Professional Documents

Culture Documents

2X2 TWIN CELL 3 Pages PDF

Uploaded by

Mwesigwa DanielOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2X2 TWIN CELL 3 Pages PDF

Uploaded by

Mwesigwa DanielCopyright:

Available Formats

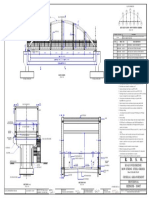

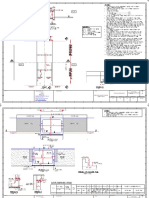

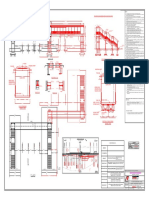

11900 300

4T12 - 15 - 200cc 4T12 - 15 - 200cc

25T12-02-200c\c T2

25T12-02-200c\c T2

63T16-01-200c\c T1

25T12 - 14 -

200CC Links

25T12-04-200c\c B2 25T12-04a-200c\c B2

63T16 - 14 - 200 B1

63T16 - 07a - 150 cc NF

Wing walls

63T16 - 07a - 150 cc FF

Gabions

2000 2000

SLOPE 0.5%

84T12-09-150c\c T1 33T12-10-150c\c T2

84T12-11-150c\c B1 33T12-12-150c\c B2

LONGITUDINAL DETAIL SECTION 1-1

12500

Cut off beam

8mm scroring scheck in both ditections

4900

300 300 1700 300 1700 300 300

63T16-01-200c\c T1

25T12-02-200c\c T2

66T12 - 11- 200 cc

63T12-13-200c\c

6T12 - 12 - 200cc

63T16-03-200c\ B1 25T12-04-200c\c B2

63T16-03-200c\c B1

300 300

63T12-13-200c\c

63T12-07-200c\c FF

63T16-07a-200c\c FF 63T12-07-200c\c FF

63T16-06-200c\c NF 63T16-7a-200c\c

2000 2000

63T16-01-200c\ T1 CUT OFF BEAM DETAILS

9T12-05-250c\c FF 9T12-05-250c\c NF

9T12-05-250c\c FF 9T12-05-250c\c FF

9T12-05-250c\c NF 300 300

84T12-09-150c\c T1

33T12-10-150c\c T2

63T12-13-200c\c

500 2000

C15 CONCRETE

BLINDING A

12500

500mm MIN HARCORE 84T12-11-150c\c B1 33T12-12-150c\c B2 63T12-13-200c\c

PLACED BELOW THE

4 X 12T12-03-200c\c

BOX CULVERT TO

THE ENGINEERS SATISFACTION

TOP SLAB REINFORCEMENT DETAILS B B

12500 4 X 12T12-04-200c\c

CROSS SECTION THROUGH BOX CULVERT

A

2500

WING WALL LAYOUT

500 2000

84T12-11-150c\c B1 300

14T10-01-200c\c 14T10-02-200c\c NOTES:

1.Excavation to be confirmed by the Engineer

11T10-07-250c\c 13T10-05-200c\c

2. Weak pockets of bearing strata to be dug out and filled

with 1:4:8 mass concrete.

3. CONCRETE MIXES

(a) Mass concrete to have a minimum works cube strength

4 X 13T12-05-200c\c

13T12-06-200c\c of 30N/mm^2 at 28days

4 X 11T12-07-250c\c C25 OUTLET

84T12-09-150c\c T1

SLAB APRON

WITH R8-200c/c 4 X 11T10-08-250c\c 8T12-10-200c\c (b) Reinforced concrete to have a minimum works cube

4 X 11T10-08-250c\c SCOUR CHECK

700 13T12-04-200c\c strength of 30N/mm^2 at 28days with 20mm maximum

4 X 13T10-06-200c\c

aggregate size.

4. REINFORCEMENT

1500 (a) High Yield bars to be square twisted cold formed bars to

2500 13T12-03-200c\c

8T12- 09 - 200cc BS4461 and are marked 'T'on these drawings.

(b) Mild steel bars Marked 'R' on these dwgs to be round bars

to BS 4483.

12500 SECTION A - A THROUGH WING WALL

SECTION B -B THROUGH WING WALL

5.MINIMUM COVER TO ALL STEEL IN

(i) base slab =40mm

BOTTOM SLAB REINFORCEMENT DETAILS (ii)Deck =25mm

(iii) Slabs = 40mm

(iv) Walls =30mm

CLIENT: STRUCTURAL ENG: DRAWING TITTLE:

WAKISO DISTRICT LOCAL GOVERNMENT BOX CULVERT LAYOUT DETAILS

NO REVISION

DESIGNED BY: DRAWN BY: JOB NO: DRG NO:

NO DATE DESCRIPTION

D.K D.K 2017/C/04 02

PROJECT: QUANTITY SURVEYOR:

PROPOSED 2mX2m TWIN CELL BOX CHECKED BY: SCALE: DATE: CLIENT'S SIGNATURE:

CULVERT D.K 1:50,1:75 AUG 2018

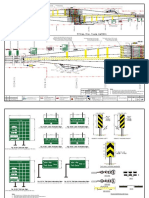

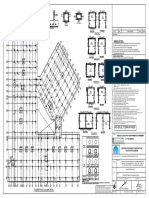

1500 7000 1500

ROADWAY

SHOULDER SHOULDER

DOWN STREAM SIDE

UP STREAM SIDE

New road Fill area WING WALL

2000

0.1%

200mm deep aprone slab Cut off beam to details

400mm thick C30 RC slab on

2 Lines of Gabion Matress 700mm deep rockfill on Geogrid

INLET SLAB APRON WITH

R8-200c/c SCOUR CHECK

FLOW DIRECTION RIVER FLOW DIRECTION

ROAD CENTRELINE

OUTLET SLAB APRON WITH INLET SLAB APRON WITH

300

R8-200c/c SCOUR CHECK R8-200c/c SCOUR CHECK

FLOW DIRECTION RIVER FLOW DIRECTION

NOTES:

1.Excavation to be confirmed by the Engineer

2. Weak pockets of bearing strata to be dug out and filled

with 1:4:8 mass concrete.

3. CONCRETE MIXES

(a) Mass concrete to have a minimum works cube strength

of 30N/mm^2 at 28days

(b) Reinforced concrete to have a minimum works cube

BOX CULVERT LAYOUT

strength of 30N/mm^2 at 28days with 20mm maximum

aggregate size.

4. REINFORCEMENT

(a) High Yield bars to be square twisted cold formed bars to

BS4461 and are marked 'T'on these drawings.

(b) Mild steel bars Marked 'R' on these dwgs to be round bars

to BS 4483.

5.MINIMUM COVER TO ALL STEEL IN

(i) base slab =40mm

(ii)Deck =25mm

(iii) Slabs = 40mm

(iv) Walls =30mm

CLIENT: STRUCTURAL ENG: DRAWING TITTLE:

WAKISO DISTRICT LOCAL GOVERNMENT BOX CULVERT LAYOUT

NO REVISION

DESIGNED BY: DRAWN BY: JOB NO: DRG NO:

NO DATE DESCRIPTION

D.K D.K 2017/C/04 01

PROJECT: QUANTITY SURVEYOR:

PROPOSED 2 CELL BOX CULVERT AT CHECKED BY: SCALE: DATE: CLIENT'S SIGNATURE:

WAKISO DISTRICT GOVERNMENT D.K 1:200, 1:100 SEPT 2018

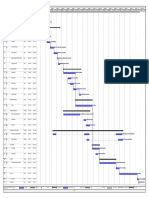

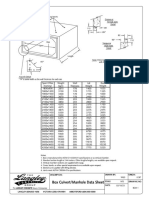

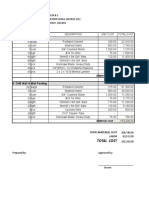

BAR BENDING SCHEDULE FOR 2mx2m BARREL BOX CULVERT

No. of No. in Total Length(m Total Weight Total Shape

Location member Mark Size each No. of A B C D E/R ) length(m) (Kg)/m weight (kg) code Remarks

1 01 T16 63 63 0.1 4.82 0.1 5.02 316.26 1.580 499.69 21 T1 Deck

1 02 T12 25 25 0.1 9.3 9.4 235.00 0.888 208.68 11 T2 Deck

1 02a T12 25 25 0.1 3.8 3.9 97.50 0.888 86.58 11 T2 Deck

1 03 T16 63 63 0.1 4.82 0.1 5.02 316.26 1.580 499.69 21 B1 Deck

1 04 T12 25 25 0.1 9.3 0.1 9.5 237.50 0.888 210.90 11 B2 Deck

1 04a T12 25 25 0.1 3.7 0.1 3.9 97.50 0.888 86.58 11 B2 Deck

3 05 T12 18 54 0.1 9.3 9.4 507.60 0.888 450.75 11 Distribution walls FF

3 05a T12 18 54 0.1 3.8 3.9 210.60 0.888 187.01 11 Distribution walls FF

2 06 T16 63 126 1 2.62 1 4.62 582.12 1.580 919.75 21 Main walls NF

2 07 T12 63 126 0.3 2.62 0.3 3.22 405.72 0.888 360.28 21 Main walls FF

2 07a T16 63 126 0.3 2.62 0.3 3.22 405.72 1.580 641.04 21 main walls

Main Box 08 Ditto 05

1 09 T12 84 84 0.1 4.82 0.1 5.02 421.68 0.888 374.45 21 Slab T1

1 10 T12 33 33 0.1 9.3 0.1 9.5 313.50 0.888 278.39 21 Slab T2

1 10a T12 33 33 0.1 3.7 0.1 3.9 128.70 0.888 114.29 21 Slab T2

1 11 T12 84 84 0.1 4.82 0.1 5.02 421.68 0.888 374.45 21 Slab B1

1 12 T12 33 33 0.1 9.3 0.1 9.5 313.50 0.888 278.39 21 Slab B2

1 12a T12 33 33 0.1 3.7 0.1 3.9 128.70 0.888 114.29 21 Slab B2

8 13 T12 63 504 0.3 0.3 1.2 1.8 907.20 0.888 805.59 25 Corner fillets

2 14 T12 25 50 0.52 0.22 0.1 0.1 1.68 84.00 0.888 74.59 51 Head wall links

2 15 T10 4 8 0.1 10.1 0.1 10.3 82.40 1.580 130.19 21 Headwall Mains

1 T12 30 30 0.4 0.288 0.14 0.14 1.256 37.68 0.888 33.46 98 Chairs

1 T12 60 60 0.4 0.188 0.14 0.14 1.056 63.36 0.888 56.26 98 Chairs

0 0

4 01 T10 14 56 1 2.46 0.1 3.56 199.36 0.617 123.01 27 Wing distribution

4 02 T10 14 56 1 2.46 0.1 3.56 199.36 0.617 123.01 28 Wing distribution

4 03 T12 13 52 0.1 1.42 0.1 1.62 84.24 0.888 74.81 21 Slab B1

4 04 T12 13 52 0.1 1.42 0.1 1.62 84.24 0.888 74.81 25 Slab T1

4 05 T10 13 52 0.1 2.5 2.6 135.20 0.617 83.42 11 Wing wall main

4 06 T12 13 52 0.3 1 1.3 67.60 0.888 60.03 28 Wing Main starter

Wing walls

4 07 T10 11 44 0.1 2.5 2.6 114.40 0.617 70.58 11 Wing wall main

4 08 T10 11 44 0.3 1 1.3 57.20 0.617 35.29 21 Wing main startrer

4 09 T12 8 32 0.1 2.42 0.1 2.62 83.84 0.888 74.45 11 B2&T2

4 10 T12 8 32 0.1 2.42 0.1 2.62 83.84 0.888 74.45 21 B1

2 11 T12 35 70 0.92 0.22 0.1 0.1 2.48 173.60 0.888 154.16 51 cut off beam links

2 12 T12 12 24 0.1 6.77 0.1 6.97 167.28 0.888 148.54 11 cut off beam mains

1 T12 30 30 0.4 0.288 0.14 0.14 1.256 37.68 0.888 33.46 98 Chairs

You might also like

- Box CUlvert Drawings 5 X 3Document2 pagesBox CUlvert Drawings 5 X 3Soni Jitubhai100% (3)

- Estimate, Bridge Open FoundationDocument86 pagesEstimate, Bridge Open Foundationकुमुद पाठकNo ratings yet

- Design of Rigid Pavement CC Road With M30Document2 pagesDesign of Rigid Pavement CC Road With M30Yedla Neelakanteshwar100% (3)

- Powershellorg Secrets of Powershell Remoting MasterDocument150 pagesPowershellorg Secrets of Powershell Remoting MasterPrateekGandhiNo ratings yet

- 60 M.bow String Girder-10411-7-RDocument1 page60 M.bow String Girder-10411-7-RkesharinareshNo ratings yet

- NH 16 To Venkatrao PalliDocument91 pagesNH 16 To Venkatrao PallilardhanNo ratings yet

- Cost Estimate - Package 1Document78 pagesCost Estimate - Package 1dheeraj sehgalNo ratings yet

- Equipment Lease AgreementDocument5 pagesEquipment Lease AgreementMwesigwa Daniel100% (2)

- Subject - Instrumentation in The Railway Super Structure Across Railway Bridge Po11io Related To Construction of ROBsRUBs.Document7 pagesSubject - Instrumentation in The Railway Super Structure Across Railway Bridge Po11io Related To Construction of ROBsRUBs.PushNo ratings yet

- Submission Date: Checking DateDocument3 pagesSubmission Date: Checking DateLikeiTNo ratings yet

- Retaining Wall DrawingDocument1 pageRetaining Wall DrawingManupriya KapleshNo ratings yet

- Bids Evaluation FormDocument8 pagesBids Evaluation FormMwesigwa DanielNo ratings yet

- Passenger Car Units (PCU) Analysis: Name of Road: Length: 6.5 KMDocument4 pagesPassenger Car Units (PCU) Analysis: Name of Road: Length: 6.5 KMTarun GuptaNo ratings yet

- 30 M Bow String Girder-10409-7rDocument1 page30 M Bow String Girder-10409-7rprejithNo ratings yet

- BoQ - Final Railway Over BridgesDocument22 pagesBoQ - Final Railway Over Bridgesrajiv kumarNo ratings yet

- Commercial Interior Design 2015-12Document92 pagesCommercial Interior Design 2015-12portatil31No ratings yet

- RDSO/B-10423/10 R0: Walls & Bridges (India) Pvt. LTDDocument1 pageRDSO/B-10423/10 R0: Walls & Bridges (India) Pvt. LTDSrikanth Patel DspNo ratings yet

- Box Culvert Twin CellDocument3 pagesBox Culvert Twin CellMwesigwa DanielNo ratings yet

- Per Pa Ration of Bridge ProjectDocument75 pagesPer Pa Ration of Bridge ProjectvsachinkumarNo ratings yet

- Client: Title:: General Notes of Vehicular Under PassDocument10 pagesClient: Title:: General Notes of Vehicular Under PassPraveen CyssanNo ratings yet

- Gad Flyover CH-5+680 PDFDocument7 pagesGad Flyover CH-5+680 PDFmrinal kayalNo ratings yet

- Plan Training Session CHSDocument51 pagesPlan Training Session CHSAnnabelle Reyes SucgangNo ratings yet

- 3 - Quantity TakeoffDocument36 pages3 - Quantity TakeoffengrfarhanAAANo ratings yet

- 36m BowString PDFDocument1 page36m BowString PDFD SRINIVAS100% (1)

- Drawings For Culvert at 293+538 PDFDocument3 pagesDrawings For Culvert at 293+538 PDFSurya GowthamNo ratings yet

- HI-SI Toll Plaza Marking R2-23-01-2020 Final PDFDocument4 pagesHI-SI Toll Plaza Marking R2-23-01-2020 Final PDFRamBhuvan SonkarNo ratings yet

- Ce A Study Guide 2014Document10 pagesCe A Study Guide 2014Mangezi TaperaNo ratings yet

- Crash Barrier EstimateDocument5 pagesCrash Barrier EstimateveevimalNo ratings yet

- Bar Bending Schedule For Box Culverts at CH: 128+820 For Service Road Total Length 40.092mDocument4 pagesBar Bending Schedule For Box Culverts at CH: 128+820 For Service Road Total Length 40.092mIrfan PatahnNo ratings yet

- R.C.C. Slab CulvertsDocument4 pagesR.C.C. Slab CulvertsDheeraj TkNo ratings yet

- Construction Work Program Sample Ms ProjectDocument1 pageConstruction Work Program Sample Ms ProjectMwesigwa Daniel100% (1)

- 5 Stance Pit Latrine BOQDocument12 pages5 Stance Pit Latrine BOQMwesigwa Daniel100% (2)

- VO-I Pac-1 MAIN REPORT - 20090915004345 PDFDocument252 pagesVO-I Pac-1 MAIN REPORT - 20090915004345 PDFSravan ChinimilliNo ratings yet

- Aor Cantilever 6m SignDocument6 pagesAor Cantilever 6m SignDaljit624No ratings yet

- Titan MicropilesDocument12 pagesTitan Micropilesmunain_gNo ratings yet

- Bathupuram Bridge Estimate (Latest Design)Document41 pagesBathupuram Bridge Estimate (Latest Design)msr1471100% (1)

- Revised Data Roadsbridges1Document404 pagesRevised Data Roadsbridges1Krishna SinghNo ratings yet

- Box Culvert 1.5X1.5Document3 pagesBox Culvert 1.5X1.5ajay kundu100% (2)

- Box CulvertDocument9 pagesBox CulvertDonald HamiltonNo ratings yet

- LTA-SDRE14-6-VIG5 (A) Vehicular Impact Guardrails - Thrie-Beam Transition PDFDocument1 pageLTA-SDRE14-6-VIG5 (A) Vehicular Impact Guardrails - Thrie-Beam Transition PDFNURLINURLINDANo ratings yet

- 36 MTR SpanDocument13 pages36 MTR SpanAnonymous sfkedkymNo ratings yet

- Bridge Model Estimate With Well FoundationDocument47 pagesBridge Model Estimate With Well Foundationsivabathy50% (6)

- Box Culvert PDFDocument1 pageBox Culvert PDFimamrohaniNo ratings yet

- Kilometer Stone, HectometerDocument1 pageKilometer Stone, Hectometerarya100% (2)

- Section B-B View A-A: Dimensional Detail Section of Retaining WallDocument1 pageSection B-B View A-A: Dimensional Detail Section of Retaining WallShivam SharmaNo ratings yet

- Retaining Wall - 10MDocument1 pageRetaining Wall - 10MManupriya KapleshNo ratings yet

- PCC Breast Wall 11-05-2021-ModelDocument1 pagePCC Breast Wall 11-05-2021-ModelEr navneet jassiNo ratings yet

- DPR 1Document188 pagesDPR 1Anonymous eKt1FCDNo ratings yet

- Master Pmgsy-ViDocument236 pagesMaster Pmgsy-ViMuani HmarNo ratings yet

- Schedules A B C D and HDocument38 pagesSchedules A B C D and HPiyuesh SharmaNo ratings yet

- 60 M.bow String Girder-10411-5-RDocument1 page60 M.bow String Girder-10411-5-RkesharinareshNo ratings yet

- Sieve Analysis of Coarse Aggregate As Per Is 2386 Part 1 - Cement Tests - India - Civil Engineering TestDocument2 pagesSieve Analysis of Coarse Aggregate As Per Is 2386 Part 1 - Cement Tests - India - Civil Engineering TestAnubhav NautiyalNo ratings yet

- Brailey Bridge Working Estimate 19.3.09Document54 pagesBrailey Bridge Working Estimate 19.3.09Kiran AEE BvrmNo ratings yet

- Pavement Design Report-R1Document38 pagesPavement Design Report-R1Harshit MoreNo ratings yet

- WMM Mix DesignDocument22 pagesWMM Mix DesignDivyesh AhirNo ratings yet

- F806faa Flexible PavementDocument24 pagesF806faa Flexible PavementWaqas Muneer Khan0% (1)

- Standard Data Book Rate Analysis PDFDocument264 pagesStandard Data Book Rate Analysis PDFGaribaldy FranciscoNo ratings yet

- DrawingsStrutures PKG V PDFDocument67 pagesDrawingsStrutures PKG V PDFMandeep Singh100% (1)

- Drawing Title: Employer Project Design Consultant: HouseDocument5 pagesDrawing Title: Employer Project Design Consultant: HouseRoshan KejariwalNo ratings yet

- Proforma - B Pradhan Mantri Gram Sadak Yojana (Pmgsy) : Package No. Jko5-State: - J&K District: JammuDocument31 pagesProforma - B Pradhan Mantri Gram Sadak Yojana (Pmgsy) : Package No. Jko5-State: - J&K District: JammuTarunNo ratings yet

- Foundation of Height GaugeDocument1 pageFoundation of Height GaugeyogendraNo ratings yet

- Boq of Fire StationDocument8 pagesBoq of Fire StationKANWARNo ratings yet

- JMPT Fob 28-01-2021 - V1 - Dyce-B&f-Bbs - P27Document1 pageJMPT Fob 28-01-2021 - V1 - Dyce-B&f-Bbs - P27RVNLPKG6B VBL-GTLM100% (1)

- Empty BBS - FormateDocument1 pageEmpty BBS - FormateHegdeVenugopal0% (1)

- General Arrangement Drawing: Sanction of Crs To Be Taken Before Execution of WorkDocument1 pageGeneral Arrangement Drawing: Sanction of Crs To Be Taken Before Execution of Workmrinal kayalNo ratings yet

- Regional Shedule & Rates PuneDocument23 pagesRegional Shedule & Rates PuneJaneshaNo ratings yet

- Longitudinal Detail Section 1-1: Top Slab Reinforcement DetailsDocument1 pageLongitudinal Detail Section 1-1: Top Slab Reinforcement DetailsMwesigwa DaniNo ratings yet

- Detail Z (1: 5) : Rabigh 3 Independent Water ProjectDocument1 pageDetail Z (1: 5) : Rabigh 3 Independent Water ProjectrenjithyesodharanNo ratings yet

- Rsag7 820 4375Document1 pageRsag7 820 4375Eduardo BresciaNo ratings yet

- 2) Foundation & Column - 621 - MC - E - S - 2001Document1 page2) Foundation & Column - 621 - MC - E - S - 2001NishantRathiNo ratings yet

- Cat - 797 Truck and Starting Aid Electrical CircuitsDocument2 pagesCat - 797 Truck and Starting Aid Electrical CircuitsneftalicastroNo ratings yet

- Interoffice Memorandum: TO: From: TM Subject: Payments To Subcontractor: Mr. Okello Date: CCDocument1 pageInteroffice Memorandum: TO: From: TM Subject: Payments To Subcontractor: Mr. Okello Date: CCMwesigwa DanielNo ratings yet

- Front/Back Elevation: DWG: Calves ShadeDocument1 pageFront/Back Elevation: DWG: Calves ShadeMwesigwa DanielNo ratings yet

- Wakiso Pre-Qualification-Goods, Services & Wrks-Fy2018-19.Document25 pagesWakiso Pre-Qualification-Goods, Services & Wrks-Fy2018-19.Mwesigwa DanielNo ratings yet

- Quote For Office Fit-Out 1 of 2-1Document1 pageQuote For Office Fit-Out 1 of 2-1Mwesigwa DanielNo ratings yet

- Procurement Log BookDocument2 pagesProcurement Log BookMwesigwa DanielNo ratings yet

- Requisition Form TemplateDocument4 pagesRequisition Form TemplateMwesigwa DanielNo ratings yet

- Item Project Sub Structure Qty Rate %Document5 pagesItem Project Sub Structure Qty Rate %Mwesigwa DanielNo ratings yet

- What Is The Difference Between A Microcontroller and A System On A Chip SoCDocument3 pagesWhat Is The Difference Between A Microcontroller and A System On A Chip SoCAnonymous oyUAtpKNo ratings yet

- Building Construction Quiz-15Document2 pagesBuilding Construction Quiz-15Nick GeneseNo ratings yet

- Boracay HotelsDocument4 pagesBoracay Hotelszotium1863100% (1)

- Basics of Electronics and Microprocessor MCQ'sDocument16 pagesBasics of Electronics and Microprocessor MCQ'srohi8975% (4)

- Vyatta Web FilteringDocument13 pagesVyatta Web Filteringduranduran11No ratings yet

- SMM7 6A External WorksDocument15 pagesSMM7 6A External WorksChee HernNo ratings yet

- Histories of Green Square PDFDocument84 pagesHistories of Green Square PDFjessicaborgespNo ratings yet

- Bill of Materials: I. Column & FootingDocument2 pagesBill of Materials: I. Column & FootingRalf Francis SaraNo ratings yet

- 1 Questionsand Answersin OSPart 1Document16 pages1 Questionsand Answersin OSPart 1Manish dixitNo ratings yet

- Din 14 2Document6 pagesDin 14 2Dule JovanovicNo ratings yet

- Compatibility ChartsDocument101 pagesCompatibility ChartsArunMuraliNo ratings yet

- "Suitability of M-Sand As Fine Aggregate in ConcretDocument40 pages"Suitability of M-Sand As Fine Aggregate in ConcretNavanitha PNo ratings yet

- ENOADDocument83 pagesENOADMarcosNo ratings yet

- Fullstack Vue Book Table of ContentsDocument4 pagesFullstack Vue Book Table of ContentsBrandon CortezNo ratings yet

- 3-Storey ResidentialDocument4 pages3-Storey ResidentialLesther RobloNo ratings yet

- Fundamentals of Microcontrollers (MCU's) : Hands-On WorkshopDocument23 pagesFundamentals of Microcontrollers (MCU's) : Hands-On WorkshopVIJAYPUTRANo ratings yet

- Adweataqaaddctranscoaadcal MirfaDocument328 pagesAdweataqaaddctranscoaadcal MirfaClark HonradoNo ratings yet

- Roof Garden Specification PDFDocument41 pagesRoof Garden Specification PDFKhushboo100% (1)

- 23 - CR Moldova - Ispra - 2013 - 326Document13 pages23 - CR Moldova - Ispra - 2013 - 326nebojsadj6411No ratings yet

- Concrete 03.06.08Document13 pagesConcrete 03.06.08Kanupriya JainNo ratings yet

- Dead LoveDocument221 pagesDead LoveJan RandNo ratings yet

- Ightham Mote To Old Soar ManorDocument3 pagesIghtham Mote To Old Soar ManorJavier DelgadoNo ratings yet

- 3M Matting Solutions BrochureDocument20 pages3M Matting Solutions Brochure0x15nakNo ratings yet

- 130129-Journal Reprint-Bondy-Two-Way PT Slabs With Bonded TendonsDocument7 pages130129-Journal Reprint-Bondy-Two-Way PT Slabs With Bonded TendonsAnonymous ELujOV3No ratings yet