture Notes - Batch 7 Bsme-3ADocument7 pagesRefrigeration Systems Lecture Notes - Batch 7 Bsme-3AkhinojidaNo ratings yet

- Experimental Investigation of A Miniature-Scale REfrig.Document10 pagesExperimental Investigation of A Miniature-Scale REfrig.u0948621No ratings yet

- Energy Performance Assessment of Heat Exchangers: Overall Heat Transfer Coefficient, UDocument18 pagesEnergy Performance Assessment of Heat Exchangers: Overall Heat Transfer Coefficient, USATISH PAWARNo ratings yet

- Comprehensive Viva Voce: School of Mechanical EngineeringDocument26 pagesComprehensive Viva Voce: School of Mechanical EngineeringKumareshg GctkumareshNo ratings yet

- Exp 12Document7 pagesExp 12Dhanush kumarNo ratings yet

- Battery Thermal Management Systems BtmsDocument32 pagesBattery Thermal Management Systems BtmsVictor del PozoNo ratings yet

- Refrigeration 3Document36 pagesRefrigeration 3May Jade Genzola EsparesNo ratings yet

- Trickle Bed Reactor, Process and Mechanical DesignDocument14 pagesTrickle Bed Reactor, Process and Mechanical DesignkhawarNo ratings yet

- Evaluation of LNG Production TechnologiesDocument42 pagesEvaluation of LNG Production TechnologiesMuhammad NaeemNo ratings yet

- TD WSC HBDDocument62 pagesTD WSC HBDShajal ChowdhuryNo ratings yet

- Condensing and Cooling Efficiently with Adiabatic SystemsDocument17 pagesCondensing and Cooling Efficiently with Adiabatic SystemsIon ZabetNo ratings yet

- K375CZ1 Compressor Technical SpecificationDocument9 pagesK375CZ1 Compressor Technical SpecificationalazarNo ratings yet

- Second Law of Thermodynamics 82Document28 pagesSecond Law of Thermodynamics 82Sivani SinghNo ratings yet

- Thermal Energy Efficiency PresentationDocument20 pagesThermal Energy Efficiency PresentationBilal El YoussoufiNo ratings yet

- Technical Data Air Cooled Chiller 105 TRDocument3 pagesTechnical Data Air Cooled Chiller 105 TRHaris Siena100% (1)

- Heat Exchanger Network Optimization for Maleic Anhydride Production ProcessDocument34 pagesHeat Exchanger Network Optimization for Maleic Anhydride Production ProcessrovshanbabayevNo ratings yet

- Fundamentals of Cryogenic Engineering and SRF TechnologyDocument95 pagesFundamentals of Cryogenic Engineering and SRF Technologyrachit_mechNo ratings yet

- Refrigeration Cycle Notes Lec9-1Document20 pagesRefrigeration Cycle Notes Lec9-1mickey.102987No ratings yet

- Methanol Recovery Calculation 31-12-2023Document1 pageMethanol Recovery Calculation 31-12-2023Preetpal SinghNo ratings yet

- Jazan University Refrigeration CyclesDocument24 pagesJazan University Refrigeration Cyclesحسن كميت hassankomeit lNo ratings yet

- Enapter Datasheet AEM-Multicore-225kg enDocument2 pagesEnapter Datasheet AEM-Multicore-225kg enRoque Alfredo Da Rosa AvilaNo ratings yet

- 1x 4FES-3Y - R14 - To - 120 - TC - 70 - Dtoh 60 - Dtcu 20,81Document4 pages1x 4FES-3Y - R14 - To - 120 - TC - 70 - Dtoh 60 - Dtcu 20,81Ashiq Elahi Design & Application EngineerNo ratings yet

- Chapter2 Air Refrigeration CycleDocument39 pagesChapter2 Air Refrigeration CycleAnil GhadgeNo ratings yet

- Bitzer Selection Software 2Document1 pageBitzer Selection Software 2dilinNo ratings yet

- AMI Organics LTD Unit II 100 TRDocument18 pagesAMI Organics LTD Unit II 100 TRVatsal VermaNo ratings yet

- Liquified Natural Gas: C2 - C5 CryogenicDocument22 pagesLiquified Natural Gas: C2 - C5 CryogenicNicolaNo ratings yet

- Air Conditioning ExampleDocument22 pagesAir Conditioning ExampleVinMaximusNo ratings yet

- Introduction to Pyro Processing Part 1: Wet, Semi-Dry and Pre-Calciner ProcessesDocument3 pagesIntroduction to Pyro Processing Part 1: Wet, Semi-Dry and Pre-Calciner ProcessesHusni BasharudinNo ratings yet

- CalcI Derivatives AppsDocument107 pagesCalcI Derivatives AppsSivaramSubramanianNo ratings yet

- Calculus I CompleteDocument578 pagesCalculus I Completexenocid3r83% (6)

- Preparation For EngineeringDocument17 pagesPreparation For EngineeringSivaramSubramanianNo ratings yet

- CalcI Derivatives AppsDocument107 pagesCalcI Derivatives AppsSivaramSubramanianNo ratings yet

- SDS Royco500Lubricant ISS150422 English PDFDocument10 pagesSDS Royco500Lubricant ISS150422 English PDFSivaramSubramanianNo ratings yet

- MathsDocument2 pagesMathsSivaramSubramanianNo ratings yet

- LM Mil HDBK 454B 151030Document208 pagesLM Mil HDBK 454B 151030SivaramSubramanianNo ratings yet

- Label1 ModelDocument1 pageLabel1 ModelSivaramSubramanianNo ratings yet

- Mahanyasam SansDocument112 pagesMahanyasam SansravisalemNo ratings yet

- Living A Dream! The Journey of A Call Centre Employee To A Successful TraderDocument8 pagesLiving A Dream! The Journey of A Call Centre Employee To A Successful TraderSivaramSubramanianNo ratings yet

- Cross Reference Sheet PDFDocument1 pageCross Reference Sheet PDFSivaramSubramanianNo ratings yet

- Spec Cross Reference PassivateDocument1 pageSpec Cross Reference PassivateSivaramSubramanianNo ratings yet

- Deriaz Turbine: Adjustable Blade Water Turbine for 20-100m HeadsDocument1 pageDeriaz Turbine: Adjustable Blade Water Turbine for 20-100m HeadsSivaramSubramanianNo ratings yet

- Mil DTL 45204DDocument14 pagesMil DTL 45204DSivaramSubramanianNo ratings yet

- GDT Wall Chart 2009 Arch - D PDFDocument1 pageGDT Wall Chart 2009 Arch - D PDFSivaramSubramanianNo ratings yet

- CATIADocument5 pagesCATIASivaramSubramanianNo ratings yet

- Project ManagementDocument1 pageProject ManagementSivaramSubramanianNo ratings yet

- Microencapsulated Phase Change Materials (PCMS) : by MikrocapsDocument8 pagesMicroencapsulated Phase Change Materials (PCMS) : by MikrocapsAzkha AvicenaNo ratings yet

- Control System in A Hybrid Solar DryerDocument5 pagesControl System in A Hybrid Solar DryerNEFTALI VAZQUEZ ESPINOSANo ratings yet

- Recent Advances in Stepped and Weir Type Solar Still: Chaturbhuj Yadav, Mahesh KumarDocument8 pagesRecent Advances in Stepped and Weir Type Solar Still: Chaturbhuj Yadav, Mahesh KumarEsskindirNo ratings yet

- PCM Free Cooling With DEC PDFDocument13 pagesPCM Free Cooling With DEC PDFqaiserNo ratings yet

- Melaku WoldeDocument97 pagesMelaku WoldeShaziashah ShaziaNo ratings yet

- CatalogueDocument7 pagesCatalogueAbdulvasea SaaitNo ratings yet

- A Comprehensive Review of Nano-Enhanced Phase Change Materials On Solar 2022Document30 pagesA Comprehensive Review of Nano-Enhanced Phase Change Materials On Solar 2022Gopi KrishnaNo ratings yet

- Mod 2 - E&E - 18ME751 - PPT 2Document36 pagesMod 2 - E&E - 18ME751 - PPT 2mohammed FaizanNo ratings yet

- Designing With Phase Change Materials For Satellite Thermal ManagementDocument223 pagesDesigning With Phase Change Materials For Satellite Thermal ManagementstephaneNo ratings yet

- Effect of Eccentricity On Melting Behavior of para N in A Horizontal Tube-In-Shell Storage Unit: An Experimental StudyDocument8 pagesEffect of Eccentricity On Melting Behavior of para N in A Horizontal Tube-In-Shell Storage Unit: An Experimental StudyMaryam EL FitiNo ratings yet

- Kabeel, El-Samadony, El-Maghlany - 2018 - Comparative Study On The Solar Still Performance Utilizing Different PCM-annotatedDocument9 pagesKabeel, El-Samadony, El-Maghlany - 2018 - Comparative Study On The Solar Still Performance Utilizing Different PCM-annotatedFatma Saad Ep JellaliNo ratings yet

- TP 5Document7 pagesTP 5joymaster_anilNo ratings yet

- A Comprehensive Review of Latent Heat Energy Storage For Various Applications: An Alternate To Store Solar Thermal EnergyDocument38 pagesA Comprehensive Review of Latent Heat Energy Storage For Various Applications: An Alternate To Store Solar Thermal EnergyPranav OmkarNo ratings yet

- Passive Thermal Management Using Phase C-1Document5 pagesPassive Thermal Management Using Phase C-1venugopalan srinivasanNo ratings yet

- Mathematical Modelling of The Thermal PCMDocument11 pagesMathematical Modelling of The Thermal PCMsg3569No ratings yet

- Concentrated Solar Thermal Energy Technologies Recent Trends and Applications by Laltu ChandraDocument264 pagesConcentrated Solar Thermal Energy Technologies Recent Trends and Applications by Laltu ChandraIBRAHIMA diop100% (1)

- Optimisation of An Innovative Cooling System For Motorsport ApplicationsDocument14 pagesOptimisation of An Innovative Cooling System For Motorsport Applicationsleone.martellucciNo ratings yet

- Design and Developement of PCM Based Thermal Energy Storage For Solar Water HeatersDocument12 pagesDesign and Developement of PCM Based Thermal Energy Storage For Solar Water HeatersVinayakNo ratings yet

- Solar Water Heater Using Multiple PCM and Porous MediumDocument7 pagesSolar Water Heater Using Multiple PCM and Porous MediumSuraj MulayNo ratings yet

- Spiral Coil HE Presentation - FinalDocument22 pagesSpiral Coil HE Presentation - Final42 Mech A Akshata KoltharkarNo ratings yet

- Recent Progress in Phase-Change Memory TechnologyDocument17 pagesRecent Progress in Phase-Change Memory Technologysabrine hamriNo ratings yet

- Using Phase Change Material in Heat Sinks To Cool Electronics Devices With Intermittent UsageDocument19 pagesUsing Phase Change Material in Heat Sinks To Cool Electronics Devices With Intermittent UsagekaushikNo ratings yet

- Battery Management Systems For Electric Vehicles: Bachelor of TechnologyDocument25 pagesBattery Management Systems For Electric Vehicles: Bachelor of TechnologyJatin YadavNo ratings yet

- Energy Conversion and Management: S.M. Shalaby, M.A. BekDocument8 pagesEnergy Conversion and Management: S.M. Shalaby, M.A. BekRab NawazNo ratings yet

- Three Different Approaches To Simulate PCM Bulk Elements in A Solar Storage TankDocument10 pagesThree Different Approaches To Simulate PCM Bulk Elements in A Solar Storage TankJosip BatistaNo ratings yet

- Design and Fabrication of Solar Water Heater Using Phase Changing MaterialDocument9 pagesDesign and Fabrication of Solar Water Heater Using Phase Changing Materialthai avvaiNo ratings yet

- DSC SubmissionDocument3 pagesDSC SubmissionGopal KumarNo ratings yet

- Lead Time Reduction and Process Enhancement For A Low Volume ProductDocument7 pagesLead Time Reduction and Process Enhancement For A Low Volume ProductHASHIM ZIANo ratings yet

- Phase-Change Material - Wikipedia, The Free EncyclopediaDocument4 pagesPhase-Change Material - Wikipedia, The Free EncyclopediaBiswa Bikash SinghNo ratings yet

- Steam and Cooling Water Saving in Sugar Factory by The Use of Phase Change MaterialsBDocument8 pagesSteam and Cooling Water Saving in Sugar Factory by The Use of Phase Change MaterialsBParthosarothy K MukherjiNo ratings yet