Professional Documents

Culture Documents

SPL TB14 - Slowsandfiltration PDF

SPL TB14 - Slowsandfiltration PDF

Uploaded by

Aini ZahraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPL TB14 - Slowsandfiltration PDF

SPL TB14 - Slowsandfiltration PDF

Uploaded by

Aini ZahraCopyright:

Available Formats

A NATIONAL DRINKING WATER CLEARINGHOUSE FACT SHEET

Slow Sand Filtration

Summary

First used in the U.S. in 1872, slow sand filters are the oldest type of municipal water filtration.

Today, they remain a promising filtration method for small systems with low turbidity or algae-

containing source waters. Slow sand filtration does not require pretreatment or extensive operator

control—which can be important for a small system operator with several responsibilities.

What is slow sand filtration? Advantages

Slow sand filtration is a simple and reliable Design and operation simplicity—as well as

process. They are relatively inexpensive to minimal power and chemical requirements—

build, but do require highly skilled operators. make the slow sand filter an appropriate technique

for removing suspended organic and inorganic

The process percolates untreated water slowly matter. These filters also may remove pathogenic

through a bed of porous sand, with the influent organisms.

water introduced over the surface of the filter,

and then drained from the bottom. Slow sand filtration reduces bacteria, cloudiness,

and organic levels—thus reducing the need for

Properly constructed, the filter consists of a disinfection and, consequently, the presence of

tank, a bed of fine sand, a layer of gravel to disinfection byproducts in the finished water.

support the sand, a system of underdrains to Other advantages include:

collect the filtered water, and a flow regulator • Sludge handling problems are minimal.

to control the filtration rate. No chemicals are • Close operator supervision is not necessary.

added to aid the filtration process. • Systems can make use of locally available

materials and labor.

Slow Sand Filter

Filter

Outlet Effluent flow Clearwell

baffle

Raw water control structure

source

Manhole

Control

valve

Raw water

Ground level

PAGE

Sand filter bed Filtered water

To sewer or

raw water one

source

OF FOUR

Support gravel

Telescoping valve

Under drain

NATIONAL DRINKING WATER CLEARINGHOUSE

Slow Sand Filtration

Typical Treatment Performance of Conventional Slow Sand Filters

TABLE 1

Water Quality Removal organic chemicals, dissolved inorganic

Paramenter Capacity substances, such as heavy metals, or tri-

halomethane (THM) precursors—chemi-

Turbidity <1.0 NTU cal compounds that may form THMs

Coliforms 1-3 log units when mixed with chlorine. Also,

waters with very fine clays are not

Enteric Viruses 2-4 log units easily treated using slow sand filters.

Giardia Cysts 2-4+log units

A granular activated carbon (GAC)

Cryptosporidium Oocysts >4 log units sandwich filter is a modified slow sand

filter that removes organic material.

Dissolved Organic Carbon <15-25% This filter uses a base sand layer that is

Biodegradable approximately 1 foot deep, an intermediate

GAC layer approximately 0.5 feet, and

Dissolved Organic Carbon <50% a top sand layer approximately 1.5 feet

deep. This modified slow sand filter

Trihalomethane Precursors <20-30%

effectively removes pesticides, total organic

Heavy Metals carbon, and THM precursors.

Zn, Cu, Cd, Pb >95-99% Slow sand filters are less effective at

Fe, Mn >67% removing microorganisms from cold

water because as temperatures decrease,

As <47% the biological activity within the filter

Source: Adapted from Collins, M.R. 1998. bed declines.

Slow sand filters also provide excellent treated- Process Description

water quality. (See Table 1.) Slow sand filters con- Slow sand filters require a very low application

sistently demonstrate their effectiveness in removing or filtration rate (0.015 to 0.15 gallons per minute

suspended particles with effluent turbidities below per square foot of bed area, depending on the

1.0 nephelometric turbidity units (NTU), achieving gradation of the filter medium and the quality of

90 to 99 + percent reductions in bacteria and the raw water). The removal action includes a

viruses, and providing virtually complete Giardia biological process in addition to physical and

lamblia cyst and Cryptosporidium oocyst removal. chemical ones.

Limitations A sticky mat of biological matter, called a

Slow sand filters do have certain limitations. “schmutzdecke,” forms on the sand surface,

They require a large land area, large quantities where particles are trapped and organic matter is

of filter media, and manual labor for cleaning. biologically degraded. Slow sand filters rely on this

cake filtration at the surface of the filter for partic-

Water with high turbidity levels can quickly clog ulate straining. As the surface cake develops during

the fine sand in these filters. Water is applied the filtration cycle, the cake assumes the dominant

to slow sand filters without any pretreatment role in filtration rather than the granular media.

when it has turbidity levels lower than 10 NTU.

Pilot testing is always necessary when designing

When slow sand filters are used with surface slow sand filters. Currently, engineers are not

waters that have widely varying turbidity levels, able to predict the performance of a slow sand

infiltration galleries or rough filters—such as up- filter with a specific quality of raw water.

OF FOUR

flow gravel filters—may be used to reduce turbidity. Operation of a small pilot filter, preferably over

several seasons of the year, will insure ade-

Waters with a very low nutrient content may quate performance of the full-scale plant.

two impair turbidity removal since some nutrients

PAGE

must be present that promote biological Remember, after the designer sets the parame-

ecosystem growth within the filter bed. ters—such as the plant filtration rate, bed depth,

and sand size—there is little a plant operator can

Slow sand filters do not completely remove all do to improve the performance of a slow sand

FOURTEEN • JUNE 2000

filter that does not produce satisfactory water. is needed for production equalization and demand.

Slow sand filter pilot plant testing does not have Monitoring and Operation Requirements

to be expensive. Pilot plant testing has been done A slow sand filter must be cleaned when the fine

using manhole segments and other prefabricated sand becomes clogged, which is measured by the

cylindrical products, such as filter vessels. head loss. The length of time between cleanings

can range from several weeks to a year, depending

Slow sand filter pilot facilities operate over long on the raw water quality. The operator cleans

periods of time—up to a year—but the level of the filter by scraping off the top layer of the filter

effort can be quite low, consisting of daily checks bed. A ripening period of one to two days is

of head loss, flow rate, water temperature, and required for scraped sand to produce a functioning

turbidity and taking coliform samples. biological filter. The filtered water quality is poor

during this time and should not be used.

Since the purification mechanism in a slow sand

filter is essentially a biological process, its efficiency In some small slow sand filters, geotextile filter

depends upon a balanced biological community material is placed in layers over the surface. In this

in the schmutzdecke. Therefore, filters should cleaning method, the operator can remove a layer

operate at a constant rate. When operation is of filter cloth periodically so that the upper

stopped, the microorganisms causing bacterio- sand layer requires less frequent replacement.

logical degradation of trapped impurities lose their

effectiveness. Intermittent operation disturbs the In climates subject to below-freezing temperatures,

continuity needed for efficient biological activity. slow sand filters usually must be housed.

Uncovered filters operating in harsh climates

Allowing the filter to operate at a declining rate develop an ice layer that prevents cleaning. Thus,

is one way of overcoming this problem. Declining they will operate effectively only if turbidity levels

rate filtration produces additional water, which is of the influent are low enough for the filter to

generally satisfactory. Moreover, the declining-rate operate through the winter months without cleaning.

mode may be applied during overnight operation, In warm climates, a cover over the slow sand filter

resulting in significant labor savings. may be needed to reduce algae growth within

the filter.

Storing filtered water is essential at a slow sand

filter plant for two reasons. First, because of the Before cleaning a slow sand filter, the operator

importance of establishing biological activity, should remove floating matter, such as leaves

using chlorine ahead of the filter is inappropriate, and algae. When one unit is shut down for

and the operator must provide disinfectant cleaning, the others are run at a slightly higher

contact time in a storage basin. Second, storage rate to maintain the plant output.

Design Summary of a Slow Sand Filter

TABLE 2

Design parameters es

Recommended range of values

Filtration rate 0.15 m3/m2•h (0.1–0.2 m3/m2•h)

Area per filter bed Less than 200 m2

(in small community water supplies to ease manual filter cleaning)

Number of filter beds Minimum of two beds

Depth of filter bed 1 m (minmum of 0.7 m of sand depth)

Filter media Effective size (ES) = 0.15–0.35 mm; uniformity coefficient (UC) = 2-3

Height of supernatant water 0.7–1 m (maximum 1.5 m)

Underdrain system

PAGE

Standard bricks

Precast concrete slabs Generally no need for further hydraulic calculations

three

Precast concrete blocks with holes on the top

OF FOUR

Porous concrete

Perforated pipes (laterals and manifold type) Maximum velocity in the manifolds and in laterals = .3 m/s

Spacing between laterals = 1.5 m

Spacing of holes in laterals = 0.15 m

Size of holes in laterals =3 mm

Source: Vigneswaran, S. and C. Visvanathan. 1995

NATIONAL DRINKING WATER CLEARINGHOUSE

After cleaning, the unit is refilled with water American Water Works Association. 1994. Slow

through the underdrains. This water can be Sand Filtration: International Compilation on

obtained from an overhead storage tank or by Recent Scientific and Operational Developments.

using water from an adjacent filter. When the Denver: American Water Works Association.

clearwell is designed, the temporary reduction

of plant output should be considered, ensuring Clark, R. M., and D. A. Clark. 1995. Drinking

that sufficient water is available for the users. Water Quality Management. Lancaster,

Pennsylvania: Technomic Publishing Company.

Once the filter is cleaned, the microorganisms

usually re-establish and produce an acceptable Collins, M. R. 1998. “Assessing Slow Sand

effluent. In cooler areas, ripening may take a Filtration and Proven Modifications.’’ In Small

few days. Even then, if the effluent’s turbidity is Systems Water Treatment Technologies: State of

sufficiently low, the water supply can be resumed the Art Workshop. NEWWA Joint Regional

after one day with adequate chlorination. Operations Conference and Exhibition.

Marlborough, Massachusetts.

Slow sand filter monitoring and operation is not

complicated. Daily tasks include reading and National Research Council. 1997. Safe Water

recording head loss, raw and filtered water tur- from Every Tap: Improving Water Services to

bidity, flow rates, and disinfectant residual. If Small Communities. Washington, D.C.: National

necessary, the operator should adjust the flow to Academy Press.

bring water production in line with demand.

U.S. Environmental Protection Agency.1990.

In addition, with the promulgation of the Environmental Pollution Control Alternatives:

Surface Water Treatment Rule, each day the Drinking Water Treatment for Small

operator needs to use the flow data and disin- Communities. Washington, D.C.: Office of

fectant residual data to calculate contact time Water. EPA/625/5-90/025

values and determine if disinfection is suffi-

ciently rigorous. These duties may require one U.S. Environmental Protection Agency. 1998.

to two hours unless automated. Small System Compliance Technology List for

the Surface Water Treatment Rule and Total

Where can I find more information? Coliform Rule. Washington, D.C.: Office of

American Water Works Association. 1993. Back Water. EPA/815/R/98/001.

to Basics Guide to Slow Sand Filtration. Denver:

American Water Works Association. Vigneswaran, S. and C. Visvanathan.1995.

Water Treatment Processes: Simple Options.

Have you read all our Tech Briefs?

“Tech Briefs,’’ drinking water treatment fact sheets have been a regular feature in the National

Drinking Water Clearinghouse (NDWC) newsletter On Tap for more than four years. NDWC

Technical Assistance Specialist Mohamed Lahlou, Ph.D., researches, compiles information, and

writes these very popular items.

To order, call the NDWC at (800) 624-8301 or (304) 293-4191. You may also order online at

ndwc_orders@mail.estd.wvu.edu or download fact sheets from our Web site at www.ndwc.wvu.edu.

OF FOUR

Additional copies of fact sheets are free; however, postal charges may be added.

For further information, comments about this fact sheet, or to suggest topics, call Dr. Lahlou at

four one of the above numbers or contact him via e-mail at mlahlou2@wvu.edu.

PAGE

FOURTEEN• JUNE 2000

You might also like

- VW EnginesDocument48 pagesVW Engines08088338100% (4)

- Irrigation DesignDocument45 pagesIrrigation Designjose03No ratings yet

- Ankit Akela Minor ProjectDocument34 pagesAnkit Akela Minor ProjectAnkit TuranNo ratings yet

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsFrom EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsNo ratings yet

- Hospital Waste Water TreatmentDocument5 pagesHospital Waste Water TreatmentNP100% (1)

- Flygt IOM 3153-095Document72 pagesFlygt IOM 3153-095jose03No ratings yet

- Sanitation Module - IndiaDocument48 pagesSanitation Module - IndiaHarish BabuNo ratings yet

- 04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFDocument8 pages04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFVic KeyNo ratings yet

- MF Uf NFDocument69 pagesMF Uf NFNguyen Huu HieuNo ratings yet

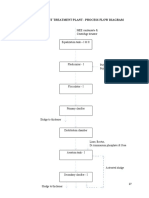

- Effluent Treatment Plant - Process Flow DiagramDocument45 pagesEffluent Treatment Plant - Process Flow DiagramAmarnath PNo ratings yet

- Chapter 4.4 - Preliminary-Primary Treatment (WW)Document32 pagesChapter 4.4 - Preliminary-Primary Treatment (WW)Siti Nurain mustafa kamal100% (1)

- Physico-Chemical Wastewater Treatment IntroductionDocument27 pagesPhysico-Chemical Wastewater Treatment IntroductionmsinsigneNo ratings yet

- Ate Huber-1Document47 pagesAte Huber-1Ravena RemaditaNo ratings yet

- ActivateSludgeVS Membrane Reactor SLIDEDocument36 pagesActivateSludgeVS Membrane Reactor SLIDEsebascian100% (2)

- Rapid Sand FiltrationDocument16 pagesRapid Sand FiltrationNurul ShafinazNo ratings yet

- Tertiary TreatmentDocument45 pagesTertiary TreatmentsunitaudayNo ratings yet

- Microsoft Word - Festo Rain Water Harvesting Flow ChartDocument5 pagesMicrosoft Word - Festo Rain Water Harvesting Flow Chartjeykumar.BalannairNo ratings yet

- Water Treatment Plant Performance Evaluations and OperationsFrom EverandWater Treatment Plant Performance Evaluations and OperationsNo ratings yet

- Sand FiltrationDocument5 pagesSand FiltrationMa Vichelle Torrejos-UyNo ratings yet

- Active Sludge PDFDocument8 pagesActive Sludge PDFDark_KiroNo ratings yet

- N Removal: CIE4485 Laboratory ExperimentDocument13 pagesN Removal: CIE4485 Laboratory ExperimentAbass MarrakchiNo ratings yet

- Chapter 4C Wastewater Treatment 3 (Disinfection and Sludge Treatment of WW) PDFDocument52 pagesChapter 4C Wastewater Treatment 3 (Disinfection and Sludge Treatment of WW) PDFFrancis TiehNo ratings yet

- Bio-Degradation of The Pollutant Components. It Is An Integral Part of Most Biological WastewaterDocument2 pagesBio-Degradation of The Pollutant Components. It Is An Integral Part of Most Biological Wastewaterglo lipaodNo ratings yet

- Optimisation - of - Water Treatment SystemDocument49 pagesOptimisation - of - Water Treatment SystemChijioke ObiNo ratings yet

- Rapid Sand Filter and Tube SettlersDocument16 pagesRapid Sand Filter and Tube Settlersnp27031990No ratings yet

- Lecture 7 DisinfectionDocument31 pagesLecture 7 DisinfectionSgakilNo ratings yet

- Trickling FilterDocument7 pagesTrickling FilterTasirmistNo ratings yet

- Training Manual For Water TreatmentDocument181 pagesTraining Manual For Water Treatmentmuhammad abdulrehman100% (1)

- Liquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentFrom EverandLiquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentNo ratings yet

- Filtration Process DescriptionDocument4 pagesFiltration Process DescriptionJoy Das MahapatraNo ratings yet

- Design ManualDocument8 pagesDesign ManualIrvin jose100% (1)

- 7.operational Problems PDFDocument42 pages7.operational Problems PDFDeva VaraNo ratings yet

- DesignDocument3 pagesDesigntata_77No ratings yet

- Wastewater TreatmentDocument25 pagesWastewater TreatmentLTE002No ratings yet

- Lamella Clarifier Leopold TexlerDocument4 pagesLamella Clarifier Leopold TexlerAntony ThanosNo ratings yet

- Design of Arraba Waste Water Treatment Plant: Prepared By: Waleed Rahhal Hamed Daghles Saleh Abdel-RhmanDocument47 pagesDesign of Arraba Waste Water Treatment Plant: Prepared By: Waleed Rahhal Hamed Daghles Saleh Abdel-RhmanMOHAMMED ABBAS NAJI MAALANo ratings yet

- Bar Screen-Grit ChamberDocument10 pagesBar Screen-Grit ChamberRaja Mani100% (1)

- Lesson 17 - Activated SludgeDocument8 pagesLesson 17 - Activated SludgeShane RodriguezNo ratings yet

- Waste Water EngineeringDocument65 pagesWaste Water EngineeringAjit DyahadrayNo ratings yet

- Uf System Operation Instruction-CrefluxDocument6 pagesUf System Operation Instruction-CrefluxLuis RamirezNo ratings yet

- Design of A Filtration System For A Small Scale Water Treatment Plant For A Rural Community Around Maiduguri Area in Borno State, NigeriaDocument5 pagesDesign of A Filtration System For A Small Scale Water Treatment Plant For A Rural Community Around Maiduguri Area in Borno State, NigeriainventionjournalsNo ratings yet

- Activated Sludge ProcessDocument10 pagesActivated Sludge ProcessSai Raghava Rajeev100% (1)

- List of SymbolsDocument11 pagesList of SymbolsKaarthic EmayNo ratings yet

- Operation and Control of STPDocument11 pagesOperation and Control of STPHari Krishna.MNo ratings yet

- CH 4 Sewage TreatmentDocument134 pagesCH 4 Sewage TreatmentGetu BogaleNo ratings yet

- Mohammed Saleh - STOAT ASM - Simulation Model of Wastewater Treatment ProcessesDocument104 pagesMohammed Saleh - STOAT ASM - Simulation Model of Wastewater Treatment ProcessesAnish Ghimire100% (1)

- A Study On Industrial Waste Effluents and Their Management at Selected Food and Beverage Industries of BangladeshDocument5 pagesA Study On Industrial Waste Effluents and Their Management at Selected Food and Beverage Industries of BangladeshAbiodun GbengaNo ratings yet

- 6.large Submersible Centrifugal PumpsDocument16 pages6.large Submersible Centrifugal PumpsOzren DjuricNo ratings yet

- EE-2 Mini Project ReportDocument7 pagesEE-2 Mini Project Report63GANESH SINGHCIVILNo ratings yet

- Dual MediaDocument12 pagesDual MediaPraveen Kesavan NairNo ratings yet

- Wastewater Treatment Plants (WWTP) : General Flow Diagram For The Wastewater Treatment PlantDocument12 pagesWastewater Treatment Plants (WWTP) : General Flow Diagram For The Wastewater Treatment PlantAhmed AmediNo ratings yet

- Principles of Sewage TreatmentDocument64 pagesPrinciples of Sewage TreatmentfelipeNo ratings yet

- Sanitiare ICEAS SBR BrochureDocument12 pagesSanitiare ICEAS SBR BrochureleommsouzaNo ratings yet

- STP PDFDocument16 pagesSTP PDFhumaidjafriNo ratings yet

- Formation Filtres Leopold (Xylem) PDFDocument40 pagesFormation Filtres Leopold (Xylem) PDFManoakiNo ratings yet

- Cost Analysis of Activated Sludge ProcessDocument19 pagesCost Analysis of Activated Sludge ProcessDevendra Sharma100% (1)

- Shortcut Nitrogen Removal-Nitrite Shunt and DeammonificationFrom EverandShortcut Nitrogen Removal-Nitrite Shunt and DeammonificationNo ratings yet

- Vatropromet Fire Twin ToughDocument2 pagesVatropromet Fire Twin Toughjose03No ratings yet

- Intervencijsko Odijelo Fire Breaker Airlock BrosuraDocument2 pagesIntervencijsko Odijelo Fire Breaker Airlock Brosurajose03No ratings yet

- Potopna Crpka PEDROLLO VXC Vortex BrosuraDocument4 pagesPotopna Crpka PEDROLLO VXC Vortex Brosurajose03No ratings yet

- Potopna Crpka PEDROLLO ZX Vortex BrosuraDocument4 pagesPotopna Crpka PEDROLLO ZX Vortex Brosurajose03No ratings yet

- Potopna Crpka PEDROLLO VX 1 Vortex BrosuraDocument4 pagesPotopna Crpka PEDROLLO VX 1 Vortex Brosurajose03No ratings yet

- Potopna Crpka PEDROLLO Top Floor BrosuraDocument4 pagesPotopna Crpka PEDROLLO Top Floor Brosurajose03No ratings yet

- Potopna Crpka PEDROLLO MC I Double Channel BrosuraDocument4 pagesPotopna Crpka PEDROLLO MC I Double Channel Brosurajose03No ratings yet

- Separation Using Foaming TechniquesDocument17 pagesSeparation Using Foaming Techniquesjose03No ratings yet

- 208 New CodesDocument5 pages208 New Codesjose03No ratings yet

- Seijsener Marina Services Brochure LLR ENGELSDocument23 pagesSeijsener Marina Services Brochure LLR ENGELSjose03No ratings yet

- Instruction ManualDocument250 pagesInstruction Manualjose03No ratings yet

- Multiple States in Open Channel Flow: A. Defina & F.M. SusinDocument26 pagesMultiple States in Open Channel Flow: A. Defina & F.M. Susinjose03No ratings yet

- CD T.PM 04.15 Lackey PDFDocument10 pagesCD T.PM 04.15 Lackey PDFjose03No ratings yet