Professional Documents

Culture Documents

FTR#CHSFL/TRG: SPH (Efe (Ate#N

Uploaded by

Maged Lotfy Abdel-aalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FTR#CHSFL/TRG: SPH (Efe (Ate#N

Uploaded by

Maged Lotfy Abdel-aalCopyright:

Available Formats

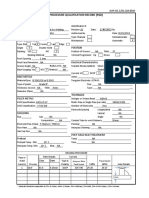

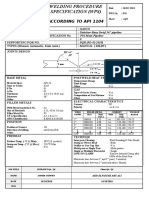

SOUTHERN Ftr#CHSfl/trg :26/B/201 0

BR,4NCII

SPH{EFE{ATE#N {WPS}

ffi Q.A / Q.c

DEPARTAfENT

ACCSRBTNG T# APE } ] #4

It/pS

Sheet

No. 02/2010

: I ofl

COMPANY NAME ENPPI

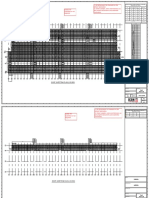

PROJECT NAME AI NOBARIA-ALSADAT- ALFAYOM P/L

WELDII.IG I,ROCEDURE SFECIFICATION No.

REVISION NO.

SUPPORTING PQR NO. PLA2/2010

TYPES ( Manual , Automatic, Semi Auto. : MANUAL ( SMAW )

JOINTS DESIGN

Tre

BASE METAL

Material Spec.

E API 5L -X 65

POSTWELD HBAT TREATMENT

Temperature Range : N.A

Grade. X-65 Time Range :N.A

Thichness 0.188STS0.75 Other :N.A

Diameter [2 < Diameter GAS

Other 36" & 4?.*.. Type of Gas or Gases : N.A

FILLER METALS Composition of Gas l\ilixture : N.A

Other ;N.A

Weld MetalAnalysis A No. : Al

ELECTRICAL CHARACTERISTICS

Size of Electrode 4.3, 4.0 , 5.0 MM

Cu rrent : D.C

No.

Filler Metal : F3

S FA Specification : A 5.1, A 5.5

Polarity :-ve&+ve

AWS Classification : E 6010, E 8010 C

\\/BLD FILLER MDTAI-

POSITION LAYBRS

Position of Groove 5G

Weld Progression AllDor.vn -Hill

E8010

Others

PRtrHEAT

"-\-.

('C 50'c 20-27

Preheat Temp. ) ( Min)

TBCHI\IQE

Interpass Temp. ('C ) ( Max.) 250"C Max Interpass Cleaning Root Grinding & Wire Bruch

String or Weave Bead Both

Orifice or Gas Cup Size : N.A

Multipass or Single Pass Multi -passes

Single or multiple Electrodes multiple

LINE UP CLAIVIP ; Remove of internal

Clamp Be after 100o/o

JOB TITLE PTJ QA / QC ENG, ENPPI QA/QC

ENG / Ahmed Fehry 'r*/

26/08/X010

Z€, t/zn t o

"'/"( ,/'rL*'I*

PETROJET -d r '"' ts>-4

d\

;:il.:;'H:ffi:",:

oneoftheEg\ptianPetroleumCoryorationCompillesffi

ffi @.f," f,q:l

'tt',,.:,,,.,

"*

3

nvfi[P-t

*&* !s,o#PJ t,*uu

,-J" JJ+II c.t-eJirj"ll /-s.rj

LirJAll

i.gitt crtt1L.ii-vt 3

LUI :rJ--Jl i-!Jl sKJ--i J)'-l

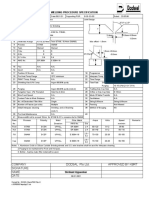

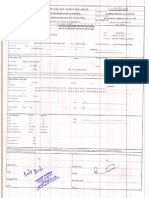

Procedure Qualification Record (PQR)

Specification for welding of class I pipelines and API Std.-l104, 1gth edition {999

llient:GASCO Contractor: PETROJET

rQR No.: PL- 0212010 Rev# 0 Date: 0110912410

//PS No: 2/2010 Rev# 0 Date:

rueldinq Processo(es): SMAW Types(s) Manual/ Semi-Auto/Automatic: Manual

Design : (Showing Joint Fitup dimension, angle

300 t 2.5o

I

!{9&

3ase Metals Technique:

ipecification API 5L Travel Speed 1.93 - 5.59 (mm/sec)

lype of Grade X65 String or weave Bead Both

). No. 1

Multipass or single pass (per side) Multi pass

fhickness of Test Coupon 16 mm

)iameter of Test Coupon 42" Single or Multiple Electrodes Single

Filler Metals Others Only internal clamp

Weld Metal Analysis A No. :A1

Size Of Electrode : 4.0 ,4.0 , 5.0 mm

Filler Metal No : F3

Electrical Characteristics :

S FASpecification :A5.'1 ,A5.5

AW S Classification :E 6010, E 8010 G

)osition

rosition of Groovs 5G lurrent and Polarity DECP

)osition Of Fillet

Neld Prooression All pases Down Hill )olarity: -ve&+ve

reheat

L- 'heat Temp.

(min) 50" C

rod of Heating Propane Torch

3, WELD FILLER METAL CIIRRENT VOI,TAGE

controlling

ethod of Digital Thermometer

trpass temp.(Min & Max) Max 250' C LAYERS Class Diam (mm) Polar. Amp. Range RANGE

Post Weld Heat Treatment N/A 1r' E6010 4.00 -ve 90-120 20-22

Heating Method N/A 2nd E8010 4.00 +ve 120-1 80 20-27

Heating Rate N/A FILL E8010 4.00 +ve 120-180 20-2'7

Soaking Temp. N/A E8010 5.00 +vo 120-1 80 20-2't

Soaking Time N/A +

Coolino Rate N/A CAP 88010 s.00 +ve t20-180 20-27

Ku ,n,LTfi gcfi",i

",,t ame: ,{q

ignature: ignature: utp,:

I

ate: ttql ") o{a ate:

You might also like

- Specifications For Plates: Chemical Composition Mechanical PropertiesDocument7 pagesSpecifications For Plates: Chemical Composition Mechanical Propertiesprajakt_pieNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Document4 pagesProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabNo ratings yet

- Thickness GaugingDocument3 pagesThickness GaugingAmit HasanNo ratings yet

- WeldDocs WPSDocument2 pagesWeldDocs WPSMDSIKKU_2005No ratings yet

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- Welding Procedure Specification (WPS) : in The Outer TubeDocument1 pageWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNo ratings yet

- TPCO ProjectDocument40 pagesTPCO ProjectJebran0% (1)

- PQR Al 6xxxDocument7 pagesPQR Al 6xxxAmin ThabetNo ratings yet

- Weld History SheetDocument2 pagesWeld History SheetAjin S100% (1)

- CV of Engineer MD Sazid Alam1Document8 pagesCV of Engineer MD Sazid Alam1Alam MD SazidNo ratings yet

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pages2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- T.C.L. Co. - Test & Control LaboratoriesDocument2 pagesT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταNo ratings yet

- BPVC Ix QW-482Document2 pagesBPVC Ix QW-482ganesh82No ratings yet

- Calified Welding Procedures List Aplicable For ASD TUG 2810 YN513513Document11 pagesCalified Welding Procedures List Aplicable For ASD TUG 2810 YN513513Costin RotaruNo ratings yet

- Aws N-1 WPS-PQR FormDocument2 pagesAws N-1 WPS-PQR FormEdwin MariacaNo ratings yet

- Voestalpine Heavy Plate TTD ALDUR E 14012013Document13 pagesVoestalpine Heavy Plate TTD ALDUR E 14012013Dragan JerčićNo ratings yet

- NoticeDocument1 pageNoticeAnirban Sen SharmaNo ratings yet

- WPS PQR-06Document9 pagesWPS PQR-06Ranjan KumarNo ratings yet

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNo ratings yet

- Ds Universal Wps Migmag enDocument6 pagesDs Universal Wps Migmag enMarija IvanovskaNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- WPS PQR-08Document8 pagesWPS PQR-08Ranjan KumarNo ratings yet

- QW 482 WPS (Gtaw+smaw) 04.01.2015Document8 pagesQW 482 WPS (Gtaw+smaw) 04.01.2015Srikant GanjiNo ratings yet

- Hyufldri Steel: "I Mill Test Certificate .YDocument1 pageHyufldri Steel: "I Mill Test Certificate .YGurumoorthy RajavijayanNo ratings yet

- Smaw Manual See Permitted Figures (Right) or Per Constr. DWG Butt JointDocument3 pagesSmaw Manual See Permitted Figures (Right) or Per Constr. DWG Butt JointNirmala DeshaNo ratings yet

- TC VerificationDocument33 pagesTC VerificationmaheshNo ratings yet

- ASTM A36 DatasheetDocument4 pagesASTM A36 DatasheetRene D. ArrietaNo ratings yet

- Hardox 450 Data SheetDocument2 pagesHardox 450 Data SheetmatthewpincottNo ratings yet

- SS Pipe Welding ProcedureDocument5 pagesSS Pipe Welding Procedureamit rajputNo ratings yet

- Data Sheet 2006 Strenx 700 20170420 121 371857150 enDocument2 pagesData Sheet 2006 Strenx 700 20170420 121 371857150 enRodrigoNo ratings yet

- 57 PQRDocument13 pages57 PQRAbdul Tri Hamdani HamdaniNo ratings yet

- Asme Ix Int Vol26Document17 pagesAsme Ix Int Vol26Julio CastilhosNo ratings yet

- 08 Omniscan ConventionsDocument11 pages08 Omniscan ConventionsLương Hồ VũNo ratings yet

- Mcnichols GratingsCat09Document21 pagesMcnichols GratingsCat09jasonvigilNo ratings yet

- Tips Wps FormatDocument5 pagesTips Wps FormatWaqas WaqasNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKAnonymous Ij6VfaNo ratings yet

- Test Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)Document1 pageTest Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)yskushwah16No ratings yet

- Spec Sheet - Handler 187Document4 pagesSpec Sheet - Handler 187Hobart Welding ProductsNo ratings yet

- Class P6A6Document24 pagesClass P6A6SalimNo ratings yet

- Agoco Welding Procedure Specification: Gtaw Manual JOINTS (QW-402)Document3 pagesAgoco Welding Procedure Specification: Gtaw Manual JOINTS (QW-402)Anonymous 7vljJzH100% (1)

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- Dimensional Check-Form 3TDocument3 pagesDimensional Check-Form 3Tlempeng durianNo ratings yet

- Commented - 8' PIPE TCDocument1 pageCommented - 8' PIPE TCAqib Khan VCSPNo ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless PipeashokkahirwarNo ratings yet

- Certifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itDocument1 pageCertifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itMohamed RaafatNo ratings yet

- QW-482 WPS FormatDocument2 pagesQW-482 WPS FormatMardeOpamen100% (1)

- ST 37Document7 pagesST 37rendra.farisrNo ratings yet

- Comparison ASTM A 3388 & ISO 11496Document1 pageComparison ASTM A 3388 & ISO 11496Rahul MoottolikandyNo ratings yet

- Template BUTTDocument1 pageTemplate BUTTDylan TriggNo ratings yet

- Proposed Welding Procedure Specification (PWPS) : REV:A3Document1 pageProposed Welding Procedure Specification (PWPS) : REV:A3Shanawas Abdul RazakNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- WPS PQR CompressedDocument5 pagesWPS PQR CompressedBalaje MantravadiNo ratings yet

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- Wps PQRDocument7 pagesWps PQRsobariNo ratings yet

- Weld Procedure Specification (WPS) : According To Asme Ix &Document1 pageWeld Procedure Specification (WPS) : According To Asme Ix &Mina Roger SamyNo ratings yet

- Voestolptne: S LCRDocument1 pageVoestolptne: S LCRYoga ArdiansyahNo ratings yet

- Eaton Fuel HoseDocument6 pagesEaton Fuel HoseKeron TrotzNo ratings yet

- UL - PotterDocument3 pagesUL - PotterMaged Lotfy Abdel-aalNo ratings yet

- OSYSU-1, - 2: Outside Screw and Yoke Valve Supervisory SwitchDocument4 pagesOSYSU-1, - 2: Outside Screw and Yoke Valve Supervisory SwitchMaged Lotfy Abdel-aalNo ratings yet

- Kozziza REV01 PDFDocument11 pagesKozziza REV01 PDFMaged Lotfy Abdel-aalNo ratings yet

- BL 02 FM200 T&C CommentsDocument1 pageBL 02 FM200 T&C CommentsMaged Lotfy Abdel-aalNo ratings yet

- Recommended Practice of EGWDocument7 pagesRecommended Practice of EGWMaged Lotfy Abdel-aalNo ratings yet

- Welding Procedure Specification (WPS) : According To Api 1104Document1 pageWelding Procedure Specification (WPS) : According To Api 1104Maged Lotfy Abdel-aal100% (1)

- PWHDocument1 pagePWHMaged Lotfy Abdel-aalNo ratings yet

- Profile of J.M.S Company: For Trade & EngineeringDocument1 pageProfile of J.M.S Company: For Trade & EngineeringMaged Lotfy Abdel-aalNo ratings yet

- ECITB Technical Testing System Certificate (4) - Eng. RomanyDocument1 pageECITB Technical Testing System Certificate (4) - Eng. RomanyMaged Lotfy Abdel-aalNo ratings yet

- Calibration Certificate HTW1500B - 2011-286386Document1 pageCalibration Certificate HTW1500B - 2011-286386Maged Lotfy Abdel-aalNo ratings yet

- WPQT CertificateDocument104 pagesWPQT CertificateMaged Lotfy Abdel-aal100% (2)

- Painting Procedures ADocument7 pagesPainting Procedures AMaged Lotfy Abdel-aal100% (1)

- PWHDocument1 pagePWHMaged Lotfy Abdel-aalNo ratings yet

- Welder Qualification Test Certificate: PetrojetDocument3 pagesWelder Qualification Test Certificate: PetrojetMaged Lotfy Abdel-aalNo ratings yet

- 0 0 0 0 0 0 0 Total 0 Rest 7 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Total 9 Rest 21Document1 page0 0 0 0 0 0 0 Total 0 Rest 7 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Total 9 Rest 21Maged Lotfy Abdel-aalNo ratings yet

- Equilibrium PractDocument2 pagesEquilibrium PractrainyNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2013/0251618 A1Document12 pagesPatent Application Publication (10) Pub. No.: US 2013/0251618 A1Todd DiNettaNo ratings yet

- Is 4308Document17 pagesIs 4308Anurodh JhaNo ratings yet

- Warmanslurrypumps 160409025643 PDFDocument25 pagesWarmanslurrypumps 160409025643 PDFCleyton L. AlvesNo ratings yet

- Elsa Manual SabreDocument50 pagesElsa Manual SabrerijalharunNo ratings yet

- DAFTAR OBAT-WPS OfficeDocument5 pagesDAFTAR OBAT-WPS OfficeTony RamirezNo ratings yet

- Research Paper On Hair ColourantsDocument4 pagesResearch Paper On Hair ColourantsShridhar AnishettyNo ratings yet

- Api List of SLDocument2 pagesApi List of SLpopoNo ratings yet

- Weld Metal Selector GuideDocument28 pagesWeld Metal Selector GuideBassam AbdelazeemNo ratings yet

- Science Stage 8 Sample Paper 1 - tcm143-595703Document15 pagesScience Stage 8 Sample Paper 1 - tcm143-595703Joseph Jerry-Oche100% (2)

- Daftar Obat "High Alert" (Termasuk Lasa & Elektrolit Konsentrat) - Lakukan Double CheckDocument2 pagesDaftar Obat "High Alert" (Termasuk Lasa & Elektrolit Konsentrat) - Lakukan Double CheckBenk Nurhidayat SusiloNo ratings yet

- ABRO 3450 Foil/Skrim/Kraft (FSK) Sealing Tape: Product InformationDocument1 pageABRO 3450 Foil/Skrim/Kraft (FSK) Sealing Tape: Product InformationKhabbab Hussain K-hNo ratings yet

- Toothpickase Lab ActivityDocument6 pagesToothpickase Lab Activityrachel4151No ratings yet

- Pressure Vessel Plates, Alloy Steel, Chromium-Molybdenum-TungstenDocument3 pagesPressure Vessel Plates, Alloy Steel, Chromium-Molybdenum-TungstenMytzy Godoy TapiaNo ratings yet

- IRR Implementing Rules and Regulations of Philippine Irr of Ra10918 090916epdfDocument42 pagesIRR Implementing Rules and Regulations of Philippine Irr of Ra10918 090916epdfDenise Marfe PedregosaNo ratings yet

- ch04 PDFDocument47 pagesch04 PDFiabureid7460No ratings yet

- FERT18Document253 pagesFERT18Margarit AnamaryaNo ratings yet

- Queen Mary Help of Christians Educational Center: San Francisco Street, Barangay Calahan, Cardona, Rizal Tel. No. 2135075Document2 pagesQueen Mary Help of Christians Educational Center: San Francisco Street, Barangay Calahan, Cardona, Rizal Tel. No. 2135075Phoebe MagosNo ratings yet

- Metal ExtractionDocument58 pagesMetal ExtractionVikasNo ratings yet

- Valve SizingDocument1 pageValve SizingdlescribdNo ratings yet

- HACH Full ProductsDocument275 pagesHACH Full ProductsHuyNo ratings yet

- I Am Sharing 'Industrial Hygiene 1' With YouDocument27 pagesI Am Sharing 'Industrial Hygiene 1' With YouFAISAL DESHPANDENo ratings yet

- Antiwashout Admixtures For Underwater ConcreteDocument2 pagesAntiwashout Admixtures For Underwater Concretemanil_5No ratings yet

- Bursting and Collapsing Pressures of ASTM A312 Stainless Steel PipesDocument1 pageBursting and Collapsing Pressures of ASTM A312 Stainless Steel PipesManuKumarMittalNo ratings yet

- Moles and Empirical FormulaDocument11 pagesMoles and Empirical FormulaZenoxu 7zNo ratings yet

- Msds Diapolisher PasteDocument10 pagesMsds Diapolisher PasteIka KusumawatiNo ratings yet

- Eh PHDocument22 pagesEh PHGörkem Efe100% (1)

- Eor Course 2012 Lecture#1 IntroductionDocument28 pagesEor Course 2012 Lecture#1 Introductioncrown212No ratings yet

- Hydraulic Breaker PDFDocument69 pagesHydraulic Breaker PDFRofie Tritho100% (1)

- Complex Permanent TissueDocument1 pageComplex Permanent TissueFirliana PramesdyaNo ratings yet