Professional Documents

Culture Documents

IA/PA Compressors Alarm and Trip Settings

Uploaded by

Junaid Baig0 ratings0% found this document useful (0 votes)

37 views2 pagesAlarms Trips

Original Title

Ia-pa Compressors Alarm & Trips

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAlarms Trips

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

37 views2 pagesIA/PA Compressors Alarm and Trip Settings

Uploaded by

Junaid BaigAlarms Trips

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

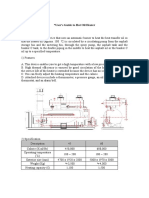

IA/PA COMPRESSORS ALARM AND TRIP SETTINGS

IA/PA Compressors = CIK-1011A/B/S

Important Parameters

Capacity of each compressor = 2100m3//h

No. of Compressors = 3

1st stage pressure = 1.7-2.6 bar

Inter-stage safety valve is set at 3.1barg (45psi) for 90-150KW compressors and 3.8 barg for

200-300 KW compressors.

2nd stage safety valve is set at 11.4 barg (165psi) max.

Currently compressor B is on load and A is on loading/unloading mode, and S is on auto restart.

Condensate Drain valve operates = after 180 seconds

Condensate Drain Valve keeps open = about 20 seconds

ALARMS & TRIPPING

1. IA/PA Compressors (CIK-1011A/B/S)

The IA/PA compressors alarm and tripping settings are following

1st stage outlet temperature ≥ 200oC (Trip)

(Normal Value = 170-185oC)

2nd stage outlet temperature ≥ 240oC (Trip)

(Normal Value = 200-210oC)

(The 1st and 2nd stage trip value temperatures can be set manually according to the

ambient conditions, for example in summer the cooling water supply temp. may

increase and less cooling effect is expected in the compressor and air temp. may

increase slightly above than normal, so set point may be increased so that

compressor won’t trip due to high temperature)

FLA =

(Normal running Amperes = 399-410A)

Bearing Oil Temperature ≥ 76oC (Trip)

(Normal bearing Temp = 55-65oC)

Bearing Oil Pressure ≤ 2.2 bar (Trip)

(Normal Bearing oil Pressure Value = 4.0-5.5 bar)

Air Filter ∆P ≥ 0.65 bar (Trip)

(Normal value of air filter ∆P = 0.02 bar)

Oil Filter ∆P = ??

(Actually there is no tripping on high differential pressure across oil filter because

if the filter chokes then the outlet bearing oil pressure decreases and there is

already tripping on low oil pressure, see point 5 above)

You might also like

- Thermoking Engine SpecsDocument6 pagesThermoking Engine SpecsMark Dwayne Fulmer75% (4)

- Basic Refrigeration TheoryDocument30 pagesBasic Refrigeration TheoryRich Foster100% (1)

- Sootblowing Sequence & TroubleshootingDocument4 pagesSootblowing Sequence & TroubleshootingJunaid BaigNo ratings yet

- Turbine Rolling ProceduresDocument15 pagesTurbine Rolling ProceduresAkhilesh VijayaKumar100% (2)

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Komatsu PC400LC-7L A86001 TESTDocument408 pagesKomatsu PC400LC-7L A86001 TESTHai Van100% (2)

- Presentation On Turbine Protection System: Prepared by Subir BiswasDocument29 pagesPresentation On Turbine Protection System: Prepared by Subir BiswasJitu Jena100% (2)

- SLAD-MXf ManualDocument10 pagesSLAD-MXf ManualReiky Aji ShaputraNo ratings yet

- Ariel compressor instrumentation requirementsDocument8 pagesAriel compressor instrumentation requirementsFaisal NaeemNo ratings yet

- Start Up SequenceDocument4 pagesStart Up Sequenceajieakbar1No ratings yet

- Duties & Responsibilities of Shift EngineerDocument35 pagesDuties & Responsibilities of Shift EngineerNaveen ChodagiriNo ratings yet

- Dana TE27/TE32 transmission operation and check portsDocument32 pagesDana TE27/TE32 transmission operation and check portsmouloudNo ratings yet

- Stage-I ALARMSDocument73 pagesStage-I ALARMSNikhilNo ratings yet

- Reasons Burners Trip and Purging RequirementsDocument2 pagesReasons Burners Trip and Purging RequirementsJunaid BaigNo ratings yet

- Design of CFBC BoilerDocument86 pagesDesign of CFBC Boilerhalder.kalyan88% (8)

- Design of CFBC BoilerDocument86 pagesDesign of CFBC Boilerhalder.kalyan88% (8)

- Main Turbine: 1 General LayoutDocument16 pagesMain Turbine: 1 General LayoutPrakash Choudhary100% (1)

- Presentation On Steam Turbine Operation by S ChandDocument36 pagesPresentation On Steam Turbine Operation by S Chandsomyaranjan das100% (1)

- Control Loop PresentationDocument169 pagesControl Loop Presentationrbdubey2020100% (1)

- API - Solid Bed AdsorbersDocument70 pagesAPI - Solid Bed AdsorbersJunaid BaigNo ratings yet

- Procedure of Turbine Cold Startup?Document3 pagesProcedure of Turbine Cold Startup?sunil601100% (1)

- Turbine Rolling-Tiroda PDFDocument11 pagesTurbine Rolling-Tiroda PDFs91No ratings yet

- GT 5-8 Alarm Trip ListDocument3 pagesGT 5-8 Alarm Trip Listmuddasirmasood100% (1)

- Working Guide to Reservoir Rock Properties and Fluid FlowFrom EverandWorking Guide to Reservoir Rock Properties and Fluid FlowRating: 3 out of 5 stars3/5 (1)

- Air Compressor ZR 160Document20 pagesAir Compressor ZR 160kattukoluNo ratings yet

- Er 56 07Document8 pagesEr 56 07Camilo Andres Cardozo FajardoNo ratings yet

- Spesification 3500 Diesel EngineCommissioningDocument3 pagesSpesification 3500 Diesel EngineCommissioningferyNo ratings yet

- 7 - Operating 2Document14 pages7 - Operating 2agvassNo ratings yet

- AE Parameter ListDocument1 pageAE Parameter ListGaby CrisNo ratings yet

- Protect From Prov. Ref. Compressor Damage-Rev1Document2 pagesProtect From Prov. Ref. Compressor Damage-Rev1Muhammed RiazNo ratings yet

- Instrumentation: TABLE 1 Required Instrumentation SummaryDocument8 pagesInstrumentation: TABLE 1 Required Instrumentation SummarySamir ELNo ratings yet

- Adani Power Limited: Rolling and Synchronising Check List For 660MW Steam Turbo GeneratorDocument4 pagesAdani Power Limited: Rolling and Synchronising Check List For 660MW Steam Turbo GeneratorBryan ScofieldNo ratings yet

- OSNA8571 R717 t0 - 33 TC 32Document5 pagesOSNA8571 R717 t0 - 33 TC 32Rajkumar GulatiNo ratings yet

- Instrument ListDocument3 pagesInstrument ListHADI JALILINo ratings yet

- Pirith PothaDocument3 pagesPirith PothaAmila Viraj Gunarathna100% (2)

- Gas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyDocument3 pagesGas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyEzequiel Juarez BenítezNo ratings yet

- Settings and LimitsDocument3 pagesSettings and LimitsmuddasirmasoodNo ratings yet

- SG653PB1 ADocument5 pagesSG653PB1 ADANILO MEDINA OSORIONo ratings yet

- Boiler Light Up & LoadingDocument13 pagesBoiler Light Up & Loadingsameer betalNo ratings yet

- Overload y CapacitoresDocument30 pagesOverload y Capacitores100046384No ratings yet

- Tgturbine 120919042138 Phpapp02Document14 pagesTgturbine 120919042138 Phpapp02maneesh_03No ratings yet

- 201.21-NM3 (LS02)Document2 pages201.21-NM3 (LS02)Qasir MughalNo ratings yet

- Testing and Adjusting AC CaterpillarDocument3 pagesTesting and Adjusting AC CaterpillarGerald BoyNo ratings yet

- Guide to Operating a Hot Oil HeaterDocument9 pagesGuide to Operating a Hot Oil HeatershadowNo ratings yet

- 4CES-9 R404A t0 - 7 TC 45Document4 pages4CES-9 R404A t0 - 7 TC 45Tedy ChriswandaNo ratings yet

- EmergencyDocument24 pagesEmergencySanjeevImproveNo ratings yet

- 17-19Document58 pages17-19RusonegroNo ratings yet

- Selection: Semi-Hermetic Reciprocating Compressors: Input ValuesDocument5 pagesSelection: Semi-Hermetic Reciprocating Compressors: Input ValuesoozNo ratings yet

- Customer: HVN Type: A330 Rev. Date: Oct 01/11 Manual: AMM Selected Effectivity: ALL 71-00-00-860-817-A - Engine Operation Limits and GuidelinesDocument7 pagesCustomer: HVN Type: A330 Rev. Date: Oct 01/11 Manual: AMM Selected Effectivity: ALL 71-00-00-860-817-A - Engine Operation Limits and GuidelinesLê Viết DũngNo ratings yet

- Maintenance Manual Ver 2Document44 pagesMaintenance Manual Ver 2Амурдеталь БлаговещенскNo ratings yet

- 06 ARO103 - Jet - Engine - Laboratory - Spring - 2010-Rev1xDocument16 pages06 ARO103 - Jet - Engine - Laboratory - Spring - 2010-Rev1xNatallia NatalliaNo ratings yet

- Spec EngineDocument1 pageSpec EnginemannaihegbaaNo ratings yet

- 19xrt CarrierDocument12 pages19xrt CarrierSuretodoNo ratings yet

- Aph Idf FDF PafDocument44 pagesAph Idf FDF Pafari wibowoNo ratings yet

- HRSGDocument4 pagesHRSGnivasssvNo ratings yet

- Compressed Air SystemDocument29 pagesCompressed Air Systemsk sajidNo ratings yet

- Spesifikasi Atlas Copco ZT 30Document5 pagesSpesifikasi Atlas Copco ZT 30Fithrul MubarokNo ratings yet

- 5 AccDocument11 pages5 AccdazcornishNo ratings yet

- L150G Volvo transmission specificationsDocument2 pagesL150G Volvo transmission specificationsHendry PardedeNo ratings yet

- Ficha Técnica CompresorDocument4 pagesFicha Técnica CompresorPaulo Aparicio PortugalNo ratings yet

- Performance Data: 345 1 BB, BCDocument2 pagesPerformance Data: 345 1 BB, BCtexwan_No ratings yet

- DCS_interlocks DH jhdDocument23 pagesDCS_interlocks DH jhdPrdptiwariNo ratings yet

- How Does A Refrigerated Air Dryer WorkDocument4 pagesHow Does A Refrigerated Air Dryer WorkSteven Louie HungNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- PumpDocument161 pagesPumpbharatonkarNo ratings yet

- FBC Boilers: Syllabus FBC Boilers: Introduction, Mechanism of Fluidized Bed Combustion, AdvantagesDocument12 pagesFBC Boilers: Syllabus FBC Boilers: Introduction, Mechanism of Fluidized Bed Combustion, AdvantagesTejas T S TejasNo ratings yet

- API - Gas Measurement (Unit 1,2) PDFDocument88 pagesAPI - Gas Measurement (Unit 1,2) PDFJunaid Baig100% (1)

- Service Air For Boiler Unit 1Document2 pagesService Air For Boiler Unit 1Junaid BaigNo ratings yet

- API - Furnace Operation (Unit 1,2,3,4)Document1 pageAPI - Furnace Operation (Unit 1,2,3,4)Junaid BaigNo ratings yet

- Service Air For Boiler Unit 1Document2 pagesService Air For Boiler Unit 1Junaid BaigNo ratings yet

- Industrial WaterDocument3 pagesIndustrial WaterJunaid BaigNo ratings yet

- Boiler 1 Machines MTR Logic ReviewDocument7 pagesBoiler 1 Machines MTR Logic ReviewJunaid BaigNo ratings yet