Professional Documents

Culture Documents

Datum Dimensioning: A Ø2 - 8 Holes B Ø10 - 11 Holes C Ø16 - 5 Holes D Ø22 - 2 Holes

Datum Dimensioning: A Ø2 - 8 Holes B Ø10 - 11 Holes C Ø16 - 5 Holes D Ø22 - 2 Holes

Uploaded by

David BumbaloughOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datum Dimensioning: A Ø2 - 8 Holes B Ø10 - 11 Holes C Ø16 - 5 Holes D Ø22 - 2 Holes

Datum Dimensioning: A Ø2 - 8 Holes B Ø10 - 11 Holes C Ø16 - 5 Holes D Ø22 - 2 Holes

Uploaded by

David BumbaloughCopyright:

Available Formats

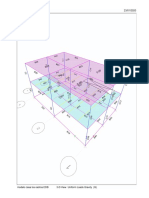

11-07 Datum Dimensioning

In this project, the objective is to identify each hole by its X and Y coordinates. The illustration shows a top view

of a part with many holes, dimensioned in the metric units. All holes use the datum dimensioning method, also

known as the ordinate dimensioning. This method offers a very easy way to create a CNC program, since all coor-

dinates are specified in the drawing, ready for use.

Make a list of XY coordinates, in the order of A-B-C-D.

120

30

55

70

75

80

95

15

A8

77 B4 B7

C5

74

68 C1

B8 64

58 D1 A7

A1 C4 A6

53

48 48

B6 43

36 B3

33

34 D2 C2

31

B9

A3 B10 28

25

18 B2 17

C3

10 A2

B11 11

8 B1 B5 A4 A5

3

0

10

15

30

35

50

56

72

42

94

110

115

121

0

A = Ø2 - 8 holes B = Ø10 - 11 holes C = Ø16 - 5 holes D = Ø22 - 2 holes

Note:

For this metric exercise, the actual hole diameters do not matter. However, for actual machining,

where the depth of each tool is very important, the diameters will make a very important difference.

Peter Smid CNC Programming Handbook 11-07 [ 1 ]

You might also like

- Portisch - Six. Hundred. EndingsDocument203 pagesPortisch - Six. Hundred. Endingsyeti975No ratings yet

- Tortort Manufacturing 80% Milled Receivers AK47Document6 pagesTortort Manufacturing 80% Milled Receivers AK47David BumbaloughNo ratings yet

- HK94, MP5, Parts KitsDocument6 pagesHK94, MP5, Parts KitsDavid BumbaloughNo ratings yet

- The Penguin Book of Chess Positions by C H O'D Alexander PDFDocument171 pagesThe Penguin Book of Chess Positions by C H O'D Alexander PDFPaulo Cohen100% (1)

- 1e4vsSicilianIII ExcerptDocument21 pages1e4vsSicilianIII Excerptnone100% (1)

- The Complete Guide To Growing Corn in Containers - Garden and HappyDocument17 pagesThe Complete Guide To Growing Corn in Containers - Garden and HappyDavid BumbaloughNo ratings yet

- I. A. Horowitz - The Golden Treasury of ChessDocument194 pagesI. A. Horowitz - The Golden Treasury of ChessSzabó István Zoltán100% (5)

- A Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsFrom EverandA Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsNo ratings yet

- 2009 - Chess Life 05Document84 pages2009 - Chess Life 05KurokreNo ratings yet

- Study Plan at Chess Level IntermediateDocument34 pagesStudy Plan at Chess Level IntermediatepiyNo ratings yet

- Grandmaster Preparation by Lev PolugaevskyDocument7 pagesGrandmaster Preparation by Lev Polugaevskyarban b25% (4)

- Macchi-Mc72 e A4 PDFDocument11 pagesMacchi-Mc72 e A4 PDFAungtin HtutNo ratings yet

- Tabela Povuceni Standardi SRPS 2010Document29 pagesTabela Povuceni Standardi SRPS 2010markodzajicNo ratings yet

- Book Review: Aron Nimzowitsch - On The Road To Chess Mastery, 1886-1924 - Per Skjoldager and Jørn Erik NielsenDocument7 pagesBook Review: Aron Nimzowitsch - On The Road To Chess Mastery, 1886-1924 - Per Skjoldager and Jørn Erik NielsenChess India Community100% (1)

- Livshitz August Test Your Chess Iq Grandmaster ChallengeDocument139 pagesLivshitz August Test Your Chess Iq Grandmaster ChallengeTickle AccountNo ratings yet

- Effective Length MODULE 7Document16 pagesEffective Length MODULE 7Carmel NavinNo ratings yet

- TheQueensIndian ExcerptDocument16 pagesTheQueensIndian ExcerptjulioNo ratings yet

- Attacking Chess KI, Vol 1 ExtractDocument7 pagesAttacking Chess KI, Vol 1 ExtractRenzo Marquez100% (2)

- Exercise 18: (All Questions Originally Set in Imperial Units.)Document26 pagesExercise 18: (All Questions Originally Set in Imperial Units.)Adam SinghNo ratings yet

- Critical Path Method - Activty-3Document3 pagesCritical Path Method - Activty-3SOHRAB SHERGILLNo ratings yet

- Eham Aircraft ParkingDocument1 pageEham Aircraft ParkingNeethNo ratings yet

- NEW TDA8950J (Com Pré-Amplificador) DiagramaDocument1 pageNEW TDA8950J (Com Pré-Amplificador) DiagramaDaniel Aguilar100% (2)

- E4 E5 2. d4 Exd4 3. c3: Nc6 (Danish Gambit Declined)Document55 pagesE4 E5 2. d4 Exd4 3. c3: Nc6 (Danish Gambit Declined)VenkatesanNo ratings yet

- Quien Como El SeñorDocument3 pagesQuien Como El SeñorDavid Jonatán TiradoNo ratings yet

- Advanced Chess Tactics ExcerptDocument13 pagesAdvanced Chess Tactics ExcerptRam IyerNo ratings yet

- Yb Ocr 105 PDFDocument252 pagesYb Ocr 105 PDFJuan Angel Perez Garcia100% (3)

- 0 #N/A #N/A: Serie A Serie B Serie CDocument8 pages0 #N/A #N/A: Serie A Serie B Serie CMaria Olvera De JonasBellNo ratings yet

- 2xa3 BigBagDocument80 pages2xa3 BigBagCristian DobrescuNo ratings yet

- Mammal Hands - Kandaiki - Piano Tenor Sax TranscriptionDocument3 pagesMammal Hands - Kandaiki - Piano Tenor Sax TranscriptionPedro GoncalvesNo ratings yet

- SN 74 CBT 3245 ADocument26 pagesSN 74 CBT 3245 AXuân Đài 5.0 (xuandai.,ltd)No ratings yet

- Ac7p s7Document16 pagesAc7p s7ricardosdiotiNo ratings yet

- Parts Guide Facsimile UX-B800GR: ModelDocument21 pagesParts Guide Facsimile UX-B800GR: ModelmohammedNo ratings yet

- Chanakya Answer Key Sheet CSATDocument2 pagesChanakya Answer Key Sheet CSATLady TigerNo ratings yet

- Keterangan: Satuan: MM Skala: Digambar: Diperiksa: DisetujuiDocument1 pageKeterangan: Satuan: MM Skala: Digambar: Diperiksa: DisetujuikunNo ratings yet

- Ms - HL Multiple Choice January 2023 ExamDocument1 pageMs - HL Multiple Choice January 2023 Examhaykaslanyan6No ratings yet

- 1 MergedDocument20 pages1 MergedSagar PanchalNo ratings yet

- SSC Portal: SSC Exam Question Paper Practice Test Online SSC FormDocument6 pagesSSC Portal: SSC Exam Question Paper Practice Test Online SSC FormSIVASUBRAMANINo ratings yet

- Software Engineering Previous Year Question PaperDocument3 pagesSoftware Engineering Previous Year Question PaperShubham RNo ratings yet

- Layout Expoindustrial 2019Document1 pageLayout Expoindustrial 2019abraham_096No ratings yet

- Tinindo Trincando - Os Novos Baianos (Contrabaixo)Document3 pagesTinindo Trincando - Os Novos Baianos (Contrabaixo)Marcelo Ferreira RibeiroNo ratings yet

- Structural First Plan 30-08-23Document1 pageStructural First Plan 30-08-23goyaltanush0703No ratings yet

- Ecam25033tb 164524Document6 pagesEcam25033tb 164524Yves KempsNo ratings yet

- Ece Set ADocument3 pagesEce Set Aajaysingh95No ratings yet

- Grade 8 English KeyDocument1 pageGrade 8 English KeyVal RenonNo ratings yet

- Alañileria Muros2Document1 pageAlañileria Muros2PAMELA FRANCIA GONZALESNo ratings yet

- Alañileria Muros2Document1 pageAlañileria Muros2PAMELA FRANCIA GONZALESNo ratings yet

- Alañileria Muros2Document1 pageAlañileria Muros2PAMELA FRANCIA GONZALESNo ratings yet

- D D D D D D: SN54HC245, SN74HC245 Octal Bus Transceivers With 3-State OutputsDocument16 pagesD D D D D D: SN54HC245, SN74HC245 Octal Bus Transceivers With 3-State OutputsCan DemirciNo ratings yet

- Lembar Jawaban Try Out 5 Wwcpns 2018: Display Name: Sarkov-Sopir Dangdut Username: @etpereatmundusDocument1 pageLembar Jawaban Try Out 5 Wwcpns 2018: Display Name: Sarkov-Sopir Dangdut Username: @etpereatmundusDerry Landilala PutraNo ratings yet

- Nocturne Op. 9 No2Document3 pagesNocturne Op. 9 No2alvaro torresNo ratings yet

- OM. 333R Mark IIDocument444 pagesOM. 333R Mark IIDoru VăleanNo ratings yet

- Manual Desbrozadora Huskvarna 333r Mark IIDocument440 pagesManual Desbrozadora Huskvarna 333r Mark IIedualoviNo ratings yet

- Table Speed Chapt: Table RPM Table RPM RPM Iugh Range 8 2 1 6 0 19 5Document2 pagesTable Speed Chapt: Table RPM Table RPM RPM Iugh Range 8 2 1 6 0 19 5Tony ZuñigaNo ratings yet

- Control On 83v Sonoacer7Document1 pageControl On 83v Sonoacer7MARTIN ROJASNo ratings yet

- November 2010 (v1) MSDocument2 pagesNovember 2010 (v1) MSmvhokoNo ratings yet

- 3D-Element Application: Design Online Academy Udemy Course Ansys-Static Analysis Tutorials Duration: 30minDocument2 pages3D-Element Application: Design Online Academy Udemy Course Ansys-Static Analysis Tutorials Duration: 30minKris CunninghamNo ratings yet

- F-104 Starfighter ManualDocument24 pagesF-104 Starfighter ManualSilverioNo ratings yet

- Terminal-Entire Airport Web Version 7 Dec 2019Document1 pageTerminal-Entire Airport Web Version 7 Dec 2019Peter PetersenNo ratings yet

- Column Plan: Dr. Haridarshan Shrestha Pulchowk Campus, LalitpurDocument25 pagesColumn Plan: Dr. Haridarshan Shrestha Pulchowk Campus, LalitpurOfficial 074BCEGHNo ratings yet

- 9792 PHYSICS: MARK SCHEME For The May/June 2010 Question Paper For The Guidance of TeachersDocument2 pages9792 PHYSICS: MARK SCHEME For The May/June 2010 Question Paper For The Guidance of TeachersbobNo ratings yet

- D D D D D D: SN54HC245, SN74HC245 Octal Bus Transceivers With 3-State OutputsDocument22 pagesD D D D D D: SN54HC245, SN74HC245 Octal Bus Transceivers With 3-State OutputsChathura PriyankaNo ratings yet

- Marking Scheme Paper 2 Stage 10 Mock1Document1 pageMarking Scheme Paper 2 Stage 10 Mock1Puja DhawanNo ratings yet

- NHA8783802 Baseplate 2nd FixturDocument1 pageNHA8783802 Baseplate 2nd FixturShahbaz KhanNo ratings yet

- Skala Satuan Tanggal Digambar NIM Diperiksa:::::: 1:2 MM 01-01-2019 Fahmi Octavani 1502618058 Ahmad Kholil ST. MT. KeteranganDocument1 pageSkala Satuan Tanggal Digambar NIM Diperiksa:::::: 1:2 MM 01-01-2019 Fahmi Octavani 1502618058 Ahmad Kholil ST. MT. KeteranganALFIANNo ratings yet

- Bushing Aux - Table 1Document1 pageBushing Aux - Table 1Official AulianrNo ratings yet

- IDT74FST3390 Octal 2:1 Multiplexer Bus Switch: FeaturesDocument5 pagesIDT74FST3390 Octal 2:1 Multiplexer Bus Switch: FeaturesspotNo ratings yet

- Oem 715g2621 SCHDocument5 pagesOem 715g2621 SCHsotiris1No ratings yet

- June 2008 MS - Paper 1 CIE Biology A-LevelDocument2 pagesJune 2008 MS - Paper 1 CIE Biology A-LevelDamien SibandaNo ratings yet

- YSGD Mooring ArrangementDocument1 pageYSGD Mooring ArrangementWisnu WicaksonoNo ratings yet

- Vikram Sarabhai Space Centre: Question No Correct Option Question No Correct OptionDocument1 pageVikram Sarabhai Space Centre: Question No Correct Option Question No Correct OptionSarath S NairNo ratings yet

- (Revision Test-Pcm-Iii) : Q.P.CODE - 125770 AnswersDocument1 page(Revision Test-Pcm-Iii) : Q.P.CODE - 125770 AnswersAYUSH SHARMANo ratings yet

- GabaritosDocument10 pagesGabaritosLeonardo DelfinoNo ratings yet

- SamaraBay PriceListDocument6 pagesSamaraBay PriceListArvin RokniNo ratings yet

- Etabs 2016 16.2.1 23/01/2020: 0.05 B48 B51 B53 B40 B29 B52 B50 B4 5Document1 pageEtabs 2016 16.2.1 23/01/2020: 0.05 B48 B51 B53 B40 B29 B52 B50 B4 5erica rincónNo ratings yet

- Gab 25Document1 pageGab 25Alison SantosNo ratings yet

- Skema BM1 STPMKedah 2010Document1 pageSkema BM1 STPMKedah 2010sayadanbahasaNo ratings yet

- 74HC245 Octal 3 State Noninverting Bus Transceiver: High Performance Silicon Gate CMOSDocument9 pages74HC245 Octal 3 State Noninverting Bus Transceiver: High Performance Silicon Gate CMOSsdsNo ratings yet

- November 2009 (v1) MS - Paper 1 CIE Chemistry IGCSEDocument2 pagesNovember 2009 (v1) MS - Paper 1 CIE Chemistry IGCSEAlishba HussainNo ratings yet

- Washington Dulles Airport MapDocument1 pageWashington Dulles Airport MapJuan ScovinoNo ratings yet

- 74HC245 Octal 3 State Noninverting Bus Transceiver: High Performance Silicon Gate CMOSDocument8 pages74HC245 Octal 3 State Noninverting Bus Transceiver: High Performance Silicon Gate CMOSAmit BhatiaNo ratings yet

- Exercises After Abdominal SurgeryDocument5 pagesExercises After Abdominal SurgeryDavid BumbaloughNo ratings yet

- 44-01 Machining With TailstockDocument1 page44-01 Machining With TailstockDavid BumbaloughNo ratings yet

- Scaling Function Q+A: # Answer 1Document2 pagesScaling Function Q+A: # Answer 1David BumbaloughNo ratings yet

- Feedrate Q+A: # Answer 1Document2 pagesFeedrate Q+A: # Answer 1David BumbaloughNo ratings yet

- CNC Machining Q+A: # Answer 1Document2 pagesCNC Machining Q+A: # Answer 1David BumbaloughNo ratings yet

- 49-01 Documenting Programs Q+A PDFDocument1 page49-01 Documenting Programs Q+A PDFDavid BumbaloughNo ratings yet

- Scaling Exercise: Use T01 Ø20 End MillDocument1 pageScaling Exercise: Use T01 Ø20 End MillDavid BumbaloughNo ratings yet

- Verifying Programs Q+A: # Answer 1Document2 pagesVerifying Programs Q+A: # Answer 1David BumbaloughNo ratings yet

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDocument1 pageBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNo ratings yet

- 53-03 Contour Points 1Document1 page53-03 Contour Points 1David BumbaloughNo ratings yet

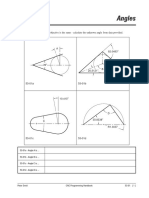

- Angles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDocument1 pageAngles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDavid BumbaloughNo ratings yet

- 46-01 Horizontal MachiningDocument1 page46-01 Horizontal MachiningDavid BumbaloughNo ratings yet

- 53-02 Locators PDFDocument1 page53-02 Locators PDFDavid BumbaloughNo ratings yet

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDocument1 pageBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNo ratings yet

- 23-02 Trial Cut For Turning PDFDocument1 page23-02 Trial Cut For Turning PDFDavid BumbaloughNo ratings yet

- Machine Zero Return Q+A: # Answer 1Document2 pagesMachine Zero Return Q+A: # Answer 1David BumbaloughNo ratings yet

- Unknown Radius: Chine Shop MagazineDocument1 pageUnknown Radius: Chine Shop MagazineDavid BumbaloughNo ratings yet

- 22 00 IntroductionDocument2 pages22 00 IntroductionDavid BumbaloughNo ratings yet

- Trig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDocument1 pageTrig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDavid BumbaloughNo ratings yet

- 25-01 Fixed Cycles Q+A PDFDocument2 pages25-01 Fixed Cycles Q+A PDFDavid BumbaloughNo ratings yet

- 23-02 Trial Cut For Turning PDFDocument1 page23-02 Trial Cut For Turning PDFDavid BumbaloughNo ratings yet

- 22-01 Simple Linear Motion 1Document1 page22-01 Simple Linear Motion 1David BumbaloughNo ratings yet

- 23-03 Skipped Holes With ObstaclesDocument1 page23-03 Skipped Holes With ObstaclesDavid BumbaloughNo ratings yet

- 3 Man Chess in The RoundDocument10 pages3 Man Chess in The RoundNijahmidoriNo ratings yet

- FFF Trading PlanDocument2 pagesFFF Trading PlanHoratiuBogdanNo ratings yet

- Christmas in New OrleansDocument1 pageChristmas in New OrleansJoe BickerstaffNo ratings yet

- Gibaud - Lazard (A45) : (,bryan)Document3 pagesGibaud - Lazard (A45) : (,bryan)radjachessNo ratings yet

- XBee USB Adapter SchematicDocument1 pageXBee USB Adapter SchematicRody Garay100% (2)

- 7th Johor International Open 2022 Prospectus-V1003Document1 page7th Johor International Open 2022 Prospectus-V1003Derry DanauNo ratings yet

- Chess Games - Content ListDocument49 pagesChess Games - Content ListGoogle12345678100% (1)

- GhostMod2 Com - Appsomniacs.da2Document3 pagesGhostMod2 Com - Appsomniacs.da2Aryan SinghNo ratings yet

- Z - Sonas - The Greatest Chess Player of All Time PDFDocument22 pagesZ - Sonas - The Greatest Chess Player of All Time PDFAnonymous oZO05CpaNo ratings yet

- Case Study On Bobby FischerDocument2 pagesCase Study On Bobby FischerZain KhanNo ratings yet

- Capibara: (Ukelele Low G)Document1 pageCapibara: (Ukelele Low G)gabrielinuzNo ratings yet

- Essay Format: A Basic Guide With Examples: Paper Due? Why Suffer? That's Our Job! Learn MoreDocument21 pagesEssay Format: A Basic Guide With Examples: Paper Due? Why Suffer? That's Our Job! Learn Moreadrian mantaringNo ratings yet