Professional Documents

Culture Documents

Crimp PLT

Uploaded by

Sai SushankOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crimp PLT

Uploaded by

Sai SushankCopyright:

Available Formats

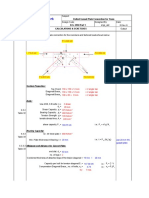

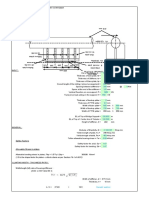

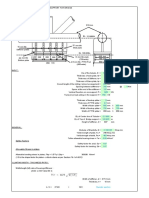

Design of Crimp Plate Section

.

Span = 2 Meters Yield Stress = 245 N/MM2

Design Pressure = 15 KN/M2

Max Bendign Moment = W L 2/10

= 6 KN-m

Moment of Ressistance of Crimp Plate Section = Z xx of Crimp Plate x F b

F b = 0.66 x Fy = 161.7 N/MM2

Z xx of Plate = 228660.9 mm3

MR= 36.97447 KN-M > 6 KN-m

OK-Section is Safe in Bending Moment

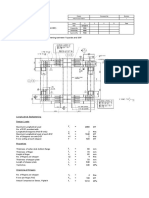

CRIMP PLATE SECTION PROPERTY CALCULATION

Crimp Height H = 150 mm

Crimp Width L = 160 mm

X X H 150

Inclined Width L1 = 75.02 mm 50

Plate Thk t = 4 mm

L L1 L

Angle of Crimp = 63.43 Deg 160 75.02 160

Length of Crimp in Plan = 395.0162 mm

Inclined Width = 164.14 mm

Per Meter Width

Area = A 1936.578 mm2 4902.528 mm2

Neutral Axis(from bottom) y 74.45906

Moment of Inertia = I xx 6823218 mm4 17273262 mm4

Section Modulus = Zxx 90324.77 mm3 228660.9 mm3

Number of Crimps per meter Width = 2.53 Nos

Actual Lenth of plt/ meter = 1225.632 mm

Weight of Plt per m^2 = 38.48485 Kg / m2

CRIMP PLATE SECTION PROPERTY CALCULATION

Crimp Height H = 150 mm

Crimp Width L = 160 mm

X X

Inclined Width L1 = 75.02 mm 50

Plate Thk t = 4 mm

L L1 L

Angle of Crimp = 63.43 Deg 160 75.02 160

Length of Crimp in Plan = 395.0162 mm

Inclined Width = 164.14 mm

Per Meter Width

Area = A 1936.578 mm2 4902.528 mm2

Neutral Axis(from bott y 74.45906

Moment of Inertia = I xx 6823218 mm4 17273262 mm4

Section Modulus = Zxx 90324.77 mm3 228660.9 mm3

Number of Crimps per meter Width = 2.53 Nos

Actual Lenth of plt/ meter = 1225.632 mm

Weight of Plt per m^2 38.48485 Kg / m2

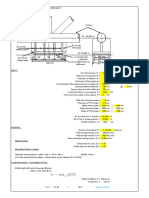

Design of Crimp Plate Section

.

Span = 2 Meters Yield Stress = 245 N/MM2

Design Pressure = 15 KN/M2

Max Bendign Moment W L 2/10

= 6 KN-m

Moment of Ressistance of Crimp Plate Secti Z xx of Crimp Plate x F b

F b = 0.66 x Fy = 161.7 N/MM2

Z xx of Plate = 228660.9 mm3

MR= 36.97447 KN-M > 6 KN-m

OK-Section is Safe in Bending Moment

H 150

You might also like

- Bearing CheckDocument6 pagesBearing CheckdhanushkaNo ratings yet

- Wind CalculatorDocument12 pagesWind Calculatorilyasmd7No ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- For Axial Compressive Load & Biaxial Bending Moments, Including Slenderness Effect, As Per Is:456-2000Document43 pagesFor Axial Compressive Load & Biaxial Bending Moments, Including Slenderness Effect, As Per Is:456-2000Mohan BhalmeNo ratings yet

- Annexure Wind LoadDocument36 pagesAnnexure Wind LoadVijeswara RaoNo ratings yet

- Pin Base ModuleDocument16 pagesPin Base ModuleMd Ahsanul KabirNo ratings yet

- 4 - PFC To Hanging Plate ConnDocument13 pages4 - PFC To Hanging Plate Connabdul khaderNo ratings yet

- Lug CalcionulatDocument1 pageLug CalcionulatkurniawanandreasNo ratings yet

- Warehouse DesignDocument3 pagesWarehouse DesignEditor IJTSRDNo ratings yet

- WE-5-2 Fin Plate ConnectionDocument10 pagesWE-5-2 Fin Plate ConnectionPedro AlmeidaNo ratings yet

- Ast For MomentDocument1 pageAst For MomenteramitdhanukaNo ratings yet

- Base Plate Design Metric Units PDFDocument8 pagesBase Plate Design Metric Units PDFVinayak PatilNo ratings yet

- Pin Connected Tension MemberDocument2 pagesPin Connected Tension MemberAUNGPSNo ratings yet

- Comparision IS VS EURO PDFDocument7 pagesComparision IS VS EURO PDFRadhaKrishnanTNo ratings yet

- WF Base Plate Design Based On AISC-ASD 9th Edition: Input Data & Design SummaryDocument2 pagesWF Base Plate Design Based On AISC-ASD 9th Edition: Input Data & Design SummaryShanoor ASNo ratings yet

- Universal Beam and Column Properties SheetDocument11 pagesUniversal Beam and Column Properties SheetkalpanaadhiNo ratings yet

- NODE NO. FOR COMBINED FOOTING CALCULATIONDocument101 pagesNODE NO. FOR COMBINED FOOTING CALCULATIONkumsbamaNo ratings yet

- Calculations For Rectangular Storage TankDocument44 pagesCalculations For Rectangular Storage TankSiva ShankarNo ratings yet

- 15 Ton Tank Concrete PlatformDocument1 page15 Ton Tank Concrete PlatformerickquintoNo ratings yet

- Steel ConnectionsDocument83 pagesSteel ConnectionsMEPNo ratings yet

- Beam - Section Classification Is 800-2007Document6 pagesBeam - Section Classification Is 800-2007ranjitNo ratings yet

- Structural Analysis and Design of Fuel Gas Coalescer Platform FoundationDocument29 pagesStructural Analysis and Design of Fuel Gas Coalescer Platform FoundationsridharNo ratings yet

- Turkey temporary facility pedestal designDocument23 pagesTurkey temporary facility pedestal designMyunSu GooNo ratings yet

- Analysis of Corrugated Web Beam To Column Extended End Plate Connection UsingDocument75 pagesAnalysis of Corrugated Web Beam To Column Extended End Plate Connection UsingLina Lina LoulouNo ratings yet

- EC 1991-4 Wind Loading CalculationDocument4 pagesEC 1991-4 Wind Loading CalculationjanethNo ratings yet

- Base Plate (Template)Document3 pagesBase Plate (Template)li yongzhongNo ratings yet

- Unit 3 Limit State of ServiceabilityDocument55 pagesUnit 3 Limit State of ServiceabilityManoj SharmaNo ratings yet

- Design of Combine Footing GridDocument2 pagesDesign of Combine Footing GridsharathkammarNo ratings yet

- M1 195 C195 AO34-4-07-X00-MC-0-DD-S164: (MM) (MM) (MM) (MM) (MM) (MM)Document2 pagesM1 195 C195 AO34-4-07-X00-MC-0-DD-S164: (MM) (MM) (MM) (MM) (MM) (MM)innovativekarthiNo ratings yet

- Design Load Basis Report Tensile Canopy - Vedvan - Noida - R0Document27 pagesDesign Load Basis Report Tensile Canopy - Vedvan - Noida - R0Neeraj KumarNo ratings yet

- Structural Analysis of 67m3 Above Ground Storage TankDocument16 pagesStructural Analysis of 67m3 Above Ground Storage TankTech DesignNo ratings yet

- Spreader Beam Design ExamplesDocument3 pagesSpreader Beam Design ExamplesBogdan DSANo ratings yet

- Structural Steelwork Connections: Bolted Gusset Plate Connection For Truss B.S. 5950 Part 1 Calculations & ScketchesDocument4 pagesStructural Steelwork Connections: Bolted Gusset Plate Connection For Truss B.S. 5950 Part 1 Calculations & ScketchessitheeqNo ratings yet

- THAIOIL - VER BRACING-L SECTION - BOLTED - 003 - Rev ADocument15 pagesTHAIOIL - VER BRACING-L SECTION - BOLTED - 003 - Rev ACivil StructureNo ratings yet

- Structural Linear BucklingDocument18 pagesStructural Linear BucklingKhusi1No ratings yet

- 21.65 Kips/bolt Shear Strength Controls: Section at ADocument3 pages21.65 Kips/bolt Shear Strength Controls: Section at ASuneesh PNo ratings yet

- Pedestal DesignDocument11 pagesPedestal DesignNikhil TawadeNo ratings yet

- Design of Pile: 400Mm Dia Pile Design (Applicable For 0M-0.5M Fill)Document3 pagesDesign of Pile: 400Mm Dia Pile Design (Applicable For 0M-0.5M Fill)sivaNo ratings yet

- Steel Stanchion Design Calcsheet v.0Document2 pagesSteel Stanchion Design Calcsheet v.0Olusegun S. Ajibola100% (2)

- Cleat Angle ConnectionDocument38 pagesCleat Angle ConnectionMadhubalan AlagarNo ratings yet

- Lashing Lug Round Bar Design: 1. GeneralDocument3 pagesLashing Lug Round Bar Design: 1. GeneralinnovativekarthiNo ratings yet

- R D H W FW: Design of Tailing LugDocument2 pagesR D H W FW: Design of Tailing LugvpjagannaathNo ratings yet

- Wind Pressure Calculation As per SP-1275Document7 pagesWind Pressure Calculation As per SP-1275Siva baalanNo ratings yet

- Steel Grating AnalysisDocument17 pagesSteel Grating AnalysisDhanraj VasanthNo ratings yet

- Calculation note for compressor shelter steel structure designDocument54 pagesCalculation note for compressor shelter steel structure designmaniaxpdfNo ratings yet

- PEC-EN-STN-C-13619-17-Mar-2014-Document169 pagesPEC-EN-STN-C-13619-17-Mar-2014-Raja RamNo ratings yet

- Calculation Sheet Connection DesignDocument1 pageCalculation Sheet Connection DesignJay SenjaliaNo ratings yet

- Moment ConnectionDocument5 pagesMoment ConnectionjanethNo ratings yet

- Bolt Load Calculation StepsDocument2 pagesBolt Load Calculation StepsSrikanth ShankarNo ratings yet

- Master Foods 12 MDocument16 pagesMaster Foods 12 MSarfarazNo ratings yet

- EMBEDPL Sample Calculation AnalysisDocument5 pagesEMBEDPL Sample Calculation AnalysisVigneshNo ratings yet

- STAAD Pro document with joint coordinatesDocument173 pagesSTAAD Pro document with joint coordinatesSaurabh GuptaNo ratings yet

- Embedded PlateDocument2 pagesEmbedded PlateAlma M. LaraNo ratings yet

- Lifting Lug Weld DesignR1aDocument1 pageLifting Lug Weld DesignR1aJohnclaude ChamandiNo ratings yet

- Chequered PlateDocument3 pagesChequered Platerammohan100% (4)

- Design of Connection:: 1. Connection Between Beam and Column PostDocument3 pagesDesign of Connection:: 1. Connection Between Beam and Column PostSaugat ThapaNo ratings yet

- A-Frame Calculation Without CoverDocument6 pagesA-Frame Calculation Without CoverimsayaaNo ratings yet

- Nabin 2 WayslabDocument22 pagesNabin 2 WayslabNabin joshiNo ratings yet

- Plan Elevation: D D B P M T T ADocument18 pagesPlan Elevation: D D B P M T T ASai SushankNo ratings yet

- Sukajadi 186 Bandung: WWW - Spiceaffair.co - Id Spiceaffair - BDGDocument3 pagesSukajadi 186 Bandung: WWW - Spiceaffair.co - Id Spiceaffair - BDGSai SushankNo ratings yet

- Shaping Citizens of Future at Highgate International SchoolDocument2 pagesShaping Citizens of Future at Highgate International SchoolSai SushankNo ratings yet

- AAE FAQs - Clean Version Final TCDocument9 pagesAAE FAQs - Clean Version Final TCSai SushankNo ratings yet

- Staircase Beam Design - 2Document28 pagesStaircase Beam Design - 2Sai Sushank67% (3)

- Calculation Note Stabbing Guide Design Design Code Check:Api RP 2A Check For Tubular Ø 323.9 X 12.70 Due To Boatlanding InstallationDocument8 pagesCalculation Note Stabbing Guide Design Design Code Check:Api RP 2A Check For Tubular Ø 323.9 X 12.70 Due To Boatlanding InstallationSai SushankNo ratings yet

- Vortex current-KERISI CPP - FINALDocument13 pagesVortex current-KERISI CPP - FINALSai SushankNo ratings yet

- Wing Plate BucklingDocument2 pagesWing Plate BucklingSai SushankNo ratings yet

- Softbrain Kid'S Academy Is OrganisingDocument2 pagesSoftbrain Kid'S Academy Is OrganisingSai SushankNo ratings yet

- Slam Force Checks for Jacket Walkway MembersDocument7 pagesSlam Force Checks for Jacket Walkway MembersSai SushankNo ratings yet

- Stiffener Local CheckingDocument1 pageStiffener Local CheckingSai SushankNo ratings yet

- Sideshell Weld CheckDocument1 pageSideshell Weld CheckSai SushankNo ratings yet

- MSF Bridge Support Stiffener DesignDocument7 pagesMSF Bridge Support Stiffener DesignSai SushankNo ratings yet

- HRD Process Platform Seafastening Design CalculationsDocument6 pagesHRD Process Platform Seafastening Design CalculationsSai SushankNo ratings yet

- Pile Stick Up LengthDocument16 pagesPile Stick Up LengthSai Sushank100% (1)

- Bridge B 1 Fixed EndDocument7 pagesBridge B 1 Fixed EndSai SushankNo ratings yet

- Crimp PLTDocument5 pagesCrimp PLTSai SushankNo ratings yet

- Stiffener Check For Pipe SupportDocument5 pagesStiffener Check For Pipe SupportSai Sushank100% (1)

- Bridge 10 Sunshade DesignDocument4 pagesBridge 10 Sunshade DesignSai SushankNo ratings yet

- DSF BoltsDocument2 pagesDSF BoltsSai SushankNo ratings yet

- CALCULATION OF MODIFIED g AND t PARAMETERSDocument17 pagesCALCULATION OF MODIFIED g AND t PARAMETERSSai SushankNo ratings yet

- Beam CheckDocument4 pagesBeam CheckSai SushankNo ratings yet

- DSF BoltsDocument2 pagesDSF BoltsSai SushankNo ratings yet

- Dent Depth CalculationDocument1 pageDent Depth CalculationSai SushankNo ratings yet

- CD CM OverridesDocument51 pagesCD CM OverridesSai SushankNo ratings yet

- SpliceDocument2 pagesSpliceSai SushankNo ratings yet

- Dent Depth CalculationDocument1 pageDent Depth CalculationSai SushankNo ratings yet

- Pile Foundation DesignDocument82 pagesPile Foundation Designcuongnguyen89% (28)

- Bridge Sliding End and Fixed End-CIFB03Document7 pagesBridge Sliding End and Fixed End-CIFB03Sai SushankNo ratings yet

- Project Pegasus Andy Contextualizes Contemporary Time Travel Research 3-18-10Document2 pagesProject Pegasus Andy Contextualizes Contemporary Time Travel Research 3-18-10Lawrence JonesNo ratings yet

- Phu Luc - Huong Dan Cau Hinh VPN L2 B0404Document14 pagesPhu Luc - Huong Dan Cau Hinh VPN L2 B0404luisNo ratings yet

- Quinta Pro Range Suggested SchematicsDocument32 pagesQuinta Pro Range Suggested SchematicsAnonymous CRQ100100% (2)

- VOLVO EW160B-5 BrakeDocument24 pagesVOLVO EW160B-5 BrakePIKO MOB100% (1)

- Facility Condition Assessment Checklist Feb 2017Document27 pagesFacility Condition Assessment Checklist Feb 2017Ghina Febriani Khairunnisa100% (1)

- AN5274 IC Audio Toshiba 21Document7 pagesAN5274 IC Audio Toshiba 21Abu AsyifaNo ratings yet

- 8th ChapterDocument39 pages8th ChapterMasthan BabuNo ratings yet

- Indonesia Digital Landscape 2018Document36 pagesIndonesia Digital Landscape 2018Yanti GintingNo ratings yet

- 7.4 Emf and Internal Resistance 09Document11 pages7.4 Emf and Internal Resistance 09b_syiera100% (1)

- Livrari Autoturisme Autohtone / Domestic Passenger Car DeliveriesDocument3 pagesLivrari Autoturisme Autohtone / Domestic Passenger Car DeliveriesBogdan PopNo ratings yet

- Hdpe PipesDocument25 pagesHdpe PipesRAMPALLI GATTAIAH100% (1)

- yamaha me432 part1Document4 pagesyamaha me432 part1Leonardo QuintanilhaNo ratings yet

- Nagios XI Product OverviewDocument2 pagesNagios XI Product Overviewphduycanh0% (1)

- UT For Duplex Stainless Steel WeldsDocument5 pagesUT For Duplex Stainless Steel WeldsvsnaiduqcNo ratings yet

- 231C Air Impact Wrench - Exploded View: (Dwg. TPA567-11)Document2 pages231C Air Impact Wrench - Exploded View: (Dwg. TPA567-11)julio bolivarNo ratings yet

- Design of A ThickenerDocument3 pagesDesign of A ThickenerHelenette Joy Vergara Cane100% (6)

- Description and Operation: Unison Industries Component Maintenance Manual Ignition LeadsDocument2 pagesDescription and Operation: Unison Industries Component Maintenance Manual Ignition Leadsmaty englerNo ratings yet

- Dr. Leach's Filter Potpourri: Transfer FunctionsDocument33 pagesDr. Leach's Filter Potpourri: Transfer FunctionsAhmad FauziNo ratings yet

- Industrial Training ReportDocument19 pagesIndustrial Training ReportRam PandeyNo ratings yet

- SOP Periodic Balance Check Eccentricity - e - 11793058Document4 pagesSOP Periodic Balance Check Eccentricity - e - 11793058Marcos PerezNo ratings yet

- Engineering CPWD Analysis of Rates - 1Document571 pagesEngineering CPWD Analysis of Rates - 1javedk_33No ratings yet

- Edifact Orders Idoc DescribedDocument19 pagesEdifact Orders Idoc DescribedVinod RaoNo ratings yet

- USB Flash Drive Price ListDocument1 pageUSB Flash Drive Price Listrick990No ratings yet

- OilsistemDocument212 pagesOilsistemapi-2635664650% (2)

- Logic Gate Investigatory PDFDocument12 pagesLogic Gate Investigatory PDFGaurang MathurNo ratings yet

- Vietnam - Introduce Tekla Open APIDocument34 pagesVietnam - Introduce Tekla Open API김성곤No ratings yet

- Preventing Misrepresentation of Unsalvageable Aircraft PartsDocument6 pagesPreventing Misrepresentation of Unsalvageable Aircraft Partsben foldsNo ratings yet

- IA-7 V3 ManualDocument15 pagesIA-7 V3 Manualaleksa64No ratings yet

- Implementing Selinux As Linux Security Module ReportDocument58 pagesImplementing Selinux As Linux Security Module ReportpamukumarNo ratings yet

- Four Laning Irc SP 84 2019Document3 pagesFour Laning Irc SP 84 2019Suyog Gore100% (2)