Professional Documents

Culture Documents

Boq For Box Culvert PDF

Boq For Box Culvert PDF

Uploaded by

Daniel Okere0%(1)0% found this document useful (1 vote)

41 views4 pagesOriginal Title

BOQ FOR BOX CULVERT.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0%(1)0% found this document useful (1 vote)

41 views4 pagesBoq For Box Culvert PDF

Boq For Box Culvert PDF

Uploaded by

Daniel OkereCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

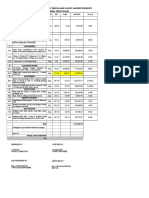

RATE

ITEM DESCRIPTION UNIT Quantity

USD

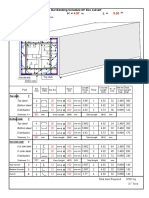

1 Box Culvert Structure

Cut to spoil in soft material to formation level

for the the box culvert shown in internal

1.1 m3

*****mmx ****mm and ****mm thick

wallsDrawing No. *******.

Backfilling with selected stock piled spoil for

excavation below formation level as directed by

the Engineer, but in 150mm compacted to 3

1.2 m

100% of the laboratory maximum dry density

(4.5 Kg rammer method using CBR mould and

62 blows per layer).

Prepare structure formation by trimiming and

compaction before subsequent operation as

1.3 m2

directed and to the satisfaction of the

Engineer.

Provide and backfill with selected stock piles

spoil material, compacted to 100% of the

laboratory maximum dry density (4.5 Kg

3

1.4 rammer method using CBR mould and 62 m

blows per layer) in layers not exceeding 150

mm behind side walls and wingwalls of the box

culvert.

2 Wadi Protection Works

Provide and install gabion protection works,

including laying of filter fabric on the sides in

2.1 Item

contact with soil and as directed by the

Engineer

3 Box Culvert Structure

Plain concrete class 15 in:

3.1 Ditto but under box culvert m3

3.2 Ditto but under the wing wall m3

3.3 Ditto but under the apron m3

3.4 Ditto but under toe m3

Vibrated Reinforced Concrete Class 20 In:

3

3.5 Ditto but toe m

3.6 Ditto but wing wall m3

3

3.7 Ditto but apron m

3.80 Ditto but box culvert m3

3.9 Ditto but head wall m3

Sawn formwork as described to:-

3.10 Sides of toe m²

3.11 Sides of wingwall m²

3.12 Sides of apron m²

3.13 Sides & soffit including props of culvert m²

3.14 Sides of head wall m²

High yield square twisted reinforcement bars to

B.S 4461

3.15 Assorted reinforcements (T10&T12) Kg

Water proofing as described to:-

Provide approved water proofing for joints for 6

Item

3.16 joints

Total of Bill carried forward to summary

AMOUNT

USD

You might also like

- AS4312 - Atmospheric Corrosivity Zones in Austr.Document41 pagesAS4312 - Atmospheric Corrosivity Zones in Austr.toddlbyrnes100% (6)

- Storm Water Drain Priced BOQ Packages To VendorsDocument3 pagesStorm Water Drain Priced BOQ Packages To VendorsSureshNo ratings yet

- PSV Calculation and PhilosophyDocument33 pagesPSV Calculation and PhilosophysbmmlaNo ratings yet

- South Horr Police StationDocument18 pagesSouth Horr Police Stationcliff machukaNo ratings yet

- Boq For Box CulvertDocument2 pagesBoq For Box CulvertDaniel Okere100% (1)

- KMDP - MSF Mod CH Handbook Annex 3 3d PresentationDocument21 pagesKMDP - MSF Mod CH Handbook Annex 3 3d PresentationDaniel OkereNo ratings yet

- Boq For Box CulvertDocument4 pagesBoq For Box CulvertDaniel OkereNo ratings yet

- Elemental Bill (Boq)Document94 pagesElemental Bill (Boq)Nur Athirah RoslanNo ratings yet

- No. 1 - Construction of Temporary DetourDocument8 pagesNo. 1 - Construction of Temporary DetourMohammed Irfan0% (1)

- Adb V Boq Format r02Document26 pagesAdb V Boq Format r02ajay kumar guptaNo ratings yet

- Bar Bending Schedule OF Box CulvertDocument1 pageBar Bending Schedule OF Box CulvertMaladi MustamilNo ratings yet

- Chizhanje Housing DevelopmentDocument8 pagesChizhanje Housing DevelopmentEdmore MukotsanjeraNo ratings yet

- BOQ 4-Storey-Residential 03282019 FInalDocument9 pagesBOQ 4-Storey-Residential 03282019 FInalCharles SiaNo ratings yet

- Complete - BOQ Format of Highway ProjectDocument53 pagesComplete - BOQ Format of Highway ProjectRajesh SinghalNo ratings yet

- MATERIAL - SCHEDULEDocument72 pagesMATERIAL - SCHEDULEMADUHU KISUJANo ratings yet

- Box Estimate.Document254 pagesBox Estimate.rahul sumanNo ratings yet

- Sewerage CalculatorDocument5 pagesSewerage CalculatorKarthikeyan SankarrajanNo ratings yet

- Pradhan Mantri Gram Sadak Yojana Cost Estimate For Road Construction Package CG03-234Document4 pagesPradhan Mantri Gram Sadak Yojana Cost Estimate For Road Construction Package CG03-234Lucky TraderNo ratings yet

- Final DubaiDocument36 pagesFinal DubaiAhmad KassemNo ratings yet

- Boq 37800Document10 pagesBoq 37800DEEPALINo ratings yet

- BOQ FOR MEZZANINE LEVEL (Draft Version)Document5 pagesBOQ FOR MEZZANINE LEVEL (Draft Version)Architects Asia100% (1)

- IPC - 122 Shitoljhorna Khal RW DraftDocument73 pagesIPC - 122 Shitoljhorna Khal RW DraftArif AbedinNo ratings yet

- Floor Finish: Estimated Unit Rate Amount Quantity (UAE DHS) (UAE DHS) Item Description UnitDocument10 pagesFloor Finish: Estimated Unit Rate Amount Quantity (UAE DHS) (UAE DHS) Item Description UnitThanuja WijesingheNo ratings yet

- Abstract of Cost: Division Road Office, BiratnagarDocument8 pagesAbstract of Cost: Division Road Office, Biratnagarnitish JhaNo ratings yet

- The Proposed Dualization of Road Kotangora Auto Saved)Document6 pagesThe Proposed Dualization of Road Kotangora Auto Saved)Felix IdeboghieNo ratings yet

- Summary Sheet (Annexure F1 & F2)Document5 pagesSummary Sheet (Annexure F1 & F2)Ajay Malik100% (1)

- COST ANALYSIS - Foundation of Gantry TowerDocument9 pagesCOST ANALYSIS - Foundation of Gantry TowerDesign explorer olomizanaNo ratings yet

- Sub GradeDocument6 pagesSub GradeIra AgcaoiliNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)thusiNo ratings yet

- Traffic Count HARARE DRIVE & NEW ROAD PDFDocument7 pagesTraffic Count HARARE DRIVE & NEW ROAD PDFMartin Takudzwa ChakadonaNo ratings yet

- Detail Measurement: SL No Description No L B H QuantityDocument6 pagesDetail Measurement: SL No Description No L B H QuantitysatyaNo ratings yet

- Road Detailed EstimateDocument8 pagesRoad Detailed Estimatenageshwarraobandi100% (1)

- Bill of Qty. N.C. Sharma, BILSI, BadaunDocument47 pagesBill of Qty. N.C. Sharma, BILSI, BadaunNazim AliNo ratings yet

- Nit Schedule For The Construction of S.D.M. Office Building at Balaghat, Dist-Balaghat M.PDocument31 pagesNit Schedule For The Construction of S.D.M. Office Building at Balaghat, Dist-Balaghat M.PDADADADGGGNo ratings yet

- Package II Part I.2 Civil BOQ For Service BlockDocument22 pagesPackage II Part I.2 Civil BOQ For Service Blockdox4useNo ratings yet

- 2017-18 DatasDocument76 pages2017-18 Datasfarhan sdNo ratings yet

- Item Description Unit QTY Rate Amount Section No. 2 Proposed Apartment Development at Eastleigh Bill No. 1Document32 pagesItem Description Unit QTY Rate Amount Section No. 2 Proposed Apartment Development at Eastleigh Bill No. 1michaelNo ratings yet

- Jayakar Combined With Sub HeadDocument11 pagesJayakar Combined With Sub HeadASSISTANT ENGINEER CIVILNo ratings yet

- Boundary Wall DrawingDocument1 pageBoundary Wall DrawingBig Boy ToyzNo ratings yet

- Construction Cost in PakistanDocument47 pagesConstruction Cost in Pakistanzahid nawaz ajamNo ratings yet

- Typical Beme For A Building ProjectDocument10 pagesTypical Beme For A Building Projectsayaya101No ratings yet

- Labour Constant Untuk Brick LayerDocument8 pagesLabour Constant Untuk Brick LayerIntan Farhana Mohd RoslanNo ratings yet

- BOQ Full Unpriced.Document118 pagesBOQ Full Unpriced.JettSoriano100% (1)

- Bill 1 BOQDocument9 pagesBill 1 BOQAaron AriifNo ratings yet

- Keenagoda BOQ FinalDocument30 pagesKeenagoda BOQ FinalChamin Subhawickrama50% (2)

- Grades of Concrete - Different Grades of Concrete - M10, M15, M20, M25 M30 Concrete GradesDocument13 pagesGrades of Concrete - Different Grades of Concrete - M10, M15, M20, M25 M30 Concrete GradesdasaribalaNo ratings yet

- Unit QTY Rate Amount Rate RefDocument9 pagesUnit QTY Rate Amount Rate RefC.SnojanNo ratings yet

- 2387 - Price Bid For VDF Flooring at PKG - IIDocument5 pages2387 - Price Bid For VDF Flooring at PKG - IIPoojaNo ratings yet

- CSR Vol-1 PDFDocument317 pagesCSR Vol-1 PDFmuhammad75makeNo ratings yet

- BOQ - Proposed HouseDocument6 pagesBOQ - Proposed HouseNadun AthukoralaNo ratings yet

- Access Road BOQDocument5 pagesAccess Road BOQNoel Priyantha LiyanageNo ratings yet

- BOQ-Controlled Blasting-V0-12-10-21Document2 pagesBOQ-Controlled Blasting-V0-12-10-21Pradeep GoudaNo ratings yet

- (381611313) BOQ EarthworkDocument39 pages(381611313) BOQ EarthworkAshish SadaNo ratings yet

- K102-2 - Final Account - BOQ - Reshaun Plumbing PDFDocument4 pagesK102-2 - Final Account - BOQ - Reshaun Plumbing PDFSharon FarmerNo ratings yet

- Design of Earthen Canals PDFDocument18 pagesDesign of Earthen Canals PDFHumbertoRalphOrtizAbacheNo ratings yet

- Blank BOQDocument58 pagesBlank BOQThushan Madu0% (1)

- Schedule BDocument43 pagesSchedule Bhardik sorathiyaNo ratings yet

- Boq RFQ142 005 2023 Repairing of Potholes 003 8Document10 pagesBoq RFQ142 005 2023 Repairing of Potholes 003 8Nontokozo FankomoNo ratings yet

- BoQ For A 3-Classroom Block 2021-22Document78 pagesBoQ For A 3-Classroom Block 2021-22mukiibi50% (2)

- Foundation QTYDocument99 pagesFoundation QTYachillies bautistaNo ratings yet

- BOQ Abiyot Phase 1 B+G+4 4BIDDERDocument5 pagesBOQ Abiyot Phase 1 B+G+4 4BIDDERKeire HussenNo ratings yet

- Mto For Bund Wall: Project: Doc No / Rev: Prepared By: TZ Activity: Checked By: CFH/ZJDocument2 pagesMto For Bund Wall: Project: Doc No / Rev: Prepared By: TZ Activity: Checked By: CFH/ZJTengku ZhafriNo ratings yet

- Sub-Structure: Concrete WorkDocument12 pagesSub-Structure: Concrete WorkAsresahgn TikoNo ratings yet

- Final BQDocument60 pagesFinal BQSee Wei ChuanNo ratings yet

- Gazebo - Type BDocument6 pagesGazebo - Type BDaniel OkereNo ratings yet

- NS NS NSDocument1 pageNS NS NSDaniel OkereNo ratings yet

- Table of Section Properties For IPE, HEA, HEB, HEM Profiles - Eurocode 3Document22 pagesTable of Section Properties For IPE, HEA, HEB, HEM Profiles - Eurocode 3Daniel OkereNo ratings yet

- Table of Section Properties For IPE, HEA, HEB, HEM Profiles - Eurocode 3Document22 pagesTable of Section Properties For IPE, HEA, HEB, HEM Profiles - Eurocode 3Daniel OkereNo ratings yet

- Solar BoqDocument40 pagesSolar BoqDaniel OkereNo ratings yet

- Box Culvert Design CalculationDocument8 pagesBox Culvert Design CalculationDaniel OkereNo ratings yet

- Machine Room RF Machine Room RFDocument1 pageMachine Room RF Machine Room RFDaniel OkereNo ratings yet

- Tapared BeamDocument4 pagesTapared BeamDaniel OkereNo ratings yet

- Midas Tut PDFDocument70 pagesMidas Tut PDFDaniel OkereNo ratings yet

- Tutorial On LusasDocument7 pagesTutorial On LusasDaniel OkereNo ratings yet

- Complete List of Equipment/Tools For Auto-Repair Shop: Brand ModelDocument38 pagesComplete List of Equipment/Tools For Auto-Repair Shop: Brand ModelDaniel OkereNo ratings yet

- Section 4 - Lift Bill of QuantitiesDocument9 pagesSection 4 - Lift Bill of QuantitiesDaniel OkereNo ratings yet

- Chapter 3: Small-Scale Construction: Brief Description of The SectorDocument18 pagesChapter 3: Small-Scale Construction: Brief Description of The SectorDaniel OkereNo ratings yet

- Compressive Behaviour Tensile BehaviourDocument24 pagesCompressive Behaviour Tensile BehaviourDaniel OkereNo ratings yet

- Concrete Work (CTD) .: Rod ReinforcementDocument2 pagesConcrete Work (CTD) .: Rod ReinforcementDaniel OkereNo ratings yet

- Specifications Bidder'S Response Explanation: A. ChassisDocument28 pagesSpecifications Bidder'S Response Explanation: A. ChassisDaniel OkereNo ratings yet

- Chapter 4.1: Brick and Tile Production: Cleaner Production Fact Sheet and Resource GuideDocument8 pagesChapter 4.1: Brick and Tile Production: Cleaner Production Fact Sheet and Resource GuideDaniel OkereNo ratings yet

- Standard - Specifications For Road Works 2000Document10 pagesStandard - Specifications For Road Works 2000Daniel OkereNo ratings yet

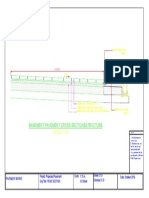

- Basement Pavement Cross-Section&Structure: SCALE 1:40Document1 pageBasement Pavement Cross-Section&Structure: SCALE 1:40Daniel OkereNo ratings yet

- Animal Food Processing PlantDocument30 pagesAnimal Food Processing PlantDaniel OkereNo ratings yet

- Data Produk & Vendor E-Catalog LKPP - KursiDocument55 pagesData Produk & Vendor E-Catalog LKPP - KursiAndi Ramdan HamdaniNo ratings yet

- Lanco Amarkantak Power LTD Korba Mechanical Vocational Training Report 2-Haxxo24 I IDocument9 pagesLanco Amarkantak Power LTD Korba Mechanical Vocational Training Report 2-Haxxo24 I Ihaxxo24No ratings yet

- Cooling Tower Selection CriteriaDocument5 pagesCooling Tower Selection CriteriaPrashant Suvarna100% (1)

- Design of A Two-Stage Cycloidal Gear Reducer WithDocument14 pagesDesign of A Two-Stage Cycloidal Gear Reducer WithAlejandro ChavezNo ratings yet

- KJLC Ed09 Sec01 Web200910Document162 pagesKJLC Ed09 Sec01 Web200910NickMoloNo ratings yet

- Thyssenkrupp C-Staehle Product Information Steel en PDFDocument18 pagesThyssenkrupp C-Staehle Product Information Steel en PDFDonatasNo ratings yet

- Panwater PCF Series Cooling Tower PDFDocument28 pagesPanwater PCF Series Cooling Tower PDFEkka Prasetia100% (1)

- 190326quadax Valves Coating SpecificationsDocument5 pages190326quadax Valves Coating SpecificationsS MhNo ratings yet

- Carrier VRF Installation Manual For 20 - 22 - 26 KWDocument16 pagesCarrier VRF Installation Manual For 20 - 22 - 26 KWMohamedNo ratings yet

- Wood Beam Design: Material PropertiesDocument2 pagesWood Beam Design: Material PropertiesNoel Guades100% (1)

- IOTDE CV Process Lead EngineerDocument6 pagesIOTDE CV Process Lead EngineerRana BiswasNo ratings yet

- Matter and Its PropertiesDocument80 pagesMatter and Its PropertiesQueen Ann JumuadNo ratings yet

- Mic World I Notes Ch.9 - Student VersionDocument19 pagesMic World I Notes Ch.9 - Student Versionakhilesh sahooNo ratings yet

- ScienceDocument8 pagesScienceTaryno BBNo ratings yet

- Conference - Solar Power in IndiaDocument5 pagesConference - Solar Power in IndiaSumit Kiroriwal VermaNo ratings yet

- STEMCO Bulletin Vanfastic 575 0071 WEBDocument2 pagesSTEMCO Bulletin Vanfastic 575 0071 WEBmauricioNo ratings yet

- Particulate Nature of MatterDocument16 pagesParticulate Nature of MatteradikmukNo ratings yet

- HMT ReportDocument50 pagesHMT Reportrakeshin100% (1)

- List of CHP EquipmentsDocument7 pagesList of CHP EquipmentsbrockNo ratings yet

- Power Trains: Lecture Note Prepared By: Tibebu MDocument52 pagesPower Trains: Lecture Note Prepared By: Tibebu MTibebu MerideNo ratings yet

- Manufacturing Engineer or Production Supervisor or Production CoDocument3 pagesManufacturing Engineer or Production Supervisor or Production Coapi-79211136No ratings yet

- Control Cable DatasheetDocument2 pagesControl Cable DatasheetSamir RNo ratings yet

- Fracture Mechanics 1 EBB 334Document37 pagesFracture Mechanics 1 EBB 334Luiz CordeiroNo ratings yet

- ACI 3521r - 89 Recommendations For Design of Slab-Column Connections in RCCDocument26 pagesACI 3521r - 89 Recommendations For Design of Slab-Column Connections in RCCVaibhav SengarNo ratings yet

- Valvulas OS&YDocument1 pageValvulas OS&Ydaniel manuel garces davilaNo ratings yet

- Gear Hobbers, Kashifuji, CNC Gear Hobbing Machines, CNC Gear Griinding Machines, Gear FinishersDocument7 pagesGear Hobbers, Kashifuji, CNC Gear Hobbing Machines, CNC Gear Griinding Machines, Gear FinishersinvolutegearNo ratings yet

- Model Exit Exam (May 2023) - Civil Engineering DepartmentDocument28 pagesModel Exit Exam (May 2023) - Civil Engineering DepartmentTadesse MegersaNo ratings yet

- EZ Path Series 44+ Fire-Rated Pathway Grid Splice Plate Installation SheetDocument2 pagesEZ Path Series 44+ Fire-Rated Pathway Grid Splice Plate Installation SheetKhairul AmriNo ratings yet