Professional Documents

Culture Documents

Inspection Report: Page 1 of 2 Vendor P.O. NO

Uploaded by

sudipta dasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Report: Page 1 of 2 Vendor P.O. NO

Uploaded by

sudipta dasCopyright:

Available Formats

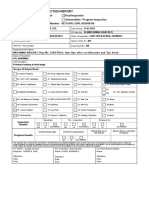

INSPECTION REPORT IR No.

: QETO/IR/SUD/ 09 Page 1 of 2

VENDOR : Balaji Industrial Enterprises Pvt. Ltd. DATE : 01.12.2018

4531034033 dt. 03/07/2018 amnt. Dt 26.11.2018

P.O. NO. : JOB NO. :

4531033730 dt. 02.06.2018

Wheel (Tread dia 500mm X 110mm groove) - 8nos. 11002.36.31.101 Rev 01,

ITEMS : Croos Head for 110t bottom pully block - 3pcs DRG NO. : 11002.03.03.141 Rev 00,

Croos Head for 90t bottom pully block - 1pc 11002.19.42.404 Rev 00

QAP NO. : Not available DATASHEET NO. : TDC no. JSPL/RPR/TDC/2002-001

CLIENT : Jindal Steel & Power Ltd. CLIENT'S P.O. NO. :

B. INSPECTION STAGE : INPROCESS INSPECTION FINAL INSPECTION

Welder Qualification (WPS/PQR/WPQ)- Fit-up / Alignment Check Performance Test Loading / Dispatch

Welder Qualification (WPS/PQR/WPQ)- Review Dimensional Check Noise Level Other Checks (If any):

Raw Material Identification Trial Assembly Check Vibration Level

Lab Witness Trial Run Test / Functional Check Strip Test

Non Destructive Testing (NDT)- UT Load Test Visual / Appearance Check

Non Destructive Testing (NDT)- RT Hardness Check (Other than lab witness) Surface Finish Check (Ra)

Non Destructive Testing (NDT)- LPT Temperature Rise Surface Preparation (Blasting)

Non Destructive Testing (NDT)- MPT Speed of Rotation Painting-DFT

Weld Edge Preparation / Bevelling Shaft Run-Out / Deflection Packing

C. OBSERVATIONS & DETAILS OF INSPECTION ACTIVITIES CARRIED:

Folllowing observations are made for 08 nos. Sorbitised, finish machined wheels :

1) Visually the wheels are acceptable. Black surface at very few spots are to be removed and complied by the supplier.

2) Dimensions are within acceptable range. Itemwise report is attached herewith.

3) UT carried out by the vendors competent authority and found free from any recordable discontinuety asper SA388 Cl.1. Report attached.

4) DP test carried out at hub portion and no discontinuety was observed.

5) Hardness on the tread dia is checked with portable hardness tester and found few wheels are having more than 350BHN against required 300-350BHN. Itemwise report attached.

6) MPI carried out by external lab agency (M/s IRC) at tread area and no recordable discontinuety found.

7) Heat treater's certificate attached.

Folllowing observations are made for 04 nos. crosshead :

1) Dimensionally acceptable.Tool marks are observed on the faces of the octagon. To be removed by grinding.

2) Chemical and mechanical test reports and heat treater's report are reviewed and found acceptable.

3) UT done and found minor indication having <10% of backwall echo at two isolated locations for 90t bottom pully which is under acceptable limit. Report attached.

One separate test piece of dia 300mm X 300mm long was stamped for mechanical and chemical testing for wheels of next lot of this PO.

Name & Sign: Name & Sign: Name & Sign :

M/s QETO Quality Services, IR Format No.: DOC-IR-01, R.0

For QETO For Client / Customer For Supplier

M/s QETO Quality Services, IR Format No.: DOC-IR-01, R.0

INSPECTION REPORT Page 2 of 2

Continuation Sheet For IR No.: QETO/IR/ Date:

D. CONCLUSIONS:

1) Materials are dimensionally acceptable, free from surface and internal defect.

2) Visually acceptable except a few black spots at OD. Complience report to be submitted by the supplier after removal of the spots before despatch.

3) Depth of hardness,mechanical and chemical testing done on sacrificial wheel of same size of earlier batch (8 nos.) dt. 26/27.10.2018

4) The supplier is advised to seek permissions for wheels with higher hardnss.

E. PHOTOGRAPHS:

Sign & Stamp: Sign & Stamp: Sign & Stamp :

For QETO For Client / Customer For Supplier

M/s QETO Quality Services, IR Format No.: DOC-IR-01, R.0

INSPECTION OFFER LIST

Ref. IR No. :

Date :

Ref Document / Inspection

Sr. Qty. Qty. Qty. Conclusion

Items Offered Drawing / Stage

No. Required Offered Accepted Point

Datasheet No. (Stage / Final)

D1/D2/D3/D

1

4….

(Note: This is the only details of items offered. For details of inspection & observations made, please refer IR)

For QETO For Client / Customer For Vendor

You might also like

- LTHEDocument5 pagesLTHEMohit Goswami100% (1)

- 05 BOPF ActionsDocument27 pages05 BOPF ActionsKalikinkar LahiriNo ratings yet

- Rhino ScriptDocument73 pagesRhino Scriptwadorno100% (1)

- DH3-31MA-T-SCT-0001 Commissioning Procedure of Complete-Set Startup of Steam Turbine REV.0Document24 pagesDH3-31MA-T-SCT-0001 Commissioning Procedure of Complete-Set Startup of Steam Turbine REV.0Lan Rung100% (1)

- Day Trading With Canlestick and Moving Averages - Stephen BigalowDocument3 pagesDay Trading With Canlestick and Moving Averages - Stephen Bigalowarashiro100% (2)

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Inspection Report: Page 1 of 3 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 3 Vendor P.O. NOsudipta dasNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/110Document2 pagesInspection Report: IR No.: QETO/IR/SUD/110sudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/118Document2 pagesInspection Report: IR No.: QETO/IR/SUD/118sudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/114Document2 pagesInspection Report: IR No.: QETO/IR/SUD/114sudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/115Document2 pagesInspection Report: IR No.: QETO/IR/SUD/115sudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/119Document2 pagesInspection Report: IR No.: QETO/IR/SUD/119sudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/116Document1 pageInspection Report: IR No.: QETO/IR/SUD/116sudipta dasNo ratings yet

- Inspection Report: QETO/IR/SUD/104) and Following Are The ObservationDocument2 pagesInspection Report: QETO/IR/SUD/104) and Following Are The Observationsudipta dasNo ratings yet

- nITP For Suspenion Hanger Pin Alt 2Document4 pagesnITP For Suspenion Hanger Pin Alt 2ABHISHEK KUMARNo ratings yet

- Checklist Fire StopDocument9 pagesChecklist Fire StopAnonymous DMdGdsOENo ratings yet

- Visit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoDocument4 pagesVisit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoVinay YadavNo ratings yet

- Bis-Dk-Ut 1152 - 1200-24-VC01Document6 pagesBis-Dk-Ut 1152 - 1200-24-VC01TomasPavlovicNo ratings yet

- Irn 20.09.2019 Fl-Smidth VoltampDocument2 pagesIrn 20.09.2019 Fl-Smidth VoltampHARI PRASATHNo ratings yet

- Pre-Commissioning Format For Reactor: I. General DetailsDocument27 pagesPre-Commissioning Format For Reactor: I. General Detailsmayur dhandeNo ratings yet

- Inspection Test Plan For Eot CraneDocument4 pagesInspection Test Plan For Eot CraneBikash ShreshthaNo ratings yet

- Alstom IRDocument4 pagesAlstom IRkasi reddyNo ratings yet

- Ir 0703Document3 pagesIr 0703sheikmoinNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Transformer Test ReportDocument46 pagesTransformer Test ReportAkshay GatkalNo ratings yet

- Cp5-Itp CWC RomanuDocument22 pagesCp5-Itp CWC RomanuherdiansyahNo ratings yet

- PROCEDURE-Direct Supply of DLC Pins From Ancillary To SPRL Doc. No. IMS/CP / Edition No.:00 Rev. No Pistons and Rings Ltd. Date: 06.07.2020Document2 pagesPROCEDURE-Direct Supply of DLC Pins From Ancillary To SPRL Doc. No. IMS/CP / Edition No.:00 Rev. No Pistons and Rings Ltd. Date: 06.07.2020Deepak SharmaNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Procurement Services: Industry & Facilities DivisionDocument6 pagesProcurement Services: Industry & Facilities DivisionVikas Mani TripathiNo ratings yet

- Inspection Report: 150 MW Dhamangaon Solar Project, MaharashtraDocument6 pagesInspection Report: 150 MW Dhamangaon Solar Project, Maharashtrakaushik21185No ratings yet

- ITS - ITP - CCED - USTS - SE 01, Rev.1.Approved ITP & DWGDocument4 pagesITS - ITP - CCED - USTS - SE 01, Rev.1.Approved ITP & DWGBasanth VadlamudiNo ratings yet

- Duqm Refinery Project EPC Package OneDocument22 pagesDuqm Refinery Project EPC Package OnePrashant KumarNo ratings yet

- Inspection Report: F-084/09 R-VM23-0012-LV-052 Rev.00Document5 pagesInspection Report: F-084/09 R-VM23-0012-LV-052 Rev.00Navid HashemiNo ratings yet

- MIghty Machine RejectDocument1 pageMIghty Machine RejectMohammad Shanawaz MNo ratings yet

- D.P. Test ReportDocument1 pageD.P. Test Reportvirendra katkeNo ratings yet

- 23-1 ShackleDocument2 pages23-1 ShackleAkhilNo ratings yet

- Fm-dt-58 Spreader Beam Lifting Beam ChecklistDocument2 pagesFm-dt-58 Spreader Beam Lifting Beam ChecklistAkhilNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- 032 Itp For Painting and Coatingpdf PDF FreeDocument19 pages032 Itp For Painting and Coatingpdf PDF FreeAli KayaNo ratings yet

- 032 Itp For Painting and Coating PDFDocument19 pages032 Itp For Painting and Coating PDFpeterNo ratings yet

- Bis-Dk-Rt-1049 - Ip2022-CeDocument2 pagesBis-Dk-Rt-1049 - Ip2022-CeTomasPavlovicNo ratings yet

- Nfe1 Ing Me Rfi 00036Document11 pagesNfe1 Ing Me Rfi 00036Deepu CNo ratings yet

- IVR-DYC.M.1.22.0004-Sr - No. 41 - Rev 00Document6 pagesIVR-DYC.M.1.22.0004-Sr - No. 41 - Rev 00Parag WadekarNo ratings yet

- International LTD: Report of Thorough ExaminationDocument1 pageInternational LTD: Report of Thorough ExaminationChisom IkengwuNo ratings yet

- IMIRDocument10 pagesIMIRvizagnucalcuttaNo ratings yet

- Itp-Ofmr - Fat PDFDocument3 pagesItp-Ofmr - Fat PDFPrabhakar SvNo ratings yet

- Joint Inspection Report MechanicalDocument8 pagesJoint Inspection Report MechanicalRohan SharmaNo ratings yet

- SACEP - RTCC - Delivery #0971407-05Document12 pagesSACEP - RTCC - Delivery #0971407-05Ryan condeNo ratings yet

- Failure Analysis Report: SIMS InformationDocument13 pagesFailure Analysis Report: SIMS InformationHasby PotterNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- D62 - 691 - 5 - C4-Specification Sheets PDFDocument26 pagesD62 - 691 - 5 - C4-Specification Sheets PDFSoumiyaNo ratings yet

- Bis-Dk-Rt-1047 - Ip2022-CeDocument2 pagesBis-Dk-Rt-1047 - Ip2022-CeTomasPavlovicNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- Stress Calculation Stress Engineering Cover SheetDocument7 pagesStress Calculation Stress Engineering Cover SheetPappu Kishore KumarNo ratings yet

- 410 CTDocument2 pages410 CTSARAVANAN ANo ratings yet

- Report-1683-1 B1 25mm 14 10 2020Document7 pagesReport-1683-1 B1 25mm 14 10 2020sakthi velNo ratings yet

- 01 Epc Di HD 003 - B Instrumentos de PesoDocument4 pages01 Epc Di HD 003 - B Instrumentos de PesoDebye101No ratings yet

- 044 ITP For Installation of Gypsum Board Buildings PDFDocument10 pages044 ITP For Installation of Gypsum Board Buildings PDFHarshvardhan PathakNo ratings yet

- Casing Stabbing BoardDocument1 pageCasing Stabbing BoardRanjithNo ratings yet

- Final Insepection Reports and WPS PQRDocument14 pagesFinal Insepection Reports and WPS PQRVikas Verma100% (1)

- Ir 5073 Ppa 005Document6 pagesIr 5073 Ppa 005ValiNo ratings yet

- 8D Problem Analysis Report: (Rotor Id Over Size)Document4 pages8D Problem Analysis Report: (Rotor Id Over Size)Kuldeep SinghNo ratings yet

- Revised Rate List Under The West Bengal Health Scheme, 2008 (Notification No. 796-F (MED) Dated 31-01-2011)Document110 pagesRevised Rate List Under The West Bengal Health Scheme, 2008 (Notification No. 796-F (MED) Dated 31-01-2011)sudipta dasNo ratings yet

- Form C: NONGPF/WB/20171123114956897/1/5 Sudipta DasDocument3 pagesForm C: NONGPF/WB/20171123114956897/1/5 Sudipta Dassudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00196Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00196sudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00194Document2 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00194sudipta dasNo ratings yet

- Qeto - Quality Services: Ultrasonic Test ReportDocument1 pageQeto - Quality Services: Ultrasonic Test Reportsudipta dasNo ratings yet

- West Bengal Health Scheme, 2008 Form E: Checklist For Reimbursement of Medical Claims/ Sanction of AdvanceDocument2 pagesWest Bengal Health Scheme, 2008 Form E: Checklist For Reimbursement of Medical Claims/ Sanction of Advancesudipta dasNo ratings yet

- West Bengal Health Scheme, 2008: Engineering Institute For Junior ExecutivesDocument3 pagesWest Bengal Health Scheme, 2008: Engineering Institute For Junior Executivessudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00197Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00197sudipta dasNo ratings yet

- Qeto - Quality Services: Penetrant Test ReportDocument1 pageQeto - Quality Services: Penetrant Test Reportsudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report NumberDocument6 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Numbersudipta dasNo ratings yet

- IR204 - Siddheswari Evaluation - SUD 06.08.21Document2 pagesIR204 - Siddheswari Evaluation - SUD 06.08.21sudipta dasNo ratings yet

- Qty - 366 Nos Material - UNS F33100 / ASTM A536 65-45-12: Z002BX0D A Ecn NoDocument1 pageQty - 366 Nos Material - UNS F33100 / ASTM A536 65-45-12: Z002BX0D A Ecn Nosudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00195Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00195sudipta dasNo ratings yet

- Qeto - Quality Services: Ultrasonic Test ReportDocument1 pageQeto - Quality Services: Ultrasonic Test Reportsudipta dasNo ratings yet

- Ingot Crack: Presentation By: Sudipta DasDocument19 pagesIngot Crack: Presentation By: Sudipta Dassudipta dasNo ratings yet

- Total Qty - 4 Nos Material - UNS F33100 / ASTM A536 65-45-12Document1 pageTotal Qty - 4 Nos Material - UNS F33100 / ASTM A536 65-45-12sudipta dasNo ratings yet

- 23-Dalalpukur-Axioscope Specs MAT With C-DIC & 305Document2 pages23-Dalalpukur-Axioscope Specs MAT With C-DIC & 305sudipta dasNo ratings yet

- Bestscope 6010TR-Specs-280619-DF&BFDocument1 pageBestscope 6010TR-Specs-280619-DF&BFsudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/114Document2 pagesInspection Report: IR No.: QETO/IR/SUD/114sudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/115Document2 pagesInspection Report: IR No.: QETO/IR/SUD/115sudipta dasNo ratings yet

- Inspection Report: QETO/IR/SUD/104) and Following Are The ObservationDocument2 pagesInspection Report: QETO/IR/SUD/104) and Following Are The Observationsudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/116Document1 pageInspection Report: IR No.: QETO/IR/SUD/116sudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/119Document2 pagesInspection Report: IR No.: QETO/IR/SUD/119sudipta dasNo ratings yet

- FAQ - How To Auto Approve Specific Override Raised Via IRIS APIDocument3 pagesFAQ - How To Auto Approve Specific Override Raised Via IRIS APIMrCHANTHANo ratings yet

- Pitching AdvantageDocument4 pagesPitching Advantageapi-474065092No ratings yet

- T Lymphocytes and Macrophages in The Intestinal Tissues of Dogs Infected With Leishmania InfantumDocument12 pagesT Lymphocytes and Macrophages in The Intestinal Tissues of Dogs Infected With Leishmania InfantumWillNo ratings yet

- Mobile JammerDocument14 pagesMobile Jammervivekanand_bonalNo ratings yet

- T014108e PDFDocument5 pagesT014108e PDFSilvester KolicNo ratings yet

- U2000 - General PunctuationDocument6 pagesU2000 - General PunctuationSándor NagyNo ratings yet

- Thermal Analysis of Cutting Tools by Using Different Cutting FluidsDocument45 pagesThermal Analysis of Cutting Tools by Using Different Cutting FluidspothanNo ratings yet

- 7 QC Tools - StratificationDocument3 pages7 QC Tools - Stratificationraja100% (1)

- KinematicsDocument28 pagesKinematicsAntwone ChaplainNo ratings yet

- BTCS (703) Network Pogramming Unit IDocument41 pagesBTCS (703) Network Pogramming Unit IVivek SoniNo ratings yet

- Scott Shenker Fundamental Design Issues of Future InternetDocument13 pagesScott Shenker Fundamental Design Issues of Future InternetSarah KhaleelNo ratings yet

- Analog TV StandardsDocument5 pagesAnalog TV StandardsJayson AlvaNo ratings yet

- (De Gruyter Stem) Dingyu Xue - Differential Equation Solutions With MATLAB - Fundamentals and Numerical Implementations (De Gruyter STEM) (2020, de Gruyter)Document454 pages(De Gruyter Stem) Dingyu Xue - Differential Equation Solutions With MATLAB - Fundamentals and Numerical Implementations (De Gruyter STEM) (2020, de Gruyter)adina crisanNo ratings yet

- Variables: Presented By: Mrs. Glaidel Love G. Fillado Teacher in Practical Research 1Document8 pagesVariables: Presented By: Mrs. Glaidel Love G. Fillado Teacher in Practical Research 1Drew TamposNo ratings yet

- RK80Document8 pagesRK80ibe_setiawanNo ratings yet

- 5.the Gamma Function (Factorial Function) : 5.1 Definition, Simple PropertiesDocument16 pages5.the Gamma Function (Factorial Function) : 5.1 Definition, Simple PropertiesOliver58No ratings yet

- DA 18 BSWS EC + AGS 502A Technical Data (500m)Document1 pageDA 18 BSWS EC + AGS 502A Technical Data (500m)Abraham PerezNo ratings yet

- Types of DamagesDocument1 pageTypes of Damagessanchitha RNo ratings yet

- Digitron 2000 Series User ManualDocument8 pagesDigitron 2000 Series User ManualFelipe Cáceres S.No ratings yet

- Sistem Thinking Dan Analisa Pengambilan KeputusanDocument47 pagesSistem Thinking Dan Analisa Pengambilan KeputusanyudiferiandiNo ratings yet

- Support Mechanisms of Rammed Aggregate Piers. I: Experimental ResultsDocument9 pagesSupport Mechanisms of Rammed Aggregate Piers. I: Experimental Resultstriple tripleNo ratings yet

- Complex PrimerDocument29 pagesComplex PrimerMaxiene Andrei GuintoNo ratings yet

- Technical Drawing, Drafting or Drawing, Is The Act andDocument11 pagesTechnical Drawing, Drafting or Drawing, Is The Act andAjhay BonghanoyNo ratings yet

- A World Leader in Valve Technology: Reliability Under PressureDocument6 pagesA World Leader in Valve Technology: Reliability Under PressureFilipNo ratings yet

- Microsoft Word Tips and Tricks To Increase ProductivityDocument16 pagesMicrosoft Word Tips and Tricks To Increase ProductivitySams RajaNo ratings yet