Professional Documents

Culture Documents

"Weldgrp" - Weld Group Analysis Program

"Weldgrp" - Weld Group Analysis Program

Uploaded by

j_herndzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

"Weldgrp" - Weld Group Analysis Program

"Weldgrp" - Weld Group Analysis Program

Uploaded by

j_herndzCopyright:

Available Formats

"WELDGRP" --- WELD GROUP ANALYSIS PROGRAM

Program Description:

"WELDGRP" is a spreadsheet program written in MS-Excel for the purpose of analysis of weld groups using

either the ultimate strength method (also known as "instantaneous center of rotation" method) or the "elastic"

(vector) method ("Alternate Method 1" in AISC Manual). A separate worksheet contains data tables for welds.

This program is a workbook consisting of eleven (11) worksheets, described as follows: 1

Worksheet Name Description

Doc This documentation sheet

Table XIX Weld group instantaneous center analysis for vertical parallel welds

Table XX Weld group instantaneous center analysis for horizontal parallel welds

Table XXI Weld group instantaneous center analysis for vertical rectangular welds

Table XXII Weld group instantaneous center analysis for horizontal rectangular welds

Table XXIII Weld group instantaneous center analysis for C-shaped welds (case 1)

Table XXIV Weld group instantaneous center analysis for C-shaped welds (case 2)

Table XXV Weld group instantaneous center analysis for L-shaped welds (case1)

Table XXVI Weld group instantaneous center analysis for L-shaped welds (case 2)

Weld Group (elastic) Weld group elastic analysis for up to 24 total weld lines and 4 load points

Weld Data Fillet Weld Data Tables

Program Assumptions and Limitations:

1. The AISC eccentric loads on weld groups worksheets (Tables XX through XXVI, pages 4-75 through 4-82) are

applicable for only in-plane shear loads and torques (moments) on the weld group. With the one exception

being the "Special Case" of out-of-plane loading for vertical parallel welds, AISC Table XIX.

2. The "Weld Group (elastic)" worksheet can be used for all cases of in-plane and out-of-plane loads on the weld

group, or where geometry limitations of the AISC Tables XIX through XXVI are ecceeded. The "elastic" method

(AISC "Alternate" Method 1) will always give conservative results when compared to using the AISC Tables.

3. The "Weld Group (elastic)" worksheet assumes a minimum of 1 weld and a maximum of 24 welds in a group.

4. In the "Weld Group (elastic)" worksheet, the welds are treated as "lines" possessing a length, but no actual

theoretical thickness. All welds are assumed to contribute to the moment of inertia of the group, and the

applied loads are linearly distributed among the welds based on the location of the welds from the centroidal

axes.

5. In the "Weld Group (elastic)" worksheet, the weld group must be composed of straight lines/segments, but

they all need not be connected. Circular or portions of a circular pattern weld may be adequately modeled by

using a series of segments.

(Note: see below for an example of modeling a circular weld pattern.)

6. In the "Weld Group (elastic)" worksheet, each weld line/segment is defined by its own start (X1,Y1) and end

(X2,Y2) sets of coordinates. Coordinates defining weld lines/segments can be input irrespective of direction.

That is, a weld line/segment may be defined from left-to-right and top-to-bottom or vice-versa.

7. The "Weld Group (elastic)" worksheet assumes an orthogonal X-Y-Z coordinate system. All welds and loads

points MUST BE located in the "positive" (1st) quadrant. "Negative" weld or load point location

coordinates are NOT permitted. "Right-Hand-Rule" sign convention is used for all applied forces and moments

at load point locations.

8. In the "Weld Group (elastic)" worksheet, the welds and load points can be numbered in any desired order.

However, the user should make sure to either clear the contents of all spreadsheet cells that are not used for

input or those cell values should be input = 0. All welds and load points MUST BE input in proper numerical

You might also like

- Dokumen - Tips Introductory Quantum Mechanics Liboff Solutions For Introductory Quantum MechanicsDocument5 pagesDokumen - Tips Introductory Quantum Mechanics Liboff Solutions For Introductory Quantum MechanicsRehan Tariq50% (2)

- Terminal Velocity ExperimentDocument3 pagesTerminal Velocity ExperimentIsabelWadeson-Lee60% (5)

- Appendix D Review of Mechanics of Materials - 2009 - Elasticity Second Edition PDFDocument14 pagesAppendix D Review of Mechanics of Materials - 2009 - Elasticity Second Edition PDFJaimeNo ratings yet

- Duracell Charger Instructions CEF27NA3 ENDocument1 pageDuracell Charger Instructions CEF27NA3 ENgiv100% (1)

- WanklingDocument34 pagesWanklingKishore MylavarapuNo ratings yet

- Eccentric and Moment Connections (Fillet Weld) : DATE: 24-SEP-2020 Gurram Vinay (L&T Wet Ic (CMPC)Document6 pagesEccentric and Moment Connections (Fillet Weld) : DATE: 24-SEP-2020 Gurram Vinay (L&T Wet Ic (CMPC)vinayNo ratings yet

- Blodgett Welds LRFD ASDDocument2 pagesBlodgett Welds LRFD ASDManoj JaiswalNo ratings yet

- Handbook of Structural Stability Part V - Compressive Strength of Flat Stiffened PanelsDocument92 pagesHandbook of Structural Stability Part V - Compressive Strength of Flat Stiffened PanelsLucas RafaelNo ratings yet

- Mechanical Design Data BookDocument69 pagesMechanical Design Data Bookvenugopalmanga100% (1)

- Torsion of Noncircular Prismatic Bars - Extract From Craig Mechanics of MaterialsDocument5 pagesTorsion of Noncircular Prismatic Bars - Extract From Craig Mechanics of MaterialsAlmudena9No ratings yet

- Model A360 CatalogDocument12 pagesModel A360 CatalogThomas StempienNo ratings yet

- Effect of Bolt Pretension in Single Lap Bolted Joint IJERTV4IS010269Document4 pagesEffect of Bolt Pretension in Single Lap Bolted Joint IJERTV4IS010269ayush100% (1)

- 2 ToolsDocument83 pages2 ToolsKileta KafusiNo ratings yet

- Guide For Bolted Join Design and Analysis PernosDocument47 pagesGuide For Bolted Join Design and Analysis PernosjeremiasNo ratings yet

- Chapter 22 Welding Joint Design and SYMBOLSDocument67 pagesChapter 22 Welding Joint Design and SYMBOLSRiddhi SarvaiyaNo ratings yet

- Sigma Fasteners - Hex NutDocument9 pagesSigma Fasteners - Hex Nutdavorp1402No ratings yet

- Stepper Motor CatalogueDocument28 pagesStepper Motor CatalogueSuvek KumarNo ratings yet

- AISC Fillet WeldDocument2 pagesAISC Fillet WeldJonathan Schauder100% (1)

- 13 Symbols DrawingsDocument13 pages13 Symbols DrawingsAlie AlbantaniNo ratings yet

- Residual Stresses in Welded Shapes of Flame-Cut Plates in Astm A5Document52 pagesResidual Stresses in Welded Shapes of Flame-Cut Plates in Astm A5zhangjlNo ratings yet

- HSS Radius 742c7a4e 5e10 4b0b 8ba8 A8516cdafd9fDocument14 pagesHSS Radius 742c7a4e 5e10 4b0b 8ba8 A8516cdafd9fTerraManNo ratings yet

- Enerpac CLRG Series CatalogDocument4 pagesEnerpac CLRG Series CatalogTitanplyNo ratings yet

- NozzlePRO 14.1NewFeatures-2019ReleaseDocument13 pagesNozzlePRO 14.1NewFeatures-2019ReleasedelitesoftNo ratings yet

- D 2609 - 00 - Rdi2mdktukve PDFDocument5 pagesD 2609 - 00 - Rdi2mdktukve PDFAndre CasteloNo ratings yet

- J R Rice - Path Independentt Integral - JAM68Document8 pagesJ R Rice - Path Independentt Integral - JAM68CJCONSTANTENo ratings yet

- Chapter 2 - Drawing Sketches With Autodesk Inventor - 2024Document66 pagesChapter 2 - Drawing Sketches With Autodesk Inventor - 2024DINESH TIWARINo ratings yet

- Torsional Stress On TubeDocument7 pagesTorsional Stress On TubeEPCFirmNo ratings yet

- Span Tables For Simply Supported Composite BeamsDocument8 pagesSpan Tables For Simply Supported Composite BeamsDenise2512No ratings yet

- Mil HDBK 727Document569 pagesMil HDBK 727madhusoodhanan_ramNo ratings yet

- ARPCatalog PDFDocument128 pagesARPCatalog PDFAnonymous wpUyixsjNo ratings yet

- Dimension:: Blind RivetsDocument1 pageDimension:: Blind RivetsrimshadtpNo ratings yet

- Compressive Buckling of Simply Supported Plates With Longitudinal StiffenersDocument24 pagesCompressive Buckling of Simply Supported Plates With Longitudinal StiffenersRamesha AswathanarayanappaNo ratings yet

- CHAPTER 4: ISO Symbols: Print CloseDocument26 pagesCHAPTER 4: ISO Symbols: Print CloseSiong Wu SiewNo ratings yet

- The Basics of Bolted JointsDocument2 pagesThe Basics of Bolted Jointshitesh_tilalaNo ratings yet

- Asce 7 Wind ComparisonsDocument1 pageAsce 7 Wind ComparisonsHomer SilvaNo ratings yet

- Accurate Involute Gears in SolidWorks - Tom's Maker SiteDocument5 pagesAccurate Involute Gears in SolidWorks - Tom's Maker SiteGaurav GoelNo ratings yet

- POS CAL TP No10 Vb2 C200x80x7 - 5 CVR Bolt R0 20180731Document26 pagesPOS CAL TP No10 Vb2 C200x80x7 - 5 CVR Bolt R0 20180731Nguyễn Duy QuangNo ratings yet

- Fits Si Tables Ansi b4.2-1978 r1994 0Document10 pagesFits Si Tables Ansi b4.2-1978 r1994 0SebastiánGarcíaNo ratings yet

- Bolting and WeldingDocument73 pagesBolting and Weldinggerrydimayuga100% (2)

- Fea SR CouplingsDocument67 pagesFea SR CouplingsAna Isabel Aguilar ReyesNo ratings yet

- 格特威英文样本2018 PDFDocument56 pages格特威英文样本2018 PDFBinxiang XuNo ratings yet

- Toolbox Solidworks 2016Document53 pagesToolbox Solidworks 2016brpnaidu2157No ratings yet

- Stud Bolt Length For UploadDocument1 pageStud Bolt Length For UploadDan PastorNo ratings yet

- Limits of Size-Unified Screw ThreadsDocument7 pagesLimits of Size-Unified Screw Threadsxeron7126No ratings yet

- External Threads For Machine Screws and SEMSDocument2 pagesExternal Threads For Machine Screws and SEMSez1010No ratings yet

- Inertia Base FrameDocument2 pagesInertia Base FrameLasandu WanniarachchiNo ratings yet

- A Practical Design Guide For Welded Connections Basic Concepts and Weld SymbolsDocument20 pagesA Practical Design Guide For Welded Connections Basic Concepts and Weld Symbolsbs_facebookNo ratings yet

- Internal Gear Pump DesignDocument14 pagesInternal Gear Pump Designafriyan.inbox capcxNo ratings yet

- Beam DiagramsDocument7 pagesBeam Diagramscobradnf100% (1)

- Y14 32 1M 1994Document72 pagesY14 32 1M 1994deepdreamx6400No ratings yet

- Assembly of Screwed Fastenings: Preloads and Tightening Torque For Fasteners From SteelDocument1 pageAssembly of Screwed Fastenings: Preloads and Tightening Torque For Fasteners From SteelDani Quirante Flaaut EtcNo ratings yet

- Universal Beams and Columns Imperial UnitsDocument1 pageUniversal Beams and Columns Imperial UnitsPratama YogaNo ratings yet

- Connection Steel DesignDocument18 pagesConnection Steel DesignHalina HamidNo ratings yet

- Bossard Taptite Self Tapping Screw CatalogueDocument10 pagesBossard Taptite Self Tapping Screw CataloguepmlmkpNo ratings yet

- Limit States Design in Structural Steel: Eighth EditionDocument12 pagesLimit States Design in Structural Steel: Eighth EditionJesus OrtizNo ratings yet

- Welded Design Theory and Practice: John HicksDocument2 pagesWelded Design Theory and Practice: John HicksGhenoiu PaulNo ratings yet

- Weldgrp - Weld Group Analysis ProgramDocument16 pagesWeldgrp - Weld Group Analysis ProgramemoriderNo ratings yet

- Weldgrp - Weld Group Analysis ProgramDocument16 pagesWeldgrp - Weld Group Analysis ProgramnamasralNo ratings yet

- "Weldgrp" - Weld Group Analysis ProgramDocument16 pages"Weldgrp" - Weld Group Analysis ProgramMario BertiNo ratings yet

- "Weldgrp" - Weld Group Analysis ProgramDocument20 pages"Weldgrp" - Weld Group Analysis Programbharathanin0% (1)

- Batailly How To Extract Structural Matrices in ANSYS To MATLABDocument13 pagesBatailly How To Extract Structural Matrices in ANSYS To MATLABOmar CaballeroNo ratings yet

- Note AnsysDocument13 pagesNote AnsysJobby GeorgeNo ratings yet

- Class 2 D BF (T) TF TW R bf/4tf HC/TW W24x104 PGW24A W24x84 PGW24B FlangeDocument1 pageClass 2 D BF (T) TF TW R bf/4tf HC/TW W24x104 PGW24A W24x84 PGW24B Flangej_herndzNo ratings yet

- Class 2 D BF (T) TF TW R bf/4tf HC/TW W24x104 PGW24A W24x84 PGW24B FlangeDocument1 pageClass 2 D BF (T) TF TW R bf/4tf HC/TW W24x104 PGW24A W24x84 PGW24B Flangej_herndzNo ratings yet

- Class 2 D BF (T) TF TW R bf/4tf HC/TW W24x104 PGW24A W24x84 PGW24B FlangeDocument1 pageClass 2 D BF (T) TF TW R bf/4tf HC/TW W24x104 PGW24A W24x84 PGW24B Flangej_herndzNo ratings yet

- Class 2 D BF (T) TF TW R bf/4tf HC/TW W24x104 PGW24A W24x84 PGW24B FlangeDocument1 pageClass 2 D BF (T) TF TW R bf/4tf HC/TW W24x104 PGW24A W24x84 PGW24B Flangej_herndzNo ratings yet

- Eccentric Loads On C-Shaped Weld GroupsDocument1 pageEccentric Loads On C-Shaped Weld Groupsj_herndzNo ratings yet

- Eccentric Loads On L-Shaped Weld GroupsDocument1 pageEccentric Loads On L-Shaped Weld Groupsj_herndzNo ratings yet

- Installation of Columns: Installation Recommendations For Precast Reinforced Concrete Production Edition 1 September 2008Document14 pagesInstallation of Columns: Installation Recommendations For Precast Reinforced Concrete Production Edition 1 September 2008j_herndz100% (1)

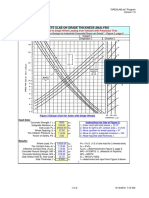

- Concrete Slab On Grade Thickness AnalysisDocument1 pageConcrete Slab On Grade Thickness Analysisj_herndzNo ratings yet

- Experimental Setup Result: Discussion ApplicationDocument1 pageExperimental Setup Result: Discussion ApplicationMir Hasib Ul LatifNo ratings yet

- The Electromagnetic Spectrum: Multiple ChoiceDocument10 pagesThe Electromagnetic Spectrum: Multiple ChoiceVannie MonderoNo ratings yet

- Transmission Line Forecast StudyDocument33 pagesTransmission Line Forecast StudyumamaheshwarraoNo ratings yet

- Radioactive Worksheet IGCSEDocument2 pagesRadioactive Worksheet IGCSESyakti PerdanaNo ratings yet

- Josa 42 3 200Document4 pagesJosa 42 3 200jan dildoNo ratings yet

- Lab Act 1Document8 pagesLab Act 1Kenji HiguchiNo ratings yet

- Velocity and Acceleration AnalysisDocument6 pagesVelocity and Acceleration AnalysisPrithviNo ratings yet

- AP CH 6 PP MomentumDocument50 pagesAP CH 6 PP MomentumCharlene VillanoNo ratings yet

- True FalseDocument6 pagesTrue FalsePhương Chu Thị BíchNo ratings yet

- S Ramp CalculationsDocument4 pagesS Ramp CalculationsRonald Peeters0% (1)

- Process Calculations Assignment - 1Document3 pagesProcess Calculations Assignment - 1mahendra shakyaNo ratings yet

- Nota Padat Fizik F5 ElectricDocument32 pagesNota Padat Fizik F5 Electricslokkro97% (38)

- Powder Technology: Yuan Yu, Wenjing Ren, Jiaxiang LiuDocument5 pagesPowder Technology: Yuan Yu, Wenjing Ren, Jiaxiang Liudavibraga8041No ratings yet

- Is 2993 1998 IEC 252 1993 A.C. Motor CapacitorsDocument33 pagesIs 2993 1998 IEC 252 1993 A.C. Motor Capacitorskirandevi1981100% (2)

- Preview of Essential University Physics 2nd EditionDocument10 pagesPreview of Essential University Physics 2nd EditionAnthony BetancourthNo ratings yet

- The Ancient and Modern History of EM Ground-Wave PropagationDocument18 pagesThe Ancient and Modern History of EM Ground-Wave PropagationAllan MastinoNo ratings yet

- Stopwatch 3 Standard Test U6Document3 pagesStopwatch 3 Standard Test U6MARIANA SORIA HIDALGONo ratings yet

- SHM SOLUTION 1,2,3,4,5 - Solutions PDFDocument39 pagesSHM SOLUTION 1,2,3,4,5 - Solutions PDFPrajwal SolankiNo ratings yet

- ENGRD 2210 Syllabus 2011Document4 pagesENGRD 2210 Syllabus 2011aoeusnthidNo ratings yet

- Design of New DGS Hairpin Microstrip Bandpass Filter Using Coupling Matrix MethodDocument5 pagesDesign of New DGS Hairpin Microstrip Bandpass Filter Using Coupling Matrix MethodĐoàn GiangNo ratings yet

- Directions: Choose The Best Answer For Each Multiple Choice Question. Write The Best Answer On The BlankDocument3 pagesDirections: Choose The Best Answer For Each Multiple Choice Question. Write The Best Answer On The BlankRanulfo MayolNo ratings yet

- Nuclear PhysicsDocument109 pagesNuclear PhysicsFathi Marzuqi PiliangNo ratings yet

- Unit 1 - How To Access The Portal: Assignment0Document4 pagesUnit 1 - How To Access The Portal: Assignment0Prasenjit DeyNo ratings yet

- Example A Hollow Tube of CurrentDocument7 pagesExample A Hollow Tube of CurrentNITISH KUMARNo ratings yet

- AHU IsolationDocument1 pageAHU IsolationNandkumar PatilNo ratings yet

- Latent Heat QuestionsDocument2 pagesLatent Heat Questionsannmarie100% (1)

- Physics 4.1,4.2Document16 pagesPhysics 4.1,4.2Fatima FiazNo ratings yet

- Physics EEDocument13 pagesPhysics EEGhostlyBot 16No ratings yet