Professional Documents

Culture Documents

Shaft-Mounted Speed Reducers: Torque Arm Design Considerations For

Shaft-Mounted Speed Reducers: Torque Arm Design Considerations For

Uploaded by

anush_swaminathanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shaft-Mounted Speed Reducers: Torque Arm Design Considerations For

Shaft-Mounted Speed Reducers: Torque Arm Design Considerations For

Uploaded by

anush_swaminathanCopyright:

Available Formats

Torque Arm Design

Considerations for

Shaft-

Mounted

Todd R. Bobak has worked in the gear

industry for 15 years. He has held positions

in technical service, design and development, Speed

Reducers

and quality assurance. He is a product en-

gineer for Sumitomo Drive Technologies in

Chesapeake, VA.

Todd R. Bobak

Introduction

In the power transmission industry, shaft-

mounted speed reducers provide one possible

solution to meet the speed reduction/power

generation needs for an application. As the

name implies, a shaft-mounted speed reducer

(SMSR) is a speed reducer mounted directly

onto, and statically supported by, a driven

shaft—the type of setup that may be found on

a conveyor. Typically, the SMSR incorporates a

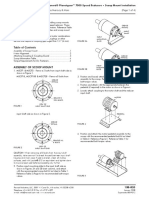

Figure 1—Manufacturers often provide multiple mounting holes for the hollow bore (with keyway, tapered bushing or

placement of a torque arm, as seen in this picture of a Sumitomo Cyclo Bevel some other coupling mechanism) to facilitate

Buddybox. mounting onto the driven shaft.

The SMSR may be “fixed” to the machine

using an output flange or, in certain instances,

its housing may be bolted directly onto the

machine. However, situations exist where direct

attachment of the SMSR is either not possible

or desirable. In such situations, the SMSR is

supported only by the shaft that it is intended

to drive. When the SMSR is mounted directly

onto a driven shaft with no other external

support, it must have a torque arm attached to

it. A torque arm is a pivoted, connecting link

between the reducer and a fixed anchor point

intended to resist the torque developed by the

Figure 2—Output torque capacity can be determined from a manufacturer’s reducer. Quite simply, a torque arm transmits

spec sheet based on the model’s motor input speed rpm and gear reduction

ratio. the reaction torque produced by the SMSR

26 powertransmissionengineering april 2008 www.powertransmission.com

into the structure of the machine, thereby

preventing the counter-rotation of an SMSR

during operation. Most manufacturers of shaft-

mounted speed reducers have designed, and

offer for purchase, standard torque arms for

their products. Situations may exist, however,

where a manufacturer’s torque arm does not

meet the needs of a certain application (due

to space limitations, for example). In such

situations, the machine designer may be

required to design his or her own torque arm

to fit within the constraints of the application.

This article provides some design guidelines for

such a situation.

Resultant Force

In considering the design of a torque arm,

first you need to understand the amount of load

Figure 3—Manufacturer’s specifications will also reveal the exact location of

(or force) that the torque arm may see during the mounting holes relative to the center of the reducer’s output bore.

unit operation. To determine this force, you

need two pieces of critical information:

1. The torque capacity of the SMSR. As the

name implies, this is the mechanical capacity

(typically expressed in terms of inch-pounds

or Newton-meters) that the SMSR is capable

of developing at its output. While it may be

tempting to simply multiply the motor output

torque by the reducer’s reduction ratio to obtain

an output torque value, it is recommended

to consider (at a minimum) the larger of the

following values: the SMSR’s output torque

capacity (as listed in the product catalog) or,

the product of the motor’s output torque and

reduction ratio times an additional 2.5—to take

into account the motor’s starting torque.

2. The dimensional location on the SMSR

where the torque arm will be mounted. Figure 4a—In order to maintain pure tension loading for the torque arm,

the pivot point of the torque arm should run along, or parallel to, the line of

Manufacturers of shaft-mounted speed reducers action. The line of action (see figure 4b) is defined as the right angle formed

provide at least one mounting location for a by a line joining the pivot point and the center of the SMSR’s output bore.

torque arm (Fig. 1). Note that the point where

the torque arm attaches to the reducer (either mounting holes relative to the center of the

directly or indirectly through a bracket) is reducer’s output bore (Fig. 3).

known as the pivot point. Many manufacturers With this information, you can now

provide more than one potential location for calculate the force acting at the selected pivot

the torque arm in order to accommodate the point, given the fact that torque is the product

various mounting configurations available of force and distance. You can determine the

for a given product. The location(s) of these unknown force (F) using these formulas:

mounting holes/positions may be found in

catalog cut sheets or through manufacturer- Torque (T) = Force (F) • Distance (L), or

supplied product drawings. F=T/L (1)

Using Figure 1 as an example, let’s say an

application requires a bracket-style torque arm, It is important to note that during operation,

and this bracket will be attached to the housing the SMSR will tend to rotate about the driven

at both identified mounting holes. Using the shaft in the direction opposite to that of the

unit model size, reduction ratio, and motor driven shaft’s rotation. With this in mind, it is

input speed, you can determine the output significant that the calculated force F (above)

torque capacity from the reducer catalog ratings acts in pure tension on the torque arm. This fact

table (Fig. 2). is especially important for torque arms that are

You can also use the catalog dimension long—if they are exposed to compressive forces,

sheet to determine the location of the identified they may buckle. Figure 4a shows the correct

www.powertransmission.com april 2008 powertransmissionengineering 027

method of mounting a torque arm so that it is

in tension.

Using values from the manufacturer’s

specifications (Figures 2 and 3 for our example),

you can calculate the resultant force acting at

the pivot point as follows:

T = (F)(L)

F = T/L

= 8,990 in.-lbs./4.49 in.

= 2,002 lbs.

(2)

In essence, the connection method at the

pivot point you chose (i.e., bolt, threaded rod,

etc.) must be able to withstand this calculated

Figure 4b—Determining the line of action. force when in tension. If you find that the

calculated force exceeds the physical limits of

the connection method, you may choose to

incorporate a different, stronger material for

the torque arm.

A way to minimize this force is to increase

the distance L of the pivot point, as shown in

Figures 5 and 6. In these examples, the reducer

has a T-type torque arm mounted to it, which

moves the pivot point an additional 1.85 inches

farther from the center of the reducer’s bore.

If all other factors remain the same, this

increase in distance yields a decrease of nearly

600 pounds in the force on the torque arm.

Thus:

T = (F)(L)

F = T/L

= 8,990 in.-lbs./(4.49 + 1.85) in.

= 1,417 lbs.

(3)

Once again, this calculated force must be

compared to the yield stress of the torque arm

material to assure that the material limitations

Figure 5—In this example, the reducer has a T-type torque arm mounted to are not exceeded.

it, which moves the pivot point an additional 1.85 inches farther from the

center of the reducer’s bore.

A Turnbuckle for a Torque Arm

Provided that it will fit within the design

constraints of your application, you may opt to

use a turnbuckle for a torque arm. A turnbuckle

is a device commonly used to tighten a rod

or rope. Its components include a sleeve with

screwed connections of opposite hands (left and

right) at each end. Upon turning the sleeve, the

connected parts (threaded rods) will be drawn

together, taking up slack and producing tension

(Fig. 7).

You can calculate the force acting at the

pivot point in this situation using the same

formula for force as in the previous examples.

Figure 6—A shaft-mounted speed reducer in a conveyor application with a Figures 8-9 show a typical mounting style for a

T-type torque arm. turnbuckle torque arm.

280 powertransmissionengineering april 2008 www.powertransmission.com

A Note About Mounting Hardware

In addition to assuring that the forces

acting on the torque arm itself do no exceed

the limitations of the torque arm material, you

must also consider the effects of the force on

the mounting hardware (nuts, bolts, etc.).

When taking this into account, you must

note that the force is not acting on the hardware

in tension, but rather in shear. Depending on the Figure 7—A typical turnbuckle.

location of such hardware, bending movements

induced by the force may also be acting on the

hardware.

Hardware manufacturers usually provide

yield and shear limitations for their products.

Once again, it is important to compare the

calculated forces/stresses acting on the hardware

against the published limiting values to assure

that the critical points are not exceeded.

A Note About Reversing Rotation

In reversing applications, the output of the

SMSR rotates in one direction for a period

of time, and then reverses and rotates in the

opposite direction for a period of time. This

application type requires considering the

compressive forces that the torque arm must

also bear.

Recalling that, ideally, a torque arm is

mounted so it is in tension, in a reversing

application, the torque arm may see a period of Figure 8—A typical mounting style for a turnbuckle-style torque arm.

time when it also receives compressive forces.

Such compressive forces, if great enough, could

buckle the torque arm. For such applications,

designers may want to add a second torque

arm on the opposite side of the SMSR. The

second torque arm would take the tension

forces generated by the reverse rotation while

minimizing the compressive forces on the first

torque arm.

Angles Other Than 90°

Although it is important to maintain a

pivot point at 90° to the center of the SMSR

output hub, it may not always be possible due

to limitations in the machine onto which the

SMSR will be mounted. This is not uncommon,

and reducer manufacturers who supply

turnbuckle torque arms with their SMSR units

often note that the torque arm may be mounted

with an angular variation, such as ±15°.

In such situations, the designer needs to

evaluate the effects of the resultant forces acting

on the torque arm. Figure 10 shows a torque

arm mounted to an SMSR at some angle (θ)

that is less than 90°. Figure 9—A turnbuckle-type torque arm being used on a Sumitomo helical

Because the torque arm is not acting at a 90° shaft mount unit.

angle to the output bore of the SMSR, there are

two forces acting on it. The free-body diagram

in Figure 11 details these forces.

The resultant forces (FT and FS) are the

www.powertransmission.com april 2008 powertransmissionengineering 29

component forces of Force “F” acting on the

torque arm. These resultant forces place not

only a force in tension (FT) acting on the

torque arm, but also a shear force (FS). Both

forces must be considered when evaluating the

strength of the torque arm design.

The Effect of Shaft Runout

Despite a high degree of accuracy in

manufacturing processes, shaft runout

sometimes occurs. Such runout (on the driven

shaft) may cause the reducer to “wobble” on

the shaft during operation. This could be

particularly troublesome if the torque arm is

rigidly mounted to the anchor point. A rigidly

mounted torque arm attached to an SMSR

driving a shaft with a high degree of runout

may result in (among other things) a broken

driven shaft, cracks at the anchor point, a

decrease in the life of the output bearings of

Figure 10—A torque arm mounted to an SMSR at less than 90°. the SMSR and/or the conveyor and lubrication

leakage. Introducing some “float” in the torque

arm at the anchor point will counteract these

problems.

Float may be introduced at the pivot point

by attaching rubber bushings to the pivot and

anchor points, as shown in Figure 12.

If dual rotation of the output shaft is possible

in the application, manufacturers recommend

installing rubber bushings on both sides of

the pivot and anchor points so float is possible

regardless of the direction of rotation.

A loose clearance designed between the

bolts and through holes in the torque arm

bracket may also assist in creating float.

In addition to taking precautions to

eliminate a rigid mount, designers must also

ensure the torque arm is properly aligned when

Figure 11—When a torque arm is mounted at an angle other than 90°, mounting it to the SMSR. Misalignment may

force F is composed of both tension (FT) and shear (FS) forces. Both must be

considered when evaluating the strength of the torque arm design.

inadvertently cause binding that could decrease

or entirely eliminate this float.

Conclusion

Although seemingly simple in concept, a

torque arm is an important component when

considering a shaft-mounted speed reducer

for an application. Before selecting a potential

torque arm design, designers should evaluate

the offering supplied by the manufacturer of the

shaft-mounted speed reducer. In doing so, they

may determine that the standard offering fits

into the application constraints. Additionally,

some manufacturers offer more than one

standard design (i.e., turnbuckle, T-type) to

meet a variety of applications. However, if

the existing available designs fail to meet the

established application criteria, following the

methodology detailed in this article will help

to develop a functional and robust torque arm

Figure 12—Rubber bushings installed at the anchor point and/or pivot point design.

will provide “float” to compensate for runout in the driven shaft.

30 powertransmissionengineering april 2008 www.powertransmission.com

You might also like

- Schlumberger Motor Hand Book CompleteDocument139 pagesSchlumberger Motor Hand Book Completewaheed2286100% (3)

- Torque Arm Design Consideration For Shaft Mounted ReducersDocument16 pagesTorque Arm Design Consideration For Shaft Mounted Reducersreddym44No ratings yet

- White Paper - Torque Arm - Final EditDocument16 pagesWhite Paper - Torque Arm - Final EditMikeReyNo ratings yet

- Frameless-Brushless Mounting en-USDocument6 pagesFrameless-Brushless Mounting en-USkv123No ratings yet

- Pathfinder Motor HandbookDocument83 pagesPathfinder Motor Handbookchristianyankel100% (4)

- 3919-Article Text-14973-1-10-20180917 PDFDocument21 pages3919-Article Text-14973-1-10-20180917 PDFAbdelwahab AliouatNo ratings yet

- ServoUnits 10 15AB FINALDOC Rev CDocument8 pagesServoUnits 10 15AB FINALDOC Rev CNirbhayNo ratings yet

- Engine Mounts and Powertrain Mounting SystemsDocument22 pagesEngine Mounts and Powertrain Mounting SystemsErdiner ParmaksızNo ratings yet

- NASA Ames Research CenterDocument8 pagesNASA Ames Research CenteradhyharmonypngNo ratings yet

- Optimisation of The Geometry of Closed Rotor Slots For Cage Induction MotorsDocument8 pagesOptimisation of The Geometry of Closed Rotor Slots For Cage Induction MotorsJuanRamosNo ratings yet

- Alignment With Target Values Reduces Vibrations PDFDocument4 pagesAlignment With Target Values Reduces Vibrations PDFSantyagoNo ratings yet

- Caso Estudio Alineamiento de EjesDocument8 pagesCaso Estudio Alineamiento de EjesBacoNo ratings yet

- Dctorque-Km BR 000385 Reva Ecn3Document12 pagesDctorque-Km BR 000385 Reva Ecn3Basam RazNo ratings yet

- Influence of Elastic Foundation Structures On The Rotor Dynamics PDFDocument8 pagesInfluence of Elastic Foundation Structures On The Rotor Dynamics PDFyonex215317No ratings yet

- Torque SensorDocument6 pagesTorque SensorBayu Ari MurtiNo ratings yet

- HB ManualDocument5 pagesHB ManualZuzanna Kat-ToporskaNo ratings yet

- Direct Drive DC Torque Motors Catalog 2005Document12 pagesDirect Drive DC Torque Motors Catalog 2005Itoitz Biain ArakistainNo ratings yet

- Modeling Simulation and Analysis of Permanent-Magnet Motor Drives. I. The Permanent-Magnet Synchronous Motor DriveDocument9 pagesModeling Simulation and Analysis of Permanent-Magnet Motor Drives. I. The Permanent-Magnet Synchronous Motor DriveArthur CaiNo ratings yet

- MotoringDocument6 pagesMotoringmitsuiNo ratings yet

- Kollmorgen BMS Large Dia Frameless Motors 230712Document17 pagesKollmorgen BMS Large Dia Frameless Motors 230712Arun Chand C VNo ratings yet

- SEM Term AssignmentDocument9 pagesSEM Term Assignmentexamresult.dp4No ratings yet

- Calculation of Cogging Torque in A Surface Permanent Magnet MotorDocument3 pagesCalculation of Cogging Torque in A Surface Permanent Magnet MotorAdrian David ScottNo ratings yet

- PM-Synchronous MotorsDocument54 pagesPM-Synchronous MotorsDivyam GargNo ratings yet

- Backlashvs LostMotion PDFDocument4 pagesBacklashvs LostMotion PDFjeyaselvanmNo ratings yet

- Thomson Stepper Motor LinearDocument48 pagesThomson Stepper Motor LinearEnkhbaatar TumenjargalNo ratings yet

- RBE (H) Series Motors: Data PublicationDocument44 pagesRBE (H) Series Motors: Data PublicationKOMATSU SHOVELNo ratings yet

- RBE Series Motors Brochure en-US 2003Document44 pagesRBE Series Motors Brochure en-US 2003derribo78No ratings yet

- DQ InductanceDocument11 pagesDQ Inductancegthulasi789193No ratings yet

- Selección de BandasDocument84 pagesSelección de Bandasrod3662No ratings yet

- AC Motor DataDocument20 pagesAC Motor DataFalak KhanNo ratings yet

- Permanent Magnet MotorsDocument6 pagesPermanent Magnet MotorsHadeedAhmedSherNo ratings yet

- White Paper - A Comparison of The Characteristics of AC and DC Motors - B7096-2Document13 pagesWhite Paper - A Comparison of The Characteristics of AC and DC Motors - B7096-2tekhakkoNo ratings yet

- Application Characteristics of Permanent Magnet Synchronous and Brushless DC Motors For Servo DrivesDocument11 pagesApplication Characteristics of Permanent Magnet Synchronous and Brushless DC Motors For Servo DrivessambhanimadhubabuNo ratings yet

- Harshit Robotics 10Document13 pagesHarshit Robotics 10harshitkargathara21No ratings yet

- Determining Engine Torque: From The Engine-Speed SignalDocument4 pagesDetermining Engine Torque: From The Engine-Speed SignalFrank WhittleNo ratings yet

- Aspec Paper - Rotating - Steel - Shafts PDFDocument3 pagesAspec Paper - Rotating - Steel - Shafts PDFaNo ratings yet

- Sensorless FOC For PMSM Using Reduced Order Luenberger ObserverDocument23 pagesSensorless FOC For PMSM Using Reduced Order Luenberger ObserverAldo HernandezNo ratings yet

- Motor Torque, Load Torque and Selection of MotorsDocument22 pagesMotor Torque, Load Torque and Selection of Motorsrobertovm2002No ratings yet

- Load Torque MotorDocument30 pagesLoad Torque MotorcalecaleNo ratings yet

- Maska TechnicalDocument62 pagesMaska TechnicalAnonymous uXdS9Y7No ratings yet

- RBE Series Motors Brochure en-US 2003 1Document44 pagesRBE Series Motors Brochure en-US 2003 1Animesh GhoshNo ratings yet

- A Particle Swarm Optimization Tool For Decoupling Automotive Powertrain Torque Roll AxisDocument8 pagesA Particle Swarm Optimization Tool For Decoupling Automotive Powertrain Torque Roll AxisDavid NeihgukNo ratings yet

- Brushed Direct-Current Motors: 5.1 Review of Motor TheoryDocument32 pagesBrushed Direct-Current Motors: 5.1 Review of Motor TheoryEvren SoydanNo ratings yet

- Optimal Flux Weakening in Surface PM Machines UsinDocument12 pagesOptimal Flux Weakening in Surface PM Machines UsinakhilnandanNo ratings yet

- A Novel Switched Reluctance Motor With C-Core StatorsDocument8 pagesA Novel Switched Reluctance Motor With C-Core Statorsapi-26587237No ratings yet

- Segmented Rotor Mutually Coupled Switched Reluctance MAchine For Low Torque Ripple ApplicationsDocument13 pagesSegmented Rotor Mutually Coupled Switched Reluctance MAchine For Low Torque Ripple ApplicationsedumacerenNo ratings yet

- Irjet V7i480Document7 pagesIrjet V7i480DushyantNo ratings yet

- Scope For Designing High Torque Switched Reluctance Motor With Low RipplesDocument12 pagesScope For Designing High Torque Switched Reluctance Motor With Low RipplesEl Manaa BarhoumiNo ratings yet

- Technical Paper: Precision Planetary Servo GearheadsDocument13 pagesTechnical Paper: Precision Planetary Servo GearheadsKumar SanthanamNo ratings yet

- Lee 2016Document6 pagesLee 2016Vinay KashyapNo ratings yet

- Application Characteristics of Permanent Magnet Synchronous Motors (Case Study)Document6 pagesApplication Characteristics of Permanent Magnet Synchronous Motors (Case Study)RakeshconclaveNo ratings yet

- Paper CT4 Load Assumptions For Pitch System Manj 041Document5 pagesPaper CT4 Load Assumptions For Pitch System Manj 041mbreuking6943No ratings yet

- 123 - 3 - Cutting Edge Upper Intermediate Teacher's Book - 2013 - 110pDocument9 pages123 - 3 - Cutting Edge Upper Intermediate Teacher's Book - 2013 - 110pМария КонсуловаNo ratings yet

- Super-High-Speed Switched Reluctance Motor For Automotive TractionDocument8 pagesSuper-High-Speed Switched Reluctance Motor For Automotive TractionHarshitha AspariNo ratings yet

- Sizes Mercury & Mars (Page 1 of 4) : Figure 3ADocument4 pagesSizes Mercury & Mars (Page 1 of 4) : Figure 3AFreddy Arratia HerreraNo ratings yet

- Selection and Performance: Criteria For Power Transmission CouplingsDocument10 pagesSelection and Performance: Criteria For Power Transmission Couplingsamir moniriNo ratings yet

- 03 - ED Technical Training Part 3Document18 pages03 - ED Technical Training Part 3Калин АнгеловNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet