Professional Documents

Culture Documents

Shotcrete PDF

Uploaded by

Anonymous 9eC6ncOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shotcrete PDF

Uploaded by

Anonymous 9eC6ncCopyright:

Available Formats

Concrete Technology

Shotcrete

Concrete Technology

Field Application of

Shotcrete

An overview of field shotcrete operations

Concrete Technology

Excavate

Professor Kamran M. Nemati

Winter Quarter 2015 1

Concrete Technology

Shotcrete

Concrete Technology

Muck

Material removed in the process of excavating or mining

3

Concrete Technology

Support

Professor Kamran M. Nemati

Winter Quarter 2015 2

Concrete Technology

Shotcrete

Concrete Technology

Concrete Technology

Introduction and History

The shotcrete process has grown into an

important and widely used construction technique.

In 1910, a double chambered cement gun was

introduced to the construction industry.

The sand-cement product of this device was given

the proprietary name Gunite.

In the ensuing years, trade marks such as

Guncrete, pneucrete, Blastcrete, Blocrete,

Jetcrete, and the terms pneumatically applied

mortar and concrete, were introduced to describe

similar processes.

Professor Kamran M. Nemati

Winter Quarter 2015 3

Concrete Technology

Shotcrete

Concrete Technology

Introduction and History

The early 1930s saw the generic term

“shotcrete” introduced by the American

Railway Engineering Association to describe the

Gunite process.

In 1951, the American Concrete Institute (ACI)

adopted the term shotcrete to describe the dry-

mix process.

Shotcrete is now applied to the wet-mix

process and has gained universal acceptance in

the United States.

Concrete Technology

Definition Of Terms /References

Gunite / Mortar: Maximum aggregate size = sand

Shotcrete : Maximum aggregate size = 3/8” typical

(1/2” max)

AKA: Sprayed Concrete (Europe)

Relevant ACI Publications

506R-90 Guide to Shotcrete

506.3R-91 Guide to Certification of Shotcrete

Nozzlemen

506.4R-94 Guide for the Evaluation of Shotcrete

506.2-95 Specification for Materials, Proportioning

and Application of Shotcrete

506.1R-98 State of the Art Report on Fiber

Reinforced Shotcrete

8

Professor Kamran M. Nemati

Winter Quarter 2015 4

Concrete Technology

Shotcrete

Concrete Technology

American Concrete Institute Publications

Internet Address:

http://aci-int.org

506R-90 = $52.95

(This is the base document)

Concrete Technology

Component Materials

Aggregate

Fine = 60 - 70% of combined weight of aggregates

Coarse = 30-40% of combined weight of aggregate

Portland Cement

Types I, II = 6.5 - 9.0 sack (611 - 846 lb/yd )

3

Water (potable)

Target W/C = 0.33 - 0.45

WRA

Objective = workability with reduction of W/C ratio

Microsilica

Typical range = 5% - 15% by weight of cement

Latex Modifier

More commonly used in thin layer repair work than in ground support

Accelerator

Silicates

Aluminates

Dosage = 2 - 5% by weight of cementitious material

10

Professor Kamran M. Nemati

Winter Quarter 2015 5

Concrete Technology

Shotcrete

Concrete Technology

Strength Development

(MPa)

2900 psi

1450 psi

725 psi

290 psi

145 psi

11

Concrete Technology

Shotcrete Applications

Sealing of Ground Mass Interface

Prevent erosion and/or air slaking (crumbling)

Deter exfiltration/infiltration

Component of Excavation Support System

Sole Support

Rockbolt / shotcrete system

Rockbolt / shotcrete / lattice girder system

Final Lining

Practical, functional or esthetic considerations do

not require formed concrete

Repair Work

12

Professor Kamran M. Nemati

Winter Quarter 2015 6

Concrete Technology

Shotcrete

Concrete Technology

What is Shotcrete Good For?

Very wet conditions

Frozen ground conditions

Ground conditions wherein

bond is unreliable

Intermittent application -

small quantities - remote

areas

13

Concrete Technology

Dry Process Technique + Flow Chart

Dry process - Dry materials

are combined in a "pot",

transported pneumatically to a

nozzle where water, any liquid

admixtures and accelerator are

introduced into the streamfeed

and then immediately sprayed

onto the target surface with a

velocity developed by

compressed air under a

pressure of 90 - 100 psi.

14

Professor Kamran M. Nemati

Winter Quarter 2015 7

Concrete Technology

Shotcrete

Concrete Technology

Wet Process Technique + Flow Chart

Wet process - All materials

with exception of accelerator

are combined within a

batch/mix plant, transported

via positive displacement

pump to a nozzle where

accelerator is introduced into

the streamfeed and then

immediately sprayed onto

the target surface with a

velocity developed by

compressed air under a

pressure of 90 - 100 psi.

15

Concrete Technology

Comparison of the Dry- and Wet-Mix

Processes

Dry-mix process Wet-mix process

1. Instantaneous control over mixing 1. Mixing water is controlled at the

water and consistency of mix at the delivery equipment and can be

nozzel to meet variable field accurately measured

conditions.

2. Better suited for placing mixes 2. Better assurance that the mixing

containing lightweight aggregates, water is thoroughly mixed with

refractory materials and shotcrete other ingredients

requiring early strength properties

3. Capable of being transported longer 3. Less dusting and cement loss

distances accompanies the gunning

operation

4. Start and stop placement 4. Normally has less rebound

characteristics are better with resulting in less material waste

minimal waste and greater

placement flexibility

5. Capable of higher strengths 5. Capable of greater production

16

Professor Kamran M. Nemati

Winter Quarter 2015 8

Concrete Technology

Shotcrete

Concrete Technology

Weigh Batch / mix Equipment Selection

Batch/Mix Equipment

Weigh batcher

Drum (turbine-screw) mixer

Admixture feeder(s) - furnished by

supplier

Fiber feeder - furnished by supplier

ASTM Spec ref = C94-90

Standard Specification for Ready-

Mixed Concrete

17

Concrete Technology

Volumetric Batch/mix Equipment Selection

Volumetric batcher

Screw (drum, turbine) mixer

Admixture feeder(s) - furnished by suppliers

Fiber feeder - furnished by suppliers

ASTM Specification reference =C685-90

Standard Specification for Concrete Made By Volumetric

Batching and Continuous Mixing

18

Professor Kamran M. Nemati

Winter Quarter 2015 9

Concrete Technology

Shotcrete

Concrete Technology

Transport Equipment Selection

Transit (drum) mixer

Agitating vessel

Non-agitating vessel

Pneumatic transport (dry process material)

Pump Transport (wet process material)

19

Concrete Technology

Placement Equipment Selection

Wet Process Equipment

Compressed Air

Water (construction water for cleanup)

Positive displacement pump (or shotcrete pot)

Accelerator dosing pump

Robotized placer

20

Professor Kamran M. Nemati

Winter Quarter 2015 10

Concrete Technology

Shotcrete

Concrete Technology

Typical Wet Process Spread

21

Concrete Technology

Placement Equipment Selection

Dry Process Equipment

Compressed Air

Water (potable)

Shotcrete Pot

Accelerator dosing device

Robotized placer

22

Professor Kamran M. Nemati

Winter Quarter 2015 11

Concrete Technology

Shotcrete

Concrete Technology

Selected Dry Process Equipment

23

Concrete Technology

Selected Dry Process Equipment

24

Professor Kamran M. Nemati

Winter Quarter 2015 12

Concrete Technology

Shotcrete

Concrete Technology

Other Selection Considerations

Required operating parameters

Role of shotcrete in the intended operation

Strength gain constraints

Accessibility to appropriate equipment

Process type selection as a function of labor supply

Recent volume of similar work in the area

Labor agreements, local economic situations which would deter

importing skilled labor.

Quality and work ethic of labor force.

Wet process favored when any of preceding are negative.

Opinion: wet process offers better control of more of the

critical variables:

W/C ratio is determined by the batch/mix process

Moisture content of the raw materials is less critical

Calibrated accelerator dosage

Wet mix affords a more uniform mix in place (more coarse

aggregate, less rebound)

25

Concrete Technology

Preparation

Although the dry process is similar,

let’s assume the wet process for

procedural discussion. Preparation

requires:

Procure materials (compatibility testing)

Develop trial mixes (compatibility

testing!!!)

Mobilize equipment and labor force

Shoot test panels

26

Professor Kamran M. Nemati

Winter Quarter 2015 13

Concrete Technology

Shotcrete

Concrete Technology

Operation

Surface preparation is essential - will probably require

pressure washing

Make up a cement /water mix about the consistency of

mayonnaise (a volume of 1 ft3)

Pour this lubricating mix into pump hose before starting

to pump the production mixture

When the pumped production mixture reaches the

nozzle, turn on compressed air, accelerator and robotic

placer motions

Using good nozzle technique, apply shotcrete evenly to

target surfaces

Clean pump lines by blowing a rabbit and finishing with

a thorough water flush of the entire system

Cure of in place material = important consideration

(+85% humidity = best solution) 27

Concrete Technology

Nozzle Technique

28

Professor Kamran M. Nemati

Winter Quarter 2015 14

Concrete Technology

Shotcrete

Concrete Technology

Nozzle Technique

29

Concrete Technology

Administrative Nuances of Shotcrete

Measurement For Payment

Shotcrete by the unit price

Measurement for payment = calculated area (volume)

All plant and process waste

All rebound

All variations in thickness

All variations in plant yield

All materials expended in test phase

Measurement for payment = plant cubic yard

It poses minimal risk

Shotcrete paid as a lump sum

30

Professor Kamran M. Nemati

Winter Quarter 2015 15

You might also like

- 3D Concrete Printing Technology: Construction and Building ApplicationsFrom Everand3D Concrete Printing Technology: Construction and Building ApplicationsNo ratings yet

- TG2May09 Asfalto Espumado PDFDocument148 pagesTG2May09 Asfalto Espumado PDFfredy cardenasNo ratings yet

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringFrom EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringRating: 4 out of 5 stars4/5 (5)

- SubSylPDF 936Document2 pagesSubSylPDF 936Ujjval SolankiNo ratings yet

- Ceramic Matrix Composites: Materials, Modeling and TechnologyFrom EverandCeramic Matrix Composites: Materials, Modeling and TechnologyNo ratings yet

- Civil Sem 4Document27 pagesCivil Sem 4malik mohsinNo ratings yet

- Method Statement - Asphaltic Concrete Works: April 2018Document11 pagesMethod Statement - Asphaltic Concrete Works: April 2018Shahab Bashir KhanNo ratings yet

- Elastic, Plastic and Yield Design of Reinforced StructuresFrom EverandElastic, Plastic and Yield Design of Reinforced StructuresNo ratings yet

- Thesis Concrete TechnologyDocument7 pagesThesis Concrete TechnologyPayPeopleToWritePapersAlbuquerque100% (2)

- ShotcreteDocument37 pagesShotcretemishraciv100% (1)

- Le Rôle de La Construction Structurelle Précoce Dans La Fabrication Numérique Avec Du BétonDocument10 pagesLe Rôle de La Construction Structurelle Précoce Dans La Fabrication Numérique Avec Du BétonKhalid EL ABBAOUINo ratings yet

- Cone Penetration Testing: Methods and InterpretationFrom EverandCone Penetration Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (3)

- Seminar Report at RachithaDocument18 pagesSeminar Report at RachithaMegha KallihalNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Sprayed Conc BookDocument127 pagesSprayed Conc Bookz_sheri0% (1)

- Magnetic Particle Inspection: Techniques, Applications, Interviews Q&A, and GlossaryFrom EverandMagnetic Particle Inspection: Techniques, Applications, Interviews Q&A, and GlossaryNo ratings yet

- 899 2811 2 PBDocument12 pages899 2811 2 PBpau roxasNo ratings yet

- Concrete Materials: Properties, Specifications, and TestingFrom EverandConcrete Materials: Properties, Specifications, and TestingRating: 4.5 out of 5 stars4.5/5 (5)

- Literature Review On Concrete Containing Crumb Rubber - Bharuch2k15c0107 - (Pg. 22-24)Document3 pagesLiterature Review On Concrete Containing Crumb Rubber - Bharuch2k15c0107 - (Pg. 22-24)Er Devraj Khandelwal67% (3)

- Method Statement For Formwor 2Document28 pagesMethod Statement For Formwor 2Simplicio Goncalves100% (1)

- 19 Types of Cement - Properties and Uses in Construction - Cement ConcreteDocument9 pages19 Types of Cement - Properties and Uses in Construction - Cement Concretevishnu ksNo ratings yet

- LATICRETE Mass Transit Ceramic Tile & Stone Technical Design ManualDocument264 pagesLATICRETE Mass Transit Ceramic Tile & Stone Technical Design ManualLATICRETE® InternationalNo ratings yet

- Practical PDFDocument127 pagesPractical PDFZhir nawzadNo ratings yet

- Performance of Flowable Concrete For Application in Underground Structures - NATM Tunnel and Station Box of Mumbai Metro ProjectDocument19 pagesPerformance of Flowable Concrete For Application in Underground Structures - NATM Tunnel and Station Box of Mumbai Metro ProjectIJRASETPublicationsNo ratings yet

- Shortcrete Technology by Anuj Chaudhary & Abdul QadirDocument3 pagesShortcrete Technology by Anuj Chaudhary & Abdul QadirAnuj ChaudharyNo ratings yet

- Prefabricated Construction Using Fiber Cement BoardsDocument25 pagesPrefabricated Construction Using Fiber Cement BoardsKmw18 ce013No ratings yet

- UsShotcrete MiningDocument85 pagesUsShotcrete MiningFranzAvilaRiveraNo ratings yet

- MOS For Footing Concrete Pouring PDFDocument11 pagesMOS For Footing Concrete Pouring PDFYe YintNo ratings yet

- Production and Properties of Foamed Concretep: February 2013Document11 pagesProduction and Properties of Foamed Concretep: February 2013kinley dorjeeNo ratings yet

- IJSTEV3I12079Document5 pagesIJSTEV3I12079Ritesh BomdyalNo ratings yet

- Capsule 09-4cDocument2 pagesCapsule 09-4cwalaywanNo ratings yet

- Different Types of Cement and Their Uses - We Civil EngineersDocument10 pagesDifferent Types of Cement and Their Uses - We Civil EngineersMuhammad YaseenNo ratings yet

- Study of Gold Mine Tailings Utilization As Fine Aggregate Material For Producing Shotcrete Based On Concept of Green TechnologyDocument11 pagesStudy of Gold Mine Tailings Utilization As Fine Aggregate Material For Producing Shotcrete Based On Concept of Green TechnologyWisam BadarNo ratings yet

- Miss Design ManualDocument65 pagesMiss Design Manualengsam777No ratings yet

- Concret Mix Design (M10 To M100)Document65 pagesConcret Mix Design (M10 To M100)Rajesh Kollipara93% (14)

- Lecture1 PDFDocument17 pagesLecture1 PDFVelmuruganNo ratings yet

- Concrete TechnologyDocument183 pagesConcrete TechnologyRitik SinghNo ratings yet

- Final WorkDocument18 pagesFinal WorkTasmay EnterprisesNo ratings yet

- Tremie ConcreteDocument14 pagesTremie ConcreteHaris Alam100% (1)

- SCDocument91 pagesSCMARISETTI YAMININo ratings yet

- Experimental Investigation of Chemical and Physical Properties of Cements Manufactured in PakistanDocument15 pagesExperimental Investigation of Chemical and Physical Properties of Cements Manufactured in PakistanAyesha AyubNo ratings yet

- A Review of Design and Construction paraDocument3 pagesA Review of Design and Construction parachengotom300No ratings yet

- Asphalt Concrete Mix Design Development of More Rational Approaches STP1041-EB.35513 PDFDocument141 pagesAsphalt Concrete Mix Design Development of More Rational Approaches STP1041-EB.35513 PDFSri RamyaNo ratings yet

- Study On Partial Replacement of Cement by Saw Dust Ash in ConcreteDocument6 pagesStudy On Partial Replacement of Cement by Saw Dust Ash in ConcreteYonas D. Ebren100% (1)

- Method Statement - ASPHALT CONCRETE WORKS PDFDocument10 pagesMethod Statement - ASPHALT CONCRETE WORKS PDFTAHER AMMAR100% (6)

- Method Statement For Concrete WorksDocument6 pagesMethod Statement For Concrete WorksChamux skalNo ratings yet

- Method Statement For Footing Concrete PouringDocument9 pagesMethod Statement For Footing Concrete PouringKishore KumarNo ratings yet

- MTRD 24 1 1994Document41 pagesMTRD 24 1 1994benedict110903No ratings yet

- Materials: On Phase Identification of Hardened Cement Pastes by Combined Nanoindentation and Mercury Intrusion MethodDocument18 pagesMaterials: On Phase Identification of Hardened Cement Pastes by Combined Nanoindentation and Mercury Intrusion MethodMirza BasitNo ratings yet

- Concrete TechnologyDocument88 pagesConcrete TechnologysalahNo ratings yet

- Shotcrete As A Good Looking Final FinishDocument10 pagesShotcrete As A Good Looking Final FinishAnonymous Re62LKaACNo ratings yet

- Compression Test On Concrete PDFDocument13 pagesCompression Test On Concrete PDFAudia SavitriNo ratings yet

- Analysis and Design Study of Concrete Paver Blocks With Feedback LoopDocument7 pagesAnalysis and Design Study of Concrete Paver Blocks With Feedback LoopMaestro ConstructionNo ratings yet

- Method Statement For Concrete Core CuttingDocument5 pagesMethod Statement For Concrete Core CuttingSimon GikonyoNo ratings yet

- SCM Tech Brief USDocument8 pagesSCM Tech Brief USRameshNayakaNo ratings yet

- Road Design & ConstructionDocument157 pagesRoad Design & ConstructionSekichi Yamada80% (10)

- Injection Molding Troubleshooting For Common Design DefectsDocument3 pagesInjection Molding Troubleshooting For Common Design DefectsAlmgihty ZeusNo ratings yet

- Client Name: Project Name:: Ezar For Engineering and Technical ServicesDocument1 pageClient Name: Project Name:: Ezar For Engineering and Technical ServicesdhahiNo ratings yet

- A Proposal To The Construction of A 10 Storey BuildingDocument2 pagesA Proposal To The Construction of A 10 Storey BuildingChristine Noquis100% (1)

- Ecospace: Hoistway Plan ViewDocument1 pageEcospace: Hoistway Plan ViewHoward RoarkNo ratings yet

- Refrieration Unit Lab ReportDocument29 pagesRefrieration Unit Lab ReportNor Elina Ahmad100% (9)

- RAF10 - FLOAT CONTROL VALVE InlineDocument4 pagesRAF10 - FLOAT CONTROL VALVE InlineTeoxNo ratings yet

- FINAL - TCH Bruhn - Sept. 20 Presentation To DoS - 20170920Document12 pagesFINAL - TCH Bruhn - Sept. 20 Presentation To DoS - 20170920Lachlan LabereNo ratings yet

- Institutional Arrangement in Drinking Water SupplyDocument5 pagesInstitutional Arrangement in Drinking Water SupplySandeep ReddyNo ratings yet

- Concrete Design Excel Sheet2Document27 pagesConcrete Design Excel Sheet2alvin lumawagNo ratings yet

- Curriculum Vitae: ObjectiveDocument3 pagesCurriculum Vitae: ObjectiveNaCE groupNo ratings yet

- Tender For Carrying Out Construction of Compound W Tender Notice 22486835 HPCL UttaranchalDocument5 pagesTender For Carrying Out Construction of Compound W Tender Notice 22486835 HPCL UttaranchalVeena NageshNo ratings yet

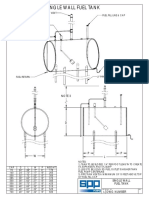

- Deposito Diessel-Newberry - Data Sheet - Drawing - Single Fuel Tank PDFDocument4 pagesDeposito Diessel-Newberry - Data Sheet - Drawing - Single Fuel Tank PDFRolan PonceNo ratings yet

- Bridgette (OTC)Document31 pagesBridgette (OTC)mhel vianney bariquitNo ratings yet

- Chennai CMBT Metro Station AIC Access Audit ReportDocument44 pagesChennai CMBT Metro Station AIC Access Audit ReportDisability Rights AllianceNo ratings yet

- BS en 14576-2005Document15 pagesBS en 14576-2005bdr85No ratings yet

- Measurement of in Situ Shear Strength of Rock Mass: Rajbal SinghDocument12 pagesMeasurement of in Situ Shear Strength of Rock Mass: Rajbal SinghManish Kumar SinghNo ratings yet

- Ramset SARB ANZ Ed.3 DynaBolt Plus SLEEVE ANCHORSDocument2 pagesRamset SARB ANZ Ed.3 DynaBolt Plus SLEEVE ANCHORSScott McCallumNo ratings yet

- Affa Tiles BookletDocument41 pagesAffa Tiles BookletAnonymous iTzCnMNo ratings yet

- 4935-w0 Standard For Purchase of Full-Encirclement Welded Split SleevesDocument3 pages4935-w0 Standard For Purchase of Full-Encirclement Welded Split SleevesLorenaNo ratings yet

- Floor FinishesDocument24 pagesFloor FinishesEdgar JavierNo ratings yet

- 01 The Law and Practice of Delay Claims A Practical Introduction TrainorDocument19 pages01 The Law and Practice of Delay Claims A Practical Introduction TrainorMOHNo ratings yet

- Viking VGIC365Document53 pagesViking VGIC365薛泽绵No ratings yet

- Greater Bridgeport Combined Sewer Overflow Guide For ResidentsDocument2 pagesGreater Bridgeport Combined Sewer Overflow Guide For ResidentsBridgeportCT100% (1)

- Asco Valves Series T298Document2 pagesAsco Valves Series T298OceanexNo ratings yet

- MS-CVL-009 Erection of Hollowcore Slabs 1Document12 pagesMS-CVL-009 Erection of Hollowcore Slabs 1Suju RajanNo ratings yet

- Correct Duct SizingDocument3 pagesCorrect Duct Sizingnim_gourav1997100% (1)

- Tigges Catalogue PDFDocument119 pagesTigges Catalogue PDFwal1547No ratings yet

- B.O.Q of Electro-Mechanical Works 26Document1 pageB.O.Q of Electro-Mechanical Works 26asdsd dsdaNo ratings yet

- Gebe005 Aug08 PDFDocument22 pagesGebe005 Aug08 PDFأسامة خالدNo ratings yet