Professional Documents

Culture Documents

03 4 Performance Calculatio

Uploaded by

barnibar1Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

03 4 Performance Calculatio

Uploaded by

barnibar1Copyright:

Available Formats

ESTIMATING TRACTOR DRAWBAR PULL

FROM SOIL PROPERTIES

by

H. P. Harrison R. G. Cessford

Member CSAE Junior Member CSAE

Department of Agricultural Engineering Department of Agricultural Engineering

University of Alberta University of Alberta

Edmonton, Alberta Edmonton, Alberta

INTRODUCTION tractors. In view of this it is also which is noted below, is appropriate.

The ability to predict the perfor probably adequate to evaluate dif r — 0.Q6M (pn + 20) + a- +

ferent sizes of two wheel drive trac

mance of a tractor in the field has PI 0.6 2

tors and even different tire sizes and

long been a goal of the agricultural

engineer. Extension personnel, and

amounts of ballast. The latter are where r — shear stress (psi)

common queries of farmers because o- = normal stress (psi)

some farmers, have been guided by

taking some percentage of the draw of the options provided by the tractor M — moisture con

bar pull reported by the Nebraska manufacturers. tent (%)

Tractor Tests. Friesen and Domier Unfortunately equation 1 cannot be PI — lower plastic limit

(2) more recently suggest the use applied for local soils as the soil Pn — plasticity number —

of the coefficient of traction (static) dynamic parameters C and <f> are un .6 (% clay) - 12

as a guide. In general, farmers solve known. Rutledge and MacHardy (9) The distinct advantage for either

this problem on a trial and error in their study on the influence of relationship is that the plastic param

basis. Only.when a tractor of a dif weather on field tractability circum eters are known for most of the soils

ferent size is purchased is difficulty vented this difficulty by using a in Alberta. Equation 1 then becomes:

experienced and then questions of linear relationship between the shear •06aM

tire size, amount of ballast, allowable force and the plastic parameters of P = (R + + (.6c +

PI

slippage, etc., are raised. Reece (8) soil developed by NichoFs (6). For 8))X .. 3

has stated, "The principal problem is their purpose they chose the relation

to determine the maximum thrust ship for soils within the plastic range. where c is the clay content of the soil

that the tractor can exert and the way Since tillage is not normally carried in percent. With the exception of R,

in which it grows with slip". He has out in this range NichoFs relationship values required are readily available

modified Coulomb's equation for for soils below the plastic range, and appear in Tables 1 and 4.

shear stress as follows:

TABLE I. MECHANICAL ANALYSIS OF ALBERTA SOILS (Ap horizon)*

P _ (aC + R tan <f>)X 1

where P = soil thrust (lbs.) Plasticity

Soil Zone Soil Series Soil Class Mechanical Liquid

a = tire contact area Analysis Number** Limit***

(sq. in.) %S %Si %C Pn P

u

C — cohesion (psi)

R — dynamic soil reac Brown Cavendish SL 77 11 12 19

tion, driving wheels Foremost L 45 35 20 0 29

(lbs.) Seven Persons C 18 32 50 18.0 46

Dark Carmangay LS 81 10 9 19

<f> — internal angle of Brown Granum L 42 37 21 0.6 26

friction (degrees) Coaldale CL-C 28 30 42 13.2 43

Thin Irma LS-SL 77 12

X — slip function. 11 23

Black Elnora L 37 38 25 3.0 39

Three Hills

The derivation of the slip function C 16 36 58 22.8 59

Black Peace Hills LS 82 10 8 20

(X) cannot be noted here but it is

Angus Ridge L 42 33 25 3.0 42

essentially a function of the slippage Malmo SIC 15 35 50 18.0 60

and the length of the tire contact, L. Grey Culp LS 80 8 12 14

In addition, Reece has determined Wooded Breton L 42 36 22 1.2 26

values of the slip function at maxi Maywood CL-SICL 30 42 28 4.8 36

mum drawbar horsepower as a func

tion of L. This provides a logical Based on data obtained from the Department of Soil Science,

basis for comparing tractive perfor University of Alberta.

mance. Reece concludes that the Calculated by the formula Pn = 0.6C-12

theory is oversimplified but feels it Although values are given for liquid limit for the soil classes

is probably adequate for evaluating LS-SL, it should be noted that the liquid limit for cohesionless

two wheel versus four wheel drive soils is meaningless (5).

62 CANADIAN AGRICULTURAL ENGINEERING, VOL. 11, No. 2, NOVEMBER 1969

The validity of using NichoFs equa TABLE II. ANALYSIS OF VARIANCE OF THE DIRECT SHEAR RESULTS

tion for soil strength is questioned in

the light of recent investigations. Ad

Source of Variation Degrees of Sum of Mean

ditional variables have been found

Freedom Squares Squares F

which effect the shear strength. Han

son, Johnson and Young (4), for ex

ample, found that soil densities and Replicates 2 0.22 0.11 0.06

loading velocities are significant. Soils (S) 1 951.06 951.06 490.24*

Vomcil and Chancellor (11) con Moisture (M) 2 255.12 127.56 65.75*

cluded that soil strength may change Pressure (P) 2 230.44 115.22 59*. 39*

with water content in a manner not S x M 2 219.26 109.63 56.51*

adequately described by the Atter- S x P 2 59.89 29.94 15.43*

berg limits (plastic parameters). M x P 4 32.12 8.03 4.14*

S x M x P 4 7.14 1.78

These and other findings raise serious 0.92

Error 34 65.83 1.94

questions with respect to the relation Total 53 1,821.08 1.94

ship suggested by Nichols. On the

other hand because of their simplicity

it would be highly desirable if these * Significant at .01 probabi lity level (10)

equations could be applied to the

practical problems of traction and study, a method of determining shear the soil types into smaller lots and

tillage. In view of this a study to de ing stress in the soil while varying the moisturizing them to the desired

termine the practical limits of apply soil properties and normal loading levels. The three soil moisture con

ing equation 2 (and therefore equa was required. It was also desired to tents were approximately 20, 25 and

tion 3) was initiated. achieve normal stresses of the ap 30 percent. TTiese levels were selected

proximate magnitude found under the to cover a range between the 1/3

EXPERIMENTAL PROCEDURE traction wheel of a rubber tired trac atmosphere and 15 atmosphere per

tor (3). The direct shear apparatus centages for both soil types. Samples

A completely randomized factorial was chosen because it met the above of air-dry soil were placed in a con

design was used for the experiment. requirements and in addition provided tainer and sufficient water was added

It was a 2 X 3 X 3 factorial with the direct, easily computed results with a to achieve the desired moisture

following levels: minimum of sample preparation. levels. Each moisturized sample was

Soil, S — 2: i = 1,2. The type of shear apparatus used then mixed for 5 minutes before

Moisture, M — 3: j — 1. . . 3. was "box shear" (as distinct from ring being transferred to a sealed plastic

shear) which consists basically of a bag. The sealed samples were left for

Normal stress, a- — 3: k — 1. . . 3. rectangular box the top half of which 7 days to allow the moisture to reach

can slide over the bottom half. The equilibrium within each sample.

Replicates, R — 3: 1 — 1. . . 3.

The complete mathematical descrip inside dimensions of the shear box

were 2.37 X 2.37 inches giving an Procedure

tion for any observation is

initial shear area of 5.62 in2. The nor Soil samples were placed in the

xijkl = f* + S, + M,+ <rk + mal load on the failure plane was ap shear box removing the larger voids

plied through a load cap by means of in the process. All samples were al

(SM)„ + (So-).k + (cr)|k + a crossbar and loading yoke. The base

lowed to consolidate for 5 minutes

(SMor).jk + el|kl 4 and load cap both had projecting while subject to the normal stress in

metal gratings imbedded in the in order to achieve a uniform level of

Since a fixed effects model was used terior surfaces to ensure a uniform

(i.e. S, M and a- were fixed) the distribution of stress along the failure density. In all cases the rate of de

error term, ejjkl, was used for testing surface. Movements of the shear box formation had become extremely slow

by the end of the 5-minute interval.

main effects and interactions. The re were measured by means of dial

Each sample was sheared at a

sults of the statistical analysis appear gauges and the horizontal (shearing) velocity of approximately 1.5 inch per

in Table 2. force was measured by means of a

calibrated proving ring. minute and total shearing force was

read from the calibrated proving ring

Equipment Soil dial. Shearing force was recorded at

1/25 inch increments of deformation

Soil strength parameters which Three Hills Clay and Elnora Loam, until failure was reached. The strain

estimate the shear strength of a soil both cohesive soils, were chosen on rate of 1/5 inch per minute was

may be obtained by using several the basis of widely separated clay chosen for this experiment because it

different soil shear devices. These in contents and ready availability. Both was the fastest rate at which reliable

clude the triaxial shear, shear box and were from the Ap horizon and had readings could be taken from the

annular shear ring devices. A major been ground to a maximum particle shear apparatus.

disadvantage of these methods is that diameter of 2 mm. Particle size

the strength for a given soil condition analyses for these and other soils in The soil was then removed from

is a function of the device used to Alberta may be found in Table 1. the test apparatus and part of it used

obtain it (1). for moisture content determination.

Preparation of the samples for the The results are given in Table 3 and

To meet the objectives of this shear tests involved dividing each of are plotted on a graph of maximum

CANADIAN AGRICULTURAL ENGINEERING, VOL. 11, No. 2, NOVEMBER 1969 63

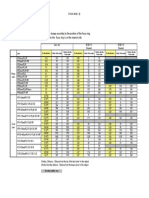

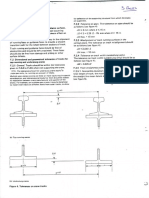

TABLE HI. COMPARISON OF EXPERIMENTAL SHEAR STRENGTHS shear stress versus soil moisture (Fig.

WITH CALCULATED VALUES 1). The maximum shear stresses as

calculated from equation 2 appear in

Soil Moisture Normal Stress Maximum Shear Strength Maximum Shear Strength-* Table 3.

Type Content(%) o(psi) Replicates x(psi) (calculated) t(psi)

____ 12 3 Mohr strength Envelopes (5) were

plotted using the experimental data

10. 41 13.21 11.61 12.67 12.48 for each soil-moisture combination.

20.8 11.83 15.71 16.43 17.14

Values of C and d> were obtained

16.90

from these curves and are shown in

19.24 23.03 21.24 21.78 21.31 Table 5.

10.41 12.14 13.03 14.46 12.88

Three RESULTS AND DISCUSSION

Hills 26.4 14.83 15.89 16.43 16.07 17.30

Clay The analysis of variance (Table 2)

19.24 20.71 19.64 18.92 21.70 indicates that not only the main

effects but all the first order inter

10.41 13.39 13.92 13.39 13.21

actions were significant. The signifi

31.1 14.83 17.32 15.89 16.07 17.63 cance of the main effects indicated

that the variations in shear strength

19.24 18.75 18.92 21.43 22.04

between soil types, among the three

moisture levels and among the three

10.41 10.00 10.36 11.78 11.45

normal pressures were statistically

18.6 14.83 13.93 13.04 13.21 16.14

significant. The first order inter

actions, soil X moisture, soil X pres

19.24 16.78 14.82 16.24 20.55 sure and moisture X pressure were

also statistically significant. The latter

EInora 10.41 6.43 6.78 6.25 11.90 indicates a differential response of

Loam

8.04 16.07** 7.32 16.32

the maximum shear stress depending

23.2 14.83

on the interactions of the factors

19.24 8.39 8.04 8.21 20.73 shown.

10.41 3.21 2.32 2.50 12.12

It can be seen (Table 3), (Fig. 1)

that shear strength was considerably

28.7 14.83 2.80 3.04 3.21 16.54 different for the two soils at approxi

mately the same moisture content.

19.24 3.32 3.39 4.11 20.95

The shear values increased directly

with normal stress as expected. In

* calculated from equation 2.

creasing the moisture content at a

** rejected as in error.

given normal stress had much less

effect on the shear strength of Three

Hills Clay than on the EInora Loam

(Fig. 1). The relation of moisture

THREE HIUS ClAY

content to maximum shear strength

shown in this figure does not agree

EINORA LOAM

with the results obtained by Nichols.

.a, 20 • <r, - 10.4 psi Nichols determined shear values from

»- • «r2 * 14.8 psi the Atterberg plasticity constants in

to

a tr, • 19.24 psi

such a way that the maximum shear

i/>

•" 15

values for the soil at any normal stress

*-

always occurred at the lower plastic

to limit. Instead they appear to corres

LOWER PLASTIC LIMIT pond more closely with those ob

X

10 V

I

(ELNORA LOAM) tained by Vomocil and Chancellor

CO

who concluded that the Atterberg

'LOWER PLASTIC LIMIT

K (THREE HILLS CLAY)

limits do not adequately describe the

5

role of water in its effects on soil

strength.

x

< It can be seen (Table 3) that ex

perimental and calculated values

15 20 25 30 35 40 45 were in fairly good agreement (at

least for practical purposes) for the

PERCENT WATER Three Hifis Clay which had a plas

ticity number, Pn, of 22.8. Some of

the calculated shear strengths were

1. Maximum shear strengths of Three Hills clay and EInora loam at different slightly higher than experimental

moisture contents and normoJ stresses.

CANADIAN AGRICULTURAL ENGINEERING, VOL, 11, No. 2, NOVEMBER 1969

64

values, particularly at higher normal ture contents up to approxi practically all of the resistance to

stresses. mately 20%. shear resulting from internal friction.

At higher moisture contents, the soil

In the case of EInora Loam, which 3. Highly plastic soils (PN>10) exhibited greater plasticity with a re

had a plasticity number of 3.0, the — equation can be used for sulting increase in the contribution of

calculated values for shear were con any moisture content up to the cohesion to shear strength. The EI

siderably higher than the experi lower plastic limit. nora Loam, on the other hand, has a

mental values, especially at the higher It should be noted, however, that this much lower clay content and a lower

moisture contents. Only at the lowest proposed grouping is based on plas liquid limit. Therefore, increases in

moisture contents and the lowest nor moisture content within the moisture

ticity number only, while equation 2

mal stress was there reasonable

includes both plasticity number and range studied resulted in reduced co

agreement. This might indicate (al lower plastic limit. Therefore, the re hesion due to the relatively thicker

though statistical evidence is lacking) liability of such a grouping may be adsorbed layers of water.

that the prediction equation would questionable. The soil types (Table

provide reasonably accurate strength Payne and Fountain (7) report the

1) were arranged according to this typical values of C and (f> to be 1.5

values for EInora Loam at moisture

classification (Table 4). psi and 34%° for 50 widely differing

contents below 20%.

soils. On this basis the cohesion and

Table 5 indicates that the angle of therefore the soil strength for the two

In view of the results obtained it

internal friction, <£>, decreases with soils tested appears large. This would

appears that the soils (Table 1) can increasing moisture content for both

be divided into three arbitrary classes also appear to be suggested by the

soil types. The cohesion intercept, work of Friesen and Domier (2). For

with respect to the applicability of however, varies directly with mois

equations 2 and 3. a specific tire, soil and soil moisture,

ture content for the Three Hills Clay equation 3 can be reduced and solved

1. Cohesionless soils (Pn « 0) and inversely with moisture content for the slip function where:

— equation cannot be used. for EInora Loam. In the case of Three

Hills Clay, the behavior of <£ would X = P/R + constant 5

2. Soils with an intermediate indicate that at the lowest moisture

plastic range (10>Pn>3) - This equation is now similar to that

content, the soil was behaving much for determining the coefficient of

equation can be used for mois like a dry granular material with

traction Ct. To be the same, the roll

TABLE IV. PROPOSED GROUPING OF ALBERTA SOILS

ing resistance would have to be sub

tracted from the soil thrust P, the

Group*

weight transfer from R, and the con

Soil Series Soil Class Lower Plastic Plasticity

Limit PI

stant equal to zero. The slip function

Number

for an 18.4 X 34 tire at 16% slip is

approximately .72 whereas Friesen

Cavendish SL and Domier (2) report the maximum

Foremost

Carmangay LS

L

Cf to be .55.

Irma

Peace Hills

LS-SL

LS

The discrepancy appears to be due

Culp LS

to the value of the soil strength as

Granum L 0.6 determined by the direct shear ap

Breton L 1.2 paratus or predicted by equation 2.

EInora L 36 3.0 This may be partly explained by the

II Angus Ridge L 39 3.0 fact that both the Atterberg limits

Maywood CL-SiCL 31 4.8 and the experimental shear values

Coaldale CL-C 30 13.2 were obtained from re-moulded soil

III Seven Persons C 28 18.0 samples while traction in the field

Malmo SIC 42

Three Hills C 36

18.0

22.8

depends on in place shear values.

Consequently, soil may fail in a dif

Group I: equation 2 not applicable. ferent manner under a traction tire

Group II: equation 2 applicable up to approximately 20% mc. than in the direct shear apparatus

Group III: equation 2 applicable up to lower plastic limit. used. In view of the above, equation

3 should be limited for the present to

TABLE V. EXPERIMENTAL VALUES OF C AND <£ comparisons of tractor sizes, tires and

ballast and with certain soils and

Soil Moisture Content <%) moisture contents.

C(psi) 4(degrees)

CONCLUSIONS

Three Hills Clay 20.8 1.2 46

26.4 5.6 36 Difficulties in predicting tractor

31.1 6.1 34 performance in the field still remain.

The results of this study show that

EInora Loam 18.6 4.9 29 Nichols* relationship for determining

23.2 4.1 12.5

28.7 1.1 7

continued on page 73

CANADIAN AGRICULTURAL ENGINEERING, VOL. 11, No. 2, NOVEMBER 1969 65

torily. Air temperatures of 50°F and velopment of the refrigeration and 1965. Comparison of Methods of

80 percent relative humidity have chilled water storage. Thanks are Measuring Soil Shear Strength

been held for 3 days with ± 0.5°F also due to Mr. W. Anderson and Using Artificial Soils. Transac

dry bulb and ± 1°F wet bulb varia Mr. D. Lunam (3rd year Mechanical tions of the A.S.A.E., 8: (2) 153-

tion. Temperatures of 100°F and Engineering students) who con 156, 160.

relative humidities from 35 to 90 per structed the equipment. Apprecia 2. Friesen, O. H. and Domier, K. W.

cent with ± 1°F dry bulb and tion is also expressed to the Canada 1967 and 1968. Traction Tests.

± 1.5°F wet bulb variation during a Department of Agriculture Research Extension Service Branch, Mani

3 day test have been obtained. Tests Branch for financial support of this toba Department of Agriculture.

with birds in the chamber and at project.

intermediate temperature and humid 3. Gill, W. R. and VandenBerg,

ity values have been maintained for REFERENCES

G. E. 1967. Soil Dynamics in

up to 6 weeks of continuous opera Tillage and Traction. Agriculture

tion within the variation mentioned 1. Longhouse, A. D., H. Ota, R. E. Handbook No. 316. Agricultural

previously. Emerson, J. O. Heishman, 1967. Research Service. U.S. Dept. Agr.

Heat and Moisture Design Data pp. 355-362.

Surface temperature variations on for Broiler Houses. A.S.A.E. Paper 4. Hanson, T. L., Johnson, H.P. and

the thermal radiation plates of ±- No. 67-442.

2.5°F were encountered. This was

Young, D. F. 1967. Dynamic

found to be the result of non uniform

Shearing Resistance of Soils.

2. Roberts, C. W. 1964. Estimation Transactions of the A.S.A.E., 10:

air velocities from the air inlets. Re of Early Growth Rate in the (4) 439-443, 447.

designing the air inlets for a more Chicken. Poultry Science 43: 238-

streamlined flow will alleviate this 252.

5. Means, R. E. and Parcher, J. V.

problem. 1964. Physical Properties of Soils.

Charles E. Merrill Books Inc.,

The water spray in addition to 3. Skoglund, W. C. and D. H. Palmer,

Columbus, Ohio.

maintaining pre-selected humidities 1962. Light Intensity Studies with

also removes fine dust, ammonia and Broilers. Poultry Science 41: 1839- 6. Nichols, M. L. 1932. The Dyna

excess carbon dioxide. 1842. mic Properties of Soil III. Shear

Values of Uncemented Soils. Agr.

Temperatures of water entering 4. {Staley, L. M., C. W. Roberts and Eng., 13 (8), 201-204.

and leaving heating and chilling D. C. Crober, 1967. The Effect of

coils, spray water, air entering and 7. Payne, P. C. J. and Fountaine,

Thermal Radiation on Early E. R. 1954. The Mechanism of

leaving the chamber, air leaving the Growth of the New Hampshire

fan and spray water zone were Scouring for Cultivation Imple

Chicken. Can. Agr. Eng. 9: 39-42. ments. N.I.A.E. Tech. Memo 116.

monitored by iron-constantan thermo

couples connected to a 24 point po- 8. Reece, A. R. 1967 Tractor Design

tentiometric recorder.

5. Suggs, C. W., 1967. Temperature and Tractive Performance. Proc.

and Enthalpy Equivalence of of Agricultural Engineering Sym

A computer programme was de Thermal Radiation. Trans. Amer.

veloped to monitor the operation of posium. Inst, of Agric. Engs.,

Soc. Agr. Eng. 10: 727-729. Penn Place, Reckmansworth,

the equipment. Water volume re

Herts, U.K.

corders for the heat exchange coils ESTIMATING TRACTOR . . .

are required before the computer 9. Rutledge, P. L. and MacHardy,

programme will be able to provide continued from page 65 F. V. 1968. The Influence of the

its full potential. Weather on Field Tractability in

soil strength is not in complete agree

ment with results obtained from di Alberta. Can. Agr. Eng., 10: (2),

CONCLUSIONS 70-73.

rect shear tests on two Alberta soils.

Equipment was developed to con Predicted tractor drawbar perfor 10. Steele, R. G. D. and Torrie, J. H.

trol the environment of a 16 square mance based on soil strength as de 1960. Principles and Procedures

foot chamber for poultry by provid termined by equation 2 or by the of Statistics. McGraw Hill Book

ing accurate control of thermal radia direct shear apparatus may not cor Company, Inc., New York.

tion, air temperature, wet bulb tem respond to values obtained in actual

perature, air velocity and Hght in field tests. However, comparisons of 11. Vomocil, J. A. and Chancellor,

tensity. When all monitoring equip tractor sizes, tire sizes and ballast may W. J. 1967. Compression and

ment for input and output factors is be made provided the limitations of Tensile Failure Strengths of

added, a complete energy balance laboratory or calculated shear values Three Agricultural Soils. Trans

can be determined. With accurate are taken into consideration. actions of the A.S.A.E., 10: (6),

environment control, genotype by 771-774.

environment interactions can be Better relationships of in situ soil

evaluated. strength to soil parameters are re

quired to adequately describe tractor

ACKNOWLEDGEMENTS field performance.

The authors wish to thank Mr. F.

REFERENCES

Seipp of Broadway Refrigeration Co.,

Vancouver, for the design and de 1. Bailey, A. C. and Weber, J. A.

CANADIAN AGRICULTURAL ENGINEERING, VOL. 11, No. 2, NOVEMBER 1969 73

You might also like

- Radar Target Detection: Handbook of Theory and PracticeFrom EverandRadar Target Detection: Handbook of Theory and PracticeRating: 5 out of 5 stars5/5 (1)

- Linear Network Theory: The Commonwealth and International Library: Applied Electricity and Electronics DivisionFrom EverandLinear Network Theory: The Commonwealth and International Library: Applied Electricity and Electronics DivisionNo ratings yet

- AHMSW 8 Fiche de PhaseDocument12 pagesAHMSW 8 Fiche de PhaseBOUBAKER LOGBINo ratings yet

- AMPCO 18 SandDocument1 pageAMPCO 18 SandS BHATTACHARYYANo ratings yet

- Publication Marcellin IJARIIE - V1Document8 pagesPublication Marcellin IJARIIE - V1rktv.marcellinNo ratings yet

- Scan 22-Mar-2018 PDFDocument2 pagesScan 22-Mar-2018 PDFSrinivasa Rao MaddiNo ratings yet

- Sheet Pile Calc Sheet - 2 (Propped Cantiliver) - REV1Document5 pagesSheet Pile Calc Sheet - 2 (Propped Cantiliver) - REV1channajayamangalaNo ratings yet

- Computer Simulation On Dynamic Soil-Structure Interaction SystemDocument15 pagesComputer Simulation On Dynamic Soil-Structure Interaction SystemTarike ZohirNo ratings yet

- Final Draft Dynamic Machine Foundation - 2Document10 pagesFinal Draft Dynamic Machine Foundation - 2Isser Freddy TobingNo ratings yet

- Concrete Mix Design M40 Grade (PQC) PDFDocument41 pagesConcrete Mix Design M40 Grade (PQC) PDFJalgaon60% (5)

- 970119rev0 Breakout Torque 900HP ECI Toque TrackDocument12 pages970119rev0 Breakout Torque 900HP ECI Toque TrackProyectil De ProyectoNo ratings yet

- Problema #2Document96 pagesProblema #2Ricardo Enrique MorenoNo ratings yet

- Earthmat Calculation FOR 132/25Kv Quazigund TSS: Northern RailwayDocument4 pagesEarthmat Calculation FOR 132/25Kv Quazigund TSS: Northern RailwayRaj-Kanishk SharmaNo ratings yet

- Metal Culvert CalcDocument40 pagesMetal Culvert CalcVietanh PhungNo ratings yet

- CFEM 4th Ed Errata (April 2018)Document10 pagesCFEM 4th Ed Errata (April 2018)DudeNo ratings yet

- Prediction of DLC Friction Lifetime Based On A Local Archard Factor Density ApproachDocument17 pagesPrediction of DLC Friction Lifetime Based On A Local Archard Factor Density ApproachFathia AlkelaeNo ratings yet

- Giroud 1981 and Noiray Unpaved Road and DSCN Corrected OCRDocument39 pagesGiroud 1981 and Noiray Unpaved Road and DSCN Corrected OCRRUBEIDYSNo ratings yet

- T13mra001 Mra STR 103 SLD 004 Rev B Pile Soil InteractionDocument19 pagesT13mra001 Mra STR 103 SLD 004 Rev B Pile Soil InteractionTannaz HadizadeNo ratings yet

- Evaluation of DMT and CPT Parameters To Be Used in Numerical Modeling of PilesDocument6 pagesEvaluation of DMT and CPT Parameters To Be Used in Numerical Modeling of PilesDiego P.No ratings yet

- Rates of Spread An D Spray in Bituminous Surface-Dressing of RoadsDocument6 pagesRates of Spread An D Spray in Bituminous Surface-Dressing of RoadsEnermy-123No ratings yet

- Surface Roughness PDFDocument6 pagesSurface Roughness PDFragilfanofnokiaNo ratings yet

- A+B+C Shift 29.12.23Document1 pageA+B+C Shift 29.12.23naresh mjNo ratings yet

- 1997 04 0014 PDFDocument2 pages1997 04 0014 PDFFernando FanteNo ratings yet

- Modelling Ground Response For Deep Excavation in Soft GroundDocument10 pagesModelling Ground Response For Deep Excavation in Soft GroundBaran GulsayNo ratings yet

- Lec 1 2 in SituDocument116 pagesLec 1 2 in SituSiwadol DejphumeeNo ratings yet

- PlxValidation-Cylindrical Cavity Expansion-2018Document4 pagesPlxValidation-Cylindrical Cavity Expansion-2018hariom sharmaNo ratings yet

- 98 PDFsam Al ManuDocument1 page98 PDFsam Al Manufordownload useNo ratings yet

- Resilient Modulus of Unbound and Bituminous Bound Road MaterialsDocument9 pagesResilient Modulus of Unbound and Bituminous Bound Road MaterialsElmaz RexhepiNo ratings yet

- 0 Racking CalculationDocument6 pages0 Racking CalculationmrberatNo ratings yet

- Detailed ReportDocument16 pagesDetailed ReportJhon Guzman CALIDADNo ratings yet

- Design Calculation FOR Rigid Pavement/RoadDocument5 pagesDesign Calculation FOR Rigid Pavement/RoadghansaNo ratings yet

- API Soil Model ValidationDocument37 pagesAPI Soil Model ValidationUnwanus Sa'adahNo ratings yet

- Chapter - 12 CeramicsDocument17 pagesChapter - 12 Ceramicssuaata 1991No ratings yet

- Nur (Adv) Act-1 Paper 2 (HS)Document9 pagesNur (Adv) Act-1 Paper 2 (HS)ameenaNo ratings yet

- Unit Information:: (Max Beam Slope From RDS)Document12 pagesUnit Information:: (Max Beam Slope From RDS)A MumtazNo ratings yet

- Cofferdam Design Calculation Pier P60 and P61 Bridge #4Document64 pagesCofferdam Design Calculation Pier P60 and P61 Bridge #4Shahrul AriffinNo ratings yet

- Accelerated Ultra-Spinning Black Holes. Black Needles?Document28 pagesAccelerated Ultra-Spinning Black Holes. Black Needles?leoNo ratings yet

- Ngjhju 60Document13 pagesNgjhju 60amit986876587No ratings yet

- Gruneisen Delcorro2012Document7 pagesGruneisen Delcorro2012Jorge OrtegaNo ratings yet

- Specification: Compaction Pavement SubgradeDocument8 pagesSpecification: Compaction Pavement Subgradefor your informationNo ratings yet

- Modeling The Mechanical Response of An Aluminum Alloy Automotive RimDocument7 pagesModeling The Mechanical Response of An Aluminum Alloy Automotive Rimesmaeel ghafariNo ratings yet

- Chapter 22: Materials Selection: Economic, Environ., & Design IssuesDocument17 pagesChapter 22: Materials Selection: Economic, Environ., & Design IssuesAlex Nico JhoentaxsNo ratings yet

- 1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Document7 pages1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Tamer. ThekingNo ratings yet

- PI066-MES-500-ITS-0010-CN-S1080 - Rev.DDocument29 pagesPI066-MES-500-ITS-0010-CN-S1080 - Rev.DMuhammad Fadhly AuzanNo ratings yet

- M 25 Ultratech Opc 43Document25 pagesM 25 Ultratech Opc 43Kaushal raiNo ratings yet

- Pile CalcDocument11 pagesPile CalcADHAM HAMZANo ratings yet

- DynamicsDocument80 pagesDynamicsalexNo ratings yet

- Ground Penetrating Radar (GPRJ For Pavement Thickness: Research Investigation 96-011 January, 1999Document2 pagesGround Penetrating Radar (GPRJ For Pavement Thickness: Research Investigation 96-011 January, 1999Emre MermerNo ratings yet

- FSI Analyses of A High-Performance Solar Boat Composite T-HydrofoilDocument6 pagesFSI Analyses of A High-Performance Solar Boat Composite T-HydrofoilTomás CarreiraNo ratings yet

- 2 AerodynamicDocument1 page2 AerodynamicPooya ShayestehNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12bunheng lonNo ratings yet

- 1مختبر مواصلاتDocument99 pages1مختبر مواصلاتAhmedMahirNo ratings yet

- PLAXIS - Finite Element Code For Soil and PDFDocument2 pagesPLAXIS - Finite Element Code For Soil and PDFRayodcNo ratings yet

- Geotechnical Drilling Report NBL-GT-01Document14 pagesGeotechnical Drilling Report NBL-GT-01FakhmiNo ratings yet

- Line - Cable-Parameter-Calculation-metric MMDocument59 pagesLine - Cable-Parameter-Calculation-metric MMJoseph PoplingerNo ratings yet

- Line Cable Parameter Calculation User ManualDocument59 pagesLine Cable Parameter Calculation User Manualamit77999No ratings yet

- Toigo, Salamoni, Sousa-Coutinho, 2020Document16 pagesToigo, Salamoni, Sousa-Coutinho, 2020NatiNo ratings yet

- DMT PDFDocument6 pagesDMT PDFFabricio BozzolaNo ratings yet

- PT Cirebon Energi Prasarana: Issue For ApprovalDocument6 pagesPT Cirebon Energi Prasarana: Issue For ApprovalSiriepathi SeetharamanNo ratings yet

- Numerical Simulation of A Stage Constructed Rockfill Dam On Plastic Clay Foundation - Ashwani Kumar Verma - CWCDocument13 pagesNumerical Simulation of A Stage Constructed Rockfill Dam On Plastic Clay Foundation - Ashwani Kumar Verma - CWCdeepakverma33546No ratings yet

- Development of A Braking Model For Speed Supervision SystemsDocument18 pagesDevelopment of A Braking Model For Speed Supervision SystemsRadomir NesicNo ratings yet

- Rolling Friction and Rolling ResistanceDocument9 pagesRolling Friction and Rolling Resistancebarnibar1No ratings yet

- Stress PDFDocument13 pagesStress PDF9966197483No ratings yet

- AME101 LectureNotesDocument136 pagesAME101 LectureNotesbarnibar1No ratings yet

- Performance CalculatioDocument3 pagesPerformance CalculatioGary MartinNo ratings yet

- Modelling of Locomotive Normal Load: 2. Single ValuesDocument5 pagesModelling of Locomotive Normal Load: 2. Single Valuesbarnibar1No ratings yet

- Lecture ME2105 07Document32 pagesLecture ME2105 07aliasuserNo ratings yet

- Universal Declaration of Human RightsDocument8 pagesUniversal Declaration of Human RightselectedwessNo ratings yet

- Surface CoatingDocument18 pagesSurface Coatingaaftab ahmed100% (1)

- Comparative Study Manufacturing Cost Between EN13445 and ASMEDocument32 pagesComparative Study Manufacturing Cost Between EN13445 and ASMEDries VandezandeNo ratings yet

- Mcex 01Document1 pageMcex 01barnibar1No ratings yet

- Coating For Steelwork PDFDocument16 pagesCoating For Steelwork PDFquiron2014No ratings yet

- BS466 TolerancesDocument3 pagesBS466 Tolerancesbarnibar1No ratings yet

- AutoCAD Text, Dimension and Leader Style SettingsDocument5 pagesAutoCAD Text, Dimension and Leader Style Settingsbarnibar1No ratings yet

- Metric Prefixes: ET 106 - Intro. To Engineering Technology Unit ConversionsDocument9 pagesMetric Prefixes: ET 106 - Intro. To Engineering Technology Unit Conversionsbarnibar1No ratings yet

- Cliff's Guide To Changing MK4 Golf Wishbones: 1. Jack CarDocument9 pagesCliff's Guide To Changing MK4 Golf Wishbones: 1. Jack Carbarnibar1No ratings yet

- Stress PDFDocument13 pagesStress PDF9966197483No ratings yet

- Unit ConversionsDocument9 pagesUnit Conversionsbarnibar1No ratings yet

- Stress PDFDocument13 pagesStress PDF9966197483No ratings yet

- Thermodynamics Worked ExamplesDocument13 pagesThermodynamics Worked ExamplesSalah Salman100% (1)

- Thermodynamics Worked ExamplesDocument13 pagesThermodynamics Worked ExamplesSalah Salman100% (1)

- Unfire Pressure VesselDocument146 pagesUnfire Pressure Vesselsungkang83% (6)

- Asme B16.5Document11 pagesAsme B16.5jacquesmayol100% (1)

- Metric Prefixes: ET 106 - Intro. To Engineering Technology Unit ConversionsDocument9 pagesMetric Prefixes: ET 106 - Intro. To Engineering Technology Unit Conversionsbarnibar1No ratings yet

- Of of With About From With of at in To To of For of With On With of For at of For To To To To About For About For To (-)Document1 pageOf of With About From With of at in To To of For of With On With of For at of For To To To To About For About For To (-)barnibar1No ratings yet

- Introduction To Isometric DrawingsDocument10 pagesIntroduction To Isometric Drawingsbarnibar1No ratings yet

- The Myth and Religion of Osiris The GodDocument7 pagesThe Myth and Religion of Osiris The Godbarnibar1No ratings yet

- Welding SymbolsDocument78 pagesWelding Symbolsuttamtm100% (1)

- Relative Design Test Pressures and PSV Set PointDocument6 pagesRelative Design Test Pressures and PSV Set Pointbarnibar1No ratings yet

- Geotechnical Engineering - Slope Stability PDFDocument62 pagesGeotechnical Engineering - Slope Stability PDFristif87100% (3)

- ch182 PDFDocument4 pagesch182 PDFabualamalNo ratings yet

- Slope Stability 1Document89 pagesSlope Stability 1GilbertDeVillaManaloNo ratings yet

- Duncan Friction Angle of Sand Stone11Document13 pagesDuncan Friction Angle of Sand Stone11asder02No ratings yet

- 2D 1 Tutorial (090 206)Document117 pages2D 1 Tutorial (090 206)Kate MartinezNo ratings yet

- An Innovative Computer Code For 1D Seismic Response Analysis Including Shear Strength of Soils - TropeanoDocument11 pagesAn Innovative Computer Code For 1D Seismic Response Analysis Including Shear Strength of Soils - TropeanoVicente CapaNo ratings yet

- Course Outline - Soil MechanicsDocument3 pagesCourse Outline - Soil MechanicsrajpcNo ratings yet

- Design of Small Diameter Frictional Piles and Cases StudyDocument71 pagesDesign of Small Diameter Frictional Piles and Cases StudyLeung Liang50% (2)

- Lateral Static LoadDocument87 pagesLateral Static LoadMuhammad Nur AkromuzzamanNo ratings yet

- 5.4 What Are The Causes and Effects of Landslides AnswerDocument19 pages5.4 What Are The Causes and Effects of Landslides AnswerYannie SoonNo ratings yet

- Design and Construction of Embankment DamsDocument18 pagesDesign and Construction of Embankment DamsSergio José RojasNo ratings yet

- SERRI Report 70015-003-Final ReportDocument114 pagesSERRI Report 70015-003-Final ReportBasir AbdurrahmanNo ratings yet

- Ce 3404Document17 pagesCe 3404csefmcetNo ratings yet

- A Laboratory Device To Test The Pull-OutDocument15 pagesA Laboratory Device To Test The Pull-Outj75fengNo ratings yet

- Shear Strength and Stiffness of Expansiv PDFDocument10 pagesShear Strength and Stiffness of Expansiv PDFMuhammad AfrasiyabNo ratings yet

- Tomlinson Foundation Design and ConstructionDocument4 pagesTomlinson Foundation Design and ConstructionHNo ratings yet

- Static Constitutive Relations For ConcreteDocument138 pagesStatic Constitutive Relations For Concretebadrul79No ratings yet

- I. History: Ideas." Ancient Civilizations Used Native Material Such As Straw, Tree Branches, and PlantDocument28 pagesI. History: Ideas." Ancient Civilizations Used Native Material Such As Straw, Tree Branches, and PlantdexterNo ratings yet

- Liquefaction of Earth Embankment Dams PDFDocument11 pagesLiquefaction of Earth Embankment Dams PDFSigit BintanNo ratings yet

- Application of Stone Column For Ground Improvement: A ReviewDocument12 pagesApplication of Stone Column For Ground Improvement: A ReviewRameshNo ratings yet

- Undrained Behaviour (And Modelling) : Computational Geotechnics CourseDocument46 pagesUndrained Behaviour (And Modelling) : Computational Geotechnics Courselphuong_20No ratings yet

- Typical Values of Soil Friction Angle For Different Soils According To USCSDocument5 pagesTypical Values of Soil Friction Angle For Different Soils According To USCSCHIKARANo ratings yet

- IRC Journal Part 80-1 January To March LowraseDocument58 pagesIRC Journal Part 80-1 January To March LowraseRAJNISH KUMARNo ratings yet

- LAB 9 Unconfined Compression Strength Triaxial Test LEVEL 2 Latest RepairedDocument9 pagesLAB 9 Unconfined Compression Strength Triaxial Test LEVEL 2 Latest RepairedNoradila RoslanNo ratings yet

- For Problems 2016-05-27Document42 pagesFor Problems 2016-05-27Christian D. OrbeNo ratings yet

- Determination of Residual Strength Parameters of Jointed Rock Masses Using The GSI SystemDocument19 pagesDetermination of Residual Strength Parameters of Jointed Rock Masses Using The GSI Systemcastille1956No ratings yet

- Tailings Impoundment For Uranium Mines: GuidelineDocument56 pagesTailings Impoundment For Uranium Mines: GuidelineAmine SammaaNo ratings yet

- Davis Et Al (1980) Stability of Shallow TunnelsDocument20 pagesDavis Et Al (1980) Stability of Shallow TunnelsRAJAT PURWARNo ratings yet

- Direct Shear Test ReprtDocument4 pagesDirect Shear Test ReprtShivaraj SubramaniamNo ratings yet

- ReferenceDocument139 pagesReferencethachNo ratings yet