Professional Documents

Culture Documents

Bottom

Uploaded by

Kriengsak Ruangdech0 ratings0% found this document useful (0 votes)

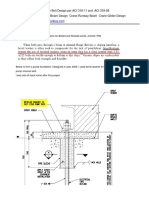

49 views1 pageThis document provides details on the bottom design of an oil palm tank, including design conditions, dimensions, materials, and thickness requirements. The minimum required thickness for the roof is 10mm based on a corroded thickness of 6mm and corrosion allowance of 3mm. The annular bottom plate thickness is selected as 12mm, meeting the minimum required corroded thickness of 9mm plus a corrosion allowance of 3mm. The width of the annular bottom plate must be at least 790mm according to the design code.

Original Description:

22

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides details on the bottom design of an oil palm tank, including design conditions, dimensions, materials, and thickness requirements. The minimum required thickness for the roof is 10mm based on a corroded thickness of 6mm and corrosion allowance of 3mm. The annular bottom plate thickness is selected as 12mm, meeting the minimum required corroded thickness of 9mm plus a corrosion allowance of 3mm. The width of the annular bottom plate must be at least 790mm according to the design code.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

49 views1 pageBottom

Uploaded by

Kriengsak RuangdechThis document provides details on the bottom design of an oil palm tank, including design conditions, dimensions, materials, and thickness requirements. The minimum required thickness for the roof is 10mm based on a corroded thickness of 6mm and corrosion allowance of 3mm. The annular bottom plate thickness is selected as 12mm, meeting the minimum required corroded thickness of 9mm plus a corrosion allowance of 3mm. The width of the annular bottom plate must be at least 790mm according to the design code.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

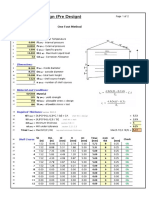

Tank Bottom Design (Pre Design) Page 2 of 2

API 650 12th Edition

Eqpt: Oil palm tank Bottom Design

1 Design Conditions

2 90 T [ºC] - Design Temperature

4 1.000 G [-] - Specific gravity

5 3.0 CAr [mm] - Roof Corrosion Allow.

6 3.0 CAb [mm] - Bottom Corrosion Allow.

7 Dimensions:

8 8.240 D [m] - inside diameter

10 10.700 H [m] - total tank height

11 8 t1 [mm] - thickness of the first shell course

12 Material and Conditions:

13 SUS304 Shell first course material

14 186 S [MPa] - actual stress @ first shell course

15 SUS304 Roof plate material

16 SUS304 Bottom plate material

17 SUS304 Annular bottom plate material

18 Minimum Thicknesses (Tr I Tb): section 5.10 - 5.4 Bottom

19 tr [mm] = minimum corroded thickness ~~ (5.10.2.2 - 5.4.1) = 6

20 t [mm] = tr + CAr I tr + CAb ~~ uncorroded thickness = 9.0

21 ut [mm] = Mill under tolerance ~~ section 2.2.1.2.3 = 0.25

22 Tr [mm] = Selected thickness = 10

23 Check Tr I Tb = Tr - ut >= t I Tb - ut >= t Ok

29 Annular bottom plate requirement & thickness: section 5.5

20 I Shell first course plate material group~~ see table 4.4.a

31 NO Annular bottom plate requirement~~ see section 5.5.1

32 tr [mm] = required minimum corroded thickness ~~ see section 5.1.a = 9

33 t [mm] = tr + CAb ~~ uncorroded thickness = 12.0

34 ut [mm] = Mill under tolerance ~~ section 2.2.1.2.3 = 0.00

35 Ta [mm] = Selected thickness 12

36 Check Ta = Ta - ut >= t 12 >= 12 = Ok

37 Annular bottom plate width: section 5.5.2

38 Wa [mm] = Max(Wa1;Wa2)~~ see section 5.5.2 = 790

39 Wa1 [mm] = 600mm + t1 + 50mm ~~ sections 5.5.2 + 5.4.2 = 660

0,5

40 Wa2 [mm] = 215 * Ta / (H * G) ~~ see section 5.5.2 = 790

You might also like

- Smart English 2 PDFDocument44 pagesSmart English 2 PDFmishhuana90% (21)

- My Electrical Revit HandbookDocument47 pagesMy Electrical Revit HandbookKriengsak Ruangdech100% (1)

- Operations Management Stevenson 11th Edition Test BankDocument10 pagesOperations Management Stevenson 11th Edition Test BankAries Gonzales Caragan50% (2)

- Scope of WorkDocument7 pagesScope of WorkKriengsak Ruangdech100% (2)

- Air Compressor Room LayoutDocument1 pageAir Compressor Room LayoutKriengsak RuangdechNo ratings yet

- Lay Planning TypesDocument1 pageLay Planning TypesGaurav Shakya100% (1)

- Structures Repair Guidelines: Engineering (Track & Civil) GuidelineDocument79 pagesStructures Repair Guidelines: Engineering (Track & Civil) GuidelinekanosriNo ratings yet

- Hydrant Water Tank Foundation Design Calc - Ebocha1Document39 pagesHydrant Water Tank Foundation Design Calc - Ebocha1Levi UbaNo ratings yet

- Outsource Activities Scope-Piping Section - 20220901Document6 pagesOutsource Activities Scope-Piping Section - 20220901SE PLNo ratings yet

- SWIODocument1 pageSWIOpreeti kumariNo ratings yet

- 3 Major Design Philosophies - Working Stress, Ultimate Load and Limit State - CivilDigitalDocument6 pages3 Major Design Philosophies - Working Stress, Ultimate Load and Limit State - CivilDigitalStacy JohnsonNo ratings yet

- Civil Works MtoDocument28 pagesCivil Works MtoNassim SabriNo ratings yet

- Calculation Report For New Substation Building C0148.64-2.41-680-B-EDocument361 pagesCalculation Report For New Substation Building C0148.64-2.41-680-B-EkarthiNo ratings yet

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument1 pageAS4041 ASME B31 - 3 Pipe Wall ThicknesselleNo ratings yet

- Annexure Wind LoadDocument36 pagesAnnexure Wind LoadVijeswara RaoNo ratings yet

- 6 - CE 511 - Base Plate Design PDFDocument33 pages6 - CE 511 - Base Plate Design PDFJayson RamosNo ratings yet

- Nawppl Bims NPPL 000 Me Cal 00001 001 - Calculation of Steel Piping SupportsDocument21 pagesNawppl Bims NPPL 000 Me Cal 00001 001 - Calculation of Steel Piping Supportsalinor_tnNo ratings yet

- Blind Calculation: This Calculation Is According To EN 13480Document2 pagesBlind Calculation: This Calculation Is According To EN 13480anas060No ratings yet

- RTRP Piping Systems - DohaDocument7 pagesRTRP Piping Systems - DohaRaziKhanNo ratings yet

- IOC/M&I/ELECT/E/18/2012 Electrical Motor Operated Valve Actuator & Master Station Rev.-0 Page 21 of 27Document6 pagesIOC/M&I/ELECT/E/18/2012 Electrical Motor Operated Valve Actuator & Master Station Rev.-0 Page 21 of 27Anonymous fLgaidVBhzNo ratings yet

- R D H W FW: Design of Tailing LugDocument2 pagesR D H W FW: Design of Tailing LugvpjagannaathNo ratings yet

- Mechanical Design Report - EX-3340 - R00Document75 pagesMechanical Design Report - EX-3340 - R00Aditya JainNo ratings yet

- Dj1 Dj2 Unb Unt Unl Ver 1.4Document2 pagesDj1 Dj2 Unb Unt Unl Ver 1.4ajayssarode100% (2)

- "EMBEDPL" Sample Calculation: (4) H.S.A. Example - "EMBEDPL" WorksheetDocument5 pages"EMBEDPL" Sample Calculation: (4) H.S.A. Example - "EMBEDPL" WorksheetVigneshNo ratings yet

- Rectangular Steel Bar DesignDocument2 pagesRectangular Steel Bar DesignAmit Kumar PaulNo ratings yet

- Baseplate Cirrcle 2018 - HUTATI LAPDocument11 pagesBaseplate Cirrcle 2018 - HUTATI LAPThinh ViproNo ratings yet

- UB Fin Plate DesignDocument8 pagesUB Fin Plate DesignWin ThanNo ratings yet

- Calculation Note For Compressor Shelter - Rev ADocument54 pagesCalculation Note For Compressor Shelter - Rev AmaniaxpdfNo ratings yet

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin55860% (1)

- Pin Base ModuleDocument16 pagesPin Base ModuleMd Ahsanul KabirNo ratings yet

- Crimp PLTDocument5 pagesCrimp PLTSai SushankNo ratings yet

- Check List For Design EngineerDocument1 pageCheck List For Design Engineerphalkejitu1No ratings yet

- Finite Element AnalysisDocument3 pagesFinite Element AnalysisAshley_RulzzzzzzzNo ratings yet

- Analysis of Corrugated Web Beam To Column Extended End Plate Connection UsingDocument75 pagesAnalysis of Corrugated Web Beam To Column Extended End Plate Connection UsingLina Lina LoulouNo ratings yet

- CS-150-2c3 - Pulled Bend Min THKDocument1 pageCS-150-2c3 - Pulled Bend Min THKJoanna NewtonNo ratings yet

- Rivet Joint Plate Tear - Tensile Strength CalculationDocument6 pagesRivet Joint Plate Tear - Tensile Strength CalculationvenkateswaranNo ratings yet

- Ug-45 Nozzle Neck Thickness: Plus The Thickness Added For AllowancesDocument2 pagesUg-45 Nozzle Neck Thickness: Plus The Thickness Added For AllowancesLcm TnlNo ratings yet

- Calculation of PipeReinforcement ASMEB31 1Document4 pagesCalculation of PipeReinforcement ASMEB31 1threedlabsNo ratings yet

- WE-5-2 Fin Plate ConnectionDocument10 pagesWE-5-2 Fin Plate ConnectionPedro AlmeidaNo ratings yet

- Piping Support Standard Specification (163-189)Document49 pagesPiping Support Standard Specification (163-189)Emilio HuertasNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Pdms CommentsDocument2 pagesPdms Commentssteepa22No ratings yet

- Is800-2007 Appendix PDFDocument85 pagesIs800-2007 Appendix PDFDebasish MondalNo ratings yet

- 01 Rpspl-Civil-Doc-Ct-01-31-01-20 PDFDocument75 pages01 Rpspl-Civil-Doc-Ct-01-31-01-20 PDFkapilNo ratings yet

- 40 Seismic ASCE 7-02-05Document2 pages40 Seismic ASCE 7-02-05mohamedabdelalNo ratings yet

- Client Hpcl-Mittal Energy Ltd. Project Offsite Unit PPU Stress Lp-Header Line SystemDocument5 pagesClient Hpcl-Mittal Energy Ltd. Project Offsite Unit PPU Stress Lp-Header Line SystemIshu VohraNo ratings yet

- Pump Shelter Steel Structure Design Calculation FEM MethodDocument79 pagesPump Shelter Steel Structure Design Calculation FEM Methodcharleshutabara951No ratings yet

- Rectangular Flange DesignDocument6 pagesRectangular Flange DesignTAHIR MAHMOODNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong Su100% (1)

- F - Deludge SystemDocument11 pagesF - Deludge Systemkelvin_totNo ratings yet

- Architectural Drawings For G+1 Residential Building: Name of Owner Plot No. LocationDocument36 pagesArchitectural Drawings For G+1 Residential Building: Name of Owner Plot No. LocationTokio87No ratings yet

- Lifting LugDocument17 pagesLifting LugbkprodhNo ratings yet

- PDO Discipline-Document Type Matrix: - Based On EPP Standard Document Types List Rev 15Document10 pagesPDO Discipline-Document Type Matrix: - Based On EPP Standard Document Types List Rev 15Qayyum KhanNo ratings yet

- Larsen & Toubro Limited - Ecc DivisionDocument1 pageLarsen & Toubro Limited - Ecc DivisionOuseppachan AmbookenNo ratings yet

- Shear Failure of Bolted Joints - ME 372 Lab: Bolt DataDocument1 pageShear Failure of Bolted Joints - ME 372 Lab: Bolt Databoo huNo ratings yet

- AutoPIPE Vessel GuideDocument5 pagesAutoPIPE Vessel Guidefiuto_rights_1404802No ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- Two-Tier Pipe Rack Connection DesignDocument4 pagesTwo-Tier Pipe Rack Connection DesignNicoleta cristianNo ratings yet

- HE Header E535Document91 pagesHE Header E535rizal mubarokNo ratings yet

- Beam Column ConnectionDocument2 pagesBeam Column ConnectionHAZIRACFS SURATNo ratings yet

- Heat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtriDocument1 pageHeat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtrivikzefgNo ratings yet

- Jeddah South Thermal Power Plant Stage-I: ProjectDocument18 pagesJeddah South Thermal Power Plant Stage-I: ProjectAmr AbdeinNo ratings yet

- Tk-02 Cone Roof - Roof & Bottom SolutionDocument2 pagesTk-02 Cone Roof - Roof & Bottom Solutionpescanova3No ratings yet

- TK-02 Supported Roof - Calculo Soporte TechoDocument5 pagesTK-02 Supported Roof - Calculo Soporte Techojoaquin torrano veraNo ratings yet

- TK-03 Caculation Sheet-Pared y FondoDocument2 pagesTK-03 Caculation Sheet-Pared y Fondojoaquin torrano veraNo ratings yet

- RCC Beam Design Task-01Document29 pagesRCC Beam Design Task-01Mohamed SaheelNo ratings yet

- Reactor 20Document1 pageReactor 20Kriengsak RuangdechNo ratings yet

- PU01-301-33-012-023-D30-002 - Z15211-414-00 - Suction Box For Existing Silo - A01Document1 pagePU01-301-33-012-023-D30-002 - Z15211-414-00 - Suction Box For Existing Silo - A01Kriengsak RuangdechNo ratings yet

- Reactor 20Document1 pageReactor 20Kriengsak RuangdechNo ratings yet

- K Nat Ser Plat 01 r01Document1 pageK Nat Ser Plat 01 r01Kriengsak RuangdechNo ratings yet

- Exception / Deviation List: Vendor InformationDocument2 pagesException / Deviation List: Vendor InformationKriengsak RuangdechNo ratings yet

- Bidder Price FormDocument14 pagesBidder Price FormKriengsak RuangdechNo ratings yet

- Tutorial Lug EvaluationDocument9 pagesTutorial Lug EvaluationKriengsak RuangdechNo ratings yet

- Work Order Request Form On-Call Engineering Service: Proposal Price: Total Man-HourDocument1 pageWork Order Request Form On-Call Engineering Service: Proposal Price: Total Man-HourKriengsak RuangdechNo ratings yet

- Tank Shell Design (Pre Design) : API 650 12th Edition Eqpt: Oil Palm Tank One Foot MethodDocument1 pageTank Shell Design (Pre Design) : API 650 12th Edition Eqpt: Oil Palm Tank One Foot MethodKriengsak RuangdechNo ratings yet

- Platform Service: Handrail Pipe 1 1/2" H 1.10 MDocument1 pagePlatform Service: Handrail Pipe 1 1/2" H 1.10 MKriengsak RuangdechNo ratings yet

- Cost EstimateDocument1 pageCost EstimateKriengsak RuangdechNo ratings yet

- YST-MS55D: Powered Multimedia SpeakersDocument15 pagesYST-MS55D: Powered Multimedia SpeakersKriengsak RuangdechNo ratings yet

- Types of Screw Conveyors - Engineering GuideDocument6 pagesTypes of Screw Conveyors - Engineering GuideKriengsak RuangdechNo ratings yet

- Types of Screw Feeders - Engineering GuideDocument7 pagesTypes of Screw Feeders - Engineering GuideKriengsak RuangdechNo ratings yet

- Pump Sizing Calculation: Tag No. Description Date by V Gas Co.,Ltd. Kriengsak R. P-101 Cooling Pum 02-04-18Document1 pagePump Sizing Calculation: Tag No. Description Date by V Gas Co.,Ltd. Kriengsak R. P-101 Cooling Pum 02-04-18Kriengsak RuangdechNo ratings yet

- PC AL Contractor Area Film ALDocument1 pagePC AL Contractor Area Film ALKriengsak RuangdechNo ratings yet

- Civil: When To Use Bevel WasherDocument1 pageCivil: When To Use Bevel WasherKriengsak RuangdechNo ratings yet

- Ip TunnelingDocument15 pagesIp TunnelingBon Tran HongNo ratings yet

- LAB Find Out The Bottle ContentsDocument4 pagesLAB Find Out The Bottle ContentschanNo ratings yet

- This Study Resource Was: MCV4U Exam ReviewDocument9 pagesThis Study Resource Was: MCV4U Exam ReviewNathan WaltonNo ratings yet

- HH220i - JAN 11Document1 pageHH220i - JAN 11Achmad GazaliNo ratings yet

- David Sacks Resume February 16 2015Document1 pageDavid Sacks Resume February 16 2015api-279280948No ratings yet

- Veerasaiva Pantha in 12th Century MaharashtraDocument2 pagesVeerasaiva Pantha in 12th Century MaharashtrarathkiraniNo ratings yet

- House Staff OrderDocument2 pagesHouse Staff OrderTarikNo ratings yet

- Cause List 2.1.2023Document4 pagesCause List 2.1.2023あいうえおかきくけこNo ratings yet

- Being Agile. Staying Resilient.: ANNUAL REPORT 2021-22Document296 pagesBeing Agile. Staying Resilient.: ANNUAL REPORT 2021-22PrabhatNo ratings yet

- FBDocument27 pagesFBBenjaminNo ratings yet

- Ultraviolet RadiationDocument3 pagesUltraviolet RadiationbirlacementNo ratings yet

- Alternatoer Lvsi804s WDG 12 v9 TdsDocument8 pagesAlternatoer Lvsi804s WDG 12 v9 TdsCris_eu09No ratings yet

- Pediatric Infectious DiseasesDocument3 pagesPediatric Infectious DiseasesAiri FirdausiaNo ratings yet

- ArticleDocument9 pagesArticleElly SufriadiNo ratings yet

- Marshall Mix Design (Nptel - ceTEI - L26 (1) )Document7 pagesMarshall Mix Design (Nptel - ceTEI - L26 (1) )andrewcwng0% (1)

- MODULE 1 - Contemporary WorldDocument4 pagesMODULE 1 - Contemporary WorldaapNo ratings yet

- Chemistry Previos Papaer 313Document19 pagesChemistry Previos Papaer 313Ashu GuptaNo ratings yet

- Self Regulated StudyDocument6 pagesSelf Regulated StudyAdelheyde HeleneNo ratings yet

- How To Spend An Hour A Day in Prayer - Matthew 26:40-41Document1 pageHow To Spend An Hour A Day in Prayer - Matthew 26:40-41Steve GainesNo ratings yet

- Task 3: New - HTMLDocument12 pagesTask 3: New - HTMLGONELA SAI LOKESH (RA2011028010100)No ratings yet

- ISA Guidelines PPF 1Document19 pagesISA Guidelines PPF 1Vasu DevanNo ratings yet

- Grade 7 Math Lesson 22: Addition and Subtraction of Polynomials Learning GuideDocument4 pagesGrade 7 Math Lesson 22: Addition and Subtraction of Polynomials Learning GuideKez MaxNo ratings yet

- SWAMINATHAN Ajanta RhapsodyDocument227 pagesSWAMINATHAN Ajanta RhapsodyRoberto E. García100% (1)

- Directorate of Technical Education, Maharashtra StateDocument47 pagesDirectorate of Technical Education, Maharashtra StatePandurang GunjalNo ratings yet

- Motor BookDocument252 pagesMotor BookKyaw KhNo ratings yet

- Climate Declaration: For White Corex PlasterboardDocument1 pageClimate Declaration: For White Corex PlasterboardAbdullah BeckerNo ratings yet

- Transformational Leadership in The UmcDocument17 pagesTransformational Leadership in The Umcapi-202352366No ratings yet