Professional Documents

Culture Documents

ELECTRICAL SERVICE INSTALLATION NOTES

Uploaded by

Dina ShresthaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ELECTRICAL SERVICE INSTALLATION NOTES

Uploaded by

Dina ShresthaCopyright:

Available Formats

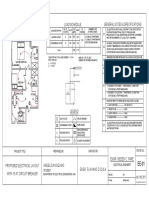

ELECTRICAL SERVICES NOTES

1.Provide new materials. Ensure installation and materials comply with the applicable

SERVICE ASSEMBLY ENCLOSURE MAIN DISCONNECT & BRANCH CIRCUIT BREAKERS

provisions of the National Electrical Code (NEC) and National Electrical Manufacturers

Association (NEMA) standards. Ensure material is Underwriters Laboratories (UL) listed.

1.Provide threaded hub for all conduit entries into the top of enclosure. 1.Field drill flange-mounted remote operator handle if needed, to

Provide and install electrical service conduits, conductors, disconnects, contactors,

No warranty of any

TxDOT assumes no responsibility for the conversion

ensure handle is lockable in both the "On" and "Off" positions.

circuit breaker panels, and branch circuit breakers as shown on the Electrical Service

2.Type galvanized steel (GS) enclosures may be used for Type C panelboards

Data chart in the plans. Faulty fabrication or poor workmanship in material, equipment,

and for Type D and T services that do not use an enclosure mounted 2.When the utility company provides a transformer larger than 50 KVA,

or installation is justification for rejection. Where manufacturers provide warranties

photocell or lighting contactor. Provide GS enclosures in accordance with verify that the available fault current is less than the circuit

and guarantees as a customary trade practice, furnish these to the State.

DMS 11080, 11082, 11083, and 11084. breaker's ampere interrupting capacity (AIC) rating and provide

of this standard to other formats or for incorrect results or damages resulting from its use.

documentation from the electric utility provider to the Engineer.

2.Provide electrical services in accordance with Electrical Details standard sheets,

3.Provide aluminum (AL) and stainless steel (SS) enclosures for Types A, C,

Departmental Material Specification (DMS) 11080 "Electrical Services,"DMS 11081

and D in accordance with DMS 11080, 11081, 11082, 11083, and 11084. Do

"Electrical Services-Type A," DMS 11082 "Electrical Services-Type C," DMS 11083

not paint stainless steel.

PHOTOELECTRIC CONTROL

"Electrical Services-Type D," DMS 11084 "Electrical Services-Type T," DMS 11085

"Electrical Services-Pedestal (PS)", and Item 628 "Electrical Services" of the 1.Provide photocell as listed on the MPL. Move, adjust, or shield the

4.Provide pedestal service (PS) enclosures in accordance with ED(9) and

Standard Specifications. Provide electrical service types A, C, and D, as listed photocell from stray or ambient night time light to ensure proper

The use of this standard is governed by the "Texas Engineering Practice Act".

DMS 11080 and 11085. Do not provide GS pedestal services. If GS is shown

on the Material Producers List (MPL) on the Department web site under "Roadway operation. Mount photocell facing north when practical. Mount top

in the PS descriptive code, provide an AL enclosure.

Illumination and Electrical Supplies," Item 628. Provide other service types as of pole photocells as shown on Top Mounted Photocell Detail.

detailed on the plans.

3.Provide all work, materials, services, and any incidentals needed to install a

complete electrical service as specified in the plans.

4.Coordinate with the Engineer and the utility provider for metering and compliance

with utility requirements. Primary line extensions, connection charges, meter

charges, and other charges by the utility company to provide power to the location * ELECTRICAL SERVICE DATA

are paid for in accordance with Item 628. Get approval for the costs associated

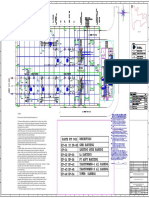

with these charges prior to engaging the utility company to do the work. Consult Elec. Plan Service Service Safety Main Two-Pole Panelbd/ Branch Branch Branch

KVA

with the utility provider to determine costs and requirements, and coordinate the Service Sheet Electrical Service Description Conduit Conductors Switch Ckt. Bkr. Contractor Loadcenter Circuit Ckt. Bkr. Circuit

work as approved. Load

ID Number Size

** No./Size Amps Pole/Amps Amps Amp Rating ID Pole/Amps Amps

5.The enclosure manufacturer will provide Master Lock Type 2 with brass tumblers SB 183 289 ELC SRV TY A 240/480 100(SS)AL(E)SF(U) 2" 3/#2 100 2P/100 100 N/A Lighting NB 2P/40 26 28.1

keyed #2195 for all custom electrical enclosures. Installing Contractor is to Lighting SB 2P/40 25

kind is made by TxDOT for any purpose whatsoever.

provide Master Lock #2195 Type 2 with brass tumblers for "off the shelf"

Underpass 1P/20 15

enclosures. Master Lock #2195 keys and locks become property of the State.

Unless otherwise approved, do not energize electrical service equipment until

locks are installed. NB Access 30 ELC SRV TY D 120/240 060(NS)SS(E)TS(O) 1 ‚" N/A 2P/60 100 Sig. Controller 1P/30 23 5.3

3/#6

30 Luminaires 2P/20 9

6.Enclosures with external disconnects that de-energize all equipment inside the

enclosure do not need a dead front trim. Protect incoming line terminations from CCTV 1P/20 3

incidental contact as required by the NEC.

2nd & Main 58 ELC SRV TY T 120/240 000(NS)GS(N)SP(O) 1 ‚" 3/#6 N/A N/A N/A 70 Flashing Beacon 1 1P/20 4 1.0

7.When galvanized is specified for nuts, screws, bolts or miscellaneous hardware,

stainless steel may be used. Flashing Beacon 2 1P/20 4

8.Provide wiring and electrical components rated for 75°C. Provide red, black, * Example only, not for construction. All new electrical services must have

electrical service data chart specific to that service as shown in the plans.

and white colored XHHW service entrance conductors of minimum size 6 American

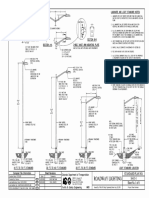

Standard 3-prong

Wire Gauge (AWG). Identify size 6 AWG conductors by continuous color jacket.

photocell

Identify electrical conductors sized 4 AWG and larger by continuous color ** Verify service conduit size with utility. Size may change due to utility meter

requirements. Ensure conduit size meets the National ELectrical Code. receptacle

jacket or by colored tape. Mark at least 6 inches of the conductor's insulation Conduit mounting

and photocell

with half laps of colored tape, when identifying conductors. Ensure each service channel(Unistrut,

entrance conductor exits through a separately bushed non-metallic opening in the Kindorf, B-line

weatherhead. The lengths of the conductors outside the weatherhead are to be or equal)

12 inches minimum, 18 inches maximum, or as required by utility. EXPLANATION OF ELECTRICAL SERVICE DESCRIPTIVE CODE Hot dipped

DISCLAIMER:

galvanized,

9.All electrical service conduit and conductors attached to the electrical service ELEC SERV TY X XXX/XXX XXX (XX) XX (X) XX (X) cast iron,

including the riser or the elbow below ground are subsidiary to the electrical

or sand cast

service. For an underground utility feed, all service conduit and conductors after 6"

Schematic Type aluminum outlet Mount Photocell

the elbow, including service conduit and conductors for the utility pole riser

box with cover. 6" to 8" measured

when furnished by the Contractor, will be paid for separately.

Service Voltage V / V from the top of

10.Provide rigid metal conduit (RMC) for all conduits on service, except for the the pole or 18

Disconnect Amp Rating to 20 feet above

• in. PVC conduit containing the electrical service grounding electrode

•" RM

conductor. Size the service entrance conduit as shown in the plans. Ensure 000 indicates main lug only/ finished grade

Conduit, bend

conduit for branch circuit entry to enclosure is the same size as that shown Typically Type T or as directed

to provide •"

on the layout sheets for branch circuit conduit. Extend all rigid metal conduits by Engineer, and

a minimum of 6 inches underground and then couple to the type and schedule of

to 1" clearance

(SS)= Safety Switch Ahead of as allowed by

the conduit shown on the layout for that particular branch circuit. Install a between photo-

Meter-Check with Utility utility company.

grounding bushing on the RMC where it terminates in the service enclosure. cell and pole.

(NS)= No safety Switch Ahead of

Meter-Check with Utility

11.Use of liquidtight flexible metal conduit (LFMC) is allowed between the meter and

service enclosure when they are mounted 90 to 180 degrees to each other. Size the Enclosure Type Service

LFMC the same size as service entrance conduit. LFMC must not exceed 3 feet in GS= Galvanized steel("off the shelf") Support

length. Strap LFMC within 1 foot of each end. LFMC less than 12 inches in length SS= Stainless steel(Custom Enclosure)See MPL

need not be strapped. Each end of LFMC must have a grounding bushing or be

AL= Aluminum (Custom Enclosure)See MPL

terminated with a grounding fitting. The LFMC must contain a grounded (neutral)

conductor. Ensure any bend in LFMC never exceeds 180 degrees. A pull test is TOP MOUNTED PHOTOCELL

Photocell Mounting Location

required on all installed conductors, with at least six inches of free conductor

movement demonstrated to the satisfaction of the Engineer. (E)= Inside Service/Enclosure Install conduit strap maximum 3 feet

Mounted from box. 5 foot maximum spacing

12.Ensure all mounting hardware and installation details of services conform to utility (T)= Top of pole between straps supporting conduit.

company specifications. (L)= Luminaire mounted

(N)= None/No Photocell or

13.For all electrical service enclosures listed under Item 628 on the MPL, the UL 508 Lighting Contactor Required Traffic

enclosure manufacturers will prepare and submit a schematic drawing unique to each Operations

service. Before shipment to the job site, place the applicable laminated schematic Service Support Type Division

drawings and the laminated plan sheet showing the electrical service data chart Standard

GC= Granite concrete

used to build the enclosure in the enclosure's data pocket. The installing contractor

OC= Other concrete

will copy and laminate the actual project plan sheets detailing all equipment and

TP= Timber pole

branch circuits supplied by that service. The laminated plan sheets are to be placed

SP= Steel pole

in the service enclosure's document pocket. Reduce 11 in. x 17 in. plan sheets to

SF= Steel frame

8 • in. x 11 in. before laminating. If the installation differs from the plan

sheets, the installing contractor is to redline plan sheets before laminating. OT= Pole by others or paid

ELECTRICAL DETAILS

for separately

14.When providing an "Off The Shelf" Type D or Type T service, provide laminated plan EX= Existing pole SERVICE NOTES & DATA

sheets detailing equipment and branch circuits supplied by that service. Reduce TS= Service on traffic

11 in. x 17 in. plan sheets to 8 • in. x 11 in before laminating. Deliver these signal pole

drawings before completion of the work to the Engineer, instead of placing in PS= Pedestal Service

enclosure that has no door pocket.

ED(5)-14

O= Overhead Service Feed

15.Do not install conduit in the back wall of a service enclosure where it would FILE: ed5-14.dgn DN: TxDOT CK: TxDOT DW: TxDOT CK: TxDOT

from Utility

penetrate the equipment mounting panel inside the enclosure. Provide grounding C TxDOT October 2014 CONT SECT JOB HIGHWAY

U= Underground Service Feed

bushings on all metal conduits, and terminate bonding jumpers to grounding bus. REVISIONS

from Utility

DATE:

FILE:

Grounding bushings are not required when the end of the metal conduit is fitted

DIST COUNTY SHEET NO.

with a conduit sealing hub or threaded boss, such as a meter base hub.

71E

You might also like

- Scame Indsutrial Socket PDFDocument36 pagesScame Indsutrial Socket PDFYoYoRamezNo ratings yet

- KV-5500/5000/3000 KV-DR1: Programmable ControllerDocument2 pagesKV-5500/5000/3000 KV-DR1: Programmable ControllerCatngoNo ratings yet

- CD Stereo System SC-AKX16: Operating InstructionsDocument2 pagesCD Stereo System SC-AKX16: Operating InstructionsOsvaldo HernandezNo ratings yet

- GB Installation Manual wiring guideDocument2 pagesGB Installation Manual wiring guiderennnNo ratings yet

- Electrical Accessories: Instructions ForDocument2 pagesElectrical Accessories: Instructions ForRavirayanpeterNo ratings yet

- Bi PumpDocument1 pageBi PumpFSO COMPRESORESNo ratings yet

- 03 Searchline Excel Cross Duct Installation Guide (English)Document2 pages03 Searchline Excel Cross Duct Installation Guide (English)Kalyan GrandhiNo ratings yet

- I-DE-3010.2G-5425-944-HG4-001 - 0 - IFD Keppel CommentsDocument1 pageI-DE-3010.2G-5425-944-HG4-001 - 0 - IFD Keppel CommentsChoong K WNo ratings yet

- Diagram & Circuit Boards Edition: © 2013-4 Printed in Ja Pan RQ005 (Y) 195 (B53-7038-00)Document54 pagesDiagram & Circuit Boards Edition: © 2013-4 Printed in Ja Pan RQ005 (Y) 195 (B53-7038-00)NickEglezosNo ratings yet

- Dual Preamp Signal Conditioner Installation GuideDocument10 pagesDual Preamp Signal Conditioner Installation Guideadamenun123No ratings yet

- Legends & Symbols Electrical Panel DiagramDocument1 pageLegends & Symbols Electrical Panel DiagramAngelice Alliah De la CruzNo ratings yet

- Network Design and Conversion Guide SpecificationDocument21 pagesNetwork Design and Conversion Guide SpecificationTodd ENo ratings yet

- Service Manual: TV-A20S2Document12 pagesService Manual: TV-A20S2ISMAIL ELECTRNo ratings yet

- Installation & Owner'S Manual: EnglishDocument8 pagesInstallation & Owner'S Manual: EnglishAdilen A. NadlorNo ratings yet

- Live Disconnection in Hazardous Areas: Technical Datasheet Technical DatasheetDocument4 pagesLive Disconnection in Hazardous Areas: Technical Datasheet Technical DatasheetRig 25 Sr. ElectricianNo ratings yet

- Bi-Pump Instruction ManualDocument2 pagesBi-Pump Instruction ManualRigoberto VillafuerteNo ratings yet

- Hino 300 S1 YXZE16C Manual 1 Electrical Wiring Diagrams EnglishDocument144 pagesHino 300 S1 YXZE16C Manual 1 Electrical Wiring Diagrams EnglishHV MOBILENo ratings yet

- TD E5 Installation ManualDocument1 pageTD E5 Installation ManualFrancisNo ratings yet

- MVP Inst CardDocument1 pageMVP Inst CardOscar Behrens ZepedaNo ratings yet

- LT 65650131r4.4 20220329 EX100 200 SpecDocument4 pagesLT 65650131r4.4 20220329 EX100 200 SpecArani Davila TineoNo ratings yet

- Valbia Actuator SetupDocument1 pageValbia Actuator SetupkikinNo ratings yet

- UGC05 - BOQ - STATIONS - MEP Elect - ICTDocument83 pagesUGC05 - BOQ - STATIONS - MEP Elect - ICTManglesh SinghNo ratings yet

- Service Manual: GR-D93US, GR-D94USDocument22 pagesService Manual: GR-D93US, GR-D94USsilictronicNo ratings yet

- Conduit installation accessories for environmental friendlinessDocument6 pagesConduit installation accessories for environmental friendlinessAdrian M FahriNo ratings yet

- Installation Manual: FX - 2AD-BDDocument3 pagesInstallation Manual: FX - 2AD-BDRovoltic SpaNo ratings yet

- Accentcablekit: ImportantDocument24 pagesAccentcablekit: ImportantLoreal VenezuelaNo ratings yet

- Clubdediagramas - TCL L32E5390 - MS63F-LADocument58 pagesClubdediagramas - TCL L32E5390 - MS63F-LAJosue Hernandez GutierrezNo ratings yet

- UVC KitDocument2 pagesUVC KitjaimegutierrezlinganNo ratings yet

- FX-300 Series: Instructions ManualDocument4 pagesFX-300 Series: Instructions Manualrogerio barbosa comamNo ratings yet

- Cellocator Cello - IQ GNSS Basic Evaluation Kit: Ordering No.: K090 - 012Document3 pagesCellocator Cello - IQ GNSS Basic Evaluation Kit: Ordering No.: K090 - 012BROCHIERNo ratings yet

- 32 File 20201104-111823 Solar-Cable PDFDocument6 pages32 File 20201104-111823 Solar-Cable PDFnictantesNo ratings yet

- WEG Molded Case Circuit Breakers: User's ManualDocument12 pagesWEG Molded Case Circuit Breakers: User's ManualfelipeNo ratings yet

- BPG - Wire Cable Marking (Wirecable)Document12 pagesBPG - Wire Cable Marking (Wirecable)Katty CachagoNo ratings yet

- Aalborg Universitet: Jensen, Christian Flytkjær Faria Da Silva, Filipe Bak, Claus Leth Wiechowski, WDocument8 pagesAalborg Universitet: Jensen, Christian Flytkjær Faria Da Silva, Filipe Bak, Claus Leth Wiechowski, WEmmanuel PugaNo ratings yet

- Mi_Benefits_IndiaDocument2 pagesMi_Benefits_IndiaAl-KaiserNo ratings yet

- 01-05 Unpacking A SwitchDocument11 pages01-05 Unpacking A SwitchRicardoCastroNo ratings yet

- Jy997d33601 (E) HDocument3 pagesJy997d33601 (E) HSalman arifNo ratings yet

- TPWRD2813540Document9 pagesTPWRD2813540khanhnd.hwNo ratings yet

- Procedure For Cutting and Respooling Fiber Optic Cable: 1. GeneralDocument9 pagesProcedure For Cutting and Respooling Fiber Optic Cable: 1. Generalafra09No ratings yet

- Legend:: Panel Board Diagram A E1Document1 pageLegend:: Panel Board Diagram A E1Anonymous 8Ec6v2No ratings yet

- 022 R01 Cable Schedules Multi Core cablesDocument1 page022 R01 Cable Schedules Multi Core cablessreeagile.esNo ratings yet

- Supplied Accessories Important: Read All Installation Manual Carefully andDocument2 pagesSupplied Accessories Important: Read All Installation Manual Carefully andkalle ankaNo ratings yet

- Safety Procedures: WarningDocument11 pagesSafety Procedures: WarningBerk bı BilgiçNo ratings yet

- Safety Procedures: WarningDocument11 pagesSafety Procedures: WarningAle Meléndez RuizNo ratings yet

- UntitledjsjjsDocument1 pageUntitledjsjjsPaulo GallardoNo ratings yet

- Installation, Operation and Maintenance Instructions: Metalarm Series 6301 Ce Metal Detector SystemDocument12 pagesInstallation, Operation and Maintenance Instructions: Metalarm Series 6301 Ce Metal Detector SystemKarin AndersonNo ratings yet

- Installation Instructions Range: Single Oven Gas RangeDocument2 pagesInstallation Instructions Range: Single Oven Gas RangeAshokNo ratings yet

- DAEWO Igual A TCL-DW50-LEDHDDocument38 pagesDAEWO Igual A TCL-DW50-LEDHDRaul Lopez ReinaNo ratings yet

- TCL L39F3300-MS63F-LA o DAEWO DW50-LEDHD PDFDocument38 pagesTCL L39F3300-MS63F-LA o DAEWO DW50-LEDHD PDFTecnodaselectronica TecnodasNo ratings yet

- Meltric Instruction DXN 1Document6 pagesMeltric Instruction DXN 1Camilo Andrés Perdomo VelascoNo ratings yet

- Power Pulse Valves PDFDocument12 pagesPower Pulse Valves PDFUrip S. SetyadjiNo ratings yet

- Integral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Document16 pagesIntegral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Kishor JadhavNo ratings yet

- WH100022 Winning Home Installation Guide 3Document4 pagesWH100022 Winning Home Installation Guide 3Andres PARDO ARAQUENo ratings yet

- BPG - Wire-Cable-Marking (Wirecable)Document12 pagesBPG - Wire-Cable-Marking (Wirecable)Banji EwinNo ratings yet

- H3AC3 English Installation GuideDocument1 pageH3AC3 English Installation Guidejmom18_647241209No ratings yet

- Rca 46smartr30 - L46f3520-Ms63f-La - 1Document61 pagesRca 46smartr30 - L46f3520-Ms63f-La - 1Mauricio Raul RotmanNo ratings yet

- DJ-01i Radio - Receiver.manual p.1.2 ENDocument2 pagesDJ-01i Radio - Receiver.manual p.1.2 ENVytautas MatulionisNo ratings yet

- Schneider Electronics Manual Provides Safety InstructionsDocument60 pagesSchneider Electronics Manual Provides Safety Instructionsjose4445No ratings yet

- SWLD SKYP1 57.5MWp TL E DWG SWG EARTH 01 - ApprovedDocument2 pagesSWLD SKYP1 57.5MWp TL E DWG SWG EARTH 01 - Approvedpriyanka k lNo ratings yet

- ITS STD Drawings April 2019Document68 pagesITS STD Drawings April 2019Dina ShresthaNo ratings yet

- Roadway Lighting Adot S-613-1Document6 pagesRoadway Lighting Adot S-613-1Dina ShresthaNo ratings yet

- Pole Top Plate: Service Support Type SP (O) - Overhead Service Service Support Type SF & SPDocument1 pagePole Top Plate: Service Support Type SP (O) - Overhead Service Service Support Type SF & SPDina ShresthaNo ratings yet

- Qualitative Questions Transportation Depth Vf18Document28 pagesQualitative Questions Transportation Depth Vf18Dina ShresthaNo ratings yet

- Pole Top Plate: Service Support Type SP (O) - Overhead Service Service Support Type SF & SPDocument1 pagePole Top Plate: Service Support Type SP (O) - Overhead Service Service Support Type SF & SPDina ShresthaNo ratings yet

- Granite Concrete (GC) & Other Concrete (Oc) Notes Timber Pole (TP) Service Support NotesDocument1 pageGranite Concrete (GC) & Other Concrete (Oc) Notes Timber Pole (TP) Service Support NotesDina ShresthaNo ratings yet

- 08 Stopping Sight DistanceDocument39 pages08 Stopping Sight Distancegetachew ambayeNo ratings yet

- Relative Influences of Individual, Social Environmental and PhysicalDocument7 pagesRelative Influences of Individual, Social Environmental and PhysicalDina ShresthaNo ratings yet

- Large Guide: Section 4Document36 pagesLarge Guide: Section 4AHmeD AbdelrahmanNo ratings yet

- Acadcal2010 11Document1 pageAcadcal2010 11Rohit TyagiNo ratings yet

- Franklin RD - Google MapsDocument1 pageFranklin RD - Google MapsDina ShresthaNo ratings yet

- Saturation Flow AssignmentDocument3 pagesSaturation Flow AssignmentDina ShresthaNo ratings yet

- 508 - Asco 7000 Series - Operator's Manual-381333 - 283bDocument10 pages508 - Asco 7000 Series - Operator's Manual-381333 - 283bGeorge AsuncionNo ratings yet

- Sim EimDocument18 pagesSim EimMarlyn Dela Vega Apolonio71% (7)

- Abu Dhabi International Airport: Structured Cabling System Layout Level 3.1 Sector 5.24CDocument1 pageAbu Dhabi International Airport: Structured Cabling System Layout Level 3.1 Sector 5.24CRavikiran SeshapuNo ratings yet

- Installation, Operation & Maintenance Manual: HL Series Electric Linear ActuatorsDocument25 pagesInstallation, Operation & Maintenance Manual: HL Series Electric Linear ActuatorsarisprakesaNo ratings yet

- Method of Statement For ELV SystemDocument7 pagesMethod of Statement For ELV SystemKo ZayNo ratings yet

- Session Plan Core 1Document25 pagesSession Plan Core 1Jdeified Dimol100% (1)

- Electrical Finishing MaterialsDocument26 pagesElectrical Finishing MaterialsphiNo ratings yet

- 65-2484RK Multi Point Detector ManualDocument43 pages65-2484RK Multi Point Detector ManualpcatruongNo ratings yet

- PPO Assignment 1 Group 1Document87 pagesPPO Assignment 1 Group 1HASSAN WASEEMNo ratings yet

- Export enDocument176 pagesExport enZagoni-Szabo Jozsef-CsabaNo ratings yet

- 2011 Nec Code Reference: 300.5 Underground InstallationsDocument8 pages2011 Nec Code Reference: 300.5 Underground InstallationsharrisvasNo ratings yet

- Final Exam - Building Systems DesignDocument24 pagesFinal Exam - Building Systems DesignChristian John SaludarNo ratings yet

- Clipsal ConduitDocument66 pagesClipsal Conduitalexwongks611850% (2)

- Tacera Installation Guide V2.6Document134 pagesTacera Installation Guide V2.6j100% (2)

- RCC Chapter 16Document20 pagesRCC Chapter 16F Azam Khan AyonNo ratings yet

- Concrete Encased Duct Bank PDFDocument8 pagesConcrete Encased Duct Bank PDF101079No ratings yet

- Cable Management SolutionsDocument11 pagesCable Management SolutionsRaja Sekhar RevanurNo ratings yet

- Fireye Burnerlogix ZB230 EngDocument80 pagesFireye Burnerlogix ZB230 Engjohn hutchingsNo ratings yet

- General notes on building orientation and constructionDocument92 pagesGeneral notes on building orientation and constructionMike VictorNo ratings yet

- Code Digest Sealing 2020Document4 pagesCode Digest Sealing 2020Bob JohnsonNo ratings yet

- Lighting & Convenience Outlet Layout: General NotesDocument1 pageLighting & Convenience Outlet Layout: General NotesJayvee Latosa Dividina100% (1)

- Grounding Busbar PDFDocument6 pagesGrounding Busbar PDFAgnolas GradeNo ratings yet

- Confidential 2Document87 pagesConfidential 2franzNo ratings yet

- Electrical Symbols Legend and AbbreviationsDocument5 pagesElectrical Symbols Legend and AbbreviationsjorgeNo ratings yet

- General Notes & Specifications Load Schedule: StudentDocument1 pageGeneral Notes & Specifications Load Schedule: StudentAngelica NoquiaoNo ratings yet

- Installation Guide Hydran M2 PDFDocument58 pagesInstallation Guide Hydran M2 PDFRam SinghNo ratings yet

- EIM Test BankDocument12 pagesEIM Test BankCab Vic0% (2)

- KAM LRW Manual 0222Document44 pagesKAM LRW Manual 0222jeisson28No ratings yet

- Selection of Cables/ConductorsDocument37 pagesSelection of Cables/ConductorsshuwingNo ratings yet

- Tower Grain Dryer Electrical Installation ManualDocument139 pagesTower Grain Dryer Electrical Installation ManualRotiseria La FlammeNo ratings yet