Professional Documents

Culture Documents

S6 PE Lab Manual 2018 MATLAB PDF

Uploaded by

hariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S6 PE Lab Manual 2018 MATLAB PDF

Uploaded by

hariCopyright:

Available Formats

MATLAB/SIMULINK EXPERIMENTS

Experiment No. 1

Simulation of 1-Phase Fully-controlled Bridge Rectifier fed

Separately Excited DC Motor

AIM:

01 Simulate a 1-phase fully controlled bridge rectifier fed separately excited DC motor

using simulink/MATLAB under different load conditions and at various firing

angles.

02 Observe the waveforms armature voltage, armature current, source current Vs time

03 Observe the speed Vs time and torque Vs time characteristics

PRINCIPLE

SINGLE PHASE FULL CONVERTER

During positive half cycle, thyristors T1 and T2 are

forward biased; and when these two thryristors are

fired simultaneously at ωt=α, the load is connected to

the input supply through T1 and T2. During negative

half cycle, T3 and T4 fired simultaneously at ωt=π+α.

At this instant, T1 and T2 are automatically turned

OFF. Here, the load current is assumed to be

continuous.

Average output voltage,

π +α

1

1 2Vm

Vdc =

π ∫V

α

m sin ωtd (ωt ) =

π

cos α 50

For α > 90°, average output voltage is negative, but the

load current continues to flow in the same direction, so

output power is negative. Power flows from load to 1

+α

100

source. It is possible only for active load, i.e., when the

load has an emf source (RLE).

In a separately excited motor, it is possible to control both armature voltage and field current, so

as to control the speed over a wide range in the smooth manner. Speeds ranging from zero to base

speed may be obtained at constant torque by armature voltage control. Speeds above base speed

are possible at constant power output by weakening of the flux.

Controlled rectifier fed dc drives are widely used in applications requiring a wide range of speed

control and/or frequent starting, braking, and reversing.

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 1 of 27

A single-phase fully controlled rectifier fed separately

excited DC motor is shown below. Field supply is not

shown. When field control is required, field is fed

from a controlled rectifier, otherwise from an

uncontrolled rectifier.

When armature current does not flow continuously,

the motor is said to operate in discontinuous

conduction. When current flows continuously, the

conduction is said to be continuous.

In continuous conduction mode, armature voltage va, armature current ia and source current is are

shown in figure below.

From ωt=α to π+α, thyristors T1

and T2 are conducting. Armature

voltage va is same as the source

voltage vs and source current is is

same as the load current ia.

At ωt=π+α, T3 and T4 are turned ON. T1 and T2 are turned OFF automatically by the

reverse voltage applied due to the turning ON of T3 and T4. During ωt=π+α to 2π+α,

armature voltage, va = -vs and source current, is = - ia.

In discontinuous conduction mode, armature voltage va, armature current ia and source current is

are shown in figure below.

From ωt=α to β, thyristors T1 and T2

are conducting. Armature voltage va

is same as the source voltage vs and

source current is is same as the load

current ia. At ωt=β, armature current

ia decreases to zero and T1 and T2

are turned OFF since its anode

current falls to zero. Hence, during

ωt=β to π+α, all the devices are

OFF. Since armature current is zero,

armature voltage is same as the

back emf E.

At ωt=π+α, T3 and T4 are turned

ON. Armature voltage, va = -vs and

source current, is = - ia.

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 2 of 27

Simulink Blocks Used:-

G1&4 – Pulse generator (time-based, amplitude 5, period 1/50 sec, pulse width 10%, phase delay

0 or 1/100) Note: Firing angle ∝=45°, phase delay = 0.01/4 for T1 & T4 and = 0.01+0.01/4 for

T2 & T3

Ia, Ia – Current Measurement

Va – Voltage Measurement

T1 to T4 – Thyristor

L – Series RLC branch

Vs – AC voltage source

150V – DC voltage source

Scope

SEDCM – DC machine Preset Model 2

TL – Constant

Bus selector

Powergui

SIMULINK DIAGRAM

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 3 of 27

Armature Voltage, Armature Current and Source Current in CCM (L=80mH)

Speed Vs time and Torque Vs time characteristics in CCM

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 4 of 27

Armature Voltage, Armature Current and Source Current in DCM (L=0mH)

RESULT:

A single-phase fully controlled bridge rectifier fed separately excited DC motor (5HP, 240V,

1750rpm) was simulated and waveforms/characteristics observed

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 5 of 27

Experiment No. 2 a)

Design and Simulation of Buck Converter

AIM:

Design the values of filter inductance L and filter capacitance C of a buck converter with

input voltage Vs = 48V, average output voltage Vo = 12V and load resistance R = 10Ω.

Switching frequency is 40kHz. The peak to peak ripple inductance current is to be limited

to 0.045A and peak to peak ripple capacitor voltage is to be limited to 0.12V. Also,

simulate the circuit.

PRINCIPLE :

DC-DC CONVERTERS :

DC-DC power converters are widely used in regulated switch-mode dc power supplies and dc

motor drive applications. The input to the DC-DC converter is an unregulated dc voltage Vs. The

converter produces a regulated output voltage Vo, having a magnitude that differs from Vs.

Different DC-DC converters are i) Step-down (buck) converter, ii) Step-up (boost) converter iii)

Step-down/step-up (buck-boost) converter iv) Cuk Converter and v) SEPIC (single-ended primary

inductance) converter.

BUCK CONVERTER : A buck converter produces a lower average output voltage Vo than the

dc input voltage Vs.

During the interval when the switch is ON, the diode becomes reverse biased and the input

provides energy to the load as well as to the inductor. During the interval when the switch is off,

the inductor current flows through the diode, transferring some of its stored energy to the load.

The filter capacitor at the output is assumed to be very large so that vo(t) = Vo.

DESIGN:

Duty ratio, D = Vo = 12 = 0.25

Vs 48

Vs D (1 − D ) 48 × 0.25 × (1 − 0.25)

L= = = 5mH

f × ΔI L 40 × 103 × 0.045

Vs D (1 − D ) 48 × 0.25 × (1 − 0.25)

C= = = 1.17 μ F

8 f 2 L × ΔVc 8 × (40 × 103 ) 2 × 5 × 10−3 × 0.12

Simulink Blocks Used:-

R,L,C – series RLC branch

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 6 of 27

PG – Pulse Generator (Amplitude 1, period 2.5x10-5, pulse width 25%)

MOSFET, DIODE (from Simpower systems – Power Electronics)

48V - Dc voltage source

Voltage measurement, current measurement

RESULT:

Buck converter was designed and simulated.

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 7 of 27

Experiment No. 2 b)

Design and Simulation of Boost Converter

AIM:

Design the values of filter inductance L and filter capacitance C of a boost converter with

input voltage Vs = 5V, average output voltage Vo = 15V and load resistance R = 30Ω.

Switching frequency is 25kHz. The peak to peak ripple inductance current is to be limited

to 0.89A and peak to peak ripple capacitor voltage is to be limited to 0.06V. Also, simulate

the circuit.

PRINCIPLE:

BOOST CONVERTER : In Boost converters, the output voltage is always greater than the

input voltage.

When the switch is ON, the diode is reverse biased, thus isolating the output voltage. The input

supplies energy to the inductor. When the switch is OFF, the output stage receives energy from

the inductor as well as from the input.

DESIGN:

Vs 5

Duty ratio, D = 1 − = 1 − = 0.6667

Vo 15

Vo 15

Io = = = 0.5 A

R 30

Vs D 5 × 0.6667

L= = = 150 μ H

f × ΔI L 25 × 103 × 0.89

Io D 0.5 × 0.6667

C= = = 222 μ F

f × ΔVc 25 × 103 × 0.06

Simulink Blocks Used:-

R,L,C – series RLC branch

PG – Pulse Generator (Amplitude 1, period 4x10-5, pulse width 66.67%)

MOSFET, DIODE (from Simpower systems – Power Electronics)

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 8 of 27

5V - Dc voltage source

Voltage measurement, current measurement

RESULT:

Boost converter was designed and simulated.

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 9 of 27

Experiment No. 2 c)

Design and Simulation of Buck-Boost Converter

AIM:

Design the values of filter inductance L and filter capacitance C of a buck-boost converter

with input voltage Vs = 12V, average output voltage Vo = -4V and load resistance R =

3.2Ω. Switching frequency is 25kHz. The peak to peak ripple inductance current is to be

limited to 0.8A and peak to peak ripple capacitor voltage is to be limited to 0.06V. Also,

simulate the circuit.

PRINCIPLE:

BUCK-BOOST CONVERTER : In buck-boost converters, the output voltage is either higher

or lower than the input voltage; but the polarity of the output voltage is reversed with respect to

the input voltage.

When the switch is ON, the diode is reverse biased and input provides energy to the inductor.

When the switch is OFF, the energy stored in the inductor is transferred to the output. No energy

is supplied by the input during this interval.

DESIGN:

Duty ratio, D = Vo = 4 = 0.25

Vs + Vo 12 + 4

Vo 4

Io = = = 1.25 A

R 3.2

Vs D 12 × 0.25

L= = = 150 μ H

f × ΔI L 25 × 103 × 0.8

Io D 1.25 × 0.25

C= = = 208μ F

f × ΔVc 25 × 103 × 0.06

Simulink Blocks Used:-

R,L,C – series RLC branch

PG – Pulse Generator (Amplitude 1, period 4x10-5, pulse width 25%)

MOSFET, DIODE (from Simpower systems – Power Electronics)

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 10 of 27

12V - Dc voltage source

Voltage measurement, current measurement

RESULT:

Buck-Boost converter was designed and simulated.

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 11 of 27

Experiment No. 3

Speed Control of 3-phase Induction Motor using V/f

technique

AIM:

01 Control the speed of a 3-phase squirrel cage induction motor using stator voltage and

frequency control using sine PWM technique

PRINCIPLE

The open loop volts/hertz control of an induction motor is by far most popular method of speed

control because of its simplicity, and these types of motors are widely used in industry. Voltage is

required to be proportional to frequency so that stator flux (Φ) remains constant. This causes

maximum motor torque (Tmax) to also remain constant and independent of supply frequency.

Figure shows the torque-speed curves on example

of fan or pump load type. Speed is increasing

proportionally with frequency and maximum

torque remains constant if supply voltage also

increases with frequency. Scalar control is simple

to implement but, because of the inherent

coupling effect (i.e.

both torque and flux are functions of voltage or

current or frequency), gives sluggish response

and the system is easily prone to instability.

Simulink Blocks Used:-

550V – DC voltage source

PWM generator (3arm bridge – 6 pulses) (10kHz)

Measurement after induction motor - Bus selector

Mux

SCIM – Asynchronous machine (squirrel cage) Preset Model No. 15 (5kW, 400V, 50Hz,

1440rpm)

TL - constant

Inverter – universal bridge (3 arm)

sin_wt – Fcn

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 12 of 27

RESULT:

Speed of a 3-phase squirrel cage induction motor was controlled using V/f method using sine

PWM inverter.

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 13 of 27

Experiment No. 4

Closed Loop Speed Control of DC Motor

AIM:

Control the speed of a dc motor in closed loop using PID and hysteresis controller using a

step down chopper

PRINCIPLE

DC motors are used extensively in adjustable-speed drives and position control applications.

Their speeds below base speed can be controlled by armature voltage control. Speeds above base

speed are obtained by field-flux control. As speed control methods for dc motors are simple and

less expensive than those for ac motors, dc motors are preferred where wide-speed control range

is required.

Phase controlled converters provide an adjustable dc output voltage from a fixed ac input voltage.

DC choppers also provide dc output voltage from a fixed dc input voltage.

When variable dc voltage is to be obtained from fixed dc voltage, dc chopper is the ideal choice.

A chopper is inserted in between a fixed dc voltage source and the dc motor armature for its speed

control below base speed.

Closed loop speed control system with inner current loop is shown below.

The output of the speed controller represents a torque command. Because torque is proportional to

armature current, the output of the speed controller also represents the current command Ia*,

which is then compared with the actual current Ia. A limit on the output of the speed controller

will therefore clamp the value of the motor current Ia.

The speed controller and current controller can have P or PI control. The selection depends on the

requirements of the drive performance.

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 14 of 27

Simulink Blocks Used:-

L=10mH – series RLC branch

DC Machine (preset model 01)

GTO (from Simpower systems – Power Electronics)

12V - Dc voltage source

Voltage measurement, current measurement

Transfer Function

PI Controller (Kp=1.6, Ki=16)

Relay (Hysteresis band 0.1 & -0.1)

Bus Selector

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 15 of 27

RESULT:

Closed loop speed control of separately excited DC motor was simulated and its operation under

various load conditions was analyzed.

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 16 of 27

FAMILIARISATION OF MATLAB/SIMULINK

MATLAB (short for Matrix Laboratory) is a matrix processing language that is applicable

to scientific and engineering data processing.

To start with MATLAB, double click/open MATLAB. A command window will appear.

A cursor will start blinking on a line right after ‘>>’ (this is called a prompt).

Some interesting functions :

date

calendar x=-pi:0.01:pi;

datestr(now) % date & time y=cos(x);

clc plot(x,y)

x=5 xlabel('x')

f=x.^2+1 ylabel('y=cos(x)')

y=sqrt(5) title('Graph of cosine’)

x=[6,7,8,9] plot(x,y,’g’)

x’

y=[6;7;8;9] Note:

z=[6,7;8,9] title used to put title on graph

p=zeros(2,3) xlabel labels x-axis

q=ones(2,3) ylabel labels y-axis

u=[1:8] axis freezes the axis limits

v=[1:2:8] plot performs linear x-y plot

A=[1 2 3; 4 5 6; 7 8 9] stem discrete-time plot

A=[2,3] grid adds grid to a plot

sin(pi/4)

t=[0:0.1:1]

k=exp(t)

clc

MATLAB allows operations involving complex numbers. Complex numbers are entered

using function i or j. (eg: 3+3*i)

Color of the graph may be specified using the statement: plot(x, y, ’g’)

r – red; g - green; b – blue; k – black; w - white

syms → symbolic statement

Find the roots of the p=[1 9 23 15]; Ans:-

polynomial f ( x) = x3 + 9 x 2 + 23x + 15 r=roots(p) r = -5.000 -3.000 -

1.000

Plot File Name: ans =

threephase1 3-phase sine waves

1

x = sin(t ); t=0:pi/64:4*pi;

y = sin(t − 120); x=sin(t); 0.5

z = sin(t + 120) y=sin(t-2*pi/3);

z=sin(t+2*pi/3); 0

plot(t,x,t,y,t,z);

-0.5

title('3-phase sine

waves'); -1

0 5 10 15

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 17 of 27

Find the coefficients of the polynomial p=poly([-5 -3 -1]) Ans:-

if the roots are s1= -5, s2= -3 and s3= -1 p=

1 9 23 15

To create .m files : File →New→Script Editor Untitled appears Type programme Save &

Run

See the answer in Command Window

Find h(t) if File Name : invlap1 Ans:-

24 syms F s 3 - 3/exp(8*t)

H ( s) =

s ( s + 8) F=24/(s*(s+8))

(Ans:- f (t ) = 3(1 − e−8t ) ) ilaplace(F)

Solve the differential File Name : solvedif1 Ans:-

equation y = dsolve('Dy+4*y = y=

dy(t ) exp(-t)', 'y(0) = 1')

+ 4 y(t ) = e−t ; y(0) = 1

dt 1/(3*exp(t)) +

2/(3*exp(4*t))

Differentiate w.r.to t. File Name : diff1 ans =

sin( at + b) syms a b t;

f = sin(a*t + b); a*cos(b + a*t)

diff(f)

Integrate w.r.to t. File Name : int1 ans =

sin( at + b) syms a b t;

f = sin(a*t + b); -cos(b + a*t)/a

int(f)

Find h(t) if File Name : impresp1 Ans:-

s 2 + 3s + 1 num = [1 3 1 ]; r = -1 -1

H ( s) = 2 den = [1 5 6]; p = -3 -2

s + 5s + 6

Ans:- [r, p, k] = residue(num, k= 1

1 1 den)

H ( s) = 1 − −

s+3 s+2

h(t ) = δ (t ) − e−3t − e −2t

Find Z-transform File Name : ztran1 ans =

sin[an] syms a n w;

f = sin(a*n); (z*sin(a))/(z^2 - 2*cos(a)*z +

ztrans(f) 1)

Find inverse Z-transform File Name : iztran1 ans =

2z syms z

( z − 2)2 f = 2*z/(z-2)^2; 2^n + 2^n*(n - 1)

iztrans(f)

Generate sine File Name: sine2 ans =

sequence clear all;

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 18 of 27

y[ n] = cos 0.2π n N=21; sinusoidal sequence

n=0:1:N-1; 1

Amplitue

y=cos(.2*pi*n);

subplot(1,1,1); 0

stem(n,y); -1

ylabel('Amplitue'); 0 10 20

xlabel('n'); n

title('sinusoidal sequence')

Generate sine File Name: sine1 ans =

sequence clear all;

y1[t ] = cos 0.2π t N=11; cos0.2*pi*t

magnitude

t=0:0.01:N-1; 1

& y2 [t ] = sin 0.2π t

0

y1=cos(.2*pi*t);

-1

subplot(2,1,1); 0 2 4

t

6 8 10

plot(t,y1); sin0.2*pi*t

ylabel('magnitude'); 1

magnitude

xlabel('t'); 0

title('cos0.2*pi*t') -1

0 2 4 6 8 10

y2=sin(.2*pi*t); t

subplot(2,1,2);

plot(t,y2);

ylabel('magnitude');

xlabel('t');

title('sin0.2*pi*t')

Find Fourier transform File Name: fourier1 ans =

f (t ) = e −t 2 syms t;

f = exp(-t^2); pi^(1/2)/exp(w^2/4)

fourier(f)

Find the solution of the File Name: ans =

difference equation soldifeqn2 y=

y ( n) − 0.6 y (n − 1) = 4u ( n) . n=[0:9]; 0 4.0000 6.4000 7.8400

Assume y(0)=0. y(1)=0; 8.7040 9.2224 9.5334 9.7201

for m=2:10; 9.8320 9.8992

y(m)=0.6*y(m- 10

1)+4; 8

end 6

y

stem(n,y,'fill'),grid 4

0

0 2 4 6 8

Find the partial fraction File Name: partialf1 ans =

expansion of the transfer [r,p,k]=residuez([1,-10,- r = -1.5000 0.5000

function given below 4,4],[2,-2,-4]) p= 2 -1

k= 1.5000 -1.0000

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 19 of 27

1 − 10 z −1 − 4 z −2 + 4 z −3

X ( z) = −1.5 0.5

2 − 2 z −1 − 4 z − 2 X ( z) = + + 1.5 − z −1

−1

(Note: 1− 2z 1 + z −1

bo + b1 z −1 + b2 z −2 + b3 z −3 )

X ( z) =

1 + a1 z −1 + a2 z −2

Find the linear File Name: linconv1 ans =

convolution of n=1:7; y=

two sequences x=[1,2,3,4]; 1 3 6 10 9 7 4

x(n) = {1, 2,3, 4} h=[1,1,1,1];

and y=conv(x,h)

h(n) = {1,1,1,1} stem(n,y,'fill'),grid

Note: ‘fill’ → color the circle at the end of the stem

Find the first 5 terms of the File Name: partialf1 ans =

inverse z- b=[1 2 1]; 1.0000 3.0000 3.6439

1 + 2 z −1 + z −2 a=[1 -1 0.3561]; 2.5756 1.2780

transform X ( z ) = n=5;

1 − z −1 + 0.3561z −2

b=[b zeros(1,n-1)];

[x,r]=deconv(b,a);

disp(x)

Draw the pole-zero plot of File Name: pzplot1 ans =

−1

1.2 − 2.2 z + 1.5 z −2

b=[1.2 -2.2 1.05 0];

Y ( z) = a=[1 -2 1.25 -0.25];

1 − 2 z −1 + 1.25 z −2 − 0.25 z −3

. zplane(b,a);

Generate File Name: sawtooth1 ans =

sawtooth fs = 10000; 1

waveform t = 0:1/fs:1.5;

0.5

x = sawtooth(2*pi*50*t);

plot(t,x), 0

axis([0 0.2 -1 1])

-0.5

-1

0 0.05 0.1 0.15 0.2

Generate File Name: sinc1 ans =

sinc(x) x = linspace(-5,5);

y = sinc(x);

plot(x,y),grid

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 20 of 27

1

0.5

-0.5

-5 0 5

Find the transpose of File Name: matrix1 ans =

conjugate, transpose and m=[1+j 2-2*j; 3+2*j x=

inverse of the matrix 4+3*j] 1.00 - 1.00i 3.00 - 2.00i

⎛ 1 + j1 2 − j 2 ⎞ x=m' 2.00 + 2.00i 4.00 - 3.00i

m=⎜ ⎟. y=m.' y=

⎝ 3 + j 2 4 + j3 ⎠

z=inv(m) 1.00 + 1.00i 3.00 + 2.00i

2.00 - 2.00i 4.00 + 3.00i

z=

-0.0556 - 0.3889i 0.2222 +

0.0000i

0.0556 + 0.2778i 0-

0.1111i

Response of an RC File Name: ans =

circuit response1 6

Response of an RC circuit

t = 0:0.1:2.5;

voltage in volts

y = 6*exp(-2*t); 4

plot (t, y)

2

title ('Response of an

RC circuit') 0

xlabel ('time in 0 0.5 1 1.5

time in seconds

2 2.5

seconds')

ylabel ('voltage in

volts')

grid

Find the residues of File Name: matrix1 ans =

4s 4 + 3s 3 + 6s 2 + 10s + 20 num = [4 3 6 10 r=

H ( s) = 4 20]; -1.6970 + 3.0171i

s + 2 s 3 + 5s 2 + 2 s + 8

r r r N den = [1 2 5 2 8]; -1.6970 - 3.0171i

H ( s) = 1 + 2 + ..... + n + ∑ kn s n [r, p, k] = -0.8030 - 0.9906i

s − p1 s − p2 s − pn n =0 residue(num, den) -0.8030 + 0.9906i

p=

-1.2629 + 1.7284i

-1.2629 - 1.7284i

0.2629 + 1.2949i

0.2629 - 1.2949i

k=

4

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 21 of 27

Plot step response File Name: ans =

s stepres1

H (s) =

Step Response

s 2 + 2 s + 101 num=[1,0];

den=[1 2 101]; 0.05

step(num,den)

Amplitude

0

-0.05

0 1 2 3 4 5 6

Time (seconds)

=====================================================================

SIMULINK - Tutorial

TUTORIAL 1

Generate 3-phase sine waves with amplitude 10.

Blocks used : sine wave, bus creater, scope

TUTORIAL 2

Find the current through & voltage across the RC series branch.

Blocks used: AC voltage source, current measurement, voltage measurement, RLC series

branch, scope

TUTORIAL 3

Simulate the open circuit and short circuit tests on a 1-phase transformer 2.5kVA,

230/115V.

Transformer parameters:

Linear Transformer

2500VA, 50Hz

Primary : [V1=230V R1=0.020035p.u. L1=0.013093p.u.]

Secondary : [V2=115V R2=0.020036p.u. L2=0.013093p.u.]

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 22 of 27

Rm= 44.643p.u. Lm=8.5118p.u.

Simulink blocks used :-

RMS, Series RLC branch, Active & Reactive Power, Display, Current measurement,

Voltage measurement, AC voltage source, Scope, Ground

TUTORIAL 4

Simulate the No Load & Blocked Rotor tests on a 3-phase squirrel cage induction motor.

Induction motor parameters:-

Squirrel Cage 3750VA 415V 50Hz

R1=1.54ohm L1=0.00624H]

R2=1.77ohm L2=0.00624H

Lm=0.219

Pole pairs = 3

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 23 of 27

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 24 of 27

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 25 of 27

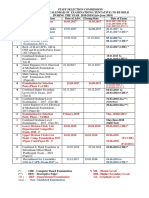

POWER ELECTRONICS LAB

MODEL QUESTIONS

1. By conducting suitable experiment, determine the latching current IL and holding current IH of

the given SCR (TYN612 – VDRM/VRRM = 600V, IT(RMS) = 12A, IT(AV)=8A)

2. By conducting suitable experiment, determine the I-V characteristics of the given SCR in i)

reverse blocking mode, ii) forward blocking mode and ii) forward conduction mode. (Given

SCR TYN612 – VDRM/VRRM = 600V, IT(RMS) = 12A, IT(AV)=8A)

3. Design and set up an R firing circuit for a half-wave controlled rectifier (Given SCR TYN612).

Observe the waveforms across RL & SCR for a firing angle of 45°. Take Input voltage Vs =

12V rms, IGFM = 250mA, VRGM = 5V, VGT = 1.3V, IGT = 13mA, Limit the maximum load

current to 200mA. (Note : Study the working of R firing circuit with waveforms)

4. Design and set up an RC firing circuit for a half-wave controlled rectifier (Given SCR

TYN612). Observe the waveforms across RL & SCR for a firing angle of 45°. Take Input

voltage Vs = 12V rms, IGFM = 250mA, VRGM = 5V, VGT = 1.3V, IGT = 13mA, f = 50Hz, C =

2μF, Limit the maximum load current to 200mA. (Note : Study the working of RC firing

circuit with waveforms)

5. Design and set up a UTJ firing circuit for a half-wave controlled rectifier (Given SCR TYN612

& UJT 2N2646). Observe the waveforms across RL & SCR for a firing angle of 45°. Given

VBB = 12V, VZ = 12V, VD = 0.7V, Vv = 1.5V, η = 0.65, Iv = 4mA, Ip = 5μA, IL = 200mA,

VTM = 1.6V, T = 10 mS, RBB = 7K, Pz = 0.4W, C = 0.1μF, R2 = 100Ω.Limit the maximum

load current to 200mA. (Note: Study the working of UJT triggering circuit)

6. Set up a 1-phase AC voltage regulator to control the output voltage across a 1K,5W load

resistor. Observe the waveforms across load resistor, TRIAC and capacitor. Input voltage is

50Vrms. (Note: Study the working of AC voltage controllers with waveforms). Use BT 136

TRIAC & DB136 DIAC.

7. Design and set up a single phase fully controlled converter to control the average voltage across

an R-L load with and without freewheeling diode and observe the waveform. Given SCR

TYN612. Take Input voltage Vs = 12V rms, IGFM = 250mA, VRGM = 5V, VGT = 1.3V, IGT =

2mA, Limit the maximum load current to 200mA. (Note : Study the working of a 1-phase full

converter with R and RL loads with waveforms and derivation of average output voltage)

8. Design and set up a MOSFET based step down dc chopper to control the speed of a dc

motor.Use IRF 540 MOSFET. Given switching frequency = 350Hz. Take C=0.1μF. Use

IC555 for pulse generation. (Note: Study the working of a Buck converter with waveforms)

9. Simulate a 1-phase full wave controlled rectifier with R/RL load at a firing angle of i) 0° &

45°. Observe the following waveforms in same scope i) source voltage, ii) load voltage, iii) load

current and iv) source current. Also, find the THD in the source current in each case. What is

the expected (theoretical) value of THD assuming continuous and ripple free load current at a

firing angle of 45°? Supply = 230Vrms, 50Hz; R = 25Ω, L = 25mH.

10. Simulate a 3-phase thyristor bridge controlled rectifier (6-pulse converter) connected to R load

at a firing angle of i) 0° and ii) 30°. Observe the following waveforms in same scope i) input

voltage vAB, ii) load voltage iii) gate pulse to any one thyristor and ii) load current. Assume

input voltage 400V (line) and R = 25Ω.

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 26 of 27

11. Simulate an sine PWM inverter fed 3-phasesquirrel cage induction motor (Preset Model 8 :

5HP, 575V,60Hz, 1750rpm) running at rated load (TL = Prated/ωrated) with modulation index

0.9 and switching frequency 5kHz. Select the correct value of DC link voltage. Observe the

following waveforms in same scope i) line current iA, ii) line voltage vAB, iii) speed in rpm and

iv) torque in Nm.

12. Simulate the speed control of a 3-phase squirrel cage induction motor (Preset Model 8 : 5HP,

575V,60Hz, 1750rpm) running at 1/4th rated load (TL = Prated/ωrated) using scalar (V/f

control) and sine PWM technique. Select switching frequency 5kHz. Observe the following

waveforms in same scope i) line current iA, ii) line voltage vAB, iii) speed in rpm and iv) torque

in Nm. (Note: Study the principle of V/f control of induction motor)

13. Design the values of filter inductance L and filter capacitance C of a boost converter with input

voltage Vs = 5V, average output voltage Vo = 20V and load resistance R = 25Ω. Switching

frequency is 25kHz. The peak to peak ripple inductance current is to be limited to 0.8A and

peak to peak ripple capacitor voltage is to be limited to 0.05V. Also, simulate the circuit.

(Note: Study the working of boost converter)

14. Design the values of filter inductance L and filter capacitance C of a buck converter with input

voltage Vs = 30V, average output voltage Vo = 10V and load resistance R = 10Ω. Switching

frequency is 25kHz. The peak to peak ripple inductance current is to be limited to 0.04A and

peak to peak ripple capacitor voltage is to be limited to 0.1V. Also, simulate the circuit. (Note:

Study the working of Buck converter)

15. Design the values of filter inductance L and filter capacitance C of a buck-boost converter with

input voltage Vs = 15V, average output voltage Vo = -5V and load resistance R = 3Ω.

Switching frequency is 25kHz. The peak to peak ripple inductance current is to be limited to

0.75A and peak to peak ripple capacitor voltage is to be limited to 0.05V. Also, simulate the

circuit. (Note: Study the working of Buck-boost converter)

16. Simulate the speed control of a separately excited dc motor (Preset Model 6, 20HP, 240V,

1750rpm, Field 300V) in closed loop using a step down chopper.

S7 Power Electronics Lab Manual as on 01-07-2016, EED, GEC Thrissur Page 27 of 27

You might also like

- Single Phase Half Wave Controlled RectifierpdfDocument14 pagesSingle Phase Half Wave Controlled RectifierpdfRîtzî Saxena92% (37)

- PSIM MANUAL For StudentsDocument23 pagesPSIM MANUAL For StudentsSomnath Khamaru75% (4)

- Common Emitter UnbypassedDocument38 pagesCommon Emitter Unbypassedaliffuden 123No ratings yet

- Four Quadrant Operation of DC Drives: - Dual ConvertersDocument12 pagesFour Quadrant Operation of DC Drives: - Dual ConvertersDr.K.Krishna Veni ProfessorNo ratings yet

- Introduction To Power ElectronicsDocument23 pagesIntroduction To Power ElectronicsNovie Ayub WindarkoNo ratings yet

- Design of Electrical MachinesDocument2 pagesDesign of Electrical MachinesAlluri Appa Rao64% (11)

- NSX 100-630 User ManualDocument152 pagesNSX 100-630 User Manualagra04100% (1)

- Pic ProjectsDocument6 pagesPic ProjectsAmr GhonemNo ratings yet

- SPWMDocument16 pagesSPWMSatyanarayana GurramNo ratings yet

- Linear and Digital Integrated Circuits: Uni T - 1 Operati Onal Ampli FierDocument116 pagesLinear and Digital Integrated Circuits: Uni T - 1 Operati Onal Ampli FierBOGGULA SURENDAR REDDYNo ratings yet

- EE - Power Electronics Short NotesDocument34 pagesEE - Power Electronics Short NotesRavinder RangaNo ratings yet

- A McMurray InverterDocument2 pagesA McMurray Inverteranshu71% (7)

- Power Electronics Kuestion PDFDocument25 pagesPower Electronics Kuestion PDFkibrom atsbhaNo ratings yet

- Control System Lab ManualDocument76 pagesControl System Lab ManualYuvaraj Shan50% (2)

- Chap1 - The Operational AmplifierDocument40 pagesChap1 - The Operational AmplifierzalikaseksNo ratings yet

- Programmable Logic Controller (PLC)Document16 pagesProgrammable Logic Controller (PLC)Manish Kumar sharma100% (19)

- Power Electronics: AC To DC Converters (Rectifiers)Document79 pagesPower Electronics: AC To DC Converters (Rectifiers)Frew FrewNo ratings yet

- Industry Process Automation Using Programmable SwitchingDocument5 pagesIndustry Process Automation Using Programmable SwitchingMd. Arif Ahmed100% (1)

- Power Electronics - 2 MARKSDocument30 pagesPower Electronics - 2 MARKSkarthik kumar50% (4)

- Pulse-Width Modulation Techniques for Voltage Source InvertersDocument35 pagesPulse-Width Modulation Techniques for Voltage Source InvertersLuis Enrique Garduño LandazuriNo ratings yet

- Power Electronics Lab ManualDocument47 pagesPower Electronics Lab Manualshaan_patil100% (1)

- EEE-338 Power Electronics Lab Manual FAll2021Document66 pagesEEE-338 Power Electronics Lab Manual FAll2021Muhammad DawoodNo ratings yet

- Electric DrivesDocument2 pagesElectric DrivesnikunjNo ratings yet

- Bifpcl Question Solve - 2015: R 5+3+2 10 V 20+20 40 Sor 10 P 40 / (4 X 10)Document7 pagesBifpcl Question Solve - 2015: R 5+3+2 10 V 20+20 40 Sor 10 P 40 / (4 X 10)Mazharul HaqueNo ratings yet

- A Report On The "3-Phase Line Fault Detector" Ee344 Minor Project - IDocument34 pagesA Report On The "3-Phase Line Fault Detector" Ee344 Minor Project - IDhruv PatelNo ratings yet

- Electronic Circuit Laboratory MANUAL PDFDocument94 pagesElectronic Circuit Laboratory MANUAL PDFAbel KalavadakkenNo ratings yet

- Two-Port Network ParametersDocument19 pagesTwo-Port Network ParametersRohit Gandhi0% (1)

- Power Electronics: Single Phase AC-AC ConvertersDocument18 pagesPower Electronics: Single Phase AC-AC ConvertersMaruti MohiteNo ratings yet

- Design FIR FilterDocument22 pagesDesign FIR Filtersaran52_eceNo ratings yet

- Electri Circuits Lab Manual 1Document11 pagesElectri Circuits Lab Manual 1Sri RoNo ratings yet

- Lec 1 Introduction To Power ElectronicsDocument38 pagesLec 1 Introduction To Power ElectronicsAfiqah Zainuddin100% (1)

- Chapter Five: Ac-Ac Conversion: Ac Voltage ControllerDocument56 pagesChapter Five: Ac-Ac Conversion: Ac Voltage Controllerfor lifeNo ratings yet

- Control System Lab Manual 18EEL66Document70 pagesControl System Lab Manual 18EEL66ADARSH SHINDE100% (1)

- Synchronous Motor Drive Control MethodsDocument17 pagesSynchronous Motor Drive Control MethodssidharthNo ratings yet

- Electronic Circuits & Logic Design Lab ManualDocument83 pagesElectronic Circuits & Logic Design Lab ManualsunandaalurNo ratings yet

- Electronic Devices and Circuit Theory: Operational AmplifiersDocument26 pagesElectronic Devices and Circuit Theory: Operational AmplifiersLarry CubillasNo ratings yet

- Glover 10 ExDocument13 pagesGlover 10 ExAseel Bait MaditNo ratings yet

- Question Bank-EE2352 - Solid State DrivesDocument4 pagesQuestion Bank-EE2352 - Solid State Drivesdgsgovind100% (1)

- Project Status Review Semester: 7 EE (Group No: 2) Project I (2170001)Document51 pagesProject Status Review Semester: 7 EE (Group No: 2) Project I (2170001)UmangNo ratings yet

- Three Phase Synchronous MachinesDocument14 pagesThree Phase Synchronous MachinesMohdFirdausNo ratings yet

- Electrical Braking of Three Phase Induct PDFDocument4 pagesElectrical Braking of Three Phase Induct PDFFranc Lami100% (1)

- DC-Choppers Class A B C D EDocument18 pagesDC-Choppers Class A B C D EAnonymous iTJLpNVNo ratings yet

- Merz Price Differential Protection For TransformerDocument2 pagesMerz Price Differential Protection For TransformerapjbalamuruganNo ratings yet

- Induction Motor BrakingDocument26 pagesInduction Motor BrakingAshwini Singh100% (3)

- EPL Lab ManualDocument74 pagesEPL Lab ManualPrince Vineeth67% (3)

- EE6604-Design of Electrical Machines - QBDocument16 pagesEE6604-Design of Electrical Machines - QBmadhu balanNo ratings yet

- ECE 8830 - Electric Drives: Topic 13: Vector Control of AC Induction MotorsDocument61 pagesECE 8830 - Electric Drives: Topic 13: Vector Control of AC Induction MotorsVikas PatelNo ratings yet

- Lab ReportDocument26 pagesLab Reportsanjana972No ratings yet

- CPE223-Signals and Systems Lab ManualDocument135 pagesCPE223-Signals and Systems Lab ManualMuhammad Hamza TariqNo ratings yet

- EE1001 Special Electrical Machines Two Mark Questions and AnswersDocument23 pagesEE1001 Special Electrical Machines Two Mark Questions and Answersmohamedfahims64% (11)

- Line Commutated Converters ExplainedDocument10 pagesLine Commutated Converters ExplainedJay Romar PabianiaNo ratings yet

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- Exp 2Document6 pagesExp 2College ISMNo ratings yet

- Controlled Rectifiers and AC Voltage ControllersDocument35 pagesControlled Rectifiers and AC Voltage ControllersAishwaryaNo ratings yet

- Power Electronics Lab Manual-withoutreadingsandprepostlab-EE0314Document69 pagesPower Electronics Lab Manual-withoutreadingsandprepostlab-EE0314Sankaran Nampoothiri KrishnanNo ratings yet

- Modelling & Simulation of Power Network LAB (EE-22381) : Experiment-1Document3 pagesModelling & Simulation of Power Network LAB (EE-22381) : Experiment-1ohioNo ratings yet

- III I PE Lab Manual PDFDocument28 pagesIII I PE Lab Manual PDFSwaranjali RawatNo ratings yet

- 3-Phase Converter Lab OverviewDocument5 pages3-Phase Converter Lab OverviewPavan Kumar A GNo ratings yet

- 722 10 8 2003Document95 pages722 10 8 2003RisingFromDepthsNo ratings yet

- Sinusoidal Permanent Magnet AC Drives, Load-Commutated-Inverter Synchronous Motor Drives, and Synchronous GeneratorsDocument23 pagesSinusoidal Permanent Magnet AC Drives, Load-Commutated-Inverter Synchronous Motor Drives, and Synchronous GeneratorshariNo ratings yet

- LicenseDocument1 pageLicensehariNo ratings yet

- 5 6262662951564476494Document30 pages5 6262662951564476494hariNo ratings yet

- DLG 50Document6 pagesDLG 50hariNo ratings yet

- 22Document3 pages22hariNo ratings yet

- EE401 Electronic Communication PDFDocument2 pagesEE401 Electronic Communication PDFhariNo ratings yet

- HPCL Application PDFDocument1 pageHPCL Application PDFhariNo ratings yet

- Distributed Energy Resources ReportDocument50 pagesDistributed Energy Resources ReportTaylor Martinez100% (1)

- ReadmerDocument79 pagesReadmersatyajtiNo ratings yet

- KEL Report..Document86 pagesKEL Report..Neena Justin Justin80% (10)

- Exam Schedule 2015Document2 pagesExam Schedule 2015Manas TaraiNo ratings yet

- PlaceholderDocument1 pagePlaceholderRichard BirchNo ratings yet

- Base SPB16.50.000 README Kitlist - WintDocument12 pagesBase SPB16.50.000 README Kitlist - WinthariNo ratings yet

- Change LogDocument2 pagesChange LogDanielDavidBarriosFernándezNo ratings yet

- How To Use KeygenDocument2 pagesHow To Use KeygenhariNo ratings yet

- How To Install & RegisterDocument2 pagesHow To Install & RegisteritshartNo ratings yet

- How To InstallDocument1 pageHow To InstallhariNo ratings yet

- 2018-06-08Document1 page2018-06-08hari100% (1)

- KeywordsDocument1 pageKeywordshariNo ratings yet

- LogsDocument1 pageLogshariNo ratings yet

- Version NameDocument1 pageVersion NamehariNo ratings yet

- PowerISO Troubleshooting and Offline Installation GuideDocument2 pagesPowerISO Troubleshooting and Offline Installation GuidehariNo ratings yet

- ReadmerDocument79 pagesReadmersatyajtiNo ratings yet

- KeysDocument1 pageKeyshariNo ratings yet

- LogsDocument1 pageLogshariNo ratings yet

- Install NotesDocument1 pageInstall NoteshariNo ratings yet

- Install NotesDocument1 pageInstall NoteshariNo ratings yet

- Tiny WC Arduino CodeDocument23 pagesTiny WC Arduino CodehariNo ratings yet

- U-KLEEN Moly Graph MsdsDocument2 pagesU-KLEEN Moly Graph MsdsShivanand MalachapureNo ratings yet

- Timber, PVCu and aluminium window and door hardware systemsDocument24 pagesTimber, PVCu and aluminium window and door hardware systemsOmul Fara NumeNo ratings yet

- English Extra Conversation Club International Women's DayDocument2 pagesEnglish Extra Conversation Club International Women's Dayevagloria11No ratings yet

- Pharma TestDocument2 pagesPharma TestMuhammad AdilNo ratings yet

- Interesting Facts (Compiled by Andrés Cordero 2023)Document127 pagesInteresting Facts (Compiled by Andrés Cordero 2023)AndresCorderoNo ratings yet

- 3 - Content - Introduction To Java, JVM, JDK PDFDocument8 pages3 - Content - Introduction To Java, JVM, JDK PDFAnonymous zdY202lgZYNo ratings yet

- Airs-Lms - Math-10 - q3 - Week 3-4 Module 3 Rhonavi MasangkayDocument19 pagesAirs-Lms - Math-10 - q3 - Week 3-4 Module 3 Rhonavi MasangkayRamil J. Merculio100% (1)

- European Business in China Position Paper 2017 2018 (English Version)Document408 pagesEuropean Business in China Position Paper 2017 2018 (English Version)Prasanth RajuNo ratings yet

- Proposed Panel Antenna: Globe Telecom ProprietaryDocument2 pagesProposed Panel Antenna: Globe Telecom ProprietaryJason QuibanNo ratings yet

- GD&T WIZ Tutor Covers The Vast Breadth of Geometric Dimensioning and Tolerancing Without Compromising On The Depth. The Topics Covered AreDocument1 pageGD&T WIZ Tutor Covers The Vast Breadth of Geometric Dimensioning and Tolerancing Without Compromising On The Depth. The Topics Covered AreVinay ManjuNo ratings yet

- Document-SAP EWM For Fashion 1.0: 1.general IntroductionDocument3 pagesDocument-SAP EWM For Fashion 1.0: 1.general IntroductionAnonymous u3PhTjWZRNo ratings yet

- Project Report On Evaporative CoolerDocument12 pagesProject Report On Evaporative Coolersourabh singh tomerNo ratings yet

- Manual Handling Risk Assessment ProcedureDocument6 pagesManual Handling Risk Assessment ProcedureSarfraz RandhawaNo ratings yet

- 3.1 C 4.5 Algorithm-19Document10 pages3.1 C 4.5 Algorithm-19nayan jainNo ratings yet

- Muv PDFDocument6 pagesMuv PDFDenisse PxndithxNo ratings yet

- Integrating Therapeutic Play Into Nursing and Allied Health PracticeDocument214 pagesIntegrating Therapeutic Play Into Nursing and Allied Health PracticeIbrahim SabraNo ratings yet

- Year 10 Maths PlaneDocument62 pagesYear 10 Maths Planehal wangNo ratings yet

- Apps Tables Excel FRMTDocument4 pagesApps Tables Excel FRMTSunil ReddyNo ratings yet

- More Than Moore: by M. Mitchell WaldropDocument4 pagesMore Than Moore: by M. Mitchell WaldropJuanjo ThepresisNo ratings yet

- Komatsud65ex 16dozerbulldozerservicerepairmanualsn80001andup 200727063646Document26 pagesKomatsud65ex 16dozerbulldozerservicerepairmanualsn80001andup 200727063646juan santa cruzNo ratings yet

- PAPERBOARD QUALITYDocument8 pagesPAPERBOARD QUALITYaurelia carinaNo ratings yet

- Fermat points and the Euler circleDocument2 pagesFermat points and the Euler circleKen GamingNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- Strategic Flexibility: The Evolving Paradigm of Strategic ManagementDocument3 pagesStrategic Flexibility: The Evolving Paradigm of Strategic Managementnanthini kanasanNo ratings yet

- DCAD OverviewDocument9 pagesDCAD OverviewSue KimNo ratings yet

- Software Client Linux 21 01Document81 pagesSoftware Client Linux 21 01BronskyNo ratings yet

- Business Analysis FoundationsDocument39 pagesBusiness Analysis FoundationsPriyankaNo ratings yet

- J Ipm 2019 102121Document17 pagesJ Ipm 2019 102121bilalNo ratings yet

- Bhakti Trader Ram Pal JiDocument232 pagesBhakti Trader Ram Pal JiplancosterNo ratings yet