Professional Documents

Culture Documents

Potential Failure Mode and Effects Analysis (Process FEMA)

Uploaded by

Asif IqbalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Potential Failure Mode and Effects Analysis (Process FEMA)

Uploaded by

Asif IqbalCopyright:

Available Formats

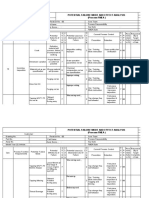

POTENTIAL FMEA #:

FAILURE MODE AND EFFECTS ANALYSIS Reference Specs:

(PROCESS FMEA)

Item/Component: Process Responsibility: Prepared by:

Model: Part Number: Date (Orig.)

CoreTeam: Date (last revised)

Approved by:

The Sev and RPN columns auto-calculate.

DETECT

OCCUR

Action Results

CLASS

RPN

SEV

Process Function/ Potential Effect(s) of Potential Cause(s)/ Current Process Controls Current Process Controls Responsibility & Target

# Potential Failure Mode Recommended Actions S O D R.

Requirements Failure Mechanism(s) of Failure Prevention Detection Completion Date

Actions Taken e c e P.

v c t N.

Nut not properly tighten 3 1 1 3 3 0

Missing rubber isoletor 3 1 1 3 3 0

rubber collar not outside the

compressor base plate

3 1 1 3 3 0

Base plate with Thread problem 1 1 1 1 1 0

1

compressor assembly

base plate not proper paint 1 1 1 1 1 0

grounding wire not use in

compressor

2 1 1 2 2 0

Stud missalign 1 1 1 1 1 0

not properly tighten screws 3 3 2 18 3 0

capillary chip & crack 3 1 1 3 3 0

Service valve and capillary Lnkey nut thread slip

2 5 2 1 10 5 0

fix on valve plate

lock of valve plate fixing miss 1 1 1 1 1 0

copper tube damages 4 1 1 4 4 0

condenser fins broken & damage 2 2 1 4 2 0

copper tubes damage & chip 3 2 1 6 3 0

Condenser fix on base

3 ubend leakage & chip 3 1 1 3 3 0

plate

Condenser fixing hole block &

miss

1 1 1 1 1 0

not properly tighten screws 2 1 1 2 2 0

4-way valve & solenoid coil are

not same brand

2 1 1 2 2 0

tubes damage & chip 3 2 1 6 3 0

4-way valve damage 2 1 1 2 2 0

4-way valve fixing &

4

copper tubes fitment all tubes & capillary fixing not

2 1 1 2 2 0

properly

all tubes & capillary missalign 1 1 1 1 1 0

Solenoid coil screw loose 1 1 1 1 1 0

not proper welding 3 1 1 3 3 0

nitrogen pressure not inside the

5 Welding copper tube

1 1 1 1 1 0

leakage problem 2 1 1 2 2 0

motor nut not properly tighten 2 1 1 2 2 0

bracket screws not properly

tighten

2 1 1 2 2 0

Pre-assemble motor fixing

6 & motor bracket fixing on motor wire clip damage 2 1 1 2 2 0

base plate

bracket clip of wire fixing not use 1 1 1 1 1 0

motor body damage 1 1 1 1 1 0

wiring not properly against

wiring diagram

3 1 1 3 3 0

wire damage 1 1 1 1 1 0

Compressor wiring & gasket miss of terminal cover 2 1 1 2 2 0

7

blanket fixing

terminal cover nut not properly

tighten

2 1 1 2 2 0

blanket not proper rapping on

compressor

1 1 1 1 1 0

Partation plate screws not

properly tighten

2 1 1 2 2 0

Spoung miss 1 1 1 1 1 0

partation plate fix on base grove 1 1 1 1 1 0

fixing partation plate &

8

PFC / Capacitor PFC/Capacitor fixing screws not

properly tighten

2 1 1 2 2 0

PFC damage 2 1 1 2 2 0

Service and art pipe coupler not

proper fix 1 1 1 1 1 0

not proper vacuuming 3 1 1 3 3 0

Coupler not proper fix 1 1 1 1 1 0

wiring not properly against

wiring diagram

3 1 1 3 3 0

wire clip damage 1 1 1 1 1 0

PCB damage 2 1 1 2 2 0

Vacuuming, wiring &

9 PCB cover not properly fix 1 1 1 1 1 0

axial fan fixing

all sensor not properly fix 1 1 1 1 1 0

all wires not properly tie 1 1 1 1 1 0

PCB parts damage 2 1 1 2 2 0

axial fan damage 1 1 1 1 1 0

axial fan fixing nut not properly

tighten

2 1 1 2 2 0

dumper not proper paste on

capillary tube

1 1 0 0 1 0

refrigerant not proper fill against

gas weight sheet

3 1 1 3 3 0

The machine charged the leak

unit

3 1 1 3 3 0

Refrigerant filling &

10

Pinch off Gas weight not verification 2 1 0 0 2 0

Pinch pillar not proper pinch 2 1 1 2 2 0

Gas leakage 2 1 1 2 2 0

Welding not properly pinch off 1 1 0 0 1 0

machine working not properly 3 2 1 6 3 0

machine not calibrate 2 1 1 2 2 0

Leak check with Inficon

11

machine Untrained inspector work in leak

check station

2 1 0 0 2 0

Inspector check unit very fast 2 1 0 0 2 0

not properly tighten screws 2 1 1 2 2 0

PCB box damage 1 1 0 0 1 0

Right side plate, PCB box, not proper screw use in 1 1 0 0 1 0

12 Ground wire & Front panel grounding wire

fixing

Electric terminal broken 1 1 0 0 1 0

ground wire screw not properly

tighten

2 1 1 2 2 0

Earth wire not proper work 5 2 1 10 5 0

Insulation resistance test not ok 5 2 1 10 5 0

13 Electrical safety test

wiring problem 3 1 1 3 3 0

Electrical Safety test not ok 5 2 1 10 5 0

testing panel not check before

unit testing

3 1 1 3 3 0

Heating process not check 3 1 1 3 3 0

Current (A) not proper check

against given supplier 3 1 1 3 3 0

specification sheet

Online testing

14 Running pressure not proper

(Performance test) check against given supplier 2 1 1 2 2 0

specification sheet

Inverter PCB not check properly

with supplier device

4 1 1 4 4 0

Power not proper check against

given suppler specification sheet

2 1 1 2 2 0

valve cap not fix & miss 1 1 1 1 1 0

Remove coupler, fix valve diagram sticker miss 2 1 1 2 2 0

cap, diagram paste on

right side handle, rating rating label sticker miss 1 1 1 1 1 0

15 label paste on right side

plate, right side handle fix water collector broken 1 1 1 1 1 0

on eclectic plate & water

collector fixing right side handle broken 1 1 1 1 1 0

Power cable fixing clip miss 1 1 1 1 1 0

not proper cleaning 1 1 1 1 1 0

Cleaning, Packing

installation kit miss 2 1 1 2 2 0

(Polythen bag, installation

17

kit, hole cover & pvc roll polythen bag miss 1 1 1 1 1 0

tape

hole cover & pvc tape miss 1 1 1 1 1 0

carton damage & broken 1 1 1 1 1 0

Packing carton

18 & EPS top miss 1 1 1 1 1 0

Packing strip

packing strip loose 1 1 1 1 1 0

Carton reopen not properly 1 1 1 1 1 0

Dismantling & unit reopen not properly 1 1 1 1 1 0

1

Parts segregation

unit damage to the dismantling

process

2 1 1 2 2 0

3 1 1 3 3 0

not properly screw tighten

2 1 1 2 2 0

cross flow fan broken

Cross flow fan & indoor 2 1 1 2 2 0

2

motor assemble motor shaft tapper

2 1 1 2 2 0

motor wire damage

2 1 1 2 2 0

bearing base not proper place

evaporator fins damage 2 2 1 4 2 0

copper tubes damage & chip 2 1 1 2 2 0

ubend damage & chip 2 1 1 2 2 0

heat exchanger pipe damage &

chip 2 1 1 2 2 0

3 Evaporator fixing

not properly screws tighten 2 2 1 4 2 0

motor cover not proper fix 2 1 1 2 2 0

cover screw not properly tighten 2 1 1 2 2 0

evaporator not properly fix 2 1 1 2 2 0

not properly screw tighten 2 1 1 2 2 0

PCB box damage 1 1 1 1 1 0

PCB with box & ground

4

wire fixing PCB component damage 3 2 1 6 3 0

ground wire not properly screw

tighten

2 1 1 2 2 0

Power cord wire not properly

tighten

2 1 1 2 2 0

terminal broken 2 1 1 2 2 0

Indoor motor wire jack not fix in

the PCB

2 1 1 2 2 0

5 Wiring swing motor wire jack not fix the

PCB

2 1 1 2 2 0

Air & Coil sensor wire jack not fix

the PCB

2 1 1 2 2 0

Coil sensor not fix in evaporator

coil

2 1 1 2 2 0

Enclosure not properly fix 2 1 1 2 2 0

top panel not properly fix 1 1 1 1 1 0

Enclosure & Top panel,

6 filter miss 2 1 1 2 2 0

Filter & Louver flap

not properly screw tighten 2 1 1 2 2 0

louver flap miss & broken 2 1 1 2 2 0

Remote function not check

properly

4 2 1 8 4 0

Inverter PCB not check properly

Online Indoor Testing with supplier device

4 2 1 8 4 0

7

(Performance Test)

louver moment not check 2 1 1 2 2 0

unit vibration not properly check 2 1 1 2 2 0

Hanging plate miss 3 1 1 3 3 0

wrong hanging plate dispatch 2 1 1 2 2 0

Hanging plate &

8 hanging plate damage 2 1 1 2 2 0

Terminal cover

terminal cover not fix 1 1 1 1 1 0

terminal cover broken 1 1 1 1 1 0

not proper cleaning 1 1 1 1 1 0

Cleaning & Packing Power cable miss 1 1 1 1 1 0

9 (Polythen bag & Power

Cable) polythen bag miss 1 1 1 1 1 0

Scratches 1 1 1 1 1 0

Packing carton carton damage & broken 1 1 1 1 1 0

10 &

Packing strip packing strip loose 1 1 1 1 1 0

BE-PDP-FR-07 / Rev D (14-Nov-13) Johnson Controls, Inc. Page 1 of 1

Confidential and Proprietary

You might also like

- PDF Bobcat 873 G Parts Manual SN 514140001and Above SN 514240001 and Above SN 517911001 and AboveDocument387 pagesPDF Bobcat 873 G Parts Manual SN 514140001and Above SN 514240001 and Above SN 517911001 and AboveАлексей75% (4)

- Preamble 2023Document94 pagesPreamble 2023SAIGAL TANKERNo ratings yet

- Design Fmea 1 ST Pipe Teflon HoseDocument11 pagesDesign Fmea 1 ST Pipe Teflon HoseSandeep PandeyNo ratings yet

- SCU E-Mobility - 2022Document22 pagesSCU E-Mobility - 2022omedinaNo ratings yet

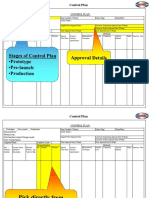

- Control plan optimizationDocument11 pagesControl plan optimizationRadhika GuptaNo ratings yet

- Potential Failure Mode and Effect Analysis: (Process Fmea)Document9 pagesPotential Failure Mode and Effect Analysis: (Process Fmea)SACHIN KUMARNo ratings yet

- FMEA ExampleDocument4 pagesFMEA ExampleBALAJINo ratings yet

- Xfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following FormsDocument6 pagesXfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following FormsRoland JoldisNo ratings yet

- PFMEA Process Failure Modes and Effects AnalysisDocument15 pagesPFMEA Process Failure Modes and Effects AnalysisPrakash RanjanNo ratings yet

- PFMEA - Process FMEADocument23 pagesPFMEA - Process FMEANavnath TamhaneNo ratings yet

- Updates Dec09 AIAG FMEA-Ranking-TablesDocument3 pagesUpdates Dec09 AIAG FMEA-Ranking-TablesSuresh Velu100% (1)

- PCP & FmeaDocument4 pagesPCP & FmeaDaniela AscolaniNo ratings yet

- Failure Modes Effect AnalysisDocument33 pagesFailure Modes Effect AnalysisAkhmas MerajNo ratings yet

- FMEA SampleDocument94 pagesFMEA SampleKaran MalhiNo ratings yet

- RA Excavation & Backfilling WorkDocument6 pagesRA Excavation & Backfilling Workshamshad ahamedNo ratings yet

- Intelligent Use of FMEA Presented By: Quality Associates InternationalDocument66 pagesIntelligent Use of FMEA Presented By: Quality Associates Internationalpradeep100% (1)

- Process Flow Chart - Incoming TestingDocument1 pageProcess Flow Chart - Incoming Testingraza239No ratings yet

- Failure Mode and Effect AnalysisDocument25 pagesFailure Mode and Effect AnalysislokelooksNo ratings yet

- Hazard Identification and Risk Assessment Form: Project ProcessDocument4 pagesHazard Identification and Risk Assessment Form: Project ProcessAli Al-GhamghamNo ratings yet

- I'm sorry, I don't have enough information to give you tax advice over the phone. You'll need to consult a tax professional or the IRS website for guidance on your specific situationDocument39 pagesI'm sorry, I don't have enough information to give you tax advice over the phone. You'll need to consult a tax professional or the IRS website for guidance on your specific situationaliahmad422No ratings yet

- RED615 BrochureDocument72 pagesRED615 BrochuredkompogiorgasNo ratings yet

- Risk Assessment Form: Work/Activity Detail: Date: Officer in Charge: Team Member/sDocument2 pagesRisk Assessment Form: Work/Activity Detail: Date: Officer in Charge: Team Member/sNitai MittalNo ratings yet

- Jayson Industries: F-54 Midc Gokul ShirgaonDocument16 pagesJayson Industries: F-54 Midc Gokul ShirgaonDhananjay PatilNo ratings yet

- Cause Mapping Investigation Template - GeneralDocument20 pagesCause Mapping Investigation Template - GeneralMickloSoberanNo ratings yet

- PFMEA Process Failure Mode and Effect Analysis for Distribution AssemblyDocument50 pagesPFMEA Process Failure Mode and Effect Analysis for Distribution AssemblySameer SaxenaNo ratings yet

- Process Flow Chart AnalysisDocument4 pagesProcess Flow Chart Analysisakav123No ratings yet

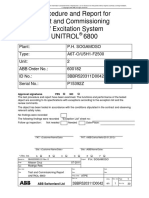

- Routine Verification Checklist ABBDocument5 pagesRoutine Verification Checklist ABBMustapha HadjriNo ratings yet

- Log Monitoring & Security StandardsDocument12 pagesLog Monitoring & Security StandardssharadNo ratings yet

- Satistical Process Control Study: Data Collections:-Sample D2 A2 D4Document1 pageSatistical Process Control Study: Data Collections:-Sample D2 A2 D4cqi9nNo ratings yet

- DFMEA New Version TemplateDocument22 pagesDFMEA New Version Templatelalit GuptaNo ratings yet

- Environment Improvement PlanDocument2 pagesEnvironment Improvement PlanmuhinNo ratings yet

- Cause & Effect TypesDocument5 pagesCause & Effect TypesArun BiswalNo ratings yet

- Delphi Supplier Quality Fmea Severity RankingsDocument3 pagesDelphi Supplier Quality Fmea Severity Rankingsmani317No ratings yet

- Process: Process Control Chart Chart No'Document1 pageProcess: Process Control Chart Chart No'AngelikaNo ratings yet

- Controlling assembly processes with SPCDocument6 pagesControlling assembly processes with SPCSRIDHAREEE61No ratings yet

- PF Improvement On DG SetsDocument8 pagesPF Improvement On DG SetsAnupam SharmaNo ratings yet

- FMEADocument55 pagesFMEAVijay Kumar100% (1)

- Air Compressor Risk MG T FormDocument8 pagesAir Compressor Risk MG T Formashraf100% (1)

- Oee PDFDocument5 pagesOee PDFsdvikkiNo ratings yet

- FLSmidth-Cement_ECS_ProcessExpert_BrochureDocument13 pagesFLSmidth-Cement_ECS_ProcessExpert_BrochureAmin BaigNo ratings yet

- Pfmea - Aiag-VdaDocument108 pagesPfmea - Aiag-VdaGLAUCIO DOS SANTOS SILVANo ratings yet

- Collection of PLC Signals in STEP 7 With Subsequent Excel EvaluationDocument41 pagesCollection of PLC Signals in STEP 7 With Subsequent Excel Evaluationwww.otomasyonegitimi.comNo ratings yet

- Setco Automotive LTD.: NP ChartDocument4 pagesSetco Automotive LTD.: NP ChartDisha ShahNo ratings yet

- Capacity Verification Run at Rate IpaDocument4 pagesCapacity Verification Run at Rate IpaBES100% (1)

- Risk Assessment - AHUDocument5 pagesRisk Assessment - AHUManzur AhmadNo ratings yet

- Problem Solution - 5 Why-S-AnalysisDocument4 pagesProblem Solution - 5 Why-S-AnalysisLucas LapajNo ratings yet

- Quality Tool Box Talk ChecklistDocument1 pageQuality Tool Box Talk Checklistआनंद चव्हाणNo ratings yet

- 02 FMEA Training - How To DoDocument45 pages02 FMEA Training - How To DoRamkumar PerumalNo ratings yet

- Customer:: Potential Failure Mode and Effect Analysis (Process FMEA)Document8 pagesCustomer:: Potential Failure Mode and Effect Analysis (Process FMEA)Rajnish PotdarNo ratings yet

- Control Plan & FMEADocument13 pagesControl Plan & FMEAAmit LuniaNo ratings yet

- 3bbr520311d0042 - Test Report 2 - p15392z - Rev 1Document30 pages3bbr520311d0042 - Test Report 2 - p15392z - Rev 1manuelazo78No ratings yet

- Agilent Calibration FrequencyDocument6 pagesAgilent Calibration Frequencyzilangamba_s4535No ratings yet

- Date: Stage: PDC Furnace / Top Heating: S.No What WHY WHO HOW Component Name Responsibility Name & SignatureDocument6 pagesDate: Stage: PDC Furnace / Top Heating: S.No What WHY WHO HOW Component Name Responsibility Name & SignatureAnonymous ijGnA6CWEaNo ratings yet

- 203 LSS Gbo - FmeaDocument47 pages203 LSS Gbo - FmeaRocker byNo ratings yet

- DFMEADocument1 pageDFMEAPrabh GarchaNo ratings yet

- Anpqp - Design Potential FmeaDocument2 pagesAnpqp - Design Potential FmeaJoaquinNo ratings yet

- Potential Failure Mode and Effect Analysis: (Pfmea)Document2 pagesPotential Failure Mode and Effect Analysis: (Pfmea)Mohit KaushikNo ratings yet

- Potential Failure Mode and Effective Analysis (Process FMEA)Document1 pagePotential Failure Mode and Effective Analysis (Process FMEA)nainarmuthuramalingamNo ratings yet

- F-PD-06 PfmeaDocument1 pageF-PD-06 PfmeaTrivesh SharmaNo ratings yet

- Pfmea TemplateDocument6 pagesPfmea TemplatekatalinaNo ratings yet

- DFMEA-Oven RacksDocument8 pagesDFMEA-Oven RacksEdgar MonteroNo ratings yet

- Design FMEA Template Rev 1.0Document8 pagesDesign FMEA Template Rev 1.0Lê Hoàn VũNo ratings yet

- Markov Model Predicts AttritionDocument16 pagesMarkov Model Predicts AttritionWojood AlkhanNo ratings yet

- A Review of Bring Your Own Device OnDocument11 pagesA Review of Bring Your Own Device OnNurrul JannathulNo ratings yet

- Nikhil ResumeDocument2 pagesNikhil ResumeJaikumar KrishnaNo ratings yet

- The Shrinking and Swelling of Wood and Its Effect On FurnitureDocument26 pagesThe Shrinking and Swelling of Wood and Its Effect On FurnitureHozaifaNo ratings yet

- Application of Power Electronic Converters in Electric Vehicles andDocument22 pagesApplication of Power Electronic Converters in Electric Vehicles andfekadu gebeyNo ratings yet

- What Is Automation: Delegation of Human Control Functions To Technical Equipment Aimed Towards AchievingDocument26 pagesWhat Is Automation: Delegation of Human Control Functions To Technical Equipment Aimed Towards AchievingVeeraperumal ArumugamNo ratings yet

- Final Manuscript RevisionDocument16 pagesFinal Manuscript RevisionArya AdilaksaNo ratings yet

- Ridgewood Community School - WinterSpring 2017Document48 pagesRidgewood Community School - WinterSpring 2017ShellyStantonNo ratings yet

- Valencia v. Sandiganbayan DIGESTDocument2 pagesValencia v. Sandiganbayan DIGESTkathrynmaydevezaNo ratings yet

- Catalytic Application of NanomaterialsDocument23 pagesCatalytic Application of NanomaterialsViji VijithaNo ratings yet

- Maharishi Dayanand University, Rohtak Haryana: Project Report OnDocument62 pagesMaharishi Dayanand University, Rohtak Haryana: Project Report OnHitesh Yaduvanshi100% (1)

- 7Document11 pages7Va PolNo ratings yet

- Harvard Referencing GuideDocument73 pagesHarvard Referencing GuideCassidy WilliamsNo ratings yet

- 231025+ +JBS+3Q23+Earnings+Preview VFDocument3 pages231025+ +JBS+3Q23+Earnings+Preview VFgicokobayashiNo ratings yet

- Definition of Terms in Practical ResearchDocument4 pagesDefinition of Terms in Practical Researchscarlet chikky endinoNo ratings yet

- Simplex 4081-0002Document2 pagesSimplex 4081-0002vlaya1984No ratings yet

- Ebook PDF Understandable Statistics Concepts and Methods 12th Edition PDFDocument41 pagesEbook PDF Understandable Statistics Concepts and Methods 12th Edition PDFjimmie.smith693100% (32)

- Insurance As A Investment Tool at Icici Bank Project Report Mba FinanceDocument73 pagesInsurance As A Investment Tool at Icici Bank Project Report Mba FinanceBabasab Patil (Karrisatte)No ratings yet

- Alrehman Pirani Resume LMCDocument1 pageAlrehman Pirani Resume LMCapi-307195944No ratings yet

- Arm Multiple ChoiceDocument4 pagesArm Multiple ChoiceStalin Sbr33% (9)

- Daftar PustakaDocument2 pagesDaftar PustakaRidhal FauzanNo ratings yet

- Accenture The Long View of The Chip ShortageDocument20 pagesAccenture The Long View of The Chip ShortageOso genialNo ratings yet

- Isolating Antagonistic BacteriaDocument12 pagesIsolating Antagonistic BacteriaDesy rianitaNo ratings yet

- Sustainable Development & Environmental Assessment QuizDocument2 pagesSustainable Development & Environmental Assessment QuizramananNo ratings yet

- De La Salle University College of Business Course Checklist: Basirec SystandDocument2 pagesDe La Salle University College of Business Course Checklist: Basirec SystandncllpdllNo ratings yet

- GAD Project ProposalDocument2 pagesGAD Project ProposalMa. Danessa T. BulingitNo ratings yet

- DSP1800 Temperature and Humidity ProbeDocument2 pagesDSP1800 Temperature and Humidity ProbeGerardo SanchezNo ratings yet