Professional Documents

Culture Documents

Result:: Data Sheet For Mechanical Properties

Result:: Data Sheet For Mechanical Properties

Uploaded by

নৈঃশব্দের শব্দ0 ratings0% found this document useful (0 votes)

4 views1 pageThe document provides data on the mechanical properties, residual stresses test results, and microstructures of pure aluminum and dirty aluminum castings. Pure aluminum has a slightly higher tensile strength and elongation but lower density and porosity compared to dirty aluminum. Residual stress testing of aluminum cast at 850°C showed a small thermal strain of 1.49x10-3 and corresponding residual stress of 97.9 MPa. Figures 1 and 2 show the microstructures of pure and dirty aluminum castings before and after etching.

Original Description:

Test result

Original Title

Ex-07 test

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides data on the mechanical properties, residual stresses test results, and microstructures of pure aluminum and dirty aluminum castings. Pure aluminum has a slightly higher tensile strength and elongation but lower density and porosity compared to dirty aluminum. Residual stress testing of aluminum cast at 850°C showed a small thermal strain of 1.49x10-3 and corresponding residual stress of 97.9 MPa. Figures 1 and 2 show the microstructures of pure and dirty aluminum castings before and after etching.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageResult:: Data Sheet For Mechanical Properties

Result:: Data Sheet For Mechanical Properties

Uploaded by

নৈঃশব্দের শব্দThe document provides data on the mechanical properties, residual stresses test results, and microstructures of pure aluminum and dirty aluminum castings. Pure aluminum has a slightly higher tensile strength and elongation but lower density and porosity compared to dirty aluminum. Residual stress testing of aluminum cast at 850°C showed a small thermal strain of 1.49x10-3 and corresponding residual stress of 97.9 MPa. Figures 1 and 2 show the microstructures of pure and dirty aluminum castings before and after etching.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

Result:

Data Sheet for Mechanical Properties:

Alloy Tensile

Elongation, % Density, g/cc Porosity, %

Condition Strength, MPa

Pure Al 80.76 7.23 2.5216 5.55

Dirty Al 79.76 5.59 2.625 12.5

Data Sheet for Residual Stresses Test:

Pouring Strain, Residual Stress,

L1, cm L2, cm

Temperature, oC ε= (L2-L1)/L1= α∆T σ=εE, MPa

-3

850 14.09 14.11 1.49*10 97.9

Here, α= coefficient of thermal expansion of the alloy, and ∆T is the temperature difference during

casting (i.e., pouring temperature-room temperature).

Fig1: Microstructure of Pure Al and dirty Al casting before etching

Fig2: Microstructure of Pure Al and dirty Al casting after etching

You might also like

- EN 13480-3 Straight Pipes PDFDocument1 pageEN 13480-3 Straight Pipes PDFmasatusNo ratings yet

- European Steel and Alloy Grades: About Us EN 10207Document2 pagesEuropean Steel and Alloy Grades: About Us EN 10207farshid KarpasandNo ratings yet

- C1990-EH(HC)ver 1 0英文Document6 pagesC1990-EH(HC)ver 1 0英文顏健軒No ratings yet

- Shell and Tube Heat Exchanger Design: Fluid AllocationDocument6 pagesShell and Tube Heat Exchanger Design: Fluid AllocationLungeloNo ratings yet

- Scope: Ferritic Heat-Resistant Steel TK 1.4762Document5 pagesScope: Ferritic Heat-Resistant Steel TK 1.4762Siis IngenieriaNo ratings yet

- ε, which can be determined in an approximate fashion by assuming that the initial δ, namely, ε = δDocument10 pagesε, which can be determined in an approximate fashion by assuming that the initial δ, namely, ε = δjuan silvaNo ratings yet

- AW60Document1 pageAW60Fitra VertikalNo ratings yet

- CuZn30 PDFDocument2 pagesCuZn30 PDFavinashchauhan2695No ratings yet

- AmuDocument2 pagesAmuavinashchauhan2695No ratings yet

- Spur Gear Spec Some Manufactures Dimension PDFDocument52 pagesSpur Gear Spec Some Manufactures Dimension PDFagus wahyudiNo ratings yet

- T10-MFM Tech SpecDocument2 pagesT10-MFM Tech SpecMiltonNo ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- Conical Shells (7.6.4) EN 13445-3Document3 pagesConical Shells (7.6.4) EN 13445-3met-calcNo ratings yet

- NEDAL Datasheet-3003Document1 pageNEDAL Datasheet-3003Manoranjan MohapatraNo ratings yet

- Thermocouple Thermometry 2006Document4 pagesThermocouple Thermometry 2006smartbellNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- Robertopereira 2014Document6 pagesRobertopereira 2014ElnurNo ratings yet

- Phase 2 T25-MFG Datasheet For UniversalDocument1 pagePhase 2 T25-MFG Datasheet For UniversalMahroosh KhawajaNo ratings yet

- Welding ConsumablesDocument79 pagesWelding Consumablesazam RazzaqNo ratings yet

- AB31-41-42-Katalog-en-130111 Valvula de Prueba de Fuga PDFDocument14 pagesAB31-41-42-Katalog-en-130111 Valvula de Prueba de Fuga PDFAlejandro Alex EnriquezNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10149-2Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10149-2farshid KarpasandNo ratings yet

- Alloy Data Sheet En-Aw 6101B (Ealmgsib) : Type: High Conductivity Alloy)Document1 pageAlloy Data Sheet En-Aw 6101B (Ealmgsib) : Type: High Conductivity Alloy)Bouchra SonsuzaNo ratings yet

- Flat End With A Narrow-Face Gasket For Single Isolated OpeningDocument6 pagesFlat End With A Narrow-Face Gasket For Single Isolated OpeningEng-CalculationsNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10207Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10207farshid KarpasandNo ratings yet

- Quality 1.4362 Chemical Composition: Technical CardDocument2 pagesQuality 1.4362 Chemical Composition: Technical CardTeodor EzaruNo ratings yet

- Anchor Flange CalcDocument4 pagesAnchor Flange CalcPriyam KmNo ratings yet

- Test Parameter Comparison 29mm Thick Sparkling White Granite SR# Parameter UnitDocument3 pagesTest Parameter Comparison 29mm Thick Sparkling White Granite SR# Parameter UnitAfzal ChaudhryNo ratings yet

- European Steel and Alloy Grades: 11mnni5-3 (1.6212)Document2 pagesEuropean Steel and Alloy Grades: 11mnni5-3 (1.6212)farshid KarpasandNo ratings yet

- Earthing CalculatorDocument10 pagesEarthing CalculatorJejomar ErebarenNo ratings yet

- Earthing Calculation As Per Ieee 80Document10 pagesEarthing Calculation As Per Ieee 80أحداث الشحاتNo ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- Junction Between The Small End of A Cone and A CylinderDocument4 pagesJunction Between The Small End of A Cone and A CylinderEng-CalculationsNo ratings yet

- Rigid PVCDocument1 pageRigid PVCRND KencanaNo ratings yet

- High Efficiency Solid State Amplifiers - 1Document44 pagesHigh Efficiency Solid State Amplifiers - 1wingchaoNo ratings yet

- F-Cem-021 - Cptch-012-19a-Fcaw - Aws D1.1 - Plana-HorizontalDocument7 pagesF-Cem-021 - Cptch-012-19a-Fcaw - Aws D1.1 - Plana-Horizontalenrique.chavezNo ratings yet

- Performance Specification: Hot Side Cold SideDocument2 pagesPerformance Specification: Hot Side Cold SideStevan KrstojevicNo ratings yet

- B41OA Datasheet 2017-2018Document7 pagesB41OA Datasheet 2017-2018Turkan AliyevaNo ratings yet

- Mechanical Properties of Metals 1201349582254633 4Document26 pagesMechanical Properties of Metals 1201349582254633 4andresr36100% (3)

- Concrete Design Properties According To En1992-1-1 ( 1.50, F 500 Mpa)Document8 pagesConcrete Design Properties According To En1992-1-1 ( 1.50, F 500 Mpa)Amlaku DessieNo ratings yet

- Cu-ETP: C11000 Industrial RolledDocument4 pagesCu-ETP: C11000 Industrial Rolledsrsivaraman81No ratings yet

- Alloy Steel p22 PlatesDocument3 pagesAlloy Steel p22 PlatesMiguel PulidoNo ratings yet

- Special Steels A320 L43: American Standards AstmDocument1 pageSpecial Steels A320 L43: American Standards Astmsamirfun2006No ratings yet

- Fatigue Strength of Unwelded ComponentsDocument2 pagesFatigue Strength of Unwelded ComponentsEng-CalculationsNo ratings yet

- European Steel and Alloy Grades: S235JR (1.0038 (Dubl) )Document2 pagesEuropean Steel and Alloy Grades: S235JR (1.0038 (Dubl) )farshid KarpasandNo ratings yet

- Dupont Kalrez 4079: Product DescriptionDocument2 pagesDupont Kalrez 4079: Product DescriptionAfzal ImamNo ratings yet

- Material IDocument30 pagesMaterial IgabrieleNo ratings yet

- Earthing Calculation As Per Ieee 80Document10 pagesEarthing Calculation As Per Ieee 80ahmadkurniawan35No ratings yet

- 1.1 - Ag Plated Surfaces Status Affecting Thermomechanical Performance of Sintering Solder Joint - GiCo - MaSa - ST - V3Document21 pages1.1 - Ag Plated Surfaces Status Affecting Thermomechanical Performance of Sintering Solder Joint - GiCo - MaSa - ST - V3moyinglong1126No ratings yet

- Frenos Sauleda - ToP - 05Document1 pageFrenos Sauleda - ToP - 05Marcos LópezNo ratings yet

- SINOXX 4006 Steel: Designation by StandardsDocument3 pagesSINOXX 4006 Steel: Designation by StandardsKiranNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-2 EN 10162Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-2 EN 10162farshid KarpasandNo ratings yet

- SAMSUNG CapacitorDocument16 pagesSAMSUNG CapacitorFaraz ElectronicNo ratings yet

- Module BDocument42 pagesModule BErwin Jed RachoNo ratings yet

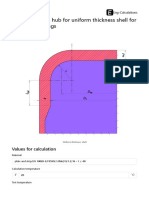

- Flat Ends With A Hub For Uniform Thickness Shell For A Pair of OpeningsDocument5 pagesFlat Ends With A Hub For Uniform Thickness Shell For A Pair of OpeningsEng-CalculationsNo ratings yet

- Instrumentation Screened CablesDocument5 pagesInstrumentation Screened Cablespriyanka236No ratings yet

- Hemispherical EndsDocument3 pagesHemispherical EndsEng-CalculationsNo ratings yet

- Early Thermal CrackingDocument5 pagesEarly Thermal CrackingSravanthi Mehar100% (1)

- NIC Components NMC High Voltage SeriesDocument5 pagesNIC Components NMC High Voltage SeriesNICCompNo ratings yet

- Dynamic Mechanical AnalysisDocument22 pagesDynamic Mechanical Analysisrudy ammeNo ratings yet