Professional Documents

Culture Documents

Weld Procedure Specification (WPS) : According To Asme Ix &

Uploaded by

Mina Roger SamyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weld Procedure Specification (WPS) : According To Asme Ix &

Uploaded by

Mina Roger SamyCopyright:

Available Formats

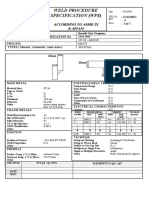

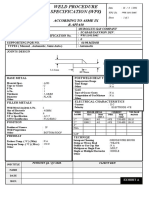

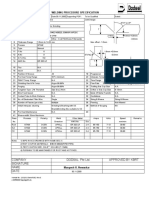

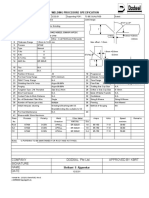

NORTHERN WELD PROCEDURE Date : 11/8/2001

BRANCH

SPECIFICATION (WPS) WPS No. : 20/01DMC

REV

: 0

Q.A / Q.C Sheet : 1 of 1

DEPARTMENT

ACCORDING TO ASME IX

& API 650

COMPANY NAME Burulls Gas Company

WELDING PROCEDURE SPECIFICATION No. 20/01 DMC

SUPPORTING PQR NO. 07/ 98 - MIDOR

PROCESS SMAW

TYPES ( Manual , Automatic, Semi Auto.) MANUAL

JOINTS DESIGN

5-14mm

SHELL

5-14 mm

30-70mm

BASE METAL POSTWELD HEAT TREATMENT

Temperature Range : N.A

Material Spec. : A 283 Time Range : N.A

Type or Grade :C Other : N.A

P No. : 01

GAS

A No. : 01

Type of Gas or Gases : N.A.

Thickness : 10.0 mm

Composition of Gas Mixture : N.A.

Diameter : PLATE

Other : N.A.

Other : Thickness Range Qualified

From 4.78 To 20.0 mm ELECTRICAL CHARACTERISTICS

FILLER METALS Current : D.C

Polarity : Electrode +ve

Weld Metal Analysis A No. : A1

Size of Electrode : 3.25 & 4.0 mm WELD FILLER METAL CURRENT VOLTAGE

LAYERS Class Diam Polar. Amp. RANGE

Filler Metal No. : F2 ( mm ) range

S F A Specification : A 5.1 1ST E6013 3.25 +ve 90-120 25 - 28

AWS Classification : E 6013 2nd E6013 4.0 +ve 120-160 25 - 28

Other

POSITION

CAP E6013 4.0 +ve 120-160 25 - 28

Position of Groove : 3G

Weld Progression : UPHILL TECHNIQE

Other : SHELL Interpass Cleaning : Grinding & Wire Brush

String or Weave Bead : String

PREHEAT

Orifice or Gas Cup Size : N.A.

Preheat Temp. ( C ) ( Min) : Ambient Temp. Multipass or Single Pass : Multipasses

Interpass Temp. ( C ) ( Max.) : 250 C Max Single or Multiple Electrodes : single

Other : Other : Back weld should be applied

JOB TITLE PTJ QA / QC ENG. RASHPETCO QA / QC

DATE

SIGN.

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Weld Procedure Specification (WPS) : According To Asme Ix &Document1 pageWeld Procedure Specification (WPS) : According To Asme Ix &Mina Roger SamyNo ratings yet

- Weld Procedure Specification (WPS) : According To Asme IxDocument1 pageWeld Procedure Specification (WPS) : According To Asme IxMina Roger Samy50% (2)

- Weld Procedure Specification (WPS) : According To Asme Ix &Document1 pageWeld Procedure Specification (WPS) : According To Asme Ix &Mina Roger SamyNo ratings yet

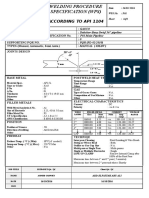

- Welding Procedure Specification (WPS) : According To Api 1104Document1 pageWelding Procedure Specification (WPS) : According To Api 1104Maged Lotfy Abdel-aal100% (1)

- PQR Procedure Qualification Record Krishna SteelDocument2 pagesPQR Procedure Qualification Record Krishna SteelHarshit Adwani100% (2)

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Ethylene Project Fillet Weld PQRDocument1 pageEthylene Project Fillet Weld PQRS GoudaNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- WPS GF170 As 1554.6Document1 pageWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Q-Chem Ethylene Project Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 pagesAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (2)

- Preliminary - Welding Procedure Specification (WPS)Document1 pagePreliminary - Welding Procedure Specification (WPS)Rudi DaNo ratings yet

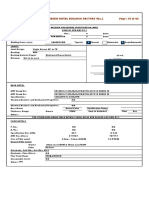

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- Ethylene Project GTAW Welding Procedure QatarDocument1 pageEthylene Project GTAW Welding Procedure QatarS GoudaNo ratings yet

- PQR - Gmaw BCCDocument2 pagesPQR - Gmaw BCCBasel MohammadNo ratings yet

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- PQR PDFDocument2 pagesPQR PDFNjoku ChijiokeNo ratings yet

- Procedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Document2 pagesProcedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Menad SalahNo ratings yet

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- 07.3 111 FW ML PF WPS 20mm EngDocument1 page07.3 111 FW ML PF WPS 20mm EngViktorNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- WELDING PROCEDURE SPECIFICATION FOR TIE-IN WORKSDocument6 pagesWELDING PROCEDURE SPECIFICATION FOR TIE-IN WORKSAshishNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- PQR 3G Fcaw SF71Document3 pagesPQR 3G Fcaw SF71long phamNo ratings yet

- WELDING PROCEDURE FOR STEERING BRACKETSDocument1 pageWELDING PROCEDURE FOR STEERING BRACKETSViktorNo ratings yet

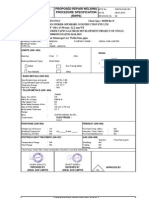

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Document1 pageWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNo ratings yet

- BHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelDocument2 pagesBHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelpradhankruhsnaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDocument2 pagesWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraNo ratings yet

- WPS & PQR VVSPLDocument3 pagesWPS & PQR VVSPLBhargav BbvsNo ratings yet

- Welding Procedure SpecificationDocument4 pagesWelding Procedure SpecificationBhargav BbvsNo ratings yet

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Tz.O.R.C R.O. Project: Second and OtherDocument5 pagesTz.O.R.C R.O. Project: Second and Otherbehzad mohammadiNo ratings yet

- PQR FLow LineDocument2 pagesPQR FLow Linesar sarNo ratings yet

- fLOW PDFDocument1 pagefLOW PDFSureshNo ratings yet

- Fe-7151 Case 3 PDFDocument1 pageFe-7151 Case 3 PDFSureshNo ratings yet

- Fe-7151 Case 1 PDFDocument1 pageFe-7151 Case 1 PDFSureshNo ratings yet

- Flow Element: Base Maximum Flow Normal Flow Property MethodDocument1 pageFlow Element: Base Maximum Flow Normal Flow Property MethodSureshNo ratings yet

- Calculation Data Sheet for Flow Element FE-7151Document1 pageCalculation Data Sheet for Flow Element FE-7151SureshNo ratings yet

- Welding Procedure Specification GuideDocument2 pagesWelding Procedure Specification GuidepoulmackNo ratings yet

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationVISAKHAPATNAM MALAYALEES WELFARE ASSOCIATIONNo ratings yet

- RPM 00342Document3 pagesRPM 00342Iswahyudi AprilyastonoNo ratings yet

- Unirub Techno India PVT 7Document7 pagesUnirub Techno India PVT 7BalajiYachawadNo ratings yet

- State of The Art of MicromachiningDocument16 pagesState of The Art of MicromachiningMarcionilo NeriNo ratings yet

- Quantum Field Theory IDocument599 pagesQuantum Field Theory IBryan Aleman100% (3)

- Aaron Chavez: 161110001@upmh - Edu.mx 442 259 0158Document3 pagesAaron Chavez: 161110001@upmh - Edu.mx 442 259 0158Aarón ChávezNo ratings yet

- JavaScript For FreeBitco inDocument11 pagesJavaScript For FreeBitco invfve vree0% (1)

- 3BSE041584-511 - En Compact Control Builder AC 800M 5.1.1 Getting StartedDocument174 pages3BSE041584-511 - En Compact Control Builder AC 800M 5.1.1 Getting StartedfranciscoproaNo ratings yet

- Numerical Method For Engineers-Chapter 14Document8 pagesNumerical Method For Engineers-Chapter 14MrbudakbaekNo ratings yet

- Pes Inv As 27bDocument5 pagesPes Inv As 27bapi-336208398No ratings yet

- Powder FlowDocument15 pagesPowder FlowSteven SastradiNo ratings yet

- Thermal PhysicsDocument29 pagesThermal PhysicsAnonymous rn5Te9MwkNo ratings yet

- Different Types of GraphsDocument12 pagesDifferent Types of GraphsKianne RM, WCAANo ratings yet

- Kerosene Isosiv Process For Production of Normal Paraffins: Stephen W. SohnDocument6 pagesKerosene Isosiv Process For Production of Normal Paraffins: Stephen W. SohnAshraf SeragNo ratings yet

- BIT Baroda Institute of Technology: Creo (Pro/ENGINEER) Training atDocument4 pagesBIT Baroda Institute of Technology: Creo (Pro/ENGINEER) Training atNIRALINo ratings yet

- Challenges For Control Research CompilationDocument76 pagesChallenges For Control Research CompilationAlexander Losada AlmonacidNo ratings yet

- Equations Needed Full Answers and Working Redox Reaction Theory Qualitative AnalysisDocument13 pagesEquations Needed Full Answers and Working Redox Reaction Theory Qualitative AnalysisEmmaNo ratings yet

- Course Work 1Document4 pagesCourse Work 1Alice PreciousNo ratings yet

- Estimation of Power and Delay of CMOS Phase Detector Using Nano TransistorsDocument57 pagesEstimation of Power and Delay of CMOS Phase Detector Using Nano TransistorsViplav SangvaiNo ratings yet

- DIAGPROG4: PROFESSIONAL DIAGNOSTIC TOOL FOR AUTOMOTIVE REPAIR AND MAINTENANCEDocument8 pagesDIAGPROG4: PROFESSIONAL DIAGNOSTIC TOOL FOR AUTOMOTIVE REPAIR AND MAINTENANCENeile CasaliNo ratings yet

- ArchModels Volume - 126 PDFDocument40 pagesArchModels Volume - 126 PDFgombestralalaNo ratings yet

- Cleaning Validation-Repassa PatrickDocument12 pagesCleaning Validation-Repassa PatrickIin Tirta SunartaNo ratings yet

- Class Exercise Simpleregression Ceo-SalaryDocument1 pageClass Exercise Simpleregression Ceo-Salaryсимона златковаNo ratings yet

- Taskalfa 6550ci Taskalfa 7550ci: Parts ListDocument117 pagesTaskalfa 6550ci Taskalfa 7550ci: Parts ListPavel VintrichNo ratings yet

- Car Racing in A Simulator: Validation and Assessment of Brake Pedal StiffnessDocument17 pagesCar Racing in A Simulator: Validation and Assessment of Brake Pedal StiffnessVaisakh N NairNo ratings yet

- GRE Math 강좌 Set 1Document25 pagesGRE Math 강좌 Set 1Hee_Eun_Jang_6656100% (1)

- Nat Reviewer Set B - Math 10Document2 pagesNat Reviewer Set B - Math 10Jo Mai Hann90% (10)

- Polyethylene Plastic Production ProcessDocument8 pagesPolyethylene Plastic Production Processkiki haikalNo ratings yet

- E11+WR1 OHL Andoolo 2 Test ReportDocument31 pagesE11+WR1 OHL Andoolo 2 Test ReportMuhammad Adrianto LubisNo ratings yet

- SREye - Fisheye Image Dewarping Module For NVR and Viewer PDFDocument16 pagesSREye - Fisheye Image Dewarping Module For NVR and Viewer PDFyshim_4No ratings yet