Professional Documents

Culture Documents

Rates of Spread An D Spray in Bituminous Surface-Dressing of Roads

Uploaded by

Enermy-123Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rates of Spread An D Spray in Bituminous Surface-Dressing of Roads

Uploaded by

Enermy-123Copyright:

Available Formats

A Paper by

C. S. Mackintosh, B.Sc.(S.A.), B.Sc.Eng.(Rand), A.M.I.C.E., M.I.Struct.E., M.I.H.E., (Member)

RATES OF SPREAD AN D SPRAY IN

BITUMINOUS SURFACE-DRESSING OF ROADS

SYNOPSIS

simple apparatus, measuring the volume of chips required to cover a standard area, gives

A the spread ratio directly on a dipstick reading and allows automatically for the shape of

the chips. The spray rate for bitumen is determined jointly from the measured voids between

chips, the nature and intensity of traffic and the texture of the existing road surface. A nomogram

obviates calculations. To allow for contraction and evaporation, a table of application factors is

given

Introduction ALD of the chips in inches,

rate of application of bituminous binder in Imperial gallons

SURFACE-DR ESSTNG of roads offers the following per sq. yd., and

proportion of final voids in [he compacted layer that are

advantages over premix carpets :-- to be filled by the binder (it ranges from 50 per cent for

heavy industrial traffic to 80 per cen t for light traffic -

I. Economy in capital outlay of plant. lor average conditiom, Hanson [()Ok P 2/3),

" 0-

2. Economy in bitumen, stone, labour and time.

3. A waterproof protection to the basecourse. 36

then S = .......... . ................... (I)

4. A non-skid, non-g lare surface. KD

To secure all these advantages, many factors must G = 0.938 PD ........................ (2)

be studied and allowed for. Uncontrollable factors

and when P = 2/3 G = 0.625 D .. .... ..................... (3)

including the weather, the mineral origin and quality

of the stone from which the chips are made, the nature These formulae have stood the test of time. Engin-

and volume of traffic, and the existing surface texture, eers who use them prod uce surface-d ressings of con-

are all important, but only the last two are discussed sistently good quality. Those who follow such standard

in this paper. specifications as : - five sq.yd . of road per gallon of

bitumen and eighty sq .yd . of road per ton of chips,

Reproduced by Sabinet Gateway under licence granted by the Publisher (dated 2011)

The controllable factors include the quality of irrespective of the variation in shape and grading

the binder, the quality of work done in producing the of the chips, procuce some good results but inevitably

chips, the preparation of the existing surface and the some fa:1ures.

working technique of the surface-dressing operation.

Only one pa rt of the technique, viz., the rates of appli- The modern instrument for measuring ALD is a

cation of binder and chips, is discussed in this paper. thickness gauge, which registers the distance between

two parallel plates in thousandths of an inch on a dial.

A verage least dirn.ension This instrument is more accurate than the vernier

Although the process of surface-dressing has been calipers used formerly. It is less fatiguing and much

used for many years, it emerged from the hit-and-miss quicker to use too. Several manufacturers of dial gauges

stage to that of scientific control only with the publica- can now offer these instruments.

tion of Hanson's ALD method in 1935 1 •

Other rn.ethods

Hanson's main findings were:- Eac h chip in a

surface-dressing settles finally with its least dimension Other writers, apparently unaware of Hanson's

vertical. The least dimension is defined as the minimum work, have also concluded that the thickness of the

distance between two parallel planes just touching the stone mat is of paramount importance in determining

chip. The average of these, called the average least the rates of application, and have given various methods

dimension or ALD, gives the thickness of the compacted of calculating tha t thickness. 2 , 3 , 4, 7.

stone mat and governs the rates of application of both Because these methods consume much time, they

binder and chips. To measure the ALD, the least cannot be carried out with the desired frequency for

dimension of 200 to 300 chips from a representative proper control. Furthermore, a knowledge of the mat

sample should be measured, and the average of these thickness, whether 100se 2 or compacted I , 4, 7 is only a

calculated. Hanson showed that if means to an end. What is really required is to know

S = Spread ratio in square yards of road per cu. yd. of chips, at what spread ratio the chips should be applied. The author

K ~ 1.6 when no chips are lost, wishes to emphasise that the spread ratio can be

1.7 if6 per cent of chips arc lost in handling,

I. fl.'; if 6 per cent of chips arc lost in hanrlling and 10 pCI' rn.easured directly, with certain obvious advantages.

cent arc whipped off hy traffic, In ;)(Iclition, other variahles also inAuellce the recJllired

DIE SIVIELE INGENIEUR in Suirl-Afrikil - Oktohr>r 19fi1 183

rates of application, the most important of these being On the road, when each bare patch is covered by

the nature and intensity of traffic and the surface texture throwing on a few more chips before rolling, there are

of the existing road. In this paper the study is taken a unavoidably a few spots where the stone lies two-chips-

step further by making quantitative allowance for these thick. This condition should be imitated as closely as

two factors. possible on the pan. The shape of the chips, either

cubical, flaky, or rounded, is automatically allowed for

Direct Measurement in this process.

In the Transvaal Roads Department, two alterna- The cylinder

tive methods are Hsed for direct measurement of the

spread ratio. . This is made from an 18 in. length of 5 in. dia.

water pipe with one end closed and two handles near

The 'box-and-tray' m.ethod the open end. The stone mat, one-chip-thick on the

This apparatus, first introduced by Mr. C. D. Roux pan, is poured into the cylinder which is then dropped

when Regional Roads Engineer at Benoni, has been ten times from a height of about three inches to shake

modified to a portable form by Mr. M. Simonovitch the chips into a stable position.

of that office.

The dipstick

A standard volume of chips, 0·1 cu.ft, is spread

on a hardboard tray, 24 in. wide and from 36 in. to This is made ofaluminium angle, 1in. k in. x} in.

42 in. long, which has three fixed walls and one end It is placed in the cylinder with its foot resting on the

surface of the chips. It is graduated so that the spread

wall movable.

ratio in square yards of road per cubic yard of ci1il)S

The area covered by the chips is adjusted by placing is read off directly at the brim of the cylinder.

the two locating pins of the movable wall first into one

pair of locating holes, then another, until the layer Measured voids

is one-chip-thick, with no bare patches. Each shift

of one inch of the movable wall corresponds to a change When the spread ratio has been recorded, water

of 5 sq.yd per cu.' yd in the spread ratio. The locating is poured into the cylinder until the voids between the

holes are marked accordingly, and the spread ratio chips are just filled. The volume of water required,

is read directly. is measured in cubic centimeters and this volume

represents the amount of binder required to completely

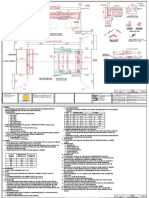

The 'pan-and-cylinder' m.ethod embed the loose chips on a circle of road surface, 22 in.

in diameter. The nomogram enables the percentage

This apparatus" developed by the Author, consists embedment to be chosen according to traffic intensity,

of a sted pan,' a steel cylinder, a dipstick and a glass and the consequent rate of application of binder is

measuring cylinder (Fig. 1) together with a nomo- read off directly.

gram (Fig. 2.).

Reproduced by Sabinet Gateway under licence granted by the Publisher (dated 2011)

Percentage em.bedm.ent of loose chips

This is the depth of binder expressed as a percentage

of the thickness of the stone mat before compaction.

The working range is from 14 for very heavy industrial

traffic to 50 for very light traffic, corresponding to

binder filling from 60 to 80 per cent of the voids in the

rolled and traffic-compacted layer. The required

depth of binder expressed as a percentage is determined

from the traffic count and modified by other variables.

Rate of application of binder

The rate of application of binder req4ired consists

of two portions, the amount required to fill the cracks

and surface voids of the existing road surface, and the

amount required to embed the chips so that they are

held securely. The former amount is determined by

the sand-patch test, and the latter from the measured

Fig. 1 'Pan-and-cylinder' apparatus voids and the traffic count.

1. Steel pan, 22 in. internal diameter. 2. Steel cylinder, :1 in. internal

diameter. 3. Dipstick. 4. Glass mea~uring cylinder.

The existing surface-texture

The pan

Even with years of experience, it is not always possi-

A single layer of chips is spread on a standard ble to estimate accurately the amount of binder needed

area, which is a steel pan of 22 in. internal diameter, to allow for the existing surface-texture. It can vary from

having a wall which varies from I t in. high to about adding as much as 0·23 gal. per sq. yd. for coarse,

lOin. The 10-in. portion is designed to facilitate pour- open, hungry surfaces to subtracting as much as O· 10

ing the chips into the cylinder. gal. per sq. yd for slick or slippery surfaces. Small

184 DIE SIVIELE INGENIEUR in Suid.Afrikil - Oktober 19tH

!;aT/atlOlls in the total application oj binder can vastly , sand is then spread over the full width of this strip

differing results, so the sand patch test is used to measure to as great a length as possible with a rubber-bladed

accurately this amount of binder. rake or squeegee and the length of the patch is recorded.

The sand represents the amount of bitumen required

The 'sand-patch' test to fill the voids in the old surface under the lower limit

The standard volume of sand used is about 534 c.c., of the new dressing. Where there are no surface voids,

measured by filling a one pint 'Consol' canned-fruit no sand should be left. The sand is sifted to pass a

jar to the brim and scraping it level. Two parallel No. 60 sieve (opening 0·0097 in.) and to be retained

lines, 18 in. apart and about 12 ft long are chalked on on a No. 200 sieve (opening 0·0029 in.). Thus it is

a portion of the road which is carefully chosen as being fine enough to enter cracks and surface voids but too

truly representative of the surface to be sealed. The coarse to blow away as dust.

30 500

-:27 550

0::

ld

-25 >

<t 600

..J

>

~ 100. 50 lLJ

II)

450 650

ci a::

a:: lLJ

;! Q.. 40 9

lI... 700

: 20 (f)

5 0

lLJ

W a:: I-

cr. a:: Z

18---...~ 0 30 ~

11 a~..J 0

(f) ~ 600 W

16 a: I.!:)

25 10

::E

ILl

15 ~ 3--

lLJ

o 20,~

Z

....

Reproduced by Sabinet Gateway under licence granted by the Publisher (dated 2011)

<t

Z

(f) lLJ

0:: U

<t a::

U 15 lLJ

Q..

o EACH HEAVY LORRY (10 TONS OR MORE)

J: Z

'u <t COUNTS AS 10U CARS.

.... II)

<t

Q..

oZ I.LI ,

<t :L 8-0

II) ::J

..J

o

lI... >

o

, 1t-6

12-

OR MORE

Fig. 2 Nomogram for determining the rate of application of bituminous binder in surface dressing of roads

DIE SIVIELE INGENIEUR in Suid-Afrika Oktober 1961

Bitumen tends to bridge rather than penetrate below 15, though difficulty is experienced in producing

cracks less than about i in. wide. In this test, therefore, - i-in. chips with an index less than 30.

the sand should be allowed to behave similarly, and

not be "worried" into the cracks. Where existing These properties of the chips are even more im-

surface voids are too big to be bridged by the chips portant than resistance to abrasion, because surface-

of the new seal, the test is likely to be misleading. As a dressings usually fail from other causes long before

rough guide, when the sand-patch is less than 4 ft the chips have been worn down to smoothness by

long the old surface needs cial attention, possibly traffic.

slurry sealing, before the 0 ary resealing.

Whip-off and handling losses

The binder nOIIlogram

Surplus chips are not only whipped off by traffic,

The left-hand scale of the nomogram, Fig. 2, is but actually cause the loosening of some chips already

double-sided. On the left are graduations for the held by the binder. 1, 2, 4. This can be verified by

length of the sand-patch, and on the right the corres- marking off two test sections, each five yards long,

ponding rate of application of binder required to fill on a resealing job. The one section is over-chipped and

the existing surface voids. the other under-chipped. An inspection after three

weeks of traffic will show invariably that the over-

Example:- chipped section will be leaner than the under-chipped

Length of sand-patch = 7' 9" one. Therefore, excess chips should not be applied as an

Bitumen required to fill surface voids .091 g.s.y. allowance for whip-off. The aim should be such accurate

Measured voids = 1180 c.c.

Equivalent traffic count = 1600 v.p.d. rates of spread and spray that there is practically no whip-off.

From nomogram, bitumen required to hold chips .185 g.s.y.

The only allowance to be made should be a

Total bitumen required .276 g.s.y. maximum of six per cent, though four per cent is

Application factor from Table I I . 103 usually enough, for handling losses and imperfect

bitumen is to be sprayed at. .. ~32~ g.s.y. workmanship. If Hanson's equation No. 1 is used, K

should never exceed l· 7.

An index line is placed across the three scales of

the nomogram, linking the measured voids and the Prevention of whip-off

percentage embedment. Where this line cuts the left- The principal means of preventing whip-off are

hand scale the rate of application of binder is read off the use of single-sized, near-cubical chips free from

again. This is added to the figure found in the sand dust, accurate control of the rates of spread and spray,

patch te~t to give t~e total rate of application desired. immediate and thorough rolling, and keeping fast traffic

Other variables off the road until the bitumen has set. Other successful

precautions are:-

The percentage embedment of chips, related on

I. Covering the dressing with a light application

Reproduced by Sabinet Gateway under licence granted by the Publisher (dated 2011)

the nomogram to an arbitrary scale of traffic intensity,

can be modified to allow for other variables, such as of sand premix.

adhesiveness of binder, dustiness and absorptive power 2. Splitting the applications of bitumen and chips

of chips, and even the weather. into two or more partial applications.

Time saved, accuracy increased 3. .il1ultiple dressings, using chips of progressively

It is essential for surface dressings of roads carrying smaller sizes, possibly finishing off with a light

modern traffic that the rates of spread and spray be application of emulsion.

accurate. The above method gives results of great 4. Persuading heavy vehicles to travel slowly

accuracy in these rates and, compared with earlier over the new dressing, covering the whole

methods, takes only a traction of the time. Rates for surface instead of a beaten track. This is heavy

both chips and binder can be determined in six minutes. pneumatic rolling and is very effective.

Quality of chips Application Factors

\Vhen the sizes of chips in a surface-dressing cover To allow for contraction of straight-run bitumens

a wide range, it is too much to hope that the smaller and tars applied hot, and for evaporation of solvent

chips will occupy the voids between the bigger ones. oils from cutbacks and water from emulsions, the

They stay where they fall, forming a mat of varying actual rate .of application must always be higher than

thickness, resulting in a bumpy and patchy road. the final rate of distribution desired. Table I gives

Experience all over the world has proved that the best the multiplying factors.

results in surfice-dressing are obtained when single

sized chips are used. I, 2, 3, 4. General principles

It is also important that the chips should be near- This quick and easy method makes it practicable

cubical in shape and free from dust. Many crusher to determine the correct rates of spread and spray

firms today can offer washed chips. In the i-in. + to suit each particular road and the chips and binder available.

i-in. size, it is possible to bring the flakiness index 6 It is not, however, the whole story. It is only one of

186 DIE SIVIELE INGENIEUR in Suid-Afrika ~ Oktober 1961

Table I

APPLICATION FACTORS

The desired rate of application of binder, as determined by ,the foregoing methods, must be multiplied by the factor in the last column to obtain the actual rate rif

application required in order to allow for reduction in Dolume due to cooling of bitumen and evaporation of solvenL; or water.

Bitumen Spraying

Type of binder and Examples content: temperature: Application

coefficien t of expansion Per cent OF factor

1. Straight bitumen, Caltex 195 road asphalt 100 350 1.103

0.00035 per 1°F. 96 paving cement

" 65 paving cement

"

Satmar 1501200 Petroleum bitumen JOO 3.')0 I. J03

80/100

" "

torbanite "

" 180/200 "

" "

petroleum "

" " " ...........-

Shell 180/200 Spramex 100 350 I. J03

80/100 Mexphalte

" 60/70

" "

Standard Oil 180/200 Sosa 100 350 1.103

80/100

" " 60/70 "

" " "

Wm Penn 150/200 Tampimex 100 350 1.103

2. Cutback bitumens: R.C.O .10 120 2.043

(a) Rapid curing,

o.000355 per I°F

All cut-backs

manufactured by

Caltex, Shell,

1 R.C.I

R.C.2

R.C.3

60

67

73

150

175

200

1.719

1.554

1,438

Satmar, Sosa.

J R.C.4

R.C.5

78

, 82·

250

275

I. 369

1.313

(b) Intermediate curing, All cut-backs ")

J 300/400 83 3S0 1.329

Reproduced by Sabinet Gateway under licence granted by the Publisher (dated 2011)

0.000355 per 1°F manufactured by Caltex, 400/500 83 350 1.329

Shell, Satmar, Sosa 500/700 83 350 1.329

(c) Medium curing, M.C.O 50 120 2.043

}

0.000355 per 1"1'. All cut-backs M.C.I 60 150 1,719

manufactured by M.G.2 67 200 1.567

Caltex, Shell, Satmar, M.C.3 73 250 1.462

Standard Oil (Sasa) M.C.4 78 275 1.379

M.C.5 82 275 1. 313

(d) Slow curing S.C.O 40 120 2.553

0.00035,1) per 1°F

I

All cutbacks

manufactured by

Caltex, Sheli, Satmar

Standard Oil (Sosa)

1r S.C.I

S.G.2

S.C.3

S.G.4

50

60

70

75

200

200

250

250

2.099

1.749

1.525

1.423

J S.C.5 80 275 1.345

3. Emulsions, 55 50 1.82

0.00025 per 1°F (Atmospheric)

5.~ 120 1.84

4. Tars, Prime Tar 150 1.021

0.00030 per 1°F 30/35 E.V.T. content 22:) 1.040

35/40 E.V.T. ]00 per cent 225 1,040

No. 1 road tar 250 1.046

No.2 road tar 2:')0 l. 046

No. 3 road tar '1.7:) 1.0:i2

The above grades are produced by

Iscor and the Dundee Coal Co.

DIE SIVIELE INGENIEUR in Suid-Afrika - Oktober 1961 187

a dozen fundamental principles which must be followed 3. As all the measurements are volumetric, the

to ensure good results. These have been ably dealt specific gravities of stone and binder are not

with elsewhere l , 2, 3, 4, 5, and need not be repeated necessary.

here. Neglect of any of these principles may cause

a surface-dressing to fail. 4. Being quick and easy, it is more likely to be done

conscientiously than a time-consuming method.

Co-operation for i:mprove:ment

Acknowledge:ment

Patent rights are not reserved. , .... The apparatus The Author wishes to thank the Director of the

can be made from the description given. The internal Transvaal Roads Department for permission to publish

diameter of a 5-in. water pipe is not exactly 5 in. so the technique worked out in the course of normal duties

each dipstick must be calibrated according to the in the Department, and acknowledges gratefully the

actual diameter of the pan and cylinder with which co-operation of Mr. K. J. Harpur, now Assistant Chief

it is teamed. A working copy of the nomogram, and Engineer of the O.F.S. Provincial Roads Department,

one for spacing !-cu.yd dumps of chips along shoulders, and Mr. F. T. Evans and the laboratory staff of the

are available on request. Transvaal Roads Department.

Engineer,s, using the apparatus and nomograms REFERENCES

are requested to pass on any new knowledge gained, so

that the techn,igue may be further improved. I. HANSON, F. M. Bituminous surface treatmen t of rural high-

ways. Trans. N.;::. Soc. Civ. Eng. 1935. (Out of print).

2. KEARBY, JEROME P. Thoughts and theories on bituminous

Conclusion surface treatments. World Construction (May-June, 1953)

and Roads and Streets (August ,1952).

3. LEE and FUIDGE. The technique of surface-dressing with

The advantages of the simple pancand-cylinder tar. Pub. by Brit. Rd. Tar. Assoc.

method for determining the rates of spread and spray in , 4. BELGIAN SPECIFICATIONS. Improved practice in surface-

bituminous surface-dressings of roads are: dressing of roads. Translated by N.l.R.R. in Afr. Rds. and

Trnspt, March-April 1958.

1. It allows automatically for the shape of the chips. 5. HANSON, F. M. H. The road structure. N.;::. Inst. Eng.

February, 1957, quoted under the title 'Why- do our roads

2. By assigning numerical values to the existing fail?' in Afr. Rds. and Trnspt, March-April 1958.

surface texture and the traffic volume enables 6. BRIT. STDS. INST. Single-sized roadstone and chippings.

Brit. Std. Spec. No. 63 of 1951.

the rates of application to be determined more 7. SOSA. Requirements for Surface Treatments. (Australian

accurately, as required by modern traffic. method). Std. Oil Co. of S.A. 1959.

"

DISCUSSION

Reproduced by Sabinet Gateway under licence granted by the Publisher (dated 2011)

Written discussion on the above paper will be accepted until December 27,1961. This, together with the Author's Re-

ply, will be published in the April, 1962, issue of The Civil Engineer in South Africa, or later. '

Such written discussion, which must be submitted in duplicate, should be in the third person present tense, and should,,'

be typed in double spacing. It should be as short as possible and should not normally exceed 600 words in length. It '

should also conform to the requirements laid down in the 'Notes for the Guidance of Authors and Contributors'

as published in the March, 1959, issue of The Civil Engineer in South Africa.

REFERENCE

Whenever reference is made to the above paper this publication should be referred to as the Transactions of the 8buth

African Institution of Civil Engineers, and the volume and date given thus: Trans. S.Afr.lnstn. Civ. Engrs. 3 (Oct.,1961)

188 DIE SIVIELE INGENIEUR In Suid-Afrika - Olitober 1961

You might also like

- Kutya - Louie The French Bulldog Puppy - Angol17fDocument17 pagesKutya - Louie The French Bulldog Puppy - Angol17fLőrinczi Fanni100% (1)

- Strat E-BookDocument61 pagesStrat E-Bookjustin100% (6)

- Durable and Economical Technology For Bituminous Surfacing of Rural Roads in IndiaDocument6 pagesDurable and Economical Technology For Bituminous Surfacing of Rural Roads in IndiaProf. Prithvi Singh Kandhal50% (2)

- (PDF) IRC-58 2015 Excel SheetDocument3 pages(PDF) IRC-58 2015 Excel SheetMadhavpokale0% (1)

- WARDHA Tender BOQ 13-12-2013 For TenderDocument23 pagesWARDHA Tender BOQ 13-12-2013 For TenderSai BabaNo ratings yet

- Attachment 1-Freight & Forwarding Charges and East Malaysia WarehouseDocument144 pagesAttachment 1-Freight & Forwarding Charges and East Malaysia Warehousedaniel_ting_1No ratings yet

- Soil GSB WMM by Sand Replacement MethodDocument1 pageSoil GSB WMM by Sand Replacement MethodBrahammanand BairwaNo ratings yet

- 1-00FreshConcrete PDFDocument6 pages1-00FreshConcrete PDFVishwakarma Vishwakarma0% (1)

- Rehabilitation of National Highway Damaged by Rain Using Geosynthetics in Hilly Terrain - A Case StudyDocument10 pagesRehabilitation of National Highway Damaged by Rain Using Geosynthetics in Hilly Terrain - A Case StudyAdarsh VaishyaNo ratings yet

- SAPEM Chapter 13 + Appendices 2nd Edition 2014Document135 pagesSAPEM Chapter 13 + Appendices 2nd Edition 2014Enermy-123100% (1)

- The Big IdeaDocument139 pagesThe Big Ideatroysantos100% (1)

- R35-17 Practica Estandar Diseño Volumetrico de Mezcla SUPERPAVEDocument29 pagesR35-17 Practica Estandar Diseño Volumetrico de Mezcla SUPERPAVEDannyChaconNo ratings yet

- Pavement Design Methods 2 PDFDocument47 pagesPavement Design Methods 2 PDFShekh Muhsen Uddin AhmedNo ratings yet

- Radar Target Detection: Handbook of Theory and PracticeFrom EverandRadar Target Detection: Handbook of Theory and PracticeRating: 5 out of 5 stars5/5 (1)

- Vishwabhumi Technologies: CHAINAGE NO.-33+796Document20 pagesVishwabhumi Technologies: CHAINAGE NO.-33+796Ajayvidyanand SharmaNo ratings yet

- Database of Garment ExportersDocument78 pagesDatabase of Garment ExportersRaj Kumar JhaNo ratings yet

- Yarn QualityDocument4 pagesYarn Qualityalireza vahabi100% (1)

- Labor Economics SolutionsDocument11 pagesLabor Economics Solutionshyld3n100% (1)

- Prediction of Surface Roughness in End-Milling Using Fuzzy Logic and Its Comparison To Regression AnalysisDocument3 pagesPrediction of Surface Roughness in End-Milling Using Fuzzy Logic and Its Comparison To Regression AnalysisspriditisNo ratings yet

- Mnl-Wtp-00-Sdl-00001-Rev02 General SpecificationDocument2 pagesMnl-Wtp-00-Sdl-00001-Rev02 General Specificationjan jhonnel punzalanNo ratings yet

- Analysis of Flexible Pavements Using IIT Pave: Harish G RDocument4 pagesAnalysis of Flexible Pavements Using IIT Pave: Harish G RAyush KumarNo ratings yet

- Analysis of Flexible Pavements Using IIT Pave: Harish G RDocument4 pagesAnalysis of Flexible Pavements Using IIT Pave: Harish G RArchan ChakrabortyNo ratings yet

- Simulation of Surface Generated in Abrasive Flow Machining ProcessDocument10 pagesSimulation of Surface Generated in Abrasive Flow Machining ProcessAbdullah Talha TuranNo ratings yet

- A Fracture Mechanics Model For The Wear of Gear Flanks by PittingDocument7 pagesA Fracture Mechanics Model For The Wear of Gear Flanks by PittingFernando RockerNo ratings yet

- Estimation of The Undrained Shear Strength of EastDocument9 pagesEstimation of The Undrained Shear Strength of EastFuad HasanNo ratings yet

- ASTM-C633-01 - Numerical StudyDocument7 pagesASTM-C633-01 - Numerical StudyKrisna Hutomo Aditya (ETSI)No ratings yet

- SW2022 KortschDocument11 pagesSW2022 KortschJuan BrugadaNo ratings yet

- Formation Compressive Strength Estimates For Predicting Drillability and PDC Bit SelectionDocument11 pagesFormation Compressive Strength Estimates For Predicting Drillability and PDC Bit SelectionJhann Carlos Varillas ArticaNo ratings yet

- Ijciet 11 10 006Document9 pagesIjciet 11 10 006aekockautNo ratings yet

- Flexible Pavement Design IN 791 FinalDocument25 pagesFlexible Pavement Design IN 791 FinalAnirudh SabooNo ratings yet

- Prediction of Flow Field For A 2-D Mixed Compression Supersonic InletDocument5 pagesPrediction of Flow Field For A 2-D Mixed Compression Supersonic InletAzeem KhanNo ratings yet

- SB PHLC 2LDocument4 pagesSB PHLC 2LjayNo ratings yet

- Journal of The Geotechnical Engineering Division: in Situ Tests by Flat DilatometerDocument4 pagesJournal of The Geotechnical Engineering Division: in Situ Tests by Flat DilatometerRenato Aldana GomezNo ratings yet

- Title:: General Arrangement Drawing For Reconstruction of MINOR BRIDGE (SPAN:1 X 16.0m)Document2 pagesTitle:: General Arrangement Drawing For Reconstruction of MINOR BRIDGE (SPAN:1 X 16.0m)Nilay GandhiNo ratings yet

- 1980 S. Marchetti Marchetti JNL of The Geotechn. Engineering Division, ASCEDocument30 pages1980 S. Marchetti Marchetti JNL of The Geotechn. Engineering Division, ASCEKarla CaNo ratings yet

- As 1289.6.2.1-2001 Methods of Testing Soils For Engineering Purposes Soil Strength and Consolidation TestsDocument2 pagesAs 1289.6.2.1-2001 Methods of Testing Soils For Engineering Purposes Soil Strength and Consolidation TestsSAI Global - APACNo ratings yet

- Digidepo 10448292 Po ART0005363685Document5 pagesDigidepo 10448292 Po ART0005363685Safak BooksNo ratings yet

- lADC/SPE 39306 The Effect of PDC Cutter Density, Back Rake, Size, and Speed On PerformanceDocument9 pageslADC/SPE 39306 The Effect of PDC Cutter Density, Back Rake, Size, and Speed On PerformancependexxNo ratings yet

- Study, of Bench Blast Row Delay Timing and Its Influence On Percent-CastDocument10 pagesStudy, of Bench Blast Row Delay Timing and Its Influence On Percent-Castmatias79No ratings yet

- Flexible Pavement Design As Per IRC: 37-2012: Jheel A. Patel Prof. Amit A. Amin Dr. L. B. Zala Mr. Hardik SukhadiyaDocument5 pagesFlexible Pavement Design As Per IRC: 37-2012: Jheel A. Patel Prof. Amit A. Amin Dr. L. B. Zala Mr. Hardik Sukhadiyasuneet kuma meenaNo ratings yet

- Combined Economic and Mechanical Performance OptimDocument15 pagesCombined Economic and Mechanical Performance OptimAy ManNo ratings yet

- MosquejDocument12 pagesMosquejdr.afroza1875No ratings yet

- Seismic Dilatometer (SDMT)Document5 pagesSeismic Dilatometer (SDMT)cfr242No ratings yet

- CASSANTO, J M. Angle-of-Attack Measurements of A Hypersonic Re-Entry Vehicle Derived From Flight Test Pressure Data. Journal Spacecraft 1966Document2 pagesCASSANTO, J M. Angle-of-Attack Measurements of A Hypersonic Re-Entry Vehicle Derived From Flight Test Pressure Data. Journal Spacecraft 1966araujo.engmecNo ratings yet

- Package B4 - Geotechnical Review BriefDocument8 pagesPackage B4 - Geotechnical Review BriefWanNo ratings yet

- IRC Method of DesignDocument6 pagesIRC Method of DesignFaraz zeeshan100% (1)

- (Asce) 0733-9410 (1995) 121 9Document2 pages(Asce) 0733-9410 (1995) 121 9Abdelmoez ElgarfNo ratings yet

- A Highly Automated Method For Simulating Airfoil Characteristics at LowDocument14 pagesA Highly Automated Method For Simulating Airfoil Characteristics at LowŘøm ËõNo ratings yet

- Balanced Cement Plug Example Calculations - Cement Plugs - CementingDocument3 pagesBalanced Cement Plug Example Calculations - Cement Plugs - Cementingazareiforoush100% (1)

- Engineering ManualDocument59 pagesEngineering ManualHuiFrankyNo ratings yet

- Excavation and Lateral Support TeklaDocument9 pagesExcavation and Lateral Support TeklaTEE Yu Yang TEENo ratings yet

- Chapter - 2: Design of Pavement OverlaysDocument37 pagesChapter - 2: Design of Pavement Overlaysbini1221No ratings yet

- Op-018. Design of Geogrid For Piled Embankment To Bs8006: Work Instructions For EngineersDocument4 pagesOp-018. Design of Geogrid For Piled Embankment To Bs8006: Work Instructions For Engineersjinwook75No ratings yet

- Pavement Design-By SAMPAKDocument44 pagesPavement Design-By SAMPAKersivarajNo ratings yet

- General Notes: (Roads, Drainage and Structures) I. at SpecificationsDocument1 pageGeneral Notes: (Roads, Drainage and Structures) I. at SpecificationsDarren ValienteNo ratings yet

- MTHL-PKG2-DS-TCN-A-00-027 Rev. 1Document10 pagesMTHL-PKG2-DS-TCN-A-00-027 Rev. 1Hemant YesajiNo ratings yet

- Mord Specifications For Rural Roads 2014 560ac148404a5Document4 pagesMord Specifications For Rural Roads 2014 560ac148404a5RicomartiniNo ratings yet

- Computer Simulation On Dynamic Soil-Structure Interaction SystemDocument15 pagesComputer Simulation On Dynamic Soil-Structure Interaction SystemTarike ZohirNo ratings yet

- Coherence Weighting Applied To FMC/TFM Data From Austenitic CRA Clad Lined PipesDocument9 pagesCoherence Weighting Applied To FMC/TFM Data From Austenitic CRA Clad Lined PipesmariliaNo ratings yet

- Study of Multi Layers Testing For Pavement: Sabaruddin Muhammad JamilDocument4 pagesStudy of Multi Layers Testing For Pavement: Sabaruddin Muhammad JamilEmilio EmiNo ratings yet

- Boq AaaDocument8 pagesBoq AaaSadiq AftabNo ratings yet

- Midas - Transportation Projects OptimizationDocument45 pagesMidas - Transportation Projects OptimizationmilkcNo ratings yet

- Construction and Building Materials: Reza MasoudniaDocument18 pagesConstruction and Building Materials: Reza MasoudniaMazenMowafyNo ratings yet

- Surface Integrity Aspects in Gear ManufacturingDocument11 pagesSurface Integrity Aspects in Gear ManufacturingEko coyNo ratings yet

- Adobe Scan Mar 22, 2022Document5 pagesAdobe Scan Mar 22, 2022Anushka Garg 5-Year IDD Mathematical SciencesNo ratings yet

- A Survey On Deep-Learning Based Techniques For Modeling and Estimation of MassiveMIMO ChannelsDocument12 pagesA Survey On Deep-Learning Based Techniques For Modeling and Estimation of MassiveMIMO ChannelsInnocent CalistNo ratings yet

- Surface Excavation & Rock Support General Notes: AFRY.4649.00.102 P1Document1 pageSurface Excavation & Rock Support General Notes: AFRY.4649.00.102 P1அம்ரு சாந்திவேலுNo ratings yet

- SPE 47323 MS PrintedDocument10 pagesSPE 47323 MS PrintedAzri HamimNo ratings yet

- 2009 P. Monaco Et Al. Is-TokyoDocument8 pages2009 P. Monaco Et Al. Is-TokyoKarla CaNo ratings yet

- 03 Horizontal Alignment - Circular CurvesDocument27 pages03 Horizontal Alignment - Circular CurvesEnermy-123No ratings yet

- 02 Cros Sectional ElementsDocument21 pages02 Cros Sectional ElementsEnermy-123No ratings yet

- 03 Horizontal Alignment - Circular CurvesDocument27 pages03 Horizontal Alignment - Circular CurvesEnermy-123No ratings yet

- 01 Geometric Design BasicsDocument45 pages01 Geometric Design BasicsEnermy-123No ratings yet

- 01 Geometric Design BasicsDocument45 pages01 Geometric Design BasicsEnermy-123No ratings yet

- Noaa 32340 DS1Document20 pagesNoaa 32340 DS1Enermy-123No ratings yet

- BOP TextBook (Phase 1)Document108 pagesBOP TextBook (Phase 1)Enermy-123No ratings yet

- Meeting Minutes/Notes: Apparel Brands Pty LTD Meeting Minutes/Notes Date: Time: Location: Attendance: Agenda ItemsDocument2 pagesMeeting Minutes/Notes: Apparel Brands Pty LTD Meeting Minutes/Notes Date: Time: Location: Attendance: Agenda ItemsnattyNo ratings yet

- Partnership Quiz 4Document8 pagesPartnership Quiz 4Kapil SawantNo ratings yet

- Daily Report Agustus 221'Document23 pagesDaily Report Agustus 221'Toha 187No ratings yet

- 10 (R) - 2022Document1 page10 (R) - 2022ANibwebNo ratings yet

- JHR (1) - JHR303 019: 2304048xfhudckDocument15 pagesJHR (1) - JHR303 019: 2304048xfhudckToni BadaaNo ratings yet

- AHCML News Watch - Jan 22, 2024Document2 pagesAHCML News Watch - Jan 22, 2024arsalan.hashmiNo ratings yet

- Mathematics 8: Learning ObjectivesDocument3 pagesMathematics 8: Learning ObjectivesThaxter QubeNo ratings yet

- Acquiring Better Seismic Data: W.C. PritchettDocument1 pageAcquiring Better Seismic Data: W.C. PritchettonurNo ratings yet

- Telangana RailWire Plans 2020Document1 pageTelangana RailWire Plans 2020Mayank GuptaNo ratings yet

- Fuel ConsumptionDocument12 pagesFuel Consumptionjeri adovelinNo ratings yet

- Syllabus Econ 211Document4 pagesSyllabus Econ 211bob1234No ratings yet

- Contemporary World - WEEK 2Document3 pagesContemporary World - WEEK 2Allyssa Jhane Del mundoNo ratings yet

- Mathematical Literacy Test 1 2021-2Document12 pagesMathematical Literacy Test 1 2021-2Liberty JoachimNo ratings yet

- Lessons in Regional IntegrationDocument9 pagesLessons in Regional Integrationwicked intentionsNo ratings yet

- PROBLEM SET 4 Continuous Probability SolutionsDocument8 pagesPROBLEM SET 4 Continuous Probability SolutionsMacxie Baldonado QuibuyenNo ratings yet

- Galileo Guide Focalpoint ShoppingDocument20 pagesGalileo Guide Focalpoint ShoppingShahid Aziz KhiljeeNo ratings yet

- Economies: A Review of Global Challenges and Survival Strategies of Small and Medium Enterprises (Smes)Document24 pagesEconomies: A Review of Global Challenges and Survival Strategies of Small and Medium Enterprises (Smes)Kelsey Olivar MendozaNo ratings yet

- Sosa PresentationDocument29 pagesSosa PresentationSa N DyNo ratings yet

- Tds - Rockal Rockwool Boards - Kraft FacingDocument4 pagesTds - Rockal Rockwool Boards - Kraft FacingelkatebskeNo ratings yet

- INVOICE Jco PassDocument3 pagesINVOICE Jco PasseldaNo ratings yet

- Account ID Account Description Date Reference JRNL Trans Description Debit Amt Credit Amt BalanceDocument1 pageAccount ID Account Description Date Reference JRNL Trans Description Debit Amt Credit Amt BalanceAladdin AdelNo ratings yet

- Hypothesis Test - Testing - Vijay KumarDocument2 pagesHypothesis Test - Testing - Vijay KumarVijay KumarNo ratings yet

- Chapter 1 Tutorial QuestionsDocument2 pagesChapter 1 Tutorial QuestionsMilanNo ratings yet