Professional Documents

Culture Documents

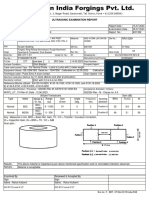

Ultrasonic Examination Report: Discharge Damper

Uploaded by

Saurav Roy0 ratings0% found this document useful (0 votes)

30 views1 pageUltrasonic testing was performed on the discharge damper welds of various components. The testing found the welds to be free of flaws and satisfactory according to inspection standards. Ultrasonic pulse echo reflection testing was conducted at 100% coverage with manual scanning and 10% overlap on the as-welded surfaces. No indications greater than 20% of the full screen height were observed, and there was no backwall loss.

Original Description:

Ultrasonic Test Report format

Original Title

UT FORMAT

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUltrasonic testing was performed on the discharge damper welds of various components. The testing found the welds to be free of flaws and satisfactory according to inspection standards. Ultrasonic pulse echo reflection testing was conducted at 100% coverage with manual scanning and 10% overlap on the as-welded surfaces. No indications greater than 20% of the full screen height were observed, and there was no backwall loss.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views1 pageUltrasonic Examination Report: Discharge Damper

Uploaded by

Saurav RoyUltrasonic testing was performed on the discharge damper welds of various components. The testing found the welds to be free of flaws and satisfactory according to inspection standards. Ultrasonic pulse echo reflection testing was conducted at 100% coverage with manual scanning and 10% overlap on the as-welded surfaces. No indications greater than 20% of the full screen height were observed, and there was no backwall loss.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

ULTRASONIC EXAMINATION REPORT

REPORT NO:UT/1718-01/26 DATE: 06/01/2018

Name of Company:

Name of Client:

Job Tested: DISCHARGE DAMPER

D’END/PIPE TO NOZZEL WELD JOINT (D1 & D2)

Material: SA 240 TP 316, SA 312 TP 316 W.O. No.: LOYAL G39/17-18 Couplant: Oil

Drawing No.:- LOYAL G39-DWG-1-01 REV-01 Job No.: LOYAL G39 M1A, M1B, M1C, M1D, M1E, M1F, M1G

Surface of Examination / Condition: AS Welded

Extent of Examination: 100% Method of Scanning & Overlap/Recording: Manual with 10% overlap

UT Procedure No: N/A

Reference Standard: ASME Sec-V Article -4.

Acceptance Standard ASME Sec-VIII Div-I App-12.

Equipment Make/ Model/ Sr. no.Cal.Due Modsonic/Einstein II DGS/E4613-0416/05-06-2018

Date:

Testing Technique: Pulse echo reflection Stage of Examination : After Welding

Technique. A-Scan.

Place of Testing: Date of Testing : 06/01/2018

Identification & Location of Scanned Area : N/A

System details with respect to Search Unit:

Search unit Make Size Sr. no frequency Range used

Angle

Angle (60º) Modsonic 8 X 9 mm 187828396 4 MHz 200 mm

Angle (45º) Modsonic 8 X 9 mm 300440689 4 MHz 125 mm

Cable type/length Used: BNC to Small Lemo connector / 2 Mtr.

Search unit Ref. Reflector Amplitude Ref.Gain Scanning Gain

Angle (60º) ¼ t, ½ t,3/4 t. 80%,40%,20% 52 db 52 db

Angle (45º) ¼ t, ½ t,3/4 t. 80%,40%,20% 55 db 55 db

Calibration Data:

Test Results:

Observations: Free from objectionable flaw. (No Indication More Than 20% Of FSH Observed. No Backwall

Loss Observed)

Result: Job found satisfactory as per standard.

Test conducted by Witnessed/received by Inspection Agency/TPI

Name Sandip Chauhan

Level II

Sign / Date

12/11/

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesFrom EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesRating: 4 out of 5 stars4/5 (1)

- Ultrasonic Exam Report Steam Drum JointsDocument3 pagesUltrasonic Exam Report Steam Drum JointsBalkishan DyavanapellyNo ratings yet

- Hil Renukoot Ut 2022-2023Document249 pagesHil Renukoot Ut 2022-2023duttcon engineeringNo ratings yet

- Electrode Qualification TestDocument5 pagesElectrode Qualification TestAbhishek Kumar VishwakarmaNo ratings yet

- Drillen UT Report-SodetailDocument1 pageDrillen UT Report-SodetailGaurang PandyaNo ratings yet

- Qa Test Format X RayDocument9 pagesQa Test Format X RayNIKHIL VERMANo ratings yet

- Example of Inspection Report 3Document11 pagesExample of Inspection Report 3SAIFUDDIN NUR AKMALNo ratings yet

- A-Star Testing & Inspection (S) Pte LTD: Magnetic Particle Testing ReportDocument4 pagesA-Star Testing & Inspection (S) Pte LTD: Magnetic Particle Testing ReportHari KarthickNo ratings yet

- NDT Magnetic Particle Inspection ProcedureDocument7 pagesNDT Magnetic Particle Inspection ProcedureCharlesNo ratings yet

- Ultrasonic pulse velocity tester declaration of conformityDocument1 pageUltrasonic pulse velocity tester declaration of conformitybinodNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- Example of Inspection Report 2Document3 pagesExample of Inspection Report 2SAIFUDDIN NUR AKMALNo ratings yet

- 915MHZ Fiberglass AntennaDocument6 pages915MHZ Fiberglass AntennaRidho FikriNo ratings yet

- YKEPL MPI Procedure For A668 RMDocument4 pagesYKEPL MPI Procedure For A668 RMDeepak HoleNo ratings yet

- 114486-UT-006 HP Primary Superheater Outlet ManifoldDocument2 pages114486-UT-006 HP Primary Superheater Outlet ManifoldDave CheungNo ratings yet

- Test Report: Terms & ConditionsDocument1 pageTest Report: Terms & Conditionschetan selokarNo ratings yet

- RONDS RH711 - RH802 Portable Vibraion Analyzer IntroductionDocument37 pagesRONDS RH711 - RH802 Portable Vibraion Analyzer IntroductionMounicaRasagyaPallaNo ratings yet

- Vibration Test PDFDocument4 pagesVibration Test PDFSameer KmNo ratings yet

- Lab Test Report Mechanical Properties SteelDocument6 pagesLab Test Report Mechanical Properties Steelvines7831No ratings yet

- M Rogers: Radiographic Test Report Bad Example 5Document1 pageM Rogers: Radiographic Test Report Bad Example 5Sundar KumarNo ratings yet

- RR3-3269 Eo1352Document2 pagesRR3-3269 Eo1352Deepak HoleNo ratings yet

- 2016 1-CheckboxDocument1 page2016 1-CheckboxbaladiroyaNo ratings yet

- Gpti Qicl 032Document2 pagesGpti Qicl 032uselessinstaid52No ratings yet

- MPI Inspection ProcedureDocument5 pagesMPI Inspection ProcedureDinesh GuptaNo ratings yet

- Ultrasonic Examination Report: The Royal Utilisation Services Pvt. LTDDocument9 pagesUltrasonic Examination Report: The Royal Utilisation Services Pvt. LTDNazmul HasanNo ratings yet

- Certificate of Relief Valve Capacity (PROCA) 7 PDFDocument1 pageCertificate of Relief Valve Capacity (PROCA) 7 PDFAdeoye OkunoyeNo ratings yet

- Test Report: Terms & ConditionsDocument1 pageTest Report: Terms & Conditionschetan selokarNo ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- Gpti Qicl J931 Mut 002Document2 pagesGpti Qicl J931 Mut 002uselessinstaid52No ratings yet

- Process Flow Diagram: 10-12-2011 Part NameDocument4 pagesProcess Flow Diagram: 10-12-2011 Part NameVenu Gopal RaoNo ratings yet

- (A) Dimensions: (D) Cupping TestDocument5 pages(A) Dimensions: (D) Cupping Testanon_115606397100% (7)

- 114486-UT-008 Attemperator Outlet T-PieceDocument2 pages114486-UT-008 Attemperator Outlet T-PieceDave CheungNo ratings yet

- RADIANT NDT SERVICES REPORT PROVIDES ULTRASONIC TESTING RESULTSDocument1 pageRADIANT NDT SERVICES REPORT PROVIDES ULTRASONIC TESTING RESULTSGoutam Kumar Deb100% (1)

- F-04 (Ultrasonic Test.) (New) Dated. 25.03.2016 JOKA123Document52 pagesF-04 (Ultrasonic Test.) (New) Dated. 25.03.2016 JOKA123Himanshu SinghNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- ANEXO7Document14 pagesANEXO7liuming farfanNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- UT-Flaw1 Detection Procedure R1 - 2Document25 pagesUT-Flaw1 Detection Procedure R1 - 2George OgbecheNo ratings yet

- LM79-20180516-10701 02 001 02Document13 pagesLM79-20180516-10701 02 001 02GunarsyahNo ratings yet

- Astec Valves Inspection Certificate SummaryDocument4 pagesAstec Valves Inspection Certificate SummaryShankar RajNo ratings yet

- Data Sheet 3SB3203-1HA20: EnclosureDocument6 pagesData Sheet 3SB3203-1HA20: EnclosureFlavioNo ratings yet

- Feed-Through Terminal Block - UT 2,5 - 3044076: Your AdvantagesDocument32 pagesFeed-Through Terminal Block - UT 2,5 - 3044076: Your AdvantagesKushal DixitNo ratings yet

- 1Document4 pages1Venu Gopal RaoNo ratings yet

- Laboratory Services: Test ReportDocument1 pageLaboratory Services: Test ReportMechtek LabNo ratings yet

- ULTRASONIC WELD SCAN REPORTDocument1 pageULTRASONIC WELD SCAN REPORTmahmoudNo ratings yet

- 5SY42167 Datasheet enDocument5 pages5SY42167 Datasheet enYurivilca Yurivilca GianmarcoNo ratings yet

- Mini Ground Terminal Block - MUT 4-PE - 3248037: Key Commercial DataDocument18 pagesMini Ground Terminal Block - MUT 4-PE - 3248037: Key Commercial DataMariana Panypani ContrerasNo ratings yet

- Punj Lloyd Limited Ultrasonic Testing Examination Procedure QualificationDocument4 pagesPunj Lloyd Limited Ultrasonic Testing Examination Procedure QualificationRajeev KumarNo ratings yet

- He Mrut 006Document3 pagesHe Mrut 006Hao TranNo ratings yet

- 10CDCF LM-1600406 (PFGD)Document2 pages10CDCF LM-1600406 (PFGD)Sohaib AhmadNo ratings yet

- Test Report: Work Order No. JSA-19-05651Document3 pagesTest Report: Work Order No. JSA-19-05651SantoshNo ratings yet

- Kamlesh Kumar Singh Engineers Pvt. LTDDocument24 pagesKamlesh Kumar Singh Engineers Pvt. LTDAADARSHNo ratings yet

- 17-05-MAR-037-01 凱銳FCC Part15B v1Document43 pages17-05-MAR-037-01 凱銳FCC Part15B v1Nisar AliNo ratings yet

- Ultrasonic Testing Procedure Qualification Record for Gas Pipeline WeldsDocument10 pagesUltrasonic Testing Procedure Qualification Record for Gas Pipeline WeldsArvind Sahani100% (1)

- Single 4 Point TB Ground 3211809Document27 pagesSingle 4 Point TB Ground 3211809adamnorazlanNo ratings yet

- Wimpey - Wacg-22-222-5Document6 pagesWimpey - Wacg-22-222-5jaas jawadNo ratings yet

- Test Reports - NBRDocument105 pagesTest Reports - NBRImtiyaz KhanNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)