Professional Documents

Culture Documents

Bhopal PDF

Uploaded by

Ratna Paramitha SariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bhopal PDF

Uploaded by

Ratna Paramitha SariCopyright:

Available Formats

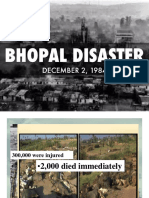

Facility Union Carbide India Ltd (UCIL), Bhopal, India.

Date 3rd December 1984

Consequences 4000 fatalities and tens of thousands permanently or totally disabled.

Description At 11.00 pm on 2nd December 1984, an operator at the plant noticed a small

of accident leak of highly toxic methyl isocyanate (MIC) gas and increasing pressure

inside a storage tank. The vent-gas scrubber, a safety device designed to

neutralize toxic discharge from the MIC system, had been turned off three

weeks prior. Apparently a faulty valve had allowed one ton of water for

cleaning internal pipes to mix with forty tons of MIC.

A 30 ton refrigeration unit that normally served as a safety component to cool

the MIC storage tank had been drained of its coolant for use in another part of

the plant. Pressure and heat from the vigorous exothermic reaction in the tank

continued to build. The gas flare safety system was out of action.

At around 1.00 am, December 3, loud rumbling reverberated around the plant

as a safety valve gave way sending a plume of MIC gas into the early morning

air.

The effect was devastating as within a short period people and animals started

dying. The cloud of toxic gas drifted towards the south and it is reported that

within 4 minutes that the cloud reached an area some 2 km from the plant, 150

people died, 200 were paralysed, 600 rendered unconscious and some 5000

were severely affected.

Key Lessons • Plant Siting

Learnt [1] o Site was close enough to populated areas prior to building of plant.

o Housing developments had been built around the plant over the

years and although these were illegal in the first instance, they were

acquiesced by the Indian authorities.

• Management of major hazard installations should be carried out by a

suitable competent management.

• Need for appreciation of the hazard from the high toxicity of a substance.

• Need to pay more attention to runaway reaction in a storage tank. Where

this reaction could act as a dispersion mechanism of a hazardous substance,

it should be carefully reviewed.

• The hazard of water in plants is generally well known, but attention needs

to be given to it when it can lead to explosive forces due to vaporisation or

exothermic reaction with a process fluid.

• The hazard of materials in storage should be properly assessed. Although

materials in process are generally considered riskier, inventories of stored

materials are usually larger.

• Priority between safety and production

o Measures to cut costs had been taken prior to the accident in the

plant. Some of these could have influenced the development or

consequences of the accident.

• Limitation of inventory in the plant: smaller amounts of toxic substances

should be considered when large inventories are not necessary.

• The problem of setting a high set pressure of relief devices need to be

appreciated when cause of potential pressure rise is a runaway reaction.

• The effect of the disabling of safety critical systems need to be recognised.

It is essential that there are strict procedures for disabling any item which is

critical for protection of the plant. The flare system was out of commission

for 3 months prior to the accident.

• Good maintenance of plant equipment and instrumentation is required as

part of a fire and explosion hazard management strategy.

o Leaking valves and malfunctioning equipment was common

throughout the Bhopal plant.

• Proper isolation procedures for maintenance were not followed at the plant.

• The effect of control of plant and process modifications need to very

carefully looked at.

• Authorities, emergency services, workers or members of the public

exposed to dangerous substances should be fully informed of the hazards.

• An emergency plan needs to be in place for major accident scenarios.

There was no effective emergency plan in place at the Bhopal plant.

Reports & 1) Lees’ Loss Prevention in the Process Industries: Hazard Identification,

Links Assessment and Control, ed. Mannan, S., 3rd edition, Elsevier Butterworth-

Heinemann, 2005

You might also like

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- SEPT 2022 - CLD 20002 - Chap 1 - Industrial SafetyDocument104 pagesSEPT 2022 - CLD 20002 - Chap 1 - Industrial SafetyAirish AirishNo ratings yet

- Safety Engineering of Process Plants (CH 404)Document79 pagesSafety Engineering of Process Plants (CH 404)ibuddhaNo ratings yet

- Hpct311:Laboratory: Week 1: Laboratory Safetyand Kinds of MicroscopeDocument3 pagesHpct311:Laboratory: Week 1: Laboratory Safetyand Kinds of MicroscopeHayzan Faith PuyaoNo ratings yet

- CSB Investigations of Incidents During Startups and ShutdownsDocument4 pagesCSB Investigations of Incidents During Startups and ShutdownsSebastian iacopiNo ratings yet

- OME754 INDUSTRIALSAFETY-Unit II NotesDocument106 pagesOME754 INDUSTRIALSAFETY-Unit II Notesraghul balaNo ratings yet

- Emergency Plan: Shankar Raman. PHDDocument59 pagesEmergency Plan: Shankar Raman. PHDAMOL RASTOGI 19BCM0012No ratings yet

- Case Study: Runaway Chemical Reaction and Vapor Cloud ExplosionDocument17 pagesCase Study: Runaway Chemical Reaction and Vapor Cloud ExplosionThing90No ratings yet

- HSSE Alert - Phillips 66 Explosion Incident - October 23Document4 pagesHSSE Alert - Phillips 66 Explosion Incident - October 23Osedebamen IraborNo ratings yet

- G.chem Bhopal Gas TragedyDocument16 pagesG.chem Bhopal Gas Tragedymrmy88tm46No ratings yet

- 12.environmental Aspects and SafetyDocument4 pages12.environmental Aspects and SafetyBhuneshwar ChelakNo ratings yet

- Introduction Applicable Regulatory Req v3Document52 pagesIntroduction Applicable Regulatory Req v3mercentNo ratings yet

- Importance of On-Site Emergency Plan inDocument5 pagesImportance of On-Site Emergency Plan infadli.lpgNo ratings yet

- 2.1 History, General, Optimization, Line Staff FunctionDocument54 pages2.1 History, General, Optimization, Line Staff FunctionKarthik SoundarrajanNo ratings yet

- CIMAH ContinuedDocument20 pagesCIMAH ContinuedDennis LingNo ratings yet

- General Design ConsiderationsDocument37 pagesGeneral Design ConsiderationsArif AmancioNo ratings yet

- 18BCH010 Termpaper PPTDocument25 pages18BCH010 Termpaper PPTFake accNo ratings yet

- Chapter 2 Maintenance Procedure - PlanningDocument69 pagesChapter 2 Maintenance Procedure - PlanningHafizuddin PjoeNo ratings yet

- Chapter 7 - Process Safety StudiesDocument39 pagesChapter 7 - Process Safety StudiesDjamel Ait MohamedNo ratings yet

- BOSH Case StudyDocument28 pagesBOSH Case StudyTinae, Vincent JayeNo ratings yet

- On Site Emergency Response Plan: Creative Textile Mills Privae LimitedDocument28 pagesOn Site Emergency Response Plan: Creative Textile Mills Privae LimitedMuntaj Ansari75% (4)

- IMSE Unit 5.2Document17 pagesIMSE Unit 5.2Umanath VeltechNo ratings yet

- M. Environmental Incident Investigation and ReportingDocument52 pagesM. Environmental Incident Investigation and ReportingAngelika CalingasanNo ratings yet

- Process SafetyDocument48 pagesProcess SafetyIbtida Sultana67% (3)

- Process Hazards in Bulk Drug Industry and Identified SolutionsDocument14 pagesProcess Hazards in Bulk Drug Industry and Identified SolutionssaikiranNo ratings yet

- Bhopal Gas Tragedy - The Scar of Process Safety: SIESO MedalDocument3 pagesBhopal Gas Tragedy - The Scar of Process Safety: SIESO Medaljdur jhdoisj curjfNo ratings yet

- Layers of Protection Analysis For Bhopal IncidentDocument3 pagesLayers of Protection Analysis For Bhopal IncidentAddison Juttie100% (1)

- Week 1: Che 61403 Safety in Process Plant DesignDocument31 pagesWeek 1: Che 61403 Safety in Process Plant DesignPorkkodi SugumaranNo ratings yet

- Agricultural Crop Production 11 - Q2 - W6Document6 pagesAgricultural Crop Production 11 - Q2 - W6Jennifer DuranNo ratings yet

- HSSE Alert - Bhopal Incident - MIC Gas Exposure - December 3rdDocument3 pagesHSSE Alert - Bhopal Incident - MIC Gas Exposure - December 3rdOsedebamen Irabor100% (1)

- Case Studies For OISD 244Document35 pagesCase Studies For OISD 244Anoop PrajapatiNo ratings yet

- Hazard Identification and Risk AssessmentDocument20 pagesHazard Identification and Risk AssessmentSaraansh SinghNo ratings yet

- Process Safety Management: Kharil Ashidi B. Abdul Jabar Q-SHE-S Dept Nippon Steel Engineering Co., LTDDocument37 pagesProcess Safety Management: Kharil Ashidi B. Abdul Jabar Q-SHE-S Dept Nippon Steel Engineering Co., LTDKay Aay100% (1)

- ETP Risk AssesmentDocument20 pagesETP Risk Assesmentvikkas verma0% (1)

- Chapter 23 External Forces TerrorismDocument30 pagesChapter 23 External Forces TerrorismPhilanderGereenPiniliNo ratings yet

- The Three Mile Island Disaster: By:-Jash (J058) Priyam (J059) Rishit (J063)Document12 pagesThe Three Mile Island Disaster: By:-Jash (J058) Priyam (J059) Rishit (J063)wander boyNo ratings yet

- Process Safety Overview 2011-109 SlidesDocument109 pagesProcess Safety Overview 2011-109 SlidesRafael SeguraNo ratings yet

- WSHC Case Studies Chemical Industry PDFDocument76 pagesWSHC Case Studies Chemical Industry PDFAnonymous FmXEu2cHxKNo ratings yet

- CS6 Bhopal DisasterDocument15 pagesCS6 Bhopal DisasterElle DyNo ratings yet

- Hazard and Risk Management - Sarika MamDocument24 pagesHazard and Risk Management - Sarika MamSharon DsouzaNo ratings yet

- Chemical Process SafetyDocument46 pagesChemical Process SafetyTowfiq Ahmed100% (1)

- Hazards Related To Chemical and Construction IndustriesDocument24 pagesHazards Related To Chemical and Construction IndustriesJon JimmyNo ratings yet

- General Lab Safety ProcedureDocument16 pagesGeneral Lab Safety ProcedureMin ingNo ratings yet

- Cpde 3aDocument172 pagesCpde 3aAbdul HaseebNo ratings yet

- Wildfire Powerpoint 2021 050422 v3 062222 508Document82 pagesWildfire Powerpoint 2021 050422 v3 062222 508Aj CabagNo ratings yet

- Xiangshui Chemical Factory's ExplosionDocument21 pagesXiangshui Chemical Factory's ExplosionnajihahNo ratings yet

- CHEN 455 Bhopal 2009 PresentationDocument21 pagesCHEN 455 Bhopal 2009 PresentationUpdesh GangwarNo ratings yet

- Bhopal Gas Tragedy: Saga of The Divided WorldDocument18 pagesBhopal Gas Tragedy: Saga of The Divided WorldArshad CM PalakkadNo ratings yet

- 14122018DIN60Q3LRiskAssessment DLFSielDocument15 pages14122018DIN60Q3LRiskAssessment DLFSielAshutosh MishraNo ratings yet

- Unit Number: Subject Code-SCHX1038Document14 pagesUnit Number: Subject Code-SCHX1038Sherly JamesNo ratings yet

- Safety: Nature of Accident and Major DisastersDocument30 pagesSafety: Nature of Accident and Major DisastersganeshNo ratings yet

- They Thought They Were Safe: BP Deepwater HorizonDocument44 pagesThey Thought They Were Safe: BP Deepwater HorizonJay MaradiyaNo ratings yet

- Mothballing Guidelines For Plant Equipme PDFDocument11 pagesMothballing Guidelines For Plant Equipme PDFamarnath jagirdar100% (1)

- Mothballing Guidelines For Plant EquipmentDocument11 pagesMothballing Guidelines For Plant EquipmentthawatchaiNo ratings yet

- Analysis of Hazards: Nptel - Chemical Engineering - Chemical Engineering Design - IIDocument2 pagesAnalysis of Hazards: Nptel - Chemical Engineering - Chemical Engineering Design - IIboeiniNo ratings yet

- Earth Quake Risk AssessmentDocument11 pagesEarth Quake Risk Assessmentamdarrif3723No ratings yet

- Explosion X Reaccion Descontr de Polimero Acrilico FGyS - 9 Ago 07 PDFDocument17 pagesExplosion X Reaccion Descontr de Polimero Acrilico FGyS - 9 Ago 07 PDFjuan_balderramaNo ratings yet

- A Presentation On Environment Management: Sanjay Kamble DSRCBM CollegeDocument15 pagesA Presentation On Environment Management: Sanjay Kamble DSRCBM CollegeSanjay KambleNo ratings yet

- College of Agriculture, Padannakkad Name: Yash S. Gulhane ADMISSION NO. 2021-11-145 Course Title: Disaster ManagementDocument13 pagesCollege of Agriculture, Padannakkad Name: Yash S. Gulhane ADMISSION NO. 2021-11-145 Course Title: Disaster ManagementPavan KumarNo ratings yet

- Unit 1Document29 pagesUnit 1poo arasanNo ratings yet

- Ges New Jhs Syllabus Career Technology CCP Curriculum For b7 b10 Draft ZeroDocument367 pagesGes New Jhs Syllabus Career Technology CCP Curriculum For b7 b10 Draft ZeroElvis Adjei Yamoah100% (1)

- ENG-PM-iM8 Series-V2.5-20190611Document2 pagesENG-PM-iM8 Series-V2.5-20190611modki27No ratings yet

- Test Bank For Oral Pathology For The Dental Hygienist 7th Edition by IbsenDocument36 pagesTest Bank For Oral Pathology For The Dental Hygienist 7th Edition by Ibsenknurtailrace.k90riy100% (39)

- Identify The Goals and Scope of Counseling Explain The Principles of CounselingDocument3 pagesIdentify The Goals and Scope of Counseling Explain The Principles of CounselingLenin RodriguezNo ratings yet

- Counseling - Its Principles, MethodsDocument36 pagesCounseling - Its Principles, MethodsCarmz PeraltaNo ratings yet

- 9.2 Group A 9.4 Group A: Exercise 1 Exercise 1Document1 page9.2 Group A 9.4 Group A: Exercise 1 Exercise 1Carolina Fernández DoradoNo ratings yet

- 347-Article Text-833-1-10-20230703Document10 pages347-Article Text-833-1-10-20230703Puspita SariNo ratings yet

- Charter of Patient's RightsDocument41 pagesCharter of Patient's RightsHarsh Sharma100% (1)

- Philippine Games For Physical Education: Utilizing and Maximizing Philippine Games in Different LevelsDocument40 pagesPhilippine Games For Physical Education: Utilizing and Maximizing Philippine Games in Different LevelsSamantha KimNo ratings yet

- Your Ewao-Ateo Benefits Plan: Putting You FirstDocument2 pagesYour Ewao-Ateo Benefits Plan: Putting You FirstDan OhNo ratings yet

- Self-Affirmation Theory and The Science of Well-Being PDFDocument19 pagesSelf-Affirmation Theory and The Science of Well-Being PDFAlex RichieNo ratings yet

- The PACE Trial: Radiotherapy Planning and Delivery Guidelines (Pace-A and Pace-C)Document33 pagesThe PACE Trial: Radiotherapy Planning and Delivery Guidelines (Pace-A and Pace-C)Анастасия АнохинаNo ratings yet

- Aku Internship Interview Exam: (Document by Khizer Rashid Siddiqui D-19)Document4 pagesAku Internship Interview Exam: (Document by Khizer Rashid Siddiqui D-19)R DNo ratings yet

- 12th Ed Twenty Questions FaqDocument6 pages12th Ed Twenty Questions FaqpatriciaNo ratings yet

- Neil HillDocument32 pagesNeil HillAndrés Felipe100% (1)

- Individual Development Plan FormDocument2 pagesIndividual Development Plan FormLielet MatutinoNo ratings yet

- 813-Article Text-1261-1-10-20180214Document5 pages813-Article Text-1261-1-10-20180214dwiky ramaNo ratings yet

- Jadwal AntigenDocument8 pagesJadwal AntigenBODACA HARI MURTINo ratings yet

- WSBB Guide For Beginners - Bench-CompressedDocument15 pagesWSBB Guide For Beginners - Bench-CompressedKatya KNo ratings yet

- Determination of Antioxidant Activity, Total Phenolic, Flavonoid and Alkaloids Content of Pandacaqui (Tabernaemontana Leaf and Flower ExtractsDocument5 pagesDetermination of Antioxidant Activity, Total Phenolic, Flavonoid and Alkaloids Content of Pandacaqui (Tabernaemontana Leaf and Flower ExtractsGenesis GenesisNo ratings yet

- Neuro Audio Screen - A4Document6 pagesNeuro Audio Screen - A4AlejandroNo ratings yet

- Effects of A Meal Replacement On Body CompositionDocument10 pagesEffects of A Meal Replacement On Body CompositionGiffariNo ratings yet

- PROJECT ManagementDocument14 pagesPROJECT ManagementIbrahim AliNo ratings yet

- PurcomDocument3 pagesPurcomJackie RodrigoNo ratings yet

- Too Unsafe To Monitor? How Board - Ceo Cognitive Conflict and Chair Leadership Shape Outside Director MonitoringDocument29 pagesToo Unsafe To Monitor? How Board - Ceo Cognitive Conflict and Chair Leadership Shape Outside Director MonitoringFatikchhari USONo ratings yet

- D2 Presentation Matt Singleton Swiss Re Dementia and InsuranceDocument13 pagesD2 Presentation Matt Singleton Swiss Re Dementia and InsuranceRishi KumarNo ratings yet

- Abortion Law and Medical EthicsDocument4 pagesAbortion Law and Medical EthicslvohNo ratings yet

- West Philippine SeaDocument4 pagesWest Philippine SeaFrancheskalane ValenciaNo ratings yet

- Unnatural Deaths in Police Lockup:Prisons of North Maharashtra Region - A 15 Year Retrospective StudyDocument231 pagesUnnatural Deaths in Police Lockup:Prisons of North Maharashtra Region - A 15 Year Retrospective StudyPablo Antonio Cifuentes GramajoNo ratings yet

- Stok 16 Juni 2023Document62 pagesStok 16 Juni 2023Icha FransiscaNo ratings yet