Professional Documents

Culture Documents

Us 3601426 Rear

Uploaded by

anup tiwari0 ratings0% found this document useful (0 votes)

25 views4 pagesThis document describes a vehicle rear assembly that connects the independent rear wheels. Each wheel is mounted on a suspension arm, which is connected to a transverse shaft member. The two shaft members are connected to each other at their inner ends and to the vehicle body at their outer ends. This allows each wheel to move independently in the vertical direction while maintaining proper wheel alignment and absorbing longitudinal forces through flexibility of the shaft member connections.

Original Description:

bumper crash test

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document describes a vehicle rear assembly that connects the independent rear wheels. Each wheel is mounted on a suspension arm, which is connected to a transverse shaft member. The two shaft members are connected to each other at their inner ends and to the vehicle body at their outer ends. This allows each wheel to move independently in the vertical direction while maintaining proper wheel alignment and absorbing longitudinal forces through flexibility of the shaft member connections.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views4 pagesUs 3601426 Rear

Uploaded by

anup tiwariThis document describes a vehicle rear assembly that connects the independent rear wheels. Each wheel is mounted on a suspension arm, which is connected to a transverse shaft member. The two shaft members are connected to each other at their inner ends and to the vehicle body at their outer ends. This allows each wheel to move independently in the vertical direction while maintaining proper wheel alignment and absorbing longitudinal forces through flexibility of the shaft member connections.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

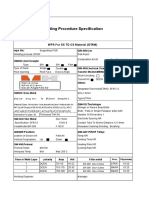

United States Patent (113,601,426

72) Inventor Jacques Hury 50) Field of Search............................................ 280/124;

Rueil-Malnaison, France 267/15, 20

21 ) Appl. No. 872,998

22 Fied Oct. 31, 1969 56) References Cited

45 Patented Aug. 24, 1971 UNITED STATES PATENTS

73) Assignees Automobile Peugeot

Paris, France; 2,823,927 2/1958 Goby............................ 267/20 (X)

Regie Nationale des Usines Renault 2,988,374 6/1961 Boyles.......... Pow 280/24

Billancourt, France 3,473,821 10/1969 Barenyi et al................. 280/124

(32) Priority Nov. 13, 1968 Primary Examiner-Milton Buchler

33 France Assistant Examiner-C. A. Rutledge

31) 173,441 Attorney-Burns, Doane, Swecker & Mathis

ABSTRACT: Rear assembly for motor vehicle, of the type

54) WECLE REAR ASSEMBLY comprising independent wheels and trailing suspension arms,

15 Claims, 4 Drawing Figs. wherein each suspension arm has fixed thereto a shaft member

52) U.S. Cl....................................................... 280/124,

extending transversely with respect to the longitudinal axis of

the vehicle, said shaft members being connected at their outer

267/15 ends to the suspended part of the vehicle and being intercon

51 int. Cl......................................................... B60g 11/32 nected at their inner ends.

3,601,426

1 2

flexibility of displacement in the direction X-X than in the

WEHICLE REAR ASSEMBLY direction Y-Y, direction X-X being parallel to the longitu

The present invention relates to a rear assembly for automo dinal axis of the vehicle.

tive vehicles with independent wheels and trailing arms. The operation of the rear assembly as above described is the

In devices of this type, each rear wheel is mounted on a following:

journal which is fixed to the end of a suspension arm which Each wheel 1 and 1 can shift in the vertical direction inde

must be fixed to the body or chassis by means of mountings pendently from the other wheel, due to the oscillation of

permitting oscillation about an axis essentially transversal with suspension arms 3 and 3 and of corresponding shaft mem

respect to the longitudinal axis of the vehicle, as well as great bers 8 and 9 about axis Y-Y.

10 The purpose of joints 10 and 11 is to permit a relative oscil

flexibility in the longitudinal direction, whilst rendering im

possible any undesirable deflection or swiveling of the wheels. latory or rotational movement between shaft members 8 and

These conditions are usually achieved: 9, although maintaining their axes substantially aligned.

either by fixing each arm to the body by two flexible joints Distance a between these joints should be such that the radial

sufficiently apart from one another, the first placed on a 15 forces which they, withstand be acceptable for the material

side-member, the second fixed towards the center of the used. The longitudinal forces parallel to direction X-X, due to

floor, but this solution makes it necessary to reinforce the uneveness of the road, are absorbed by the displacement of

latter; the outer ends of the shaft members 8 and 9 with respect to

or by linking the two suspension arms to a rigid common the vehicle body, due to the flexibility of joints 14 which in

crossmember which is itself flexibly mounted at its ends 20 turn gives good filtering-out of noise and vibration.

to the vehicle body. However, this displacement in direction X-X only brings

One object of the invention is to satisfy the above stated about in infinitely small displacement of the common axis

conditions without it being necessary to reinforce the floor or Y-Y of shaft members 8 and 9 and a pivoting of the wheels

to use the crossbeam. It provides a rear assembly for an au which is also negligible by reason of the large distance

tomotive vehicle with independent wheels and trailing suspen 25 between the two joints 14. The wheels, therefore, always stay

sion arms, each wheel being mounted on a journal fixed to a correctly aligned.

suspension arm, wherein each suspension arm is integral with If can likewise be stated that the transverse displacement of

or fixed to a shaft member extending essentially transversely the wheels is practically negligible due to the stiffness of the

with respect to the longitudinal axis of the vehicle, said two joints 14 in direction Y-X.

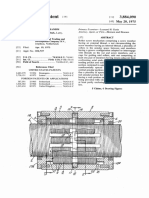

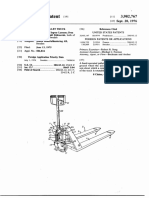

shaft members being substantially coaxial and being respec 30 FIG. 3 shows a modification according to which joints 20

tively connected at their outer ends to the suspended part of and 21 are bushings in an elastomeric material such as polyu

the vehicle and being supported one by the other at their rethane, located in housings 22 of tubular member 8, and hav

respective inner ends. ing internal circular grooves in order to reduce rubbing on

The invention will be hereinafter described, with reference shaft 9. It will, however, be understood that any other type of

to the accompanying drawing wherein: 35 joint which does not produce a torque reaction between mem

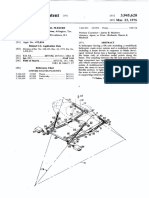

FIG. 1 is a perspective view, partly in section, of a rear as bers 8 and 9 can also be used. In particular, joints equivalent

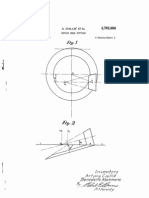

sembly according to the invention; to joints 10, 1 and 20, 21 could be ball or needle bearings.

FIG. 2 is a top plan view, partly in section, of the rear as FIG. 4 shows another modification according to which

sembly according to FIG. 1; joints 10 and 11 are replaced by elastic joints, comprising

FIGS. 3 and 4 are sectional views showing two modifica 40 bushings 30, 31, made of elastomer, bonded to two metallic

tions of the joint between the two shaft members of the as sleeves. The outer sleeve 32, 33, respectively, is mounted as a

sembly. press fit in the female shift 8, and the inner sleeve, 34, 35,

In a vehicle rear assembly, such as shown in FIG. , each respectively, is mounted as a press fit on the male shaft 9.

rear wheel 1 and 1 is mounted on a journal 2 and 2, rigidly In this case, it is necessary to provide a spacer element 36

45 between the outer sleeves 32 and 33 in order to allow of the

fixed to the end of a suspension arm 3, 3 respectively. One

each journal is also fixed, as usual, the lower part 4 of a spring assembly of joint 30 which is remote from the end of tubular

and shock absorber device comprising, for example, an shaft 8. On the other hand, bellows 12 as provided in the other

hydraulic shock absorber 5 and a coaxial coil spring 6, the embodiments become unnecessary.

upper part of this device being rigidly connected to the body 7 50 The last embodiment described with reference to FIG. 4,

which constitutes the suspended part of the vehicle. has the advantage of providing a torque reaction between

According to the invention, the arm 3 of wheel 1 is rigidly parts 8 and 9, caused by bushings 30 and 31 during opposite

connected to a shaft member 8, extending transversely with shifting of the wheels, which produces an anti-inclination or

respect to the longitudinal axis of the vehicle, and having a antiroll correction.

general tubular shape in the embodiment shown. A shaft 55 Another embodiment of the invention can be provided, ac

member 9, coaxial with shaft member 8, is rigidly connected cording to which the two half rear assemblies are identical,

to arm 3 of the other wheel 1. The two shaft members 8 and each carrying a male of female shaft member, the two shaft

9 are fitted one within the other and supported one by the members being supported one by the other by means of a

other by means of two joints 10 and 11, consisting, for exam suitable coupling. This type of coupling could be, for example,

ple, of bearing bushings made of a suitable antifriction materi 60 tubular if the two shift members are male, or solid, if the two

al. The distance between joints 10 and 11 is given by reference shaft members are tubular.

a (FIG. 2). Having now described my invention what I claim as new and

Abellows 12 in rubber, plastic or any other suitable materi desire to secure by Letters Patent is:

al, connects the end of tube 8 with shaft 9 in order to prevent 1. A rear assembly for an automotive vehicle, having inde

foreign matter from reaching joint 11. 65 pendent wheels and trailing suspension arms each wheel being

At their outer ends located out of arms 3", 3, the shaft mounted on a journal fixed to a suspension arm, wherein each

members 8 and 9 are fastened to the suspended part of the suspension arm is integral with or fixed to a shaft member ex

vehicle, in this case side-members 13, by means of elastic tending essentially transversely with respect to the longitu

joints 14, shaft members 8, 9 and joints 10, 11, 14 having a dinal axis of the vehicle, said shaft members being substan

common axis Y-Y. 70 tially coaxial, and being respectively connected at their outer

For each of the joints 14, the center member 15, consisting ends located out of said suspension arms to the suspended part

of the end of shaft member 8 and 9 respectively, is held in an of the vehicle and being supported one by the other at their

elastic collar 16 defining two shoulders 17, held between cup respective inner ends, means being provided between said

chaped elements 18 and side-member 13 by a nut 19. This shift members for allowing a relative angular movement of

type of joint 14, which is known in the art, provides a greater 75 said shafts about their common axis.

3,601,426

3 4

2. A rear assembly as claimed in claim 1, comprising spring member extending essentially transversely with respect to the

return means provided between the two shaft members, said longitudinal axis of the vehicle, said shaft members being sub

spring return means being adapted to exert a reaction torque stantially coaxial, and being respectively connected at their

between the two shaft members when said shaft members un outer ends located out of said suspension arms to the

dergo a relative rotation movement about their common axis. 5 suspended part of the vehicle and being supported one by the

3. A rear assembly as claimed in claim 2, wherein said other at their respective inner ends, means being provided

spring return means comprises two bushings of elastomer, between said shift members for allowing a relative angular

each bonded to two rigid sleeves fitted respectively to the two movement of paid shafts about their common axis.

shaft members, a tubular spacer element being provided 10. A vehicle as claimed in claim 9, comprising spring

between the two outer sleeves. 10

4. A rear assembly as claimed in claim 1, wherein one of spring return means provided between the two shaft members, said

said shaft members is tubular and surrounds the other of said return means being adapted to exert a reaction torque

between

shafts over an overlapping area, bearing means being provided dergo a relativethe two shaft members when said shaft members un

between the shaft members, respectively adjacent the ends of rotation movement about their common axis.

said overlapping area. 11. A vehicle as claimed in claim 10, wherein said spring

5 return

5. A rear assembly as claimed in claim 4, wherein said bear bonded means to two

comprises two bushings of elastomer, each

rigid sleeves fitted respectively to the two shaft

ing means comprises bushings made of antifriction material. members, a tubular spacer element being provided between

6. A rear assembly as claimed in claim 4, wherein said bear the two outer sleeves.

ing means comprises ball or needle bearings. 12. A vehicle as claimed in claim 11, wherein one of said

7. A rear assembly as claimed in claim 1, wherein the outer 20 shaft members is tubular and surrounds the other of said shafts

end of each shaft member is connected to the suspended part over an overlapping area, bearing means being provided

of the vehicle by an elastic joint having a greater stiffness in between the shaft members, respectively adjacent the ends of

the transverse direction of the vehicle than in the longitudinal said overlapping area.

direction of the vehicle.

8. A rear assembly as claimed in claim 1, wherein one of 25 13. A vehicle as claimed in claim 12, wherein said bearing

means comprises bushings made of antifriction material.

said shaft members is tubular and surrounds the other of said

shaft members over an overlapping area, a radial clearance 14. A vehicle as claimed in claim 13, wherein said bearing

being defined between said shaft members and bearing means means comprises ball or needle bearings.

being provided therebetween respectively adjacent the ends of 15. A vehicle as claimed in claim 14, wherein the outer end

said overlapping area. 30 of each shaft member is connected to the suspended part of

9. A rear assembly for an automotive vehicle, having inde the vehicle by an elastic joint having a greater stiffness in the

pendent wheels and trailing suspension arms, each wheel directiontransverse direction of the vehicle than in the longitudinal

being mounted on a journal fixed to a suspension arm, wherein of the vehicle.

each suspension arm is integral with or fixed to a shaft

35

40

45

50

55

60

65

70

75

You might also like

- Patent USPTO 4098523 Traction DeviceDocument5 pagesPatent USPTO 4098523 Traction Devicexeron7126No ratings yet

- United States Patent (19) : HermannsDocument3 pagesUnited States Patent (19) : HermannsIvan ReyesNo ratings yet

- Us4173933 PDFDocument10 pagesUs4173933 PDFRizki Fajar NovantoNo ratings yet

- Combined GearboxDocument8 pagesCombined Gearboxkats2404No ratings yet

- NasaDocument6 pagesNasaKevin DominichNo ratings yet

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDocument6 pagesDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloNo ratings yet

- FLEX BEAM Bell 206Document7 pagesFLEX BEAM Bell 206Lewis MarcvsNo ratings yet

- United States Patent (19) : Dec. 10, 1991 (45) Date of PatentDocument4 pagesUnited States Patent (19) : Dec. 10, 1991 (45) Date of PatentKeval KamaniNo ratings yet

- US Patent 3884090Document5 pagesUS Patent 3884090sthollanderNo ratings yet

- 3,328,019 June 27, 1967: Filed Oct. 20, 1965Document3 pages3,328,019 June 27, 1967: Filed Oct. 20, 1965zgregzNo ratings yet

- United States Patent (10) Patent No.: US 6,341,790 B1: Chen (45) Date of Patent: Jan. 29, 2002Document10 pagesUnited States Patent (10) Patent No.: US 6,341,790 B1: Chen (45) Date of Patent: Jan. 29, 2002Eric Manuel Mercedes AbreuNo ratings yet

- US5186686Document11 pagesUS5186686雷黎明No ratings yet

- US20110274550A1Document9 pagesUS20110274550A1雷黎明No ratings yet

- Ax Lens Us PensionDocument42 pagesAx Lens Us PensionJeremy TherkelsenNo ratings yet

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- US20140302938A1Document15 pagesUS20140302938A1雷黎明No ratings yet

- T Red.: 3. Sheets-Sheet LDocument6 pagesT Red.: 3. Sheets-Sheet LThyagaraj A HNo ratings yet

- First: United States PatentDocument7 pagesFirst: United States Patentyraju88No ratings yet

- US3580211-Method of Shaft Alignment of A Main Engine Shaft in ShipbuildingDocument3 pagesUS3580211-Method of Shaft Alignment of A Main Engine Shaft in ShipbuildingMahnooshNo ratings yet

- United States Patent: GitnesDocument9 pagesUnited States Patent: GitnesrakkaNo ratings yet

- US4827759Document7 pagesUS4827759jonyNo ratings yet

- Us 2120533asfafafDocument5 pagesUs 2120533asfafafankitsarvaiyaNo ratings yet

- United States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,121Document7 pagesUnited States Patent (19) : Anderson Et Al. 54 Yacht Mast 11) 4,072,12112348No ratings yet

- April 2, 1968.: Filed Sept 26, 1966Document7 pagesApril 2, 1968.: Filed Sept 26, 1966Pedja Bekic100% (1)

- Nov. 18, 1969 H, I, Hans EN 3,478,972: Filed Aug. 27, 1965Document3 pagesNov. 18, 1969 H, I, Hans EN 3,478,972: Filed Aug. 27, 1965Karin AndersonNo ratings yet

- Us3443375 PDFDocument3 pagesUs3443375 PDFRamos GabeNo ratings yet

- Articulated Haulage VehicleDocument20 pagesArticulated Haulage Vehicleeleuliev.berik00No ratings yet

- Universal Joints (Automobile)Document15 pagesUniversal Joints (Automobile)Anoj pahathkumburaNo ratings yet

- Dec. 27, 1955 H. Hettch 2,728,188: Af470 Ae/7cMDocument3 pagesDec. 27, 1955 H. Hettch 2,728,188: Af470 Ae/7cMparasara66No ratings yet

- United States PatentDocument6 pagesUnited States Patent155No ratings yet

- Universal JointDocument17 pagesUniversal Jointakmalzuhri96No ratings yet

- Horizontal Folding Assembly For MultihulDocument6 pagesHorizontal Folding Assembly For MultihulFlavio LuciusNo ratings yet

- Us955823 PDFDocument3 pagesUs955823 PDFSashikant SharmaNo ratings yet

- Descr: Clutch, Gearbox and Propeller ShaftsDocument17 pagesDescr: Clutch, Gearbox and Propeller ShaftsValBMSNo ratings yet

- Sept. 16, 1969 J. Marcovc-3,466,911: Filed Day L, 1967 2 Sheets-SheetDocument4 pagesSept. 16, 1969 J. Marcovc-3,466,911: Filed Day L, 1967 2 Sheets-SheetLucas RaithsNo ratings yet

- United States Patent: BauvinDocument3 pagesUnited States Patent: Bauvingibson_sx87No ratings yet

- Way Cases: Nov. 9, 1965 W. E. Schoenborn 3,216,699Document5 pagesWay Cases: Nov. 9, 1965 W. E. Schoenborn 3,216,699Thyaga RajNo ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- US3982767Document6 pagesUS3982767takanobu ouraNo ratings yet

- US4678202Document8 pagesUS4678202basarNo ratings yet

- Belt Fed BAR (Belgium) US2136512Document4 pagesBelt Fed BAR (Belgium) US2136512apoorva singhNo ratings yet

- US3977531Document15 pagesUS3977531Huy Nguyễn Võ XuânNo ratings yet

- US2726694 - Single Screw Actuated Pivoted Clamp (Saxton Clamp - Kant-Twist)Document2 pagesUS2726694 - Single Screw Actuated Pivoted Clamp (Saxton Clamp - Kant-Twist)devheadbot100% (1)

- EP09166154NWA1Document10 pagesEP09166154NWA1maes.daan1No ratings yet

- United States Patent (19) : 11 Patent Number: 4,717,169 45 Date of Patent: Jan. 5, 1988Document6 pagesUnited States Patent (19) : 11 Patent Number: 4,717,169 45 Date of Patent: Jan. 5, 1988Anonymous DxaBg8fUENo ratings yet

- Feb. 4, 1941. E. T. Shaw 2,230,338: (3N 77. E. % 2 N% Ee3Document7 pagesFeb. 4, 1941. E. T. Shaw 2,230,338: (3N 77. E. % 2 N% Ee3ValBMSNo ratings yet

- Hypoid Gear CuttingDocument9 pagesHypoid Gear CuttingHano LourensNo ratings yet

- Reverse Energy Bow Patent US 7743760 B2Document8 pagesReverse Energy Bow Patent US 7743760 B2DoukhoborNo ratings yet

- Thrust BlockDocument2 pagesThrust Blockkyaw yaNo ratings yet

- Asmit M B Armiet AxleDocument12 pagesAsmit M B Armiet AxleAsifNo ratings yet

- Ellis LupuDocument6 pagesEllis LupuPaul Ciprian TeglaNo ratings yet

- Z Z MW", 4%#: ¿,-Á 44 @WWW @enmaDocument3 pagesZ Z MW", 4%#: ¿,-Á 44 @WWW @enmabelchior alvaroNo ratings yet

- United States Patent: Chang Et AlDocument9 pagesUnited States Patent: Chang Et AlEric Manuel Mercedes AbreuNo ratings yet

- Diagrama Electrico de ControlDocument7 pagesDiagrama Electrico de ControlemernelsonmanNo ratings yet

- patent-US3165866-Crankshaft Main Journal Regrinding ProcessDocument2 pagespatent-US3165866-Crankshaft Main Journal Regrinding ProcessMahnooshNo ratings yet

- US20120056033A1Document8 pagesUS20120056033A1雷黎明No ratings yet

- United States Patent (19) : 11 Patent Number: 45) Date of Patent: Jan. 7, 1997Document9 pagesUnited States Patent (19) : 11 Patent Number: 45) Date of Patent: Jan. 7, 1997Kaustubh PanchalNo ratings yet

- US4458549Document8 pagesUS4458549Chandru VelNo ratings yet

- United States Patent (19) : Primary Examiner-Samuel ScottDocument7 pagesUnited States Patent (19) : Primary Examiner-Samuel ScottRockerss RockerssNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Convected Co OrdinatesDocument1 pageConvected Co Ordinatesrd_mechNo ratings yet

- Emp 006Document2 pagesEmp 006Brian FreemanNo ratings yet

- Bo-45 Catalogo # 2 PDFDocument957 pagesBo-45 Catalogo # 2 PDFJavier PérezNo ratings yet

- BerlinerLuft. Brochure HygCond 2017-2021 Eng. WebDocument24 pagesBerlinerLuft. Brochure HygCond 2017-2021 Eng. WebFabian FelsNo ratings yet

- Aircraft General Knowledge: Hydraulics and Landing GearDocument53 pagesAircraft General Knowledge: Hydraulics and Landing GearRizkinsya IlhamNo ratings yet

- Workshop Manual Transporter 2016 10-29Document109 pagesWorkshop Manual Transporter 2016 10-29samueleNo ratings yet

- Duo Safe Double Cont InstallDocument8 pagesDuo Safe Double Cont InstallahmedNo ratings yet

- Ball Mill Heat Balance ExplanationDocument4 pagesBall Mill Heat Balance ExplanationVisnu Sankar67% (3)

- Transmotauto 2015Document107 pagesTransmotauto 2015zoragiNo ratings yet

- Vpower en 2022-01 WebDocument18 pagesVpower en 2022-01 WebEnrique ChavezNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- Ans To IS 800 LSM CodeDocument11 pagesAns To IS 800 LSM Codeanon_854101020% (1)

- Er6n Owner ManualDocument180 pagesEr6n Owner Manualjuan_guillermo_perez100% (2)

- Manual Book Dryer HRD350 PDFDocument112 pagesManual Book Dryer HRD350 PDFGoswandi0% (1)

- Modelling The Seismic Response of An Unreinforced Masonry StructureDocument152 pagesModelling The Seismic Response of An Unreinforced Masonry Structurecandsbanda100% (1)

- Ǘǚǟǚǜǚǧǒ Ǘnjǝǘnj Engine Oils: Ambra Mastergold HSP 10W-30 Ambra Mastergold HSP 15W-40Document38 pagesǗǚǟǚǜǚǧǒ Ǘnjǝǘnj Engine Oils: Ambra Mastergold HSP 10W-30 Ambra Mastergold HSP 15W-40Orkhan Manouchehri-LaleyiNo ratings yet

- Series 4300 Vertical In-Line: SubmittalDocument2 pagesSeries 4300 Vertical In-Line: SubmittalBrianNo ratings yet

- Automatic Float Switches 836 Series ABDocument37 pagesAutomatic Float Switches 836 Series ABJorge ReyesNo ratings yet

- Plate and Frame Heat ExchangerDocument6 pagesPlate and Frame Heat ExchangerAkshay bhuranNo ratings yet

- QuizDocument1 pageQuizXiao ZenNo ratings yet

- 2301 Woodward Speed ControlDocument4 pages2301 Woodward Speed ControlManuel Otero100% (1)

- Factors Affecting MachinabilityDocument1 pageFactors Affecting MachinabilityPrasad WasteNo ratings yet

- Welding Procedure Specification: WPS For SS TO CS Material (GTAW)Document1 pageWelding Procedure Specification: WPS For SS TO CS Material (GTAW)Lipika GayenNo ratings yet

- E PR 491Document41 pagesE PR 491aizzuan_1No ratings yet

- Peugeot 307 1600cc E3 NfuDocument4 pagesPeugeot 307 1600cc E3 NfuZoli BorbelyNo ratings yet

- An Experimental Study On The Effect of MIG Welding Parameters On The Weld-Bead Shape CharacteristicsDocument5 pagesAn Experimental Study On The Effect of MIG Welding Parameters On The Weld-Bead Shape Characteristicstejap314No ratings yet

- LCV 01Document4 pagesLCV 01trilok corporationNo ratings yet

- Liebherr A309 Litronic Wheel Excavator Service Repair Manual SN20221 and Up PDFDocument170 pagesLiebherr A309 Litronic Wheel Excavator Service Repair Manual SN20221 and Up PDFjfjksekdmeikNo ratings yet

- Vacuum Bag MoldingDocument36 pagesVacuum Bag MoldingKarthick PrasadNo ratings yet

- TRANSPORT PHENOMENA - Unit 1 NotesDocument150 pagesTRANSPORT PHENOMENA - Unit 1 NotesRathi ManiNo ratings yet