Professional Documents

Culture Documents

Calculation of Axial

Calculation of Axial

Uploaded by

dikunOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation of Axial

Calculation of Axial

Uploaded by

dikunCopyright:

Available Formats

IJSTE - International Journal of Science Technology & Engineering | Volume 2 | Issue 12 | June 2016

ISSN (online): 2349-784X

Experimental Investigation of Vertical

Connections in Precast Wall Panel under Shear

Load

R. Ahilan S. Anandhi

ME Student Assistant Professor

Department of Civil Engineering Department of Civil Engineering

SRM Easwari Engineering College, Ramapuram, Chennai, SRM Easwari Engineering College, Ramapuram, Chennai,

Tamil Nadu, India Tamil Nadu, India

Dr. V Govindharajan

Chief Engineering Manager

L&T Construction Pvt. Ltd, Chennai-600089

Abstract

This Project deals with the experimental study and analysis of precast wall panel connections. The integrity of a precast system

depends on connections more than the structural members itself. The connections between panels are the key factors which

affects both the speed of erection and the overall integrity of the structure. The types connection proposed in this study is loop

connection with trapezoid shear keys. The shear keys are used to increase the shear carrying capacity of the connections. The

connection between the walls is called loop bars connection. Between the looping bars, one transverse bar is inserted as to ensure

connectivity of all the looping bars. This connection produces a gap between the walls, which would then be filled with grouting

material. The main objective of these experimental studies is to determine behaviour of loop bars connection under shear

loading.

Keywords: Wall panel connections, vertical connection, grouting, loop bars, shear loading, transverse reinforcements

________________________________________________________________________________________________________

I. INTRODUCTION

General Introduction

Prefabricated concrete shear wall panels are used extensively in high rise construction. Precast concrete structural systems

benefit from advantages, such as improved quality of construction, efficient use of materials, reduced construction time, and cost

efficiency. In addition, precast concrete allows architects and engineers to perform more innovative designs than traditional cast-

in-place concrete design.

One of the main concerns in precast concrete construction is the method by which the panels are connected. Connections must

provide adequate strength, ductility and continuity in order to insure the integrity of the structure under various loading

conditions. It is most important for a successful construction of precast reinforced concrete structures in terms of the structural

behaviour. The main purpose of the structural connection is to transfer forces between the precast concrete elements through

connections in order to obtain structural interaction once the system is loaded. The connections between panels are extremely

important, since they affect both the speed of erection and the overall integrity of the structure. Therefore, the structural

connections should design properly as the same for the precast.

The design of connections is one of the most important considerations in the structural design of a precast concrete structure.

The purpose of a connection is to transfer load, restrain movement, and provide stability. Within any one connection, there may

be several load transfers; each one must be designed for adequate strength and ductility and be appropriately detailed.

Connections in Precast Concrete

The main limitation of precast construction is that there exist joints between the precast component and adjacent structural

elements that need to be connected. The performance of a precast concrete structure is greatly influenced by the performance of

the in-situ joints and the integrity of these joints. As saving construction time is the most important advantage of using precast

concrete, the design emphasis should be such that the connections details facilitate a short construction time. Details that are too

elaborate or vulnerable should be avoided as far as possible. Methods to field-connect precast concrete elements should optimise

the safety and efficiency of crane and erection crew operation.

All rights reserved by www.ijste.org 217

Experimental Investigation of Vertical Connections in Precast Wall Panel under Shear Load

(IJSTE/ Volume 2 / Issue 12 / 040)

Connections in Reinforced Concrete wall panels

The reinforced concrete joints are usually subjected to shear, tension or flexure. The connections within reinforced concrete

joints are usually secured by the continuity of the reinforcement that may be achieved by appropriate use of splicing of

reinforcement. The connections are as follows

Lapping of bars with straight ends

Welding of bars or steel plates

Reinforcement grouted into apertures

Overlapping of reinforcement loops

Prestressing

Threaded or filled sleeving and

Threaded couplings.

Vertical wall to wall connection

The vertical joints are designed to transfer shear forces under lateral loads. The joint faces are indented to provide shear keys for

shear transfer with increasing lateral loads. Beyond cracking of concrete, a strut-and-tie action is expected to develop.

Overlapping reinforcing loops are provided along with shear keys to take up the horizontal component of the inclined

compressive strut.

A continuous vertical bar is provided inside the overlapping loops from the adjacent units. The loops thus couples the adjacent

panels. For sufficient out-of-plane support, a panel is adequately connected to the perpendicular panel through overlapping

reinforcing loops with the vertical bar. The exterior wall panels along the shorter direction of the building, which constitute the

primary shear walls to resist the lateral forces, are provided with six shear keys per storey height. In interior wall joints, reduced

number of reinforcement loops are provided per storey height since the shear demand is less.

II. SCOPE

The scope of the work comprises an experimental study on the shear load carrying capacity of vertical joints between two

adjacent precast wall panels.

The capacities of proposed vertical connections are to be tested for account.

The compressive strength of concrete in the joint and loop connection parameters.

Identify the contribution of each component used for the connections.

Comparisons studies on specimens with different loop connections

Estimate the strength due to Strut and tie action, anchorage bond strength and stress developed at the critical section.

III. OBJECTIVE

The main objectives of this project are:

To investigate failure mode of vertical connection under shear load.

To study the cracking resistance of joints with the vertical connections

To determine behaviour of loop bars connection under shear loading.

To examine the strut and tie actions of joints with shear key connections.

To determine the maximum shear stress the connection can take.

IV. LITERATURE DISCUSSION

Based on various literatures, it is that connections in precast wall panels, including shear walls, must be designed to transfer all

design forces and moments.

The presence of shear keys in the horizontal connection enhances the shear capacity in comparison to the plain surface

connection. The difference in the shear key configuration had an insignificant effect on the behaviour capacity of connection.

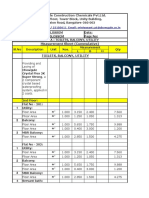

Table – 1

MIX PROPORTION

Cement Fine Aggregate Coarse Aggregate

383.3 kg/m³ 682 kg/m³ 1288kg/m³

1 1.78 3.36

Mix Design for M35 Control Concrete = 1: 1.78: 3.36

All rights reserved by www.ijste.org 218

Experimental Investigation of Vertical Connections in Precast Wall Panel under Shear Load

(IJSTE/ Volume 2 / Issue 12 / 040)

V. DIMENSIONS OF PRECAST PANELS AND CONNECTION

The wall Panels dimensions are assumed as 0.6m height, 0.4m width and 0.1m thickness. Furthermore, connection of walls

which is located in the gap between two panels is 0.3m height, 0.15m width and 0.1m thickness.

Connection parameters

The loop bar is provided with a diameter of 12 mm is used to connect the two panels.

The length of the bar is provided as development length which is 50 times the diameter.

The transverse reinforcement bars of same diameter are provided between the loops.

Shear keys of different shapes are provided to study the behavior of connection.

Fosroc Conbextra GP 2 is a ready mix dry power is used a grouting material to connect the panels.

Connection Types

Loop connection is an efficient form of reinforced concrete connection. It consists of the application of splicing the looped bars

protruding from the respective precast concrete members. In a way it is reminiscent of a spirally reinforced concrete column if

the loops are considered to act as stirrups. Three types of loop connections are considered and they are

Loop Connection Trapezoid Shear Keys (angle 45°).

1) The depth and length of the shear key are taken as 50mm and 100mm respectively.

2) The depth and length of the shear key are taken as 50mm and 100mm respectively.

3) The additional reinforcement is provided to improve ductility and to avoid failure due to tension.

Loop Connection with Trapezoid Shear Keys

1) Loop connection with trapezoid shear keys (angle 45°) and additional transverse reinforcements

2) Loop connection without shear keys.

The Connection Configurations Are Shown In Figures 6.1 to 6.3.

Fig. 1: Loop connection trapezoid shear keys

VI. RESULTS AND DISCUSSIONS

Compressive Strength of Cylinder

Specimen: Cylinder

Dimensions: 150mm X 300mm

Area of Cylinder: 176.7 X 103 Mm2

Instrument Used: Demec Gauge

Table – 2

Compressive Strength Of Cylinder

Load DemecGauge Readings Avg Stress

(Kn) At Top At Bottom Strain (Kn/Mm2)

0 0.525 0.425 0.475 0

10 0.492 0.390 0.441 0.000056

20 0.535 0.356 0.445 0.00011

30 0.500 0.362 0.431 0.00016

40 0.490 0.402 0.446 0.00022

50 0.468 0.365 0.416 0.00028

100 0.533 0.357 0.445 0.00056

All rights reserved by www.ijste.org 219

Experimental Investigation of Vertical Connections in Precast Wall Panel under Shear Load

(IJSTE/ Volume 2 / Issue 12 / 040)

150 0.553 0.422 0.4875 0.00084

200 0.517 0.340 0.428 0.00113

250 0.479 0.253 0.366 0.00141

300 0.445 0.291 0.368 0.00169

350 0.485 0.353 0.419 0.00198

400 0.400 0.242 0.321 0.00226

450 0.486 0.245 0.365 0.00254

500 0.454 0.204 0.329 0.00282

550 0.422 0.209 0.315 0.00311

600 0.475 0.244 0.359 0.00339

650 0.368 0.115 0.2415 0.00367

700 0.333 -0.017 0.158 0.00396

Fig. 2: Stress Vs Strain Graph

Concrete Cube Testing

Grade of concrete : M35

Dimensions : 100mm x 100mm

Table – 3

3rd DAY TESTING

2

Sample Weight (Kg) Yield Load (kN) Strength (N/mm )

1 2.469 221.6 22.16

2 2.579 176.24 17.62

3 2.576 224 22.4

Table – 4

7rd DAY TESTING

2

Sample Weight (Kg) Yield Load (kN) Strength (N/mm )

1 2.422 364 36.4

2 2.468 252 25.2

3 2.382 172 17.2

Table – 5

28th DAY TESTING

2

Sample Weight (Kg) Yield Load (kN) Strength (N/mm )

1 2.530 304 30.4

2 2.570 308 30.8

3 2.466 410 41

Split Tensile Test

SPECIMEN : Cylinder

MATERIAL : Concrete

DIMENSIONS : 100mm X 200mm

All rights reserved by www.ijste.org 220

Experimental Investigation of Vertical Connections in Precast Wall Panel under Shear Load

(IJSTE/ Volume 2 / Issue 12 / 040)

Table – 6

split Tensile Test

2

Sample Weight (Kg) Density Load (kN) Strength (N/mm )

1 4.108 4108 110 3.52

2 4.146 4146 104 3.33

3 4.104 4104 100 3.2

Compressive Strength of Grouting Material

Specimen : Cube

Material : FosrocConbextra Gp2

Dimensions : 40mm X 40mm

Table – 7

Compressive Strength of Grouting Material

Sample Load (KN) Strength (N/mm2)

1 109 68.125

2 55 34.38

3 126 78.75

Test Results of Non-Destructive test

Table – 8

3rd DAY TEST OF M35 GRADE CONCRETE CUBE

3

Sample Density (Kg/m ) Rh UPV (m/s)

1 2469 25.4 4785

2 2579 24.9 4785

3 2576 27.25 4673

Table – 9

7rd DAY TEST OF M35 GRADE CONCRETE CUBE

3

Sample Density (Kg/m ) Rh UPV (m/s)

1 2422 28.75 5155

2 2468 31.62 5155

3 2382 31.60 5025

Table – 10

7rd DAY TEST OF M35 GRADE CONCRETE CUBE

3

Sample Density (Kg/m ) Rh UPV (m/s)

1 2530 39.5 5855

2 2570 38.7 5654

3 2466 38.26 5575

Testing Of Panel with Vertical Connection

The wall panel is tested under Uniformly Distributed Load (UDL) conditions. The testing of panel is done with the help of

hydraulic operated jack connected to load cell. The load is applied to the beam with the help of hydraulic jack and the data is

recorded from the data acquisition system, which is attached with the load cell. One LVDT (Linear Variable Deflection

Transformer) is placed at the center of the specimen and second LVDT is placed on end of panel. The value of deflection is

obtained from LVDT.

Table – 11

Testing Of Panel With Vertical Connection

Strain Deflection (mm)

S.NO Load (kN)

X 10-6 mm Connection End

1 0.1 944 -0.20 0

2 16.4 963 -0.2 4

3 68.7 636 0.6 9

4 143 332 1.2 13

5 144 1094 1.8 16

6 146.6 1075 1.7 15

7 149.1 1046 2.2 15

8 150 1041 1.9 17

9 152 840 1.7 15

10 155 712 1 16

11 157 1020 1.3 16

All rights reserved by www.ijste.org 221

Experimental Investigation of Vertical Connections in Precast Wall Panel under Shear Load

(IJSTE/ Volume 2 / Issue 12 / 040)

12 161 945 2.1 15

13 162.7 914 1.6 15

14 164 1093 0.6 16

15 165 35406 1.7 16

16 170.2 35406 1.9 16

17 175 35406 2.1 16

18 181 35406 2.1 16

19 184 35406 1 16

20 185 35406 1.3 17

21 188.1 35406 1.4 18

22 190.1 35406 1.7 19

23 195 35406 1.3 20

24 195.2 35406 5 19

25 200 35406 5.8 2.1

26 200.8 35460 5.6 21

Fig. 3: Load Vs Deflection of Panel Test

VII. CONCLUSION

On applying loads up to 200 KN, it is observed that the connection provided for the panels are intact except for some micro

cracks. On increasing loads above 200 KN it is observed that the cracks are formed in the panels while the connection still takes

the load. So it can be concluded that the provided connection is more than adequate to resist shear load produced during

earthquakes. The connection configurations can be used for practical purposes.

REFERENCES

[1] Is 456-2000 plain and reinforcement concrete- code of practice?

[2] Is 10262-1982 recommended guidelines for concrete mix design?

[3] HaoJunbao, “Structural behaviour of precast components with loop connections”, National University of Singapore, 2004.

[4] IzniSyahrizal Ibrahim1, KhairulHazmanPadil, Hamid Mansoor, and Noor NabilahSarbini, “Ultimate Shear Capacity and Failure of Shear Key Connection

In Precast Concrete Construction”, Malaysian Journal of Civil Engineering, 26(3):414-430, 2014.

[5] Ahmad BaharuddinAbd. Rahman And Ong HernYee , “Grout Filled Steel Pipe Integrated With Shear Key for Precast Concrete Connection” .

[6] Nabila Rossley, Farah Nora Aznieta Abdul Aziz, Heng Chiang Chew and NimaFarzadnia , “Behaviour of Vertical Loop Bar Connection in Precast Wall

Subjected To Shear Load”, AENSI- Australian Journal of Basic and Applied Sciences, January 2014.

[7] Sami H. Rizkalla, “Multiple Shear Key Connections for Precast Shear Wall Panels”, PCI journal, March-April 1989.

[8] H.R.Foerster, et al., “Behaviour and design of shear connectors”, January-February 1989.

[9] RaminVagheia, FarzadHejazia, Hafez Taheria, Mohd Saleh Jaafarb and Abang, “Performance of Precast Concrete wall to wall Connection”, IC BEE 2013-

5th International Conference on Chemical, Biological and Environmental Engineering, P.177-194.

[10] Bindurani.P, A. Meher Prasad, Amlan K. Sengupta, “Analysis of Precast Multistoreyed Building – A Case Study”, IJIRSET- International Journal of

Innovative Research in Science, Engineering and Technology, ISSN:2347-6710, Vol-2, December 2013.

[11] Gheorghe Ciuhandu, ValeriuStoian, “Design of vertical joints in precast reinforced concrete shear walls”, 2015.

[12] M.L.Lau, S.H.Rizkalla and K.A.Soudki, “Connections for precast load bearing shear wall panels”.

[13] In-Hwan Yang, Kyung-Cheol Kim, and Young-Joon Kim, “Shear Strength of Dry Joints in Precast Concrete Modules”.

[14] HeeSeok Kim, Won Jong Chin, Jeong Rae Cho, Young Jin Kim, Hyejin Yoon, “An Experimental Study on the Behavior of Shear Keys According to the

Curing Time of UHPC”, Scientific Research Publishing, April 2015, 212-218.

All rights reserved by www.ijste.org 222

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Glulam Wood BeamsDocument37 pagesGlulam Wood Beamsu16sr6No ratings yet

- Chapter18 Beam Subjected To Torsion & Bending IIDocument29 pagesChapter18 Beam Subjected To Torsion & Bending IIVincent TengNo ratings yet

- Building Boq SampleDocument44 pagesBuilding Boq SampleSanjeewa Kulasooriya0% (1)

- Transmission Line FoundationsDocument23 pagesTransmission Line FoundationsSaurav Kafle100% (1)

- PIP STE03350 Vertical Vessel Foundation Design Guide 12-2008 (Last Upd) PDFDocument33 pagesPIP STE03350 Vertical Vessel Foundation Design Guide 12-2008 (Last Upd) PDFbute79100% (3)

- Coupled Shear Wall: A ReviewDocument2 pagesCoupled Shear Wall: A ReviewIJSTE100% (1)

- Verification Manual AFNOR 5.2Document77 pagesVerification Manual AFNOR 5.2Virginie ChalonNo ratings yet

- CEC025 - Rail Track CodeDocument411 pagesCEC025 - Rail Track Codealdert_pathNo ratings yet

- Method Statement TNB SubstationDocument3 pagesMethod Statement TNB SubstationAishah Zakaria86% (7)

- Development of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityDocument6 pagesDevelopment of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityIJSTENo ratings yet

- Effect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsDocument9 pagesEffect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsIJSTENo ratings yet

- Partial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderDocument7 pagesPartial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderIJSTENo ratings yet

- Design and Analysis of Magneto Repulsive Wind TurbineDocument7 pagesDesign and Analysis of Magneto Repulsive Wind TurbineIJSTENo ratings yet

- A Mixture of Experts Model For ExtubationDocument4 pagesA Mixture of Experts Model For ExtubationIJSTENo ratings yet

- An Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabDocument5 pagesAn Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabIJSTENo ratings yet

- Wireless Information Process and Power Transfer in Single-User OFDM SystemDocument6 pagesWireless Information Process and Power Transfer in Single-User OFDM SystemIJSTENo ratings yet

- Using The Touch-Screen Images For Password-Based Authentication of IlliteratesDocument6 pagesUsing The Touch-Screen Images For Password-Based Authentication of IlliteratesIJSTENo ratings yet

- Onerider The Bike TaxiDocument3 pagesOnerider The Bike TaxiIJSTENo ratings yet

- Duplicate Detection Using AlgorithmsDocument3 pagesDuplicate Detection Using AlgorithmsIJSTENo ratings yet

- Technology Advancement For Abled PersonDocument9 pagesTechnology Advancement For Abled PersonIJSTENo ratings yet

- Privacy Preserving: Slicer Based SchemeDocument3 pagesPrivacy Preserving: Slicer Based SchemeIJSTENo ratings yet

- Research On Storage Privacy Via Black Box and Sanitizable SignatureDocument6 pagesResearch On Storage Privacy Via Black Box and Sanitizable SignatureIJSTENo ratings yet

- Study On The Properties of Aerated Concrete Incorporating Fly Ash and Rubber PowderDocument6 pagesStudy On The Properties of Aerated Concrete Incorporating Fly Ash and Rubber PowderIJSTENo ratings yet

- An Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemDocument5 pagesAn Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemIJSTENo ratings yet

- An Implementation of Matlab Based Platform For The Evaluation of Modulation Techniques Using Multiuser MIMO-OFDM For Visible Light Communications Using MatlabDocument5 pagesAn Implementation of Matlab Based Platform For The Evaluation of Modulation Techniques Using Multiuser MIMO-OFDM For Visible Light Communications Using MatlabIJSTENo ratings yet

- Tutorial 1: CE F230 Civil Engineering MaterialsDocument5 pagesTutorial 1: CE F230 Civil Engineering Materialsvasu khandelwalNo ratings yet

- Column Design: Via Etabs in Accordance To ACI 318-19Document11 pagesColumn Design: Via Etabs in Accordance To ACI 318-19engrjassmaruizoNo ratings yet

- BoqDocument220 pagesBoqMuhammad Arslan GujjarNo ratings yet

- March Bill1Document38 pagesMarch Bill1ShakthivelNo ratings yet

- Draft A Roof Framing Plan ManuallyDocument41 pagesDraft A Roof Framing Plan ManuallyJennifer CaliwagNo ratings yet

- G CAST - Catalogue Prestressed BeamDocument6 pagesG CAST - Catalogue Prestressed BeamFadhli ATZNo ratings yet

- Beam Framing Plan & Detail of Ground Floor Roof SlabDocument1 pageBeam Framing Plan & Detail of Ground Floor Roof SlabA8304008005No ratings yet

- Composite Construction Method: Ii. Composite Action in BeamsDocument1 pageComposite Construction Method: Ii. Composite Action in Beamsjillian llanesNo ratings yet

- ProjectDocument6 pagesProjectJNfotoeventsNo ratings yet

- Material List Order & Received Check Form Tsme 1 Sme 1 Tsme 2 Sme 2Document14 pagesMaterial List Order & Received Check Form Tsme 1 Sme 1 Tsme 2 Sme 2Andre Brama AlvariNo ratings yet

- Is 8147Document170 pagesIs 8147Asha JatalNo ratings yet

- Minor ProjectDocument33 pagesMinor ProjectNehaNo ratings yet

- Hand CalculationDocument15 pagesHand CalculationBoreirNo ratings yet

- Concrete ADM STD Specifications For K-140 SRC & K-250 SRC ROAD WorksDocument22 pagesConcrete ADM STD Specifications For K-140 SRC & K-250 SRC ROAD WorksMubashar Islam JadoonNo ratings yet

- Reinforced Concrete Culvert PipesDocument3 pagesReinforced Concrete Culvert PipesAbdurezak AbdurehimNo ratings yet

- Construction Work Budget For Engineer OfficeDocument2 pagesConstruction Work Budget For Engineer OfficeNestor Hernandez. FuentesNo ratings yet

- Basement InteriorDocument1 pageBasement Interiorshashank sharmaNo ratings yet

- Assignment 09-Column-01Document3 pagesAssignment 09-Column-01Mohammed Junaid ShaikhNo ratings yet

- Lecture 1 - Introduction PDFDocument11 pagesLecture 1 - Introduction PDFAndrésDíazNo ratings yet

- History of Buckling of ColumnDocument10 pagesHistory of Buckling of ColumnSorin Viorel CrainicNo ratings yet

- General Data For Project 1: Head Regulator Irrigation Works DesignDocument7 pagesGeneral Data For Project 1: Head Regulator Irrigation Works DesignkhaaledNo ratings yet

- CD - AASHTO - HE-EG-LAB-LT-E-143-14-R3 (EG) June2017ConcreteDurability PDFDocument11 pagesCD - AASHTO - HE-EG-LAB-LT-E-143-14-R3 (EG) June2017ConcreteDurability PDFNithin GNo ratings yet