Professional Documents

Culture Documents

Cyclone Separators

Cyclone Separators

Uploaded by

anshika7900 ratings0% found this document useful (0 votes)

4 views2 pagesCyclone Separator for hydro power application Filteration Engineers India Pvt Ltd Design

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCyclone Separator for hydro power application Filteration Engineers India Pvt Ltd Design

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views2 pagesCyclone Separators

Cyclone Separators

Uploaded by

anshika790Cyclone Separator for hydro power application Filteration Engineers India Pvt Ltd Design

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Uncompromised

Quality.

FEIPL Cyclone Separators

Cyclone Seperator, Sand Seperator & Centifugal Seperator

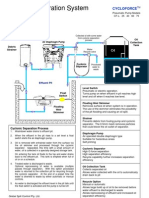

Cyclone Separators (Sand Separators) are used for separation of sand silica collection chamber which allows dirt to settle in the chamber. The drain is

like high density particles from water. Minimum operating pressure of 2 provided with electrical or pneumatic valve and a small control panel with

kg/cm2 is required for smooth functioning as these cyclones work on a timer at bottom.

centrifugal motion, for which positive operating pressure is required. It is a static equipment apart from motorized valve at the bottom. There is

Tangential entry is provided at the inlet which allows water to enter in no mechanical barrier hence there is no maintenance required. The drain

cyclonic motion. Also inside the vessel particular type of slotted pipe is valve timer is normally set between 30 to 60 seconds, duration depends on

provided which further accelerates the velocity resulting in heavier the dirt load. There is a normal pressure drop at the inlet and outlet of 0.2

particles falling at the bottom. Water being of lighter density exit from the to 0.3 kg/cm2 and as there is no blockage or choking, the pressure drop

outlet at the top. The bottom has a diverter plate with wave breakers in the remains continuous during operation.

Applications of Separators: 7 Outlet

Source Water Intake

Deep wells, surface water lakes, rivers, seawater, fire

protection system in oil jetties / refineries, injection

2

water pre-filteration in oil production. 1 Liquid/Sold enters

Liquid/Solid enters

tangentially

through tangential

Circulation Processes Sets up circular ow

slots

Before cooling towers, air conditioning systems and Accelerates into

separation chamber

heat exchangers, before oil water separators, before

membrane RO, before and after sand filter, before

3 Centrifugal force throws

cartridge and bag filters, protection of spray nozles particles heavier than

in all operations, protection of pumps. liquid into the wall of

the chamber Centrifugal

force throws particles

Degreasing Baths heavier than liquid into

Pump Protection 5

the wall of the chamber

Automative Industry 4 Particle drops in

Solid free liquid is

Coolant Filtration drawn to separator’s

central chamber due

vortex and up

In all grinding operation, motor parts, axles, shafts. to gravity

through separator

outlet

Waste Filters

Removal of sand out of sewage systems / overow 6 Solids accumulated are

purged at regular intervals

basins.

Refineries & Oils Production Purge

Fire fighting systems, mantle cooling of cracking

installations, pipe line strainers removal of sand & We are your

grit after three phase separators, protection of

motor driven centrifuges.

Sugar Industry Power Plants

Quality Partners.

Removal of cakes, particles, cooling water filtration,

cooling sump cleaning.

www.feipl.com

Cyclone Separators

Advantage

Very easy to install.

Low pressure drop.

No need for any by-pass which reduces the installation cost.

Very low water loss during cleaning.

No cost for general or periodical maintenance

Separators

Un-interruption of ow during the purging.

No Change At The Flow- Rate

Normally No Replacement of any Part Required

No Backushing

Available In Carbon Steel With Rubber Lining Strainer. Also

Can be Supplied for Food Sector.

Our Range 2 M3/h To 4500 M3/h

We are your

Quality Partners.

PERFORMANCE GRAPH

70 + microns 70 - 42 microns 42 - 22 microns

100

80

%

60

40

20

7.8 4.2 2.4 1.9 Sp. Gravity

Filteration Engineers

Plot W 62B, TTC Industrial Area, MIDC Rabale,

Navi Mumbai 400701 India.

Phone: +91 22 27608501 / 27693111

Email: sales@feipl.com

www.feipl.com

You might also like

- Problem Set 2 - Basic Calculations - SolutionsDocument3 pagesProblem Set 2 - Basic Calculations - SolutionsAshish KotwalNo ratings yet

- Lalpir Thermal Power Plant Internship ReportDocument38 pagesLalpir Thermal Power Plant Internship ReportKhawaja Muhammad MoinNo ratings yet

- Mil STD 278FDocument128 pagesMil STD 278Fexwhiskeyhouse100% (1)

- WEMCO Depurator MBLDocument6 pagesWEMCO Depurator MBLallen_renzi0% (1)

- Aldec 10+Document2 pagesAldec 10+epebeNo ratings yet

- I-P R10 Ch04Document9 pagesI-P R10 Ch04Prajin KundoorNo ratings yet

- Renk ManualDocument39 pagesRenk ManualIfnu Setyadi100% (3)

- Plumbing Design ChecklistsDocument25 pagesPlumbing Design ChecklistsParwez Khan50% (2)

- Preform Design For PET BottlesDocument4 pagesPreform Design For PET BottleseduardoNo ratings yet

- Alfa Laval DecanterDocument16 pagesAlfa Laval DecanterAKSHAY BHATKARNo ratings yet

- Alfa Laval Decanter PDFDocument16 pagesAlfa Laval Decanter PDFdaniel adamNo ratings yet

- Alfa Laval Decanter Centrifuge Technology PDFDocument14 pagesAlfa Laval Decanter Centrifuge Technology PDFLim Chee SiangNo ratings yet

- ClarifierDocument6 pagesClarifierrasithapradeepNo ratings yet

- Safegard Septic TanksDocument6 pagesSafegard Septic TankscivilaskarNo ratings yet

- Volute Dewatering PressDocument4 pagesVolute Dewatering PressCaio NunesNo ratings yet

- Wet Scrubber: We Make Air Work For YouDocument14 pagesWet Scrubber: We Make Air Work For YouvanyoNo ratings yet

- Absolute Separators - GasDocument2 pagesAbsolute Separators - GasPeterWangNo ratings yet

- Akvola Technologies Technology - WebDocument4 pagesAkvola Technologies Technology - WebHardik VavdiyaNo ratings yet

- Comparison of Centrifugal and Vane Gas Liquid SeparatorsDocument2 pagesComparison of Centrifugal and Vane Gas Liquid Separatorssaxadi4814No ratings yet

- Lecture-4 Drilling EngineeringDocument18 pagesLecture-4 Drilling Engineeringحيدر بادي - Haider BadiNo ratings yet

- 02 Complete Cleaning SolutionsDocument12 pages02 Complete Cleaning SolutionsGabriel T. BastosNo ratings yet

- VAF CatalogDocument8 pagesVAF Catalogjovski523No ratings yet

- Wilo Wastewater CollectionDocument12 pagesWilo Wastewater CollectionriyoprilianNo ratings yet

- HC Flow Diagram StandardDocument1 pageHC Flow Diagram Standardapi-3703371No ratings yet

- SERIES 7000 Paste Slakers: Fully Automated Lime Slaking SystemsDocument4 pagesSERIES 7000 Paste Slakers: Fully Automated Lime Slaking Systemssoumyarm942No ratings yet

- KSB DND Pump BrochureDocument12 pagesKSB DND Pump Brochureplantmusi2No ratings yet

- Or Series: Rivers WellsDocument4 pagesOr Series: Rivers Wellskresimir.mikoc9765No ratings yet

- ConthickDocument4 pagesConthickEray YILMAZNo ratings yet

- Corrugated Plate Separator (CPS) ForDocument2 pagesCorrugated Plate Separator (CPS) Formib_ajayNo ratings yet

- D EpuratorDocument6 pagesD EpuratorRodrigo HernandezNo ratings yet

- Pack RYTDocument41 pagesPack RYTGonzalo Alonso QuintanaNo ratings yet

- Side Stream Filter For Cooling TowersDocument4 pagesSide Stream Filter For Cooling TowersdkmauryaNo ratings yet

- Knock Out Drums and SeparatorsDocument2 pagesKnock Out Drums and SeparatorsAhmed RedaNo ratings yet

- Evaluation, Testing and Optimisation: Centrifuge FocusDocument3 pagesEvaluation, Testing and Optimisation: Centrifuge FocusCliver Santos Yupanqui MachacaNo ratings yet

- Alfa Laval Disc Stack Centrifuge TechonologyDocument8 pagesAlfa Laval Disc Stack Centrifuge TechonologyChaitanya B.AndhareNo ratings yet

- Parabolic Screen Sps2Document2 pagesParabolic Screen Sps2MariusCapraNo ratings yet

- Evaporator Automatic Tube Cleaning System For Multi Effect Evaporator Waste Water Treatment PlantDocument5 pagesEvaporator Automatic Tube Cleaning System For Multi Effect Evaporator Waste Water Treatment PlantIynulF.OmarNo ratings yet

- Manual On Industrial WaterDocument30 pagesManual On Industrial WaterAndrea GonzalezNo ratings yet

- LemitecDocument4 pagesLemitecjose restrepoNo ratings yet

- Separador Agua/aceite SullairDocument4 pagesSeparador Agua/aceite SullairFrancisco QuirozNo ratings yet

- Alfa Laval Disc Stack Separator Technology PDFDocument16 pagesAlfa Laval Disc Stack Separator Technology PDFYurizki LhzNo ratings yet

- UT OCT2011 LowDocument2 pagesUT OCT2011 LowEdison BladimirNo ratings yet

- Sutherland 2005Document5 pagesSutherland 2005Cliver Santos Yupanqui MachacaNo ratings yet

- Rotary Screen Rs Rc2Document3 pagesRotary Screen Rs Rc2MariusCapraNo ratings yet

- HC Flow DiaDocument1 pageHC Flow Diaapi-3703371No ratings yet

- Hydrocyclone Bulletin PDFDocument2 pagesHydrocyclone Bulletin PDFabdou boudifaNo ratings yet

- Separation Process in Oil and Gas - Part-2 by Anand PatelDocument10 pagesSeparation Process in Oil and Gas - Part-2 by Anand PatelAbderrahmane AbderrahmaniNo ratings yet

- Manual Flygt-SERIE-5000Document7 pagesManual Flygt-SERIE-5000Fredy NoalcaNo ratings yet

- Hydraulic Filter CartDocument3 pagesHydraulic Filter CartyovannyNo ratings yet

- AFP FilterPress Brochure PDFDocument4 pagesAFP FilterPress Brochure PDFMilan SjausNo ratings yet

- CDS Presentation 11-14-02aDocument60 pagesCDS Presentation 11-14-02adoraq7975No ratings yet

- BMV Brochure 4 Page Web - 2019Document4 pagesBMV Brochure 4 Page Web - 2019Velibor StokicNo ratings yet

- MVR MSFDocument2 pagesMVR MSFBaba DookNo ratings yet

- Vac-U-Dry: FiltrationDocument8 pagesVac-U-Dry: FiltrationNguyenloc2909No ratings yet

- Float Purger Stock Cleaning SystemDocument4 pagesFloat Purger Stock Cleaning SystemoswaldoNo ratings yet

- Bulk Storage Transfer Equipment PsDocument1 pageBulk Storage Transfer Equipment Psalvaro netoNo ratings yet

- Edible Oil Centrifuges 9997 1711 010Document6 pagesEdible Oil Centrifuges 9997 1711 010JerryChenNo ratings yet

- Report Separations FinalDocument6 pagesReport Separations FinalBrian MasauliNo ratings yet

- Volute Dewatering PressDocument4 pagesVolute Dewatering PressPj EboraNo ratings yet

- Gas - Oil Separator 8.1 Mechanical Separation, Thermodynamic TransientsDocument33 pagesGas - Oil Separator 8.1 Mechanical Separation, Thermodynamic TransientsDaniel ChiriacNo ratings yet

- Sedimentation PDFDocument1 pageSedimentation PDFsara25dec689288No ratings yet

- Datasheet ES094 1040 ENDocument6 pagesDatasheet ES094 1040 ENPhamvandong TincayNo ratings yet

- Varnish Removal Unit VRU CJCDocument6 pagesVarnish Removal Unit VRU CJCeliasdavidferreiraNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Erection Testing and CommissioningDocument70 pagesErection Testing and CommissioninghaqjmiNo ratings yet

- 3.11 Operation and MaintenanceDocument22 pages3.11 Operation and MaintenanceIfnu SetyadiNo ratings yet

- Erection Sequence For GeneratorDocument2 pagesErection Sequence For GeneratorIfnu SetyadiNo ratings yet

- 3.10 Power EvacuationDocument63 pages3.10 Power EvacuationIfnu SetyadiNo ratings yet

- Standards/Manuals/ Guidelines For Small Hydro DevelopmentDocument30 pagesStandards/Manuals/ Guidelines For Small Hydro DevelopmentIfnu SetyadiNo ratings yet

- Planning & Design Minihydro Power PlantDocument16 pagesPlanning & Design Minihydro Power PlantIfnu SetyadiNo ratings yet

- Basic Knowledge Minihydro Power PlantDocument26 pagesBasic Knowledge Minihydro Power PlantIfnu SetyadiNo ratings yet

- 3.11 Operation and Maintenance PDFDocument95 pages3.11 Operation and Maintenance PDFIfnu SetyadiNo ratings yet

- Inspection of Steel Penstocks & Pressure Conduits Vol2-8Document43 pagesInspection of Steel Penstocks & Pressure Conduits Vol2-8Manmohit Singh67% (3)

- Instalasi Turbin IIDocument10 pagesInstalasi Turbin IIIfnu SetyadiNo ratings yet

- MHP Training Modul 1Document29 pagesMHP Training Modul 1Ifnu SetyadiNo ratings yet

- Zollern PlainBearing PDFDocument20 pagesZollern PlainBearing PDFIfnu SetyadiNo ratings yet

- Welded Steel PenstockDocument63 pagesWelded Steel PenstockIfnu Setyadi100% (1)

- Penstock Branch DesignDocument38 pagesPenstock Branch DesignIfnu Setyadi100% (7)

- Micro Hydro Engineering Procedure (PTEI '08) FDocument59 pagesMicro Hydro Engineering Procedure (PTEI '08) FIfnu Setyadi100% (2)

- Turbine ConstructionDocument30 pagesTurbine ConstructionIfnu Setyadi50% (4)

- Iso 8217Document10 pagesIso 8217Sumit SamaNo ratings yet

- 3.natural & Artifical Floor FinishesDocument17 pages3.natural & Artifical Floor FinishesHouwaNo ratings yet

- Kelmo Electric Actuator Driven Ball ValvesDocument32 pagesKelmo Electric Actuator Driven Ball ValvesenergetichiddenboyNo ratings yet

- RUJUKAN MS Spesifikasi Piawai Bekalan AirDocument6 pagesRUJUKAN MS Spesifikasi Piawai Bekalan AirEdison LimNo ratings yet

- Pre-Installation Manual: Standard Frequency Series GeneratorsDocument20 pagesPre-Installation Manual: Standard Frequency Series GeneratorsLuis Fernando Garcia SNo ratings yet

- Grounding Standards PDFDocument15 pagesGrounding Standards PDFBrett HendricksNo ratings yet

- MASTERFLEX 700i v4Document2 pagesMASTERFLEX 700i v4RUDRA KARMAKARNo ratings yet

- Concrete Manure TanksDocument4 pagesConcrete Manure Tanksshivas34regalNo ratings yet

- Adobe Scan Aug 17, 2023Document3 pagesAdobe Scan Aug 17, 2023gulatisrishti15No ratings yet

- Fringe EffectsDocument3 pagesFringe EffectsVishnu Vardhan ReddyNo ratings yet

- Types of Steam FlowmeterDocument20 pagesTypes of Steam FlowmeterLidijaSpaseskaNo ratings yet

- Price List Cleaning EquipmentDocument12 pagesPrice List Cleaning EquipmentAnonymous KbDwM2BNvNo ratings yet

- ValvesDocument108 pagesValvesGautam Wayse100% (1)

- Quakewrap B26G: The Infrastructure InnovatorsDocument2 pagesQuakewrap B26G: The Infrastructure Innovatorskhoirul ramadhanNo ratings yet

- Amdry - Activated Diffusion Braze AlloysDocument6 pagesAmdry - Activated Diffusion Braze AlloysJ. BangjakNo ratings yet

- Ingersoll Turning CatalogDocument366 pagesIngersoll Turning CatalogGilang RamadanNo ratings yet

- Pressure Systems Safety W/change 3 (6/28/2017) : Glenn Safety Manual - Chapter 7Document34 pagesPressure Systems Safety W/change 3 (6/28/2017) : Glenn Safety Manual - Chapter 7mhmshabanNo ratings yet

- Hydrodesulfurization Hds Unit 32 000 BPD 84Document1 pageHydrodesulfurization Hds Unit 32 000 BPD 84Jesus ToroNo ratings yet

- Slab Track DesignDocument107 pagesSlab Track DesignSivaneswaran Sabaratnam100% (2)

- Gluing of Ferrite CoresDocument14 pagesGluing of Ferrite CoresAshish KrishnaNo ratings yet

- Molecular Sieve Desiccant Dehydrator For Natural Gas: Bettis Model DD (Standard Service) Bettis Model DD-S (Sour Service)Document4 pagesMolecular Sieve Desiccant Dehydrator For Natural Gas: Bettis Model DD (Standard Service) Bettis Model DD-S (Sour Service)Alina SmochinaNo ratings yet

- Com Kitchen Plumbing Indirect Waste Fact Sheet 2205Document3 pagesCom Kitchen Plumbing Indirect Waste Fact Sheet 2205parelkidNo ratings yet

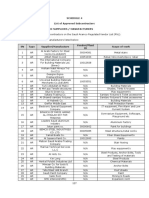

- List of Approved SubcontractorsDocument6 pagesList of Approved Subcontractorsmohammad abu alrubNo ratings yet

- Hydrocarbon Processing 03 2016 PDFDocument113 pagesHydrocarbon Processing 03 2016 PDFDivyesh Patel100% (1)

- Simple DistillationDocument6 pagesSimple DistillationAlfonso Dominguez GonzalezNo ratings yet

- Topic3 Lathe MachineDocument34 pagesTopic3 Lathe MachineLathaRajRajandrenNo ratings yet