Professional Documents

Culture Documents

Latihan - 2

Latihan - 2

Uploaded by

Sartika Nur AisyahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Latihan - 2

Latihan - 2

Uploaded by

Sartika Nur AisyahCopyright:

Available Formats

LATIHAN - 2

MATA KULIAH : Aplikasi Komputer

NAMA : Sartika Nur Aisyah

MATERI : Ms.Office

SEMESTER : II

KELAS : 2A / D3

HARI/TANGGAL :

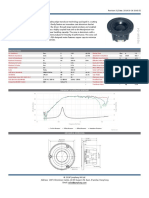

Effects of the Column and Mobile Phase Flow In GC

Why are modern GC based on a capillary column?

Back in the van Deenter Eqn, H = A+ B/u+Cu

Remember , u = flow rate

A = multiple pants

B/u = longitudinal diffusion effect

Cu = MT effect

We want tominimize H as much as possible

Which of the above affects H the most in GC?

B/u effects!

Diffusion coefficient are large in the gas phase

𝐿

𝜎 = √2𝐷

𝑢

Simply increasing the flow rate partially addresses the B/u effects in GC, but let’s now

consider the column itself.

“Older” packed column

Usualy 1/8” (3.2 mm OD,2.2 mm I.D.) diameter, 1-2 m length

Design impedes gas flow

“Newer” capillary column

0.25 mm inner diameter

Major point,less restricted flow path

Flow rate about 20 ml/minor 20 cm/min

Other major factors that influence the performance of capillary column relative to pack ones

are evident in the table below

Typing 1/8”

Spesificatoin Typical capillary Comments

packed

0.25 mm No packing material

I.D. 2.2 mm

0.1 – 0.53 mm less restricted flow

Typing 1/8”

Spesificatoin Typical capillary Comments

packed

MT for s.p. part of

Cu

Dr 5 𝜇𝑚 0.25 𝜇𝑚 2

𝑓(𝑘 ′ )𝑑

𝑓

𝐶𝑠 = 𝛼

𝐷𝑠

L 1-2 m 10-60 m HN = L

N 4,000 180,000

Lower cost Higher sep, efficiency

Adventages Easy to make Faster sep,

Larger samples Better for complex mixtures

GC stationary phases.

Older packed column – uniform silica particles (150-250𝜇𝑚) required to ensure uniform

path lenght (the “A” term in the van Deenter Eqn.) Surface are chemically modified (see

below). The column themselves were either glass or stainless steel.

Capillary column – fused silica which like the particles in the packed column require

chemical modification (below).

Mobile Phase

Stationary

OH OH OH OH OH OH OH OH

I I I I I I I I

silica

You might also like

- KV25 P PDFDocument14 pagesKV25 P PDFAbel Rivera Cuatlayotl100% (1)

- Carnoustie Golf Links - Golf Course GuideDocument11 pagesCarnoustie Golf Links - Golf Course GuideMulligan Plus100% (2)

- Simple Sentence Combining WorksheetDocument2 pagesSimple Sentence Combining WorksheetManuel Garcia Grandy50% (2)

- Latihan 1 2020 Kelas BDocument2 pagesLatihan 1 2020 Kelas BAna HanaNo ratings yet

- NC-Valve Series 09: SpecificationsDocument2 pagesNC-Valve Series 09: SpecificationsJPNo ratings yet

- Pan To Dynamics 110721Document65 pagesPan To Dynamics 110721Prof. TRDNo ratings yet

- Lecture 01Document25 pagesLecture 01shazNo ratings yet

- Calculation of The Net Head and Power GenerationDocument15 pagesCalculation of The Net Head and Power GenerationUdara PriyankaraNo ratings yet

- Spe 18370 MSDocument11 pagesSpe 18370 MSAT8iNo ratings yet

- Air Flow Principles: Duct DesignDocument49 pagesAir Flow Principles: Duct Designded endNo ratings yet

- Clarifier Settling Tank PDFDocument25 pagesClarifier Settling Tank PDFvenustasiaNo ratings yet

- Fluid Dynamics: 2.1 Surface-Tension-Controlled FillingDocument4 pagesFluid Dynamics: 2.1 Surface-Tension-Controlled FillingOskr Wero NoriegaNo ratings yet

- Paper (Vol. 40, No. 5, October, 2022, Pp. 1258-1264)Document7 pagesPaper (Vol. 40, No. 5, October, 2022, Pp. 1258-1264)Banipal yaqobNo ratings yet

- Unit 1 & 2Document97 pagesUnit 1 & 2ritesht.pg23.ecNo ratings yet

- Amr 1016 377Document7 pagesAmr 1016 377mytgamesNo ratings yet

- LIne SizingDocument8 pagesLIne SizingHua Tien DungNo ratings yet

- High Aspect Ratio: Plating PcbsDocument6 pagesHigh Aspect Ratio: Plating Pcbsdrag99onNo ratings yet

- Data Sheet N85-3 N86 E008 201701 WebDocument7 pagesData Sheet N85-3 N86 E008 201701 WebRebeca Zarazúa DíazNo ratings yet

- FEDSM2012-72094: Study of Flow Controlling On LP Turbine at Different Reynolds NumberDocument11 pagesFEDSM2012-72094: Study of Flow Controlling On LP Turbine at Different Reynolds NumberKarthikNo ratings yet

- Engineering Data Sheet: Principle Technical CharacteristicsDocument9 pagesEngineering Data Sheet: Principle Technical Characteristicsleobiec1No ratings yet

- Second Stage LC Filter DesignDocument3 pagesSecond Stage LC Filter DesignSang Young SoNo ratings yet

- Peide Aqusoften Descaler 2021Document8 pagesPeide Aqusoften Descaler 2021May XuNo ratings yet

- Thermal Simulation and Optimization of A Common-Mode Filter For A SiC InverterDocument6 pagesThermal Simulation and Optimization of A Common-Mode Filter For A SiC InverterMaurizio TrancheroNo ratings yet

- Reliability Under Hot Humid ConditionDocument4 pagesReliability Under Hot Humid ConditionE.n. ElangoNo ratings yet

- KB Fr4 61606160a6160c Raw Material Technical Information Data SheetDocument2 pagesKB Fr4 61606160a6160c Raw Material Technical Information Data Sheettrupzup7No ratings yet

- CHAPTER 3: Design of Condenser (Heat Exchanger)Document9 pagesCHAPTER 3: Design of Condenser (Heat Exchanger)Zariq NazaruddinNo ratings yet

- Sprinkler DesignDocument63 pagesSprinkler DesignChandaKundaNo ratings yet

- Tuesday, April 3, 2007, 2:00 - 3:30 P.M. Open Book Mid-Term Quiz 1.5 HOURSDocument3 pagesTuesday, April 3, 2007, 2:00 - 3:30 P.M. Open Book Mid-Term Quiz 1.5 HOURSWaqasNo ratings yet

- Printed Circuit Board Layout For Switched-Mode Power SupplyDocument37 pagesPrinted Circuit Board Layout For Switched-Mode Power SupplyThien DinhNo ratings yet

- Calculations For Short Circuit Withstand Capability of A Distribution Transformer 0976 4860 2 142 150Document10 pagesCalculations For Short Circuit Withstand Capability of A Distribution Transformer 0976 4860 2 142 150Vishnu ShankerNo ratings yet

- Reduction of Nox CompoundDocument19 pagesReduction of Nox CompoundYummy BeatsNo ratings yet

- 5.3 Heat Exchanger Chemical Design 5.3.1 Process Flow ChartDocument32 pages5.3 Heat Exchanger Chemical Design 5.3.1 Process Flow ChartLarbi HammounNo ratings yet

- P0100371 SpecsheetDocument12 pagesP0100371 SpecsheetRezeki SimamoraNo ratings yet

- Hot Strip Mill Descale Nozzle UpgradeDocument8 pagesHot Strip Mill Descale Nozzle UpgradeRakhee SinhaNo ratings yet

- Backup of Flowloss - CSDocument6 pagesBackup of Flowloss - CSSri E.Maheswar Reddy Assistant ProfessorNo ratings yet

- Stelmec VCBDocument2 pagesStelmec VCBnithinmundackal3623No ratings yet

- Duct Sizing & Fan Static Calculation - Week 3Document49 pagesDuct Sizing & Fan Static Calculation - Week 3slow_bbNo ratings yet

- MCS Design Calculation-R0Document4 pagesMCS Design Calculation-R0Jaydeep PatelNo ratings yet

- Cement Process Engineering Vade-Mecum: 8. Fluid FlowDocument10 pagesCement Process Engineering Vade-Mecum: 8. Fluid FlowHasnaoui SamirNo ratings yet

- Full Range: SpecificationsDocument1 pageFull Range: SpecificationsPablo DpNo ratings yet

- Actaris Multimag TMDocument2 pagesActaris Multimag TMmamduhdjNo ratings yet

- Chapter 9 SolutionsDocument12 pagesChapter 9 SolutionsismaelNo ratings yet

- Korisničko Uputstvo HP200M3Document30 pagesKorisničko Uputstvo HP200M3Dragan VojinovicNo ratings yet

- 2/2 Cartridge Seat Valve, Size 5: 1 DescriptionDocument6 pages2/2 Cartridge Seat Valve, Size 5: 1 DescriptionSimen EllingsenNo ratings yet

- Strainers With Flanged Connections Type 2 N Type 2 NI: ApplicationDocument4 pagesStrainers With Flanged Connections Type 2 N Type 2 NI: ApplicationAhmad Dzulfiqar RahmanNo ratings yet

- A High-Pressure Pump Recirculation Valve: by H. L. Miller and C. G. SterudDocument8 pagesA High-Pressure Pump Recirculation Valve: by H. L. Miller and C. G. Sterudserge RinaudoNo ratings yet

- Argo Hytos e 453Document6 pagesArgo Hytos e 453Raúl FigueroaNo ratings yet

- Compact Pressure Switch Series 9671X/9681X: Explosion ProofDocument1 pageCompact Pressure Switch Series 9671X/9681X: Explosion Proofwag008No ratings yet

- Nickel MPS 300 1Document12 pagesNickel MPS 300 1Francisco BocanegraNo ratings yet

- PlantDocument6 pagesPlantSiddharth MaheshwariNo ratings yet

- 2010 22 Online Gas Chromatography A Technicaland Historical Overview Fosse NPDDocument15 pages2010 22 Online Gas Chromatography A Technicaland Historical Overview Fosse NPDMd AfzanNo ratings yet

- Compression Losses in CryocoolersDocument7 pagesCompression Losses in CryocoolersksvvijNo ratings yet

- FinfetDocument71 pagesFinfetaishwarya guttedarNo ratings yet

- Spe 9723 PaDocument14 pagesSpe 9723 PaCarlos Carrillo VillavicencioNo ratings yet

- Development of Pelton Turbine Using Numerical Simulation: Home Search Collections Journals About Contact Us My IopscienceDocument9 pagesDevelopment of Pelton Turbine Using Numerical Simulation: Home Search Collections Journals About Contact Us My IopscienceDaniel ChambergoNo ratings yet

- Pda V1974Document3 pagesPda V1974Afiq AdnanNo ratings yet

- 2020-Dec CHD-413 93Document1 page2020-Dec CHD-413 93Sahil ChoudharyNo ratings yet

- Surface Tension PMD Tank For On Orbit Fluid TransferDocument18 pagesSurface Tension PMD Tank For On Orbit Fluid TransferSteve SmothNo ratings yet

- UntitledDocument15 pagesUntitledAfiq AimanNo ratings yet

- 3-Way Flow Control Valves: 1 DescriptionsDocument6 pages3-Way Flow Control Valves: 1 Descriptionsmuhammad taufik rahmanNo ratings yet

- Double Pipe / Concentric Tube / U-Bend / Hair-Pin HE:: SR# Heat Transfer Area ReferenceDocument12 pagesDouble Pipe / Concentric Tube / U-Bend / Hair-Pin HE:: SR# Heat Transfer Area ReferenceNida TasneemNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Plurijet 60 80 100 PDFDocument4 pagesPlurijet 60 80 100 PDFSartika Nur AisyahNo ratings yet

- Pedrollo Close Coupled Centrifugal Pump - Semi Open Impeller - NGA PDFDocument5 pagesPedrollo Close Coupled Centrifugal Pump - Semi Open Impeller - NGA PDFSartika Nur AisyahNo ratings yet

- Pedrollo Close Coupled Centrifugal Pump - Flange Connection - FDocument28 pagesPedrollo Close Coupled Centrifugal Pump - Flange Connection - FSartika Nur AisyahNo ratings yet

- Pedrollo Close Coupled Centrifugal Pump - Medium Flow Rate - HFDocument4 pagesPedrollo Close Coupled Centrifugal Pump - Medium Flow Rate - HFSartika Nur AisyahNo ratings yet

- Transportasi FluidaDocument7 pagesTransportasi FluidaSartika Nur AisyahNo ratings yet

- Adjective For BooksDocument3 pagesAdjective For BooksSadaf MushtaqNo ratings yet

- Piezas MecanicasDocument96 pagesPiezas MecanicasSebastian Arias100% (1)

- Capstoneproject 2Document4 pagesCapstoneproject 2api-319422841No ratings yet

- PC - PLC PW Cable RS232 Online Cable Serial Cable. - PLCSDocument3 pagesPC - PLC PW Cable RS232 Online Cable Serial Cable. - PLCSNildo TrindadeNo ratings yet

- An Introduction To Operating Amateur Radio OutsideDocument22 pagesAn Introduction To Operating Amateur Radio Outsidedod3007No ratings yet

- L1 A2 Grammar Reference EnglishDocument18 pagesL1 A2 Grammar Reference EnglishPepe Rivas García100% (1)

- Secondary Sources Websites: Everything Works!" Web. 28 Jan. 2012.Document14 pagesSecondary Sources Websites: Everything Works!" Web. 28 Jan. 2012.Tracy WongNo ratings yet

- Writing Test 9 Form (I Term) : 1. Translate Into Ukrainian (20 Points)Document2 pagesWriting Test 9 Form (I Term) : 1. Translate Into Ukrainian (20 Points)Людмила Якименко100% (1)

- Florida Chess - Wnter 2023Document28 pagesFlorida Chess - Wnter 2023George_200No ratings yet

- Crochet: Kitsch BaublesDocument108 pagesCrochet: Kitsch BaublesAitikys Ro100% (4)

- Master The PikeDocument6 pagesMaster The PikegasfaceNo ratings yet

- Digital Marketing MCQDocument16 pagesDigital Marketing MCQAmrendra KumarNo ratings yet

- Theory of Western Music 1Document11 pagesTheory of Western Music 1Prithvi KadamNo ratings yet

- Buddies 3Document64 pagesBuddies 3Hannaniel YoreizaNo ratings yet

- Brawl Stars A1Document15 pagesBrawl Stars A1Алла Радиюк100% (1)

- A1 Unit5Document4 pagesA1 Unit5freddyNo ratings yet

- BTRDL6000RBDocument1 pageBTRDL6000RBWitcher YuliNo ratings yet

- FORM B1 Photocopiables 7BDocument1 pageFORM B1 Photocopiables 7BNilda FerrariNo ratings yet

- Presentation 2Document15 pagesPresentation 2Marian FundalesNo ratings yet

- MAPEH 7 - FestivalsDocument14 pagesMAPEH 7 - FestivalsRescher Kim GalinatoNo ratings yet

- Snow White Play in FrenchDocument14 pagesSnow White Play in FrenchRebeccaNo ratings yet

- Comic BookDocument17 pagesComic BookKimberly RaelNo ratings yet

- GEntrep Chapter 6Document50 pagesGEntrep Chapter 6Xyrelle NavarroNo ratings yet

- Verb Tenses (Present - Past)Document2 pagesVerb Tenses (Present - Past)Patricia UcedaNo ratings yet

- Mixer Capacity Chart - All ModelsDocument2 pagesMixer Capacity Chart - All ModelsMahla Raj KumarNo ratings yet

- Level 3 - FrankensteinDocument15 pagesLevel 3 - Frankensteinilona713No ratings yet

- Parts of The Lockstitch Sewing MachineDocument2 pagesParts of The Lockstitch Sewing MachineLiezel Jane SimblanteNo ratings yet

- The Light Between Oceans English Essay AnnaDocument1 pageThe Light Between Oceans English Essay AnnaMaxPutnamNo ratings yet