Professional Documents

Culture Documents

MCS Design Calculation-R0

Uploaded by

Jaydeep PatelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MCS Design Calculation-R0

Uploaded by

Jaydeep PatelCopyright:

Available Formats

FORMAT NO SWL-ENGG-01-F02R0

DESIGN CALCULATION Effective

10-04-15

Date

MODULE CLEANING SYSTEM CALCULATION

PROJECT:

2X20MW SOLAR PV PROJECT

AT GOKAK, BELAGAVI DIST., KARNATAKA

CLIENT:

M/S SURYODAYA ONE ENERGY PVT. LTD.,

OWNERS CONSULTANT

M/S GENSOL ENGINEERING PVT. LTD.,

DOCUMENT NO. DOCUMENT TITLE Rev 0

MODULE CLEANING SYSTEM CALCULATION Date: 06-02-18

SWLB-SP-KA-40MW-C-CAL-MCS-109

B.S SK RS

APPROVAL PRPD. BY CHKD. BY APPR.BY

STATUS ISSUE AUTHORITY

Calculation of Design

1 Assumptions

1.1 No. of Pumping units for 40MW : 1 Units (having one main & one

standby pump)

1.2 No. 3/4" PVC braided Hose running at a : 5nos.

time by each pump (unit)

1.3 Length of each 3/4" hose pipe : 50 m

1.4 Spacing between hydrants : 18.9m

1.5 Discharge of each jet : 500 LPH max.

1.6 Maximum Working Pressure system- at : 4.5 Kg/cm2 = 45m head

nozzle

1.7 Assumed water required for cleaning one : 2.0 Litters

module

1.8 No. of modules for 40 MW : 161190 modules (max.)

1.10 Washing cycle : 15 days

2 Detail of water consumption

2.1 Total water needed for 40 MW in 15 days- : 322380Litters say 322500 lit

161190x2.0 Litters

2.2 Total water needed for 40 MW per day for 2 : 21500Litters say 21500 Litters

MCS system

Total water needed for 20 MW per day for 1 10750 litters

MCS system

2.3 Aproximate running hours of each MCS : 4.3 hours approx.

system using 5 hoses at a time=

10750/(5x500)

2.4 RO water needed per day for entire 40 MW : 21500 litters say 25000 Litters

3 Head loss calculation

3.1 Total head loss in the system- detail : 27m

attached

3.2 Head required at Nozzle : 45.0m (4.5 Bar)

3.3 Total Head required : 72m

4 Selection Pump

4.1 Total Head required : 20m

4.2 Total discharge required : 2500 LPH

4.3 Suited Pump- : Make- Crompton greaves-

booster Pump- CVM2- 18, 3

Hp, single phase

CALCULATION OF HEAD LOSS IN PIPING NETWORK- MCS

(For Farthest hydrant at Valve No.- 1, MCS- 2)

Formula used (William Hazen's Equation):

-4.871 1.852

0.3123xD xQ xL

Q= 5nozzle x 500LPH each= 2500 LPH

Sl. Perticulars- Pipe and accessories Detail Pipe length Inner Discharge Head Friction

Diameter Loss Loss

Qty Eqvlnt Total Length m mm (D) lph (D) m Kg/cm2

Length (L)

1 75mm HDPE pipe- PN-8, PE-80, (Wall thickness- 5.6 - 6.4) 1280 1280 63 2500 1.35 0.135

2 63mm HDPE pipe- PN-8, PE-80, (Wall thickness- 4.7 - 5.4) 330 330 53 2500 0.807 0.081

3 Hose Pipe 20mm- 50m (ID- 18mm) 50 50 18 500 1.196 0.120

4 2" CPVC Elbow- Equivalent Length of Straight pipe = 2.58m 3 2.58 7.74 50 2500 0.025 0.003

5 2" CPVC Tee- Equivalent Length of Straight pipe (line flow)= 2.35m 4 2.35 9.4 50 2500 0.031 0.003

6 75-63mm HDPE reducer- Equivalent Length of Straight pipe= 1.68m 1 1.68 1.68 63 2500 0.002 0.000

7 75mm HDPE Elbow- Equivalent Length of Straight pipe= 2.10m 4 2.10 8.4 63 2500 0.009 0.001

8 75mm HDPE Tee Equivalent Length of Straight pipe (line flow)= 1.56m 18 1.56 28.08 63 2500 0.03 0.003

9 75mm HDPE Tee- Equivalent Length of Straight pipe (branch flow)= 4.58m 0 4.58 0 63 2500 0 0.000

10 63mm HDPE Elbow- Equivalent Length of Straight pipe= 2.62m 1 2.62 2.62 53 2500 0.006 0.001

11 63mm HDPE Tee Equivalent Length of Straight pipe (line flow)= 1.31m 0 1.31 0 53 2500 0 0.000

12 63mm HDPE Tee- Equivalent Length of Straight pipe (branch flow)= 3.66m 0 3.66 0 53 2500 0 0.000

13 20 cum Disc Filter 2500 3.000 0.300

14 Misc.- valves, QRC, nozzle handle etc. 2500 2.000 0.200

15 Max. suction head- assumed 2500 2.500 0.250

16 Elevation Difference between Pumping unit and farthest point 2500 10.000 1.000

17 Add module top height 500 2.000 0.200

Total Head Loss- m 22.956 2.296

Add 15 % margin 26.399 2.640

R/O 27 2.7

Note: Calculation of Equvelent Lenghts

- 2" CPVC Elbow- Equivalent Length of Straight pipe = 2.58m

- 2" CPVC Tee- Equivalent Length of Straight pipe (line flow)= 2.35m

- 75mm HDPE Elbow- Equivalent Length of Straight pipe= 2.1m

- 75mm HDPE Tee- Equivalent Length of Straight pipe (line flow)= 1.56m

- 75mm HDPE Tee- Equivalent Length of Straight pipe (branch flow)= 4.58

- 75-63mm HDPE reducer- Equivalent Length of Straight pipe= 1.68m

- 63mm HDPE Elbow- Equivalent Length of Straight pipe= 2.62m

- 63mm HDPE Tee Equivalent Length of Straight pipe (line flow)= 1.31m

- 63mm HDPE Tee- Equivalent Length of Straight pipe (branch flow)= 3.66m

Project: 40MW SOLAR PV PROJECT AT GOKAK, KARNATAKA Date: 06-02-18

Revision: R0

MODULE CLEANING SYSTEM

Total No.of modules 161190 Nos

Cycle of Cleaning 15 Days

Number of modules cleaning per day 10746 Nos

Water required per module 2 Litres

Water required for one day 21492 Litres

Storage Water required 2 days

Total required water 42984.0 Litres

Round off 43000.0 Litres

No.of Module cleaning system considered 2 Nos 1 System for each 20MW

Capacity of the Each system (Raw + Treated Water) 21500 Litres

Tank capacity required System-1 21.5 KL System-2 21.5 KL

Borewater (Raw Water) tank selected 20 KL 20 KL

RO water (Treated Water) tank selected 20 KL 20 KL

R.O plant for system-1 R.O plant for system-2

Capacity - 3000 Ltrs/ Hr Capacity - 3000 Ltrs/ Hr

Working Hours : -7 hours per Day Working Hours : -7 hours per Day

Total water = 7 x 3000 = 21000 Litres per day Total water = 7 x 3000 = 21000 Litres per day

You might also like

- Mapro - Strucure Stability Report Down Shed AreaDocument26 pagesMapro - Strucure Stability Report Down Shed AreaJaydeep PatelNo ratings yet

- PT Foundation ApprovedDocument6 pagesPT Foundation ApprovedSujit RasailyNo ratings yet

- Peak Flow Calculations XYZ Dec 16,2003Document7 pagesPeak Flow Calculations XYZ Dec 16,2003Amit BhamreNo ratings yet

- Lift Station CalculationDocument14 pagesLift Station CalculationRawan Alwan ZarifNo ratings yet

- Process Calc 20 MLD STPDocument11 pagesProcess Calc 20 MLD STPAnonymous 5x5kOmyNMNo ratings yet

- Design Calculation C-Tech Basin Zone 4&5Document18 pagesDesign Calculation C-Tech Basin Zone 4&5navneet3bawaNo ratings yet

- Sizing Calculations of Thrust BlocksDocument9 pagesSizing Calculations of Thrust BlocksAbhay ThakurNo ratings yet

- Civil BoQ Document for 50MW Solar Power PlantDocument35 pagesCivil BoQ Document for 50MW Solar Power PlantRaviraj ThoratNo ratings yet

- Project Name: Proposed Icomc & BMC Building Complex Phe Design ReportDocument19 pagesProject Name: Proposed Icomc & BMC Building Complex Phe Design ReportAmit Kumar MishraNo ratings yet

- Fire Pipe Trench-Doc TemplateDocument63 pagesFire Pipe Trench-Doc TemplateSivaAgathamudiNo ratings yet

- Is 15797-2008Document17 pagesIs 15797-2008Deboline MitraNo ratings yet

- Construction of 800KL RCC ELSRDocument21 pagesConstruction of 800KL RCC ELSRSrinivasa_DRao_6174100% (1)

- Design Calculations: Clear Water ReservoirDocument2 pagesDesign Calculations: Clear Water ReservoirAnoop KumarNo ratings yet

- STP Design PDFDocument151 pagesSTP Design PDFMark Anthony AcangNo ratings yet

- Aeration Tank DesignedDocument6 pagesAeration Tank Designedkiran raghukiranNo ratings yet

- Quotation Mediambbr BDFDocument8 pagesQuotation Mediambbr BDFcitramuaraNo ratings yet

- Tractor Uno Acrylic Distemper PDFDocument2 pagesTractor Uno Acrylic Distemper PDFyashpal.pgcil6018No ratings yet

- ENGGBOQEstimation ReportDocument266 pagesENGGBOQEstimation ReportUTTAL RAYNo ratings yet

- Free Design Calculations For STP and ETP by Richa Environmental Services PVT LTD PDFDocument6 pagesFree Design Calculations For STP and ETP by Richa Environmental Services PVT LTD PDFmuradali01No ratings yet

- Pump NPSH CalculationDocument18 pagesPump NPSH CalculationDarwinNo ratings yet

- Sedimentation BasinsDocument14 pagesSedimentation Basinsفردوس سليمانNo ratings yet

- STP LBS Cost Evaluation for 1.38 MLD PlantDocument1 pageSTP LBS Cost Evaluation for 1.38 MLD PlantMashaelNo ratings yet

- Calculation Vol 5-6Document33 pagesCalculation Vol 5-6Mas Hamzah FansuriNo ratings yet

- Estimate of SBTWDocument17 pagesEstimate of SBTWSaral MajumderNo ratings yet

- Low Temp. EvaporationDocument40 pagesLow Temp. EvaporationManvi Sharma100% (1)

- PV Power Calculation Basic (3) 1Document1 pagePV Power Calculation Basic (3) 1paracelsus5netNo ratings yet

- Hydro PneumaticDocument2 pagesHydro PneumaticPassmore DubeNo ratings yet

- Wind Load Calculation (Based On CP3)Document2 pagesWind Load Calculation (Based On CP3)Darshan ShahNo ratings yet

- Solar Watere Heater QuotationDocument1 pageSolar Watere Heater QuotationAbuzar BanderkarNo ratings yet

- Design Solar Cell Support 4-Legs H=1.50mDocument25 pagesDesign Solar Cell Support 4-Legs H=1.50mSurat Warit0% (1)

- Puddle FlangeDocument1 pagePuddle FlangechiragNo ratings yet

- Soak Pit Design CalculationDocument4 pagesSoak Pit Design CalculationInvyteNo ratings yet

- Aludecor Timber E-CatalogueDocument12 pagesAludecor Timber E-CatalogueRitwik Ashish DasguptaNo ratings yet

- DNIT Vol 2 Part 1Document196 pagesDNIT Vol 2 Part 1JitendraHatwarNo ratings yet

- ECG-SUMP PUMP CalculationDocument83 pagesECG-SUMP PUMP Calculationzshehadeh100% (3)

- Balance Makeup and Drinking Water Systems Project StatusDocument17 pagesBalance Makeup and Drinking Water Systems Project Statusmecon bhilaiNo ratings yet

- Structural Design of Areator for Multi-Village Water Supply SchemeDocument16 pagesStructural Design of Areator for Multi-Village Water Supply SchemeGomatesh PatilNo ratings yet

- Geotechnical Report for Proposed Residential BuildingDocument19 pagesGeotechnical Report for Proposed Residential Buildingk.chethuNo ratings yet

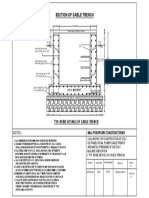

- Section of Cable Trench: Y.L Y.LDocument1 pageSection of Cable Trench: Y.L Y.LKunal ChhatlaniNo ratings yet

- Bep Rev.c-New 20 MLD WTP, NathavaliDocument380 pagesBep Rev.c-New 20 MLD WTP, NathavaliAnonymous 7l8AIyq2No ratings yet

- Concrete Mix DesignDocument9 pagesConcrete Mix DesignPradip NikamNo ratings yet

- Design Calculations For Sludge Holding Tank-R1!08!05-15Document67 pagesDesign Calculations For Sludge Holding Tank-R1!08!05-15Rajagopal GanapathyNo ratings yet

- Golden Westlake Sewage Treatment Plant Project BOQDocument1 pageGolden Westlake Sewage Treatment Plant Project BOQBarbuNo ratings yet

- Calculation ExcelDocument16 pagesCalculation ExcelAbdul rahmanNo ratings yet

- 350kl Overhead Water Intze Tank DesignDocument27 pages350kl Overhead Water Intze Tank DesignRitwick MishraNo ratings yet

- Design Report 600 KL 25 MTR Gajabandh & BadkarliDocument70 pagesDesign Report 600 KL 25 MTR Gajabandh & BadkarlishailenderNo ratings yet

- DBRDocument13 pagesDBRpsjjoshiNo ratings yet

- RCC OHSR TankDocument11 pagesRCC OHSR Tanksaxravi50% (4)

- Design of inlet chamber reinforcement detailsDocument2 pagesDesign of inlet chamber reinforcement detailsThirumaleshNo ratings yet

- Design of Sewage Treatment PlantDocument7 pagesDesign of Sewage Treatment PlantBill Harley VinsmokeNo ratings yet

- ClariflocculatorDocument1 pageClariflocculatorPabitra Kumar PuhanNo ratings yet

- BOQDocument2 pagesBOQManish Goyal100% (1)

- Navarro Eplan2 e 5Document1 pageNavarro Eplan2 e 5Ezekiel A. NavarroNo ratings yet

- CO2 Condenser 02-03-2023-15 PMDocument37 pagesCO2 Condenser 02-03-2023-15 PMahmad santosoNo ratings yet

- 5.P-0222CDEF-400x300CNGC5250-250kW - Pump Data - PDF - 21.06.2017Document4 pages5.P-0222CDEF-400x300CNGC5250-250kW - Pump Data - PDF - 21.06.2017nachiappanNo ratings yet

- Attachment Calculation and Spesification of Cooling SystemDocument10 pagesAttachment Calculation and Spesification of Cooling SystemAchmad Taufik Romadlan Nalaraka'19No ratings yet

- Transfer Pump-2Document21 pagesTransfer Pump-2sunii19847908100% (1)

- D160610-Appendix ConfirmedDocument8 pagesD160610-Appendix ConfirmedNguyễn Đức CườngNo ratings yet

- Calculation and Selection ResultDocument9 pagesCalculation and Selection ResultAlexander Paucar MateoNo ratings yet

- Annexure 8 - Brief Presentation Prepared by GPCLDocument20 pagesAnnexure 8 - Brief Presentation Prepared by GPCLJaydeep PatelNo ratings yet

- Vietnam (TCVN 2737 95)Document32 pagesVietnam (TCVN 2737 95)kimtaehyungNo ratings yet

- Module Mounting Structure Design CalculationDocument3 pagesModule Mounting Structure Design CalculationJaydeep Patel67% (3)

- VietnamDocument3 pagesVietnamJaydeep PatelNo ratings yet

- SOR GCC SOR 1516 4 Drainage SWD PipelineDocument8 pagesSOR GCC SOR 1516 4 Drainage SWD PipelineJaydeep PatelNo ratings yet

- Job Information: Engineer Checked ApprovedDocument23 pagesJob Information: Engineer Checked ApprovedJaydeep PatelNo ratings yet

- Type Designs For Intersections On National Highways PDFDocument73 pagesType Designs For Intersections On National Highways PDFJaydeep Patel100% (1)

- Final Comprehensive General Development Control Regulation-2017 DT 12 10 17Document375 pagesFinal Comprehensive General Development Control Regulation-2017 DT 12 10 17Vijay MistryNo ratings yet

- STRUCTURAL DESIGN REPORTDocument24 pagesSTRUCTURAL DESIGN REPORTJaydeep PatelNo ratings yet

- STRUCTURAL DESIGN REPORTDocument24 pagesSTRUCTURAL DESIGN REPORTJaydeep PatelNo ratings yet

- 2007 301Document5 pages2007 301Jaydeep PatelNo ratings yet

- Internal RoadDocument2 pagesInternal RoadJaydeep PatelNo ratings yet

- Geotextile SpecificationDocument4 pagesGeotextile SpecificationJaydeep PatelNo ratings yet

- Geotextile SpecificationDocument4 pagesGeotextile SpecificationJaydeep PatelNo ratings yet

- Vietnam (TCVN 2737 95)Document32 pagesVietnam (TCVN 2737 95)kimtaehyungNo ratings yet

- D e S I G N: Design.1Document43 pagesD e S I G N: Design.1Георги Савов100% (1)

- HD 4129.3F LFGpro ProsDocument13 pagesHD 4129.3F LFGpro ProsJaydeep PatelNo ratings yet

- D e S I G N: Design.1Document43 pagesD e S I G N: Design.1Георги Савов100% (1)

- President in New Jersey Resume James PirainoDocument3 pagesPresident in New Jersey Resume James PirainoJames PirainoNo ratings yet

- Lecture 04-Material Property Charts-ADocument46 pagesLecture 04-Material Property Charts-Aحبيبة امهةNo ratings yet

- FC Installation SheetDocument4 pagesFC Installation SheetSamuel Lopez BenitesNo ratings yet

- Convair New Tanker Operation & Maintenance Manual Nov 2010Document24 pagesConvair New Tanker Operation & Maintenance Manual Nov 2010engfaridmalk100% (1)

- Ea230 - Astm E2357 - E331Document11 pagesEa230 - Astm E2357 - E331Deco DluxeNo ratings yet

- Civil Works Inspection - QA - QC-Construction LTDDocument1 pageCivil Works Inspection - QA - QC-Construction LTDNashrul KarimNo ratings yet

- Asphalt Pavement Design-The Design Guide L - Khazanovich PDFDocument44 pagesAsphalt Pavement Design-The Design Guide L - Khazanovich PDFYasruddin MtNo ratings yet

- Atlanta Office of Buildings Investigation SummaryDocument3 pagesAtlanta Office of Buildings Investigation SummarythomaswheatleyNo ratings yet

- Comparison of Major Wind Codes for Sri Lankan ContextDocument15 pagesComparison of Major Wind Codes for Sri Lankan Contextjoaobarbosa22No ratings yet

- Project Case Study: Musheireb Heart of Doha - DCPDocument5 pagesProject Case Study: Musheireb Heart of Doha - DCPatiqulaNo ratings yet

- Aircraft Hardware CATDocument4 pagesAircraft Hardware CATJowiNo ratings yet

- 7-New CapitalsDocument6 pages7-New CapitalsMat KryeonNo ratings yet

- 513-2007 Solid Waste ProclamationDocument8 pages513-2007 Solid Waste ProclamationNurNo ratings yet

- Alloy 6063 General InformationDocument60 pagesAlloy 6063 General InformationKi Joko BodoNo ratings yet

- Air/Water Heat Exchanger ConstructionDocument2 pagesAir/Water Heat Exchanger ConstructionZain Ul AbideenNo ratings yet

- Perge Brochure Log Fired Heating BoilersDocument2 pagesPerge Brochure Log Fired Heating BoilersglynisNo ratings yet

- Austin ST Adelaide - Amendment190916Document92 pagesAustin ST Adelaide - Amendment190916Nguyen TongNo ratings yet

- 44AC9100-000-V.02-0110-A4 - Rev B - GENERAL SPECIFICATION FOR INSULATIONDocument51 pages44AC9100-000-V.02-0110-A4 - Rev B - GENERAL SPECIFICATION FOR INSULATIONAvinash ShuklaNo ratings yet

- Ardex CL11Document3 pagesArdex CL11farie ahmadNo ratings yet

- C - Electrical Quality Control Plan - March 2013Document36 pagesC - Electrical Quality Control Plan - March 2013mkrasanNo ratings yet

- The Greek Theatre, Bradfield College, United KingdomDocument12 pagesThe Greek Theatre, Bradfield College, United KingdomRishit KakkadNo ratings yet

- 13 Nu Drain Underground Drainage SystemDocument6 pages13 Nu Drain Underground Drainage SystemMahesh SavandappaNo ratings yet

- The Strut-and-Tie Method of Design (Online) : AppendixcDocument8 pagesThe Strut-and-Tie Method of Design (Online) : AppendixcAtul KulkarniNo ratings yet

- Rheomac GF300 Grout FluidifierDocument2 pagesRheomac GF300 Grout FluidifierDodik FKurniawanNo ratings yet

- TORO Filter Press ManualDocument12 pagesTORO Filter Press ManualRamkiNo ratings yet

- Non Conventional System of ConstructionDocument4 pagesNon Conventional System of ConstructionPeach CreamNo ratings yet

- Pavers Specification Guide PDFDocument12 pagesPavers Specification Guide PDFyamanta_rajNo ratings yet

- Ideal KitchenDocument1 pageIdeal KitchenThe Illimitable ManNo ratings yet

- Siemens Power Engineering Guide 7E 92Document1 pageSiemens Power Engineering Guide 7E 92mydearteacherNo ratings yet

- Line Punch-List for SWL-CA-2011-24000017460 ProjectDocument147 pagesLine Punch-List for SWL-CA-2011-24000017460 ProjectMITHUNNo ratings yet