Professional Documents

Culture Documents

Installation Instructions for AODE 95 Shift Solenoid Kit

Uploaded by

Guilherme ZoboliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Instructions for AODE 95 Shift Solenoid Kit

Uploaded by

Guilherme ZoboliCopyright:

Available Formats

INSTAllATION INSTRUCTIONS

--

MS AODE 95 76919

Master Solenoid Kit 00 00

FITS AODE/4R70W Bracket

some '95, '96 -'97 76923

EPC

or Lockup

AODE Shift Solenoid Dual Pack 4. Using a 13/16" open-end wrench on the

inner nut and a 12mm wrench on the

76919 20 to 40 Ohms

manual shaft flats, loosen the inner nut.

AODE MCCC Lock-up Solenoid Slide the manual shaft partially out of the

76921 10 to 16 Ohms case to complete removal of the inner nut.

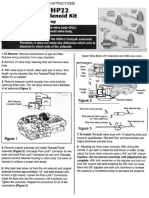

1.ToRemove:

Unplug the 5. Remove manual shaft from case and

remove rooster comb and park pawl rod

harness from the from case.

old solenoid.

6. Remove one 8mm bolt holding the EPC (Electronic

Remove the two

Pressure Control) solenoid bracket and discard OEM

bolts holding the

retaining bracket. Disconnect EPC wires and remove sole-

old solenoid to the

noid.

valve body. One

of the bolts 7. To Install: Before attempting to install the EPC solenoid

secures both the grease the snout to prevent a-rings from rolling off. Reuse the

dual solenoid and OEM bolt. Connect vehicle wiring harness to the new 76923

the MCCC Lock- EPC solenoid.

up (Figure 1). 8. Reinstall manual shaft and rooster comb with park pawl rod

Pull the dual in the case. Install inner nut on manual shaft. Using a 13/16"

solenoid directly out and discard. Remove the MCCC Lock-up open-end wrench, tighten the inner nut while holding the

solenoid. manual shaft with a 12mm wrench.

2. To Install: Insert the new Teckpak MCCC .

9. Make sure the manual valve and the rooster comb are

solenoid, (Figure 2). Then install the Dual properly lined up, and install the manual shaft retaining pin.

Shift Solenoid into the valve body (Figure 1).

f

Install manual lever detent spring and roller with one 8mm

nghten the bolts to specification. Plug the retaining bolt.

OEM harness connector into the center of

10. Install MLPS and adjust according to the manufacturer's

the new Dual solenoid, and connect the

MCCC Lock-up solenoid. Figure 2 specifications.

11. Test drive the vehicle to perform shift test.

AODE EPC

76923 2.48 to 5.66 ohms 12. Adjusting the force motor solenoid. After driving the

vehicle, if you wish to make the shift firmer or softer, simply

1. To Remove: Remove two 8mm bolts retaining manual lever

adjust the force motor solenoid using a 3/8" and 5/8" wrench.

position sensor (MLPS) to case. Remove MLPS from manual

Caution: Do not remove wrenches until adjustments are

shaft (Figure 3).

. complete. With both wrenches on the adjuster and lock nut,

Hetalmng bOlt

2. Remove one I - hold 3/8" wrench still while breaking the 5/8" lock nut loose.

8mm bolt retain- Move the 3/8" adjuster one-sixth turn clockwise to increase

Helalmng Manual shin

ing manual lever bracket retaining pin the pressure or counterclockwise to decrease the pressure.

detent spring and Line Pressure:

.Manual lever

roller assembly to "Ulm""'UI 50-75: P,D, N (closed throttle position)

position

the valve body. sensor 80-120: Reverse (closed throttle position)

3. Remove Roostercomb 160-210: P,D, N (open throttle position)

manual shaft 220-280: Reverse (open throttle position)

roll pin. If you experience high line pressure in "Park", a-ring may

Hgure J have rolled during installation. An extra a-ring is provided for

a second attempt. Please grease the snout.'c

_& AA/.."."., "ft~"",,"_":,.'W..11

~..-

You might also like

- Ms Aode: Master Solenoid KitDocument1 pageMs Aode: Master Solenoid KitGuilherme ZoboliNo ratings yet

- Installation instructions for master solenoid kitDocument1 pageInstallation instructions for master solenoid kitGuilherme ZoboliNo ratings yet

- Installation Instructions for 545L60E Master Solenoid KitDocument1 pageInstallation Instructions for 545L60E Master Solenoid KitGuilherme ZoboliNo ratings yet

- Steering SystemDocument12 pagesSteering Systemluis tocoraNo ratings yet

- Msa 4 LDDocument1 pageMsa 4 LDdrmichael29No ratings yet

- EnertorkDocument22 pagesEnertorkTj Bro BroNo ratings yet

- SKI Elec Tronic Reverse (Line-Up) - Supplement mmr2017-121 enDocument9 pagesSKI Elec Tronic Reverse (Line-Up) - Supplement mmr2017-121 enErne Lange OlsenNo ratings yet

- Ma 1500000 WMDocument7 pagesMa 1500000 WMCarlos ReyesNo ratings yet

- MS 4T60E: Master Solenoid KitDocument1 pageMS 4T60E: Master Solenoid KitGuilherme ZoboliNo ratings yet

- MS 4L80E Transmission Solenoid Installation GuideDocument1 pageMS 4L80E Transmission Solenoid Installation GuideGuilherme ZoboliNo ratings yet

- STARTER 02 01 srm0106 PDFDocument16 pagesSTARTER 02 01 srm0106 PDFcarlos maradiaga100% (1)

- S80 Replace Shift SolenoidDocument38 pagesS80 Replace Shift SolenoidZulkifli Zainal RampakNo ratings yet

- Civic 1996 2000 D16Y5 D16D8 B16A2Document176 pagesCivic 1996 2000 D16Y5 D16D8 B16A2Juan David RamirezNo ratings yet

- Asco - Solenoide Ef8017g1 Red HatDocument4 pagesAsco - Solenoide Ef8017g1 Red HatMariano DomenechNo ratings yet

- Semi Solid Link Solenoid Installation Instructions 37mt, 41mt and 42mt Starters 12v and 24vDocument6 pagesSemi Solid Link Solenoid Installation Instructions 37mt, 41mt and 42mt Starters 12v and 24vElfego Ortega GarciaNo ratings yet

- Semi Solid Link Solenoid Installation Instructions 50MT Motor 12V and 24VDocument2 pagesSemi Solid Link Solenoid Installation Instructions 50MT Motor 12V and 24VAbu Naufal HanifahNo ratings yet

- 37, 41, 42MT SSL Solenoids PDFDocument4 pages37, 41, 42MT SSL Solenoids PDFjuanNo ratings yet

- sl35 Installation InstructionsDocument2 pagessl35 Installation InstructionsHenry CanalesNo ratings yet

- Ms Axode 91: Master Solenoid KitDocument1 pageMs Axode 91: Master Solenoid KitGuilherme ZoboliNo ratings yet

- Maintenance: OS030EC (C801) OS/SS030BE (D826)Document10 pagesMaintenance: OS030EC (C801) OS/SS030BE (D826)Hector PuacNo ratings yet

- Electronic Pressure Control (EPC) Solenoid: RemovalDocument2 pagesElectronic Pressure Control (EPC) Solenoid: RemovalJavier MgzNo ratings yet

- Fpg18Fb Manual Oil Return Kit (826-1517) Installation InstructionsDocument1 pageFpg18Fb Manual Oil Return Kit (826-1517) Installation InstructionsServicios y Repuestos Jeremy Azhael 2320 C.ANo ratings yet

- 2005 S60 Front Cig Socket RemoveDocument2 pages2005 S60 Front Cig Socket RemoveЙордан ПетровNo ratings yet

- Master Solenoid Kit: MS KM-175Document1 pageMaster Solenoid Kit: MS KM-175Guilherme ZoboliNo ratings yet

- Assemble GEMO D-04 Contactless Ignition System in Under 40 StepsDocument9 pagesAssemble GEMO D-04 Contactless Ignition System in Under 40 StepsManuel Ćulibrk100% (1)

- Turn Signals 8.1: RemovalDocument8 pagesTurn Signals 8.1: RemovalMarcelo Ramos SaldanhaNo ratings yet

- Pinion Clearance - Adjust: Shutdown SIS Previous ScreenDocument3 pagesPinion Clearance - Adjust: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- Proximity Switch InstallationDocument3 pagesProximity Switch InstallationSaleh AlomariNo ratings yet

- In-Vehicle Repair: Output Shaft Speed (OSS) SensorDocument11 pagesIn-Vehicle Repair: Output Shaft Speed (OSS) SensorAlex Maceira GraterolNo ratings yet

- Removal: CH-7 SR-24Document3 pagesRemoval: CH-7 SR-24Boncu BoncuNo ratings yet

- 3) 4H.1790.06.0.00 Etp Installation Instruction DocumentDocument13 pages3) 4H.1790.06.0.00 Etp Installation Instruction DocumentAlfiya AnamNo ratings yet

- 16K in PDFDocument2 pages16K in PDFossoskiNo ratings yet

- Weldtron, Inc.: Instructions For The Installation of The Weldtron-57 R-57 Idler Control Upgrade KitDocument12 pagesWeldtron, Inc.: Instructions For The Installation of The Weldtron-57 R-57 Idler Control Upgrade KitMark trahanNo ratings yet

- KC22/32 SERIES Sealless Non-Metallic Centrifugal Pumps Installation and Maintenance Instructions AssemblyDocument6 pagesKC22/32 SERIES Sealless Non-Metallic Centrifugal Pumps Installation and Maintenance Instructions AssemblyEdwin Collado FigueroaNo ratings yet

- Points Eliminator: Conversion Part No. 2030Document2 pagesPoints Eliminator: Conversion Part No. 2030masakpNo ratings yet

- Engine PerformanceDocument33 pagesEngine PerformanceAudirwbenz RubenNo ratings yet

- Floor Shift Parking Lock CableDocument3 pagesFloor Shift Parking Lock Cablejespergl86No ratings yet

- Electric BrakeDocument14 pagesElectric BrakeHector Puac100% (1)

- Assembly Gemo d05 enDocument9 pagesAssembly Gemo d05 enbergsten532No ratings yet

- Park/Neutral Position Switch Assy (Atm) : ReplacementDocument3 pagesPark/Neutral Position Switch Assy (Atm) : ReplacementluisNo ratings yet

- MSD Ignition Installation Guide for Small EnginesDocument8 pagesMSD Ignition Installation Guide for Small EnginesrxhughesNo ratings yet

- Armatur StarterDocument4 pagesArmatur StarterIrwan DiharjoNo ratings yet

- Installation GuideDocument3 pagesInstallation GuideGregorio EspinosaNo ratings yet

- Kalmar Montacargas DCE 90-180, DCE 70-32E3-70-35E Workshop Manual (PDF - Io)Document151 pagesKalmar Montacargas DCE 90-180, DCE 70-32E3-70-35E Workshop Manual (PDF - Io)ValeriNo ratings yet

- Motor Operating Device UEMC 40 A - , B - , D - : Installation, Operating and Recycling GuideDocument38 pagesMotor Operating Device UEMC 40 A - , B - , D - : Installation, Operating and Recycling GuidecepchileNo ratings yet

- General Information: WarningDocument23 pagesGeneral Information: WarningKristian FonNo ratings yet

- Valve Body F4A222 PDFDocument1 pageValve Body F4A222 PDFSanun Automatictranmission100% (1)

- NOTICE! Starting Motor Must Be Removed From Vehicle Before The Semi-Solid Link Solenoid Can Be RemovedDocument4 pagesNOTICE! Starting Motor Must Be Removed From Vehicle Before The Semi-Solid Link Solenoid Can Be RemovedDaniel Jose FrancoNo ratings yet

- A2201 PDFDocument12 pagesA2201 PDFhamzaNo ratings yet

- Starter Upgrade From Standard (Type 400) To Over Crank Protection (Type 450) Instructions 42mtDocument4 pagesStarter Upgrade From Standard (Type 400) To Over Crank Protection (Type 450) Instructions 42mtAlexter AyalaNo ratings yet

- General Information: Checks & RepairsDocument24 pagesGeneral Information: Checks & RepairsChristian BedoyaNo ratings yet

- Body Electrical System - PDF - LIL EVODocument107 pagesBody Electrical System - PDF - LIL EVOShannon AsimNo ratings yet

- Crankshaft Front SealDocument4 pagesCrankshaft Front SealFredy QuistialNo ratings yet

- Instructions: Headlamp Visor KitDocument2 pagesInstructions: Headlamp Visor KitPaco JonesNo ratings yet

- Brake SystemDocument12 pagesBrake Systemluis tocoraNo ratings yet

- Motor 1AZ-FE OverhaulDocument29 pagesMotor 1AZ-FE OverhaulfredhNo ratings yet

- crane HI-4EDocument8 pagescrane HI-4EseowshengNo ratings yet

- 2cv Manual3Document9 pages2cv Manual3alfonsoNo ratings yet

- CGen GY6 50cc Service Manual PDFDocument199 pagesCGen GY6 50cc Service Manual PDFSharkykzn0% (1)

- Electromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationFrom EverandElectromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationRating: 4 out of 5 stars4/5 (1)

- R380 Gearbox Overhaul ManualDocument60 pagesR380 Gearbox Overhaul ManualIgnus CronjeNo ratings yet

- A604 A606 42rleDocument2 pagesA604 A606 42rleGuilherme ZoboliNo ratings yet

- Mazda R4-AEL, R4AXEL (929) : Transmission Code: 131Document2 pagesMazda R4-AEL, R4AXEL (929) : Transmission Code: 131Guilherme ZoboliNo ratings yet

- Axode Ax4sDocument2 pagesAxode Ax4sGuilherme ZoboliNo ratings yet

- A604 A606 42rle PDFDocument2 pagesA604 A606 42rle PDFGuilherme Zoboli100% (2)

- Allison 1000/2000: SOLENOID TEST: (Engine Off)Document2 pagesAllison 1000/2000: SOLENOID TEST: (Engine Off)Guilherme ZoboliNo ratings yet

- Allison WTEC II PDFDocument2 pagesAllison WTEC II PDFGuilherme ZoboliNo ratings yet

- 01 MDocument2 pages01 MGuilherme ZoboliNo ratings yet

- 01m PDFDocument2 pages01m PDFGuilherme Zoboli67% (3)

- MS 4L80E Transmission Solenoid Installation GuideDocument1 pageMS 4L80E Transmission Solenoid Installation GuideGuilherme ZoboliNo ratings yet

- Ms Axode 91: Master Solenoid KitDocument1 pageMs Axode 91: Master Solenoid KitGuilherme ZoboliNo ratings yet

- Test and repair the Subaru 4 speed 4EAT transmissionDocument2 pagesTest and repair the Subaru 4 speed 4EAT transmissionGuilherme ZoboliNo ratings yet

- Toyota Transmission Code 010 DiagnosticsDocument2 pagesToyota Transmission Code 010 DiagnosticsGuilherme ZoboliNo ratings yet

- Master Solenoid Kit: MS KM-175Document1 pageMaster Solenoid Kit: MS KM-175Guilherme ZoboliNo ratings yet

- MS 4L80E Transmission Solenoid Installation GuideDocument1 pageMS 4L80E Transmission Solenoid Installation GuideGuilherme ZoboliNo ratings yet

- MS Master Solenoid Kit: Shift Solenoid 2 Violet Blue:::::... Violet . - Shift Solenoid 1Document1 pageMS Master Solenoid Kit: Shift Solenoid 2 Violet Blue:::::... Violet . - Shift Solenoid 1Guilherme ZoboliNo ratings yet

- MS 4T60E: Master Solenoid KitDocument1 pageMS 4T60E: Master Solenoid KitGuilherme ZoboliNo ratings yet

- ZF 5hp24Document46 pagesZF 5hp24Davidoff Red100% (1)

- Modulo e Comtrole BCM Ix35Document2 pagesModulo e Comtrole BCM Ix35Guilherme ZoboliNo ratings yet

- Aliment A CaoDocument1 pageAliment A CaoGuilherme ZoboliNo ratings yet

- Focus 2009 MC9S12XHZ512 Modelo 2Document3 pagesFocus 2009 MC9S12XHZ512 Modelo 2Guilherme ZoboliNo ratings yet

- C600 - Inventec Calcutta 10Document5 pagesC600 - Inventec Calcutta 10Vika Fivi AnggrainiNo ratings yet

- Catalogo Automatizacion Rockwell PDFDocument388 pagesCatalogo Automatizacion Rockwell PDFRienzi Nicolás Guzmán AravenaNo ratings yet

- Suspension Trasera 97-98Document6 pagesSuspension Trasera 97-98kilofome05No ratings yet

- VCDS Windows Based VAG/VAS Emulator Fault Diagnosis ReportDocument3 pagesVCDS Windows Based VAG/VAS Emulator Fault Diagnosis ReportJulio Ortega WalkerNo ratings yet

- 1997 Harley Davidson Softail Models Parts CatalogDocument498 pages1997 Harley Davidson Softail Models Parts CatalogcoyoteassasinNo ratings yet

- Flow Measuring Instruments & Level Indicators from ISO 9001 CompanyDocument4 pagesFlow Measuring Instruments & Level Indicators from ISO 9001 CompanyI. Murali KrishnaNo ratings yet

- PGm304, PGm365-1 sGm304, sGm365, sGm466Document2 pagesPGm304, PGm365-1 sGm304, sGm365, sGm466MtHdJimNo ratings yet

- DSE5210 Installation Instructions PDFDocument2 pagesDSE5210 Installation Instructions PDFJose R. AlvarezNo ratings yet

- BPW EA EBS - 37041103e PDFDocument100 pagesBPW EA EBS - 37041103e PDFAyoub Ayoub100% (1)

- GTR-205 Generator Controller Manual: Web SiteDocument23 pagesGTR-205 Generator Controller Manual: Web SiteBruno MarianoNo ratings yet

- Ema PDFDocument98 pagesEma PDFIulianBurcaNo ratings yet

- Sony - FM/MW/SW Reproductor de Cassette - Xrca440x EsDocument60 pagesSony - FM/MW/SW Reproductor de Cassette - Xrca440x EsSabrina HarrisNo ratings yet

- RT75 Product Guide: Rough Terrain Crane Specs and FeaturesDocument20 pagesRT75 Product Guide: Rough Terrain Crane Specs and FeaturesKiller boyNo ratings yet

- Ahri 440-2008Document10 pagesAhri 440-2008damaso taracenaNo ratings yet

- You're Reading An Excerpt. Click Here To Read Official SAMSUNG AS24FBCN User GuideDocument5 pagesYou're Reading An Excerpt. Click Here To Read Official SAMSUNG AS24FBCN User GuideGustavo MosqueraNo ratings yet

- Varun Patil ProjectDocument22 pagesVarun Patil Projectpatil samrudhiNo ratings yet

- Program PLC CountersDocument67 pagesProgram PLC Countersanon_9215003380% (1)

- Seb01-2 R2Document11 pagesSeb01-2 R2Pedro EdilNo ratings yet

- 74LS244Document5 pages74LS244marcelloNo ratings yet

- Digital Clock Using ArduinoDocument14 pagesDigital Clock Using Arduinoshivanshu67% (3)

- Step Drive Circuit Analysis BreakdownDocument11 pagesStep Drive Circuit Analysis BreakdownYuda AditamaNo ratings yet

- Power Transistors PDFDocument4 pagesPower Transistors PDFsupriyaNo ratings yet

- Einaldrawing: Shipyard: Jinling ShipyardDocument29 pagesEinaldrawing: Shipyard: Jinling ShipyardVinay Kumar NeelamNo ratings yet

- Standard Features: Your One-Stop Source For Material Handling Control SolutionsDocument2 pagesStandard Features: Your One-Stop Source For Material Handling Control SolutionsZahir KhiraNo ratings yet

- Williams 1996 Tales of The Arabian Nights Parts ListDocument78 pagesWilliams 1996 Tales of The Arabian Nights Parts ListzokiNo ratings yet

- RHRP840, RHRP850, RHRP860: Package FeaturesDocument4 pagesRHRP840, RHRP850, RHRP860: Package Featuresbruno barbosaNo ratings yet

- Internship ReportDocument21 pagesInternship Reportshashankyuva NNo ratings yet

- 580 590 Series 3 Variable Volume Pilot Controls PDFDocument62 pages580 590 Series 3 Variable Volume Pilot Controls PDFG & C Maquinaria100% (1)

- A3M60: Absolute Encoders Multiturn, PROFIBUS: Resolution Up To 31 BitsDocument16 pagesA3M60: Absolute Encoders Multiturn, PROFIBUS: Resolution Up To 31 BitsRaghdaNo ratings yet

- Panasonic TC-P50C1 (SM)Document111 pagesPanasonic TC-P50C1 (SM)Afton RobertNo ratings yet