Professional Documents

Culture Documents

ANSI B16.5 Dimnsion Toleran PDF

Uploaded by

alvaro espinosaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ANSI B16.5 Dimnsion Toleran PDF

Uploaded by

alvaro espinosaCopyright:

Available Formats

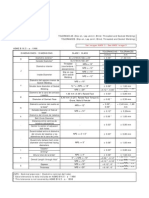

MAASS FLANGE CORPORATION

DIMENSIONAL TOLERANCES FOR ANSI B16.5 FLANGES

THREADED, SLIP-ON LAP JOINT WELDING NECK FLANGES

AND BLIND FLANGES

When OD is 24" ±0.06 When OD is 24" ±0.06

Outside Outside

or less or less

Diameter* # Diameter* #

When OD is over 24" ±0.13 When OD is over 24" ±0.13

Threaded Within limits on 10" and smaller ±0.03

boring gauge Inside 12" through 18" ±0.06

Inside Diameter

Diameter Slip-On and Lap Joint: 20" and larger +0.13, –0.06

10" and smaller +0.03, –0 1/16" Raised Face ±0.03

12” and larger +0.06, –0 Diameter of 1/4" Raised Face

Contact Face Tongue and Groove ±0.02

Diameter of Same as for

Counterbore

1 inside Diameter or Male and Female

1/16" Raised Face ±0.03 Diameter of Hub 5" and smaller +0.09, –0.03

Diameter of 1/4" Raised Face at Point of Welding 6" and larger +0.09, –0.03

Contact Face Tongue and Groove ±0.02 When Hub Base is

or Male and Female 24" or less ±0.06

Outside Diameter Diameter of

12" and smaller ±0.094, –0.06 Hub at Base* When Hub Base is

of Hub* 14" and larger ±0.13 over 24" ±0.13

Bolt Circle ±0.06 Bolt Circle ±0.06

Drilling Drilling

Bolt hole spacing ±0.03 Bolt hole spacing ±0.03

Eccentricity Eccentricity

Bolt Circle & Bolt Circle & 21/2" and smaller 0.03 Max

Facing (with 21/2" and smaller 0.03 Max Facing (with

Respect to Bore*) Respect to Bore*) 3" and larger 0.06 Max

3" and larger 0.06 Max

Length 4" and smaller ±0.06

Length Thru Hub 5" to 10" +0.06, –0.13

18" and smaller +0.13, –0.03

Thru Hub* 12" and larger +0.13, –0.19

20" and larger +0.19, –0.06

18" and smaller +0.13, –0

18" and smaller +0.13, –0 Thickness

Thickness 20" and larger +0.19, –0

20" and larger +0.19, –0

* Tolerance for these dimensions not covered by ANSI B16.5. # Actual Flange OD, other size references mean Nominal Pipe Size.

1 150# Threaded Flanges do not require a counterbore.

REDUCING FLANGES SLIP-ON AND THREADED PER ANSI B16.5

1

__________ 2

___________________ 3

__________ 4

___________________ 5

__________ 6

___________________

Smallest Size Smallest Size Smallest Size

Nominal of Reducing Outlet Nominal of Reducing Outlet Nominal of Reducing Outlet

Size Requiring Hub Flanges Size Requiring Hub Flanges Size Requiring Hub Flanges

1 1/2 31/2 11/2 12 31/2

11/4 1/2 4 11/2 14 31/2

11/2 1/2 5 11/2 16 4

2 1 6 21/2 18 4

21/2 11/4 8 3 20 4

3 11/4 10 31/2 24 4

1 Drilling, OD, Thickness and Facing Dimensions. Flange drilling, 4 BORE or TAPPING:–Reducing Slip-On flanges are bored to the

OD, thickness and facing are the same as those of the standard same diameters as full size flanges of the size to which the reduc-

flange of the size from which the reduction is being made. tion is being made.

2 Hub Dimensions Reducing Threaded flanges in the 150 lb. Standard do not

Threaded and Slip-on Flanges. The hub dimensions shall be at require a counterbore. On 300 lb. and higher Pressure Standards

least as large as those of the standard flange of the size to which depth of counterbore is 1/4" for tappings 2" and smaller and 3/8” for

the reduction is being made, except flanges reducing to a size tappings 2 1/2" and larger. Counterbore diameters are the same as

smaller than those of columns 2, 4 and 6, which may be made for full size flanges of identical tapping.

from blind flanges.

5 Raised Faces 1/16 " thick on 150 lb. and 300 lb. reducing flanges are

3 Welding Neck Flanges. The hub dimensions shall be the same as included in listed flange thickness dimensions, but 1/4" Raised

those of the standard flange of the size to which the reduction is Faces on flanges in the 400 lb. and higher Pressure Standards are

being made. not included. Other facings can be furnished.

You might also like

- REPAIR ManualDocument140 pagesREPAIR Manualbachir500100% (9)

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Blacksmithing For Beginners - Everything You Need To Know ToDocument35 pagesBlacksmithing For Beginners - Everything You Need To Know ToFREEDOM Saliendo De La Caverna100% (1)

- Heat TreatmentDocument56 pagesHeat TreatmentAakarsh RastogiNo ratings yet

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderFrom EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderRating: 5 out of 5 stars5/5 (2)

- All About PipingDocument46 pagesAll About PipingRakesh RanjanNo ratings yet

- Flat Face Vs Raised FaceDocument6 pagesFlat Face Vs Raised Facedidlakiran100% (4)

- Asme B16.5Document11 pagesAsme B16.5jacquesmayol100% (1)

- Standard Holes and Tapping ChartDocument1 pageStandard Holes and Tapping ChartajaykrishnaaNo ratings yet

- Searunner Construction Manual PDFDocument291 pagesSearunner Construction Manual PDFRyan Warren100% (3)

- Butt Weld Stainless Steel FittingsDocument16 pagesButt Weld Stainless Steel Fittingsbayu susiloNo ratings yet

- Introduction, Types and Function of Different Flanges .PDFXDocument25 pagesIntroduction, Types and Function of Different Flanges .PDFXMajid Sattar100% (1)

- Pressure Vessel Dimension InspectionDocument6 pagesPressure Vessel Dimension Inspectionsatya_chaganti100% (1)

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2From EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2No ratings yet

- Heat Treatment LectureDocument58 pagesHeat Treatment LectureKeith Tanaka Magaka100% (1)

- Piping:: Selection, Sizing, Routing and InstallationDocument25 pagesPiping:: Selection, Sizing, Routing and Installationwnew2me428No ratings yet

- Pipe Schedule: Welded and Seamless Wrought Steel PipeDocument10 pagesPipe Schedule: Welded and Seamless Wrought Steel PipePrasad BhosaleNo ratings yet

- Cabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsFrom EverandCabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsRating: 5 out of 5 stars5/5 (2)

- Pressure Vessel Dimension InspectionDocument12 pagesPressure Vessel Dimension Inspectionalokbdas100% (3)

- 06 GTAW Stainless SteelDocument4 pages06 GTAW Stainless SteelMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Valves Pipe Fittings DimensionsDocument37 pagesValves Pipe Fittings DimensionstsoheilNo ratings yet

- TolranceDocument18 pagesTolranceDiego MiseNo ratings yet

- ANSI Fittings WeightsDocument42 pagesANSI Fittings Weightsmatthewwalls4386No ratings yet

- Drill Sizes For TappingDocument15 pagesDrill Sizes For Tappinghsrao77100% (1)

- Introduction GASKETSDocument11 pagesIntroduction GASKETSradharaman_znaNo ratings yet

- Lecture Slides On Metrology and Inspection - PPTDocument30 pagesLecture Slides On Metrology and Inspection - PPTDeb PradhanNo ratings yet

- Tolerancias Ansi b16-5Document2 pagesTolerancias Ansi b16-5marcoedgNo ratings yet

- Ansi Flange HandbookDocument76 pagesAnsi Flange HandbookSuperstarVirgo100% (1)

- Clow FittingsDocument21 pagesClow Fittingsnjsmith5No ratings yet

- MixtureDocument12 pagesMixtureNaseer Ahmed SokhalNo ratings yet

- Flanges 2Document15 pagesFlanges 2chicotonyxdNo ratings yet

- CatalogueDocument212 pagesCatalogueSiva Venkateswara Rao BollaNo ratings yet

- ASME Buttweld Fittings ExplainedDocument13 pagesASME Buttweld Fittings ExplainedMarine SleimanNo ratings yet

- Bolted and Welded ConnectionsDocument2 pagesBolted and Welded ConnectionsKrunalsinh VirpuraNo ratings yet

- Head Tolerances: Head Thickness Standard Straight Flange Minimum Straight Flange 1"Document3 pagesHead Tolerances: Head Thickness Standard Straight Flange Minimum Straight Flange 1"Zohaib RafiqNo ratings yet

- Mech 102 Lecture 6 - Limits and FitsDocument80 pagesMech 102 Lecture 6 - Limits and FitsJoyfulNo ratings yet

- Fitting Acero Carbono A SoldarDocument21 pagesFitting Acero Carbono A Soldarcaod1712No ratings yet

- BS 4504 FlangeDocument11 pagesBS 4504 FlangeAlon BalonNo ratings yet

- KEYSTONE Manufacturing, Inc.: Tolerances and Standards For Turned Shafts and Interupted KeywaysDocument1 pageKEYSTONE Manufacturing, Inc.: Tolerances and Standards For Turned Shafts and Interupted KeywaysZoran DanilovNo ratings yet

- Dimensions of Steel Pipes ASME B36.10 and B36.19 Suffix (S) : NPS 2 3 3 4 5 OD 73 88.9 101.6 114.3 141.3Document2 pagesDimensions of Steel Pipes ASME B36.10 and B36.19 Suffix (S) : NPS 2 3 3 4 5 OD 73 88.9 101.6 114.3 141.3MaysaraNo ratings yet

- Templates For Drilling FlangesDocument2 pagesTemplates For Drilling FlangesessnelsonNo ratings yet

- What Does Pipe Schedule Mean Pipe Size Chart and Pipe Schedule 40 ThicknessDocument10 pagesWhat Does Pipe Schedule Mean Pipe Size Chart and Pipe Schedule 40 ThicknessVenkata Haritasa MamidannaNo ratings yet

- What Does Pipe Schedule Mean Pipe Size Chart and Pipe Schedule 40 Thickness PDFDocument10 pagesWhat Does Pipe Schedule Mean Pipe Size Chart and Pipe Schedule 40 Thickness PDFVKT TiwariNo ratings yet

- Páginas desdeASME B16.5 - 2009Document1 pagePáginas desdeASME B16.5 - 2009Mario BarrientosNo ratings yet

- Exhaust and CombustionDocument1 pageExhaust and CombustionKhoinguyen NguyenNo ratings yet

- Fire Piping-Astm A106Document4 pagesFire Piping-Astm A106sinahimsNo ratings yet

- Anexo 1: Thickness of Base MetalDocument2 pagesAnexo 1: Thickness of Base MetalJesus TecNo ratings yet

- STP CatalogueDocument37 pagesSTP CataloguemmkattaNo ratings yet

- Tolerances On Pressure VesselDocument10 pagesTolerances On Pressure VesselJaydip VyasNo ratings yet

- Specification For Carbon Steel Piping MaterialsDocument8 pagesSpecification For Carbon Steel Piping MaterialsAmro HarasisNo ratings yet

- Standard Installation Clearances: Panel Length Panel Length Bearing BarsDocument1 pageStandard Installation Clearances: Panel Length Panel Length Bearing BarsFWICIPNo ratings yet

- Pressure Vessel Dimension Inspection: Home About Services Contact What's New! Privacy PolicyDocument15 pagesPressure Vessel Dimension Inspection: Home About Services Contact What's New! Privacy PolicymuthuinchristNo ratings yet

- Drill Bit Size PDFDocument7 pagesDrill Bit Size PDFbalramkinageNo ratings yet

- Racing Rings Installation PDFDocument4 pagesRacing Rings Installation PDFSara KhanNo ratings yet

- Punch Tech DataDocument3 pagesPunch Tech DataanjanmaheshNo ratings yet

- Unified Thread StandardDocument3 pagesUnified Thread Standardeogus9021No ratings yet

- FAQ - Comparison Chart DN To NPSDocument1 pageFAQ - Comparison Chart DN To NPSERONo ratings yet

- Machine Screw ThreadsDocument2 pagesMachine Screw ThreadsMoaed KanbarNo ratings yet

- FNW Fig.B7Document2 pagesFNW Fig.B7kinjalpatel12345No ratings yet

- JIC Tube FlareDocument2 pagesJIC Tube FlarethangavijayNo ratings yet

- Disston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderFrom EverandDisston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderNo ratings yet

- Hex Head Bolts - UNC - BS 1768Document7 pagesHex Head Bolts - UNC - BS 1768ssureshkar7699No ratings yet

- Info On Short BoltingDocument2 pagesInfo On Short Boltingshahbaz1979No ratings yet

- Angle Head Half Operation ManualDocument7 pagesAngle Head Half Operation ManualZira FitriNo ratings yet

- Valery Marinov, Manufacturing TechnologyDocument168 pagesValery Marinov, Manufacturing TechnologyAbir Roy100% (3)

- Mini DVAS DrilDocument54 pagesMini DVAS DrilĐồng Đăng HảiNo ratings yet

- Material EsDocument54 pagesMaterial EsRichardNo ratings yet

- Luren Hob Resharpening Machines (Presentation) PDFDocument52 pagesLuren Hob Resharpening Machines (Presentation) PDFFrancisco ArévaloNo ratings yet

- Format For Work Instruction MatrixDocument2 pagesFormat For Work Instruction MatrixKodhansNo ratings yet

- 0050 EN 2019 10 - Alpine Agiated Ball - ANR WebDocument7 pages0050 EN 2019 10 - Alpine Agiated Ball - ANR WebIvan MatijevićNo ratings yet

- QJet M GeneralDocument12 pagesQJet M GeneralWalter SantosNo ratings yet

- Find Solid Wood Processing, Gewinn Solid Wood ProcessingDocument4 pagesFind Solid Wood Processing, Gewinn Solid Wood ProcessingMuhmmmad BilalNo ratings yet

- Customer Return AnalysisDocument28 pagesCustomer Return AnalysisVikas KashyapNo ratings yet

- M05 MicroKom Hi-FlexDocument16 pagesM05 MicroKom Hi-Flexjimmy_bikerNo ratings yet

- November 2022 Surplus Record Machinery & Equipment DirectoryDocument720 pagesNovember 2022 Surplus Record Machinery & Equipment DirectorySurplus RecordNo ratings yet

- Under WAter WeldingDocument16 pagesUnder WAter WeldingMayank Agarwal100% (1)

- Machine Tools Assignments 1 N 2Document3 pagesMachine Tools Assignments 1 N 2Sunkeswaram Deva PrasadNo ratings yet

- E.2.2 Sheet Metal WorkingDocument18 pagesE.2.2 Sheet Metal WorkingMesfin SisayNo ratings yet

- Data SheetDocument2 pagesData SheetArielNo ratings yet

- Part Number: Part Name: Model: Cutomer:: Measurement Weight (1-5)Document10 pagesPart Number: Part Name: Model: Cutomer:: Measurement Weight (1-5)Mark Daryl MayandocNo ratings yet

- Duratomic TP Brochure GT15-214 PDFDocument24 pagesDuratomic TP Brochure GT15-214 PDFDeysi CardenasNo ratings yet

- 3.125 11ns THread SpecificationDocument4 pages3.125 11ns THread SpecificationvijaygalaxyNo ratings yet

- Presentation Jig and FixturesDocument11 pagesPresentation Jig and FixturesFan Ted LeeNo ratings yet

- MTO Pipe Support LOT-1 - Rev.A - 04.06.2022Document2 pagesMTO Pipe Support LOT-1 - Rev.A - 04.06.2022Pratama - Mech.Eng.No ratings yet