Professional Documents

Culture Documents

PAT Iflex5 Parte005

Uploaded by

lecuellarq85gmailcomCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PAT Iflex5 Parte005

Uploaded by

lecuellarq85gmailcomCopyright:

Available Formats

Description Of The System 3

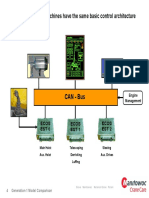

3.3 DESCRIPTION OF THE SYSTEM COMPONENTS

Pressure Transducer: The pressure transducer transforms hydraulic pressure into an electric

signal. A pressure transducer block houses two transducers, CAN bus converter board, and two bus

connectors. One pressure transducer is connected to the piston side of the lift cylinder and the other to

the rod side.

The Length-Angle Transducer: The length-angle sensor (LWG), often referred to as the “cable reel”,

is a combination of two transducers in one box, installed at the base section of the boom. It measures

the length and the angle of the boom.

A reeling drum drives a potentiometer, which is the length transducer. Part of the length transducer

circuit is the length cable on the drum, which is a two-conductor cable (screen and live). It is

connected to the anti-two-block switch at the boom head and to a slip ring body in the LWG.

The angle transducer is a potentiometer driven by a weighted pendulum that is oil damped. Both length

and angle transducer are connected to a CAN bus controller board, which is connected to the bus

system.

Anti-Two-Block Switch: The anti-two-block switch monitors the load block and it’s relationship with

the head of the boom. In working condition the switch is closed. When the hook block strikes the

weight the circuit opens, disengaging a relay output to the lock out solenoid valves, where applicable.

To check the cable for damage, (short circuit to ground) there is a 4.7k resistor between ground and

the contact of the switch, to give a signal back to the central unit. The weight at the anti-two-block

switch keeps the switch closed until the hook block strikes it.

Console: The graphic console displays all geometrical information such as length and angle of main

boom, working radius and head height of the boom. It also displays the actual load and the maximum

load permitted by load chart. Furthermore, it has an alarm horn, a warning light for overload, and a pre-

warning light. The graphic display allows for a simple interactive configuration setup, as well as sensor

calibration (zero adjustment), and troubleshooting sensor output screen. The console has a warning

light for anti-two-block conditions and an override switch for overload or anti-block condition.

Central Unit: Inside the central unit there is a CPU and connection board. The board has a hard

mounted connector for power, ground, bus controller, and slew indication. The board has a green LED,

indicating relay energized and a communication LED that flashes through red, yellow, and green

colors.

© PAT Rev. F 07/29/03 IFLEX 5 REV_F

EQ: HC-3 / SN: 223090

4 Service Manual iFLEX5

4 WHAT’S WRONG?

So, what’s wrong? Assuming you are reading these pages because of some kind of problem with the

PAT system, let us try to guide you quickly to solving the problem. In most cases, your problem will fall

under the following categories:

4.1 I HAVE AN ERROR CODE INDICATED ON THE CONSOLE

Please go to section Error Codes!

4.2 THE DISPLAYED ANGLE DOES NOT MATCH THE ACTUAL BOOM ANGLE

Start in section Angle Sensing to check the indicated angle.

4.3 THE DISPLAYED LENGTH DOES NOT MATCH THE ACTUAL BOOM LENGTH

Start in section Length Sensing to check the indicated length.

4.4 THE DISPLAYED SLEWING DOES NOT MATCH THE ACTUAL SLEWING ANGLE

Refer to section Slewing Sensing to check the slew sensor.

4.5 THE DISPLAYED LOAD DOES NOT MATCH THE ACTUAL LOAD

Please note that the indicated load is calculated by the system from the geometry information in the

computer, the operator’s selections, and all the sensor inputs. If the load display is off, it can therefore

be due to an error in any or several of these inputs! Refer to section Load sensing to narrow down the

source of your problem.

4.6 THE CONSOLE DISPLAY IS BLANK

If the console does not show any sign at all (no lights, no buzzer, no display), the problem is either in

the wiring between console and central unit, or the console itself. Refer to section No console display

for further troubleshooting.

4.7 I HAVE AN A2B PROBLEM

Please go to sectionA2B PROBLEM

4.8 I HAVE A CAN-BUS PROBLEM

Please go to section CAN-Bus Communication!

4.9 I NEED TO IDENTIFY A SPARE PART

Please go to the Spare Part Listings!

4.10 I HAVE NOTICED WATER IN SOME PART OF THE SYSTEM

Please go to section Troubleshooting Moisture!

© PAT Rev. F 07/29/03 IFLEX 5 REV_F

EQ: HC-3 / SN: 223090

You might also like

- Hfe Classe Audio Cap-80 101 ServiceDocument19 pagesHfe Classe Audio Cap-80 101 Servicehesso1No ratings yet

- SOP Kalibrasi BWDocument12 pagesSOP Kalibrasi BWJong JavaNo ratings yet

- Avo Biddle 27000Document5 pagesAvo Biddle 27000blem_0075No ratings yet

- Module 7 (Maintenance Practices) Sub Module 7.4 (Avionic General Test Equipment) PDFDocument16 pagesModule 7 (Maintenance Practices) Sub Module 7.4 (Avionic General Test Equipment) PDFshareyhou100% (1)

- Electronic Workbench Tutorial: Copy As BitmapDocument18 pagesElectronic Workbench Tutorial: Copy As Bitmapmclade01No ratings yet

- EWB TutorialDocument18 pagesEWB TutorialXereal SuarezNo ratings yet

- Optimizer2008 - 2 Calculo de PararrayosDocument278 pagesOptimizer2008 - 2 Calculo de PararrayosshfedericoNo ratings yet

- Capacitance Adapter For Multimeter: (Document Subtitle)Document11 pagesCapacitance Adapter For Multimeter: (Document Subtitle)Kashif Hassan100% (1)

- Cd34install EnglishDocument24 pagesCd34install EnglishZoltán VéberNo ratings yet

- Mark 4K Service Manual EnglishDocument74 pagesMark 4K Service Manual EnglishSlavik100% (2)

- Power Wave Observer User Manual Version 3.2fDocument21 pagesPower Wave Observer User Manual Version 3.2fJaime ArreolaNo ratings yet

- Cx108V ManualDocument44 pagesCx108V ManualTommy HoNo ratings yet

- Transformer Fault Detection Using Zigbee and GSMDocument46 pagesTransformer Fault Detection Using Zigbee and GSMIrfan Baig100% (1)

- 2012 Chevrolet K2500 HD Pickup Silverado: DTC C0710Document5 pages2012 Chevrolet K2500 HD Pickup Silverado: DTC C0710alberto navasNo ratings yet

- Camshaft Sensor - Hall EffectDocument4 pagesCamshaft Sensor - Hall Effectopenjavier5208No ratings yet

- Aircraft power supply improvementsDocument5 pagesAircraft power supply improvementsĐỗ Minh KhôiNo ratings yet

- JVC TV Power Supply Training GuideDocument110 pagesJVC TV Power Supply Training GuidePanagiotis Argyropoulos60% (5)

- ForewordDocument423 pagesForewordRicardo VieiraNo ratings yet

- EAGLE DuplexerDocument3 pagesEAGLE DuplexerrujanacNo ratings yet

- Term Project: Topic: Function of Cro (Cathod Ray Osciiloscope) & Application of Function GeneratorDocument8 pagesTerm Project: Topic: Function of Cro (Cathod Ray Osciiloscope) & Application of Function Generatorshailesh singhNo ratings yet

- HHO PWM55 v1.8 +EFIEv1.3+LCD1.1Document10 pagesHHO PWM55 v1.8 +EFIEv1.3+LCD1.1هيثم خماش0% (1)

- 4100 & 2500 Wireless Remote Control ORANGE JoystickDocument19 pages4100 & 2500 Wireless Remote Control ORANGE Joystickpavlestepanic9932No ratings yet

- CW62B Color TV Service ManualDocument29 pagesCW62B Color TV Service Manualbogdanb1100% (1)

- LG 21fu1rlxDocument30 pagesLG 21fu1rlxElectronica Lider100% (2)

- Service Manual Compact Balances: Kern FCBDocument17 pagesService Manual Compact Balances: Kern FCBLiliana RafaelNo ratings yet

- TV and Monitor Deflection SystemsDocument41 pagesTV and Monitor Deflection SystemsspencerNo ratings yet

- Electrical M07 Sensors enDocument28 pagesElectrical M07 Sensors enFredy Manrique AstoNo ratings yet

- Using An OscilloscopeDocument23 pagesUsing An Oscilloscopemaddabdul100% (1)

- Test TP Sensor Using OscilloscopeDocument8 pagesTest TP Sensor Using OscilloscopeMustafa AliNo ratings yet

- Philips Mod 21pt9470-55 - 44 - 21sl9 - Chasis Sk8.0l CADocument36 pagesPhilips Mod 21pt9470-55 - 44 - 21sl9 - Chasis Sk8.0l CACarlos MedinaNo ratings yet

- LC221Document24 pagesLC221MisterMMNo ratings yet

- 29fs4alx RLXDocument32 pages29fs4alx RLXJose SantanaNo ratings yet

- TV Plasma LG 42px4rv Rva 42px4rv Rva Za Chassis MFDocument37 pagesTV Plasma LG 42px4rv Rva 42px4rv Rva Za Chassis MFelpibecapoNo ratings yet

- ALFA 5KVA Service Manual 201509ADocument46 pagesALFA 5KVA Service Manual 201509Asaif ul noorNo ratings yet

- Philips 21pt5520 CH L01.2e-AbDocument60 pagesPhilips 21pt5520 CH L01.2e-Abhammer_adyNo ratings yet

- Project MR Aamir Abdul LateefDocument8 pagesProject MR Aamir Abdul Lateeflatanyahusted33234No ratings yet

- JVC TV Power Supply Training GuideDocument110 pagesJVC TV Power Supply Training GuideLuis Granadillo Ojeda100% (1)

- 4 Channel Relay Controller Board: User GuideDocument11 pages4 Channel Relay Controller Board: User GuidehansleybheenuckNo ratings yet

- 2015 Belt-Way Manual 2 1 WebDocument72 pages2015 Belt-Way Manual 2 1 WebanhNo ratings yet

- Sony+Kd 55x9000a+Chassis+Rb1fsDocument154 pagesSony+Kd 55x9000a+Chassis+Rb1fswagnertvsNo ratings yet

- LVX6048 Service ManualDocument27 pagesLVX6048 Service ManualfritzzagNo ratings yet

- CISE 204 Digital System Design Lab Manual PDFDocument44 pagesCISE 204 Digital System Design Lab Manual PDFEng-Mohammed KayedNo ratings yet

- Operation Manual Bosch ChargerDocument35 pagesOperation Manual Bosch ChargerSujeeth SurendranNo ratings yet

- BTS Field Maintenance SupportDocument28 pagesBTS Field Maintenance SupportHafid Errabiy100% (2)

- LG Cw62a Chassis 29fs2al TV SMDocument32 pagesLG Cw62a Chassis 29fs2al TV SMfox7878No ratings yet

- Diversified Accumulation Conveyor ManualDocument32 pagesDiversified Accumulation Conveyor ManualProyectos Trans roll, C.A. OficinaNo ratings yet

- GEN3 Powertrain Controller Transmission Control User's ManualDocument22 pagesGEN3 Powertrain Controller Transmission Control User's ManualJuan IdrovoNo ratings yet

- XK3101 (KM05) User ManualDocument17 pagesXK3101 (KM05) User ManualmanhNo ratings yet

- LG 29fx4bl CH Cw62a SMDocument30 pagesLG 29fx4bl CH Cw62a SMJesus Garcia Hernandez100% (1)

- Bhel - Proportional Servo Based Ehc Control - Analysys and TroubleshootingDocument6 pagesBhel - Proportional Servo Based Ehc Control - Analysys and Troubleshootingckstarun22No ratings yet

- Shield User ManualDocument11 pagesShield User Manualmd75hyNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- Radio Control for Model Ships, Boats and AircraftFrom EverandRadio Control for Model Ships, Boats and AircraftRating: 5 out of 5 stars5/5 (1)

- PAT Iflex5 Parte004Document2 pagesPAT Iflex5 Parte004lecuellarq85gmailcomNo ratings yet

- All Generation 1 Machines Have The Same Basic Control ArchitectureDocument1 pageAll Generation 1 Machines Have The Same Basic Control Architecturelecuellarq85gmailcomNo ratings yet

- Cranes - Notable Features - RT775Document1 pageCranes - Notable Features - RT775lecuellarq85gmailcomNo ratings yet

- Band-pass and band-rejection filter design responsesDocument1 pageBand-pass and band-rejection filter design responseslecuellarq85gmailcomNo ratings yet

- Notice: Service Manual iFLEX5Document2 pagesNotice: Service Manual iFLEX5lecuellarq85gmailcomNo ratings yet

- A) A DW) A) A DW +: Table 16-2. Values of For Different Filter Types and Different QsDocument1 pageA) A DW) A) A DW +: Table 16-2. Values of For Different Filter Types and Different Qslecuellarq85gmailcomNo ratings yet

- Op Amps36Document1 pageOp Amps36lecuellarq85gmailcomNo ratings yet

- PAT Iflex5 Parte003Document2 pagesPAT Iflex5 Parte003lecuellarq85gmailcomNo ratings yet

- Example 16-5. Second-Order MFB Band-Pass Filter With F 1 KHZDocument1 pageExample 16-5. Second-Order MFB Band-Pass Filter With F 1 KHZlecuellarq85gmailcomNo ratings yet

- Op Amps37Document1 pageOp Amps37lecuellarq85gmailcomNo ratings yet

- 16.5.1.2 Multiple Feedback Topology: Figure 16-34. MFB Band-PassDocument1 page16.5.1.2 Multiple Feedback Topology: Figure 16-34. MFB Band-Passlecuellarq85gmailcomNo ratings yet

- Figure 16-24. Developing The Gain Response of A High-Pass FilterDocument21 pagesFigure 16-24. Developing The Gain Response of A High-Pass Filterlecuellarq85gmailcomNo ratings yet

- 16.5.1.1 Sallen-Key TopologyDocument1 page16.5.1.1 Sallen-Key Topologylecuellarq85gmailcomNo ratings yet

- F 10 KHZ 1.036 9.653 KHZ F 10 KHZ 1.036 10.36 KHZ: Filter 1: Filter 2Document1 pageF 10 KHZ 1.036 9.653 KHZ F 10 KHZ 1.036 10.36 KHZ: Filter 1: Filter 2lecuellarq85gmailcomNo ratings yet

- Example 16-6. Fourth-Order Butterworth Band-Pass FilterDocument1 pageExample 16-6. Fourth-Order Butterworth Band-Pass Filterlecuellarq85gmailcomNo ratings yet

- Low-Pass to Band-Pass Filter TransitionDocument1 pageLow-Pass to Band-Pass Filter Transitionlecuellarq85gmailcomNo ratings yet

- 16.5.1 Second-Order Band-Pass Filter: A(s) A 1 S 1 S 1 SDocument1 page16.5.1 Second-Order Band-Pass Filter: A(s) A 1 S 1 S 1 Slecuellarq85gmailcomNo ratings yet

- Op Amps22Document24 pagesOp Amps22lecuellarq85gmailcomNo ratings yet

- First-Order High-Pass Filter Circuit Diagrams and Transfer FunctionsDocument1 pageFirst-Order High-Pass Filter Circuit Diagrams and Transfer Functionslecuellarq85gmailcomNo ratings yet

- A C C A 2C C R CC B 2C C R CC: High-Pass Filter DesignDocument26 pagesA C C A 2C C R CC B 2C C R CC: High-Pass Filter Designlecuellarq85gmailcomNo ratings yet

- Adjustable second-order low-pass filter transfer function and coefficientsDocument1 pageAdjustable second-order low-pass filter transfer function and coefficientslecuellarq85gmailcomNo ratings yet

- 16.4 High-Pass Filter Design: Figure 16-22. Fifth-Order Unity-Gain Butterworth Low-Pass FilterDocument1 page16.4 High-Pass Filter Design: Figure 16-22. Fifth-Order Unity-Gain Butterworth Low-Pass Filterlecuellarq85gmailcomNo ratings yet

- 16.4.2.2 Multiple Feedback Topology: Figure 16-29. Second-Order MFB High-Pass FilterDocument25 pages16.4.2.2 Multiple Feedback Topology: Figure 16-29. Second-Order MFB High-Pass Filterlecuellarq85gmailcomNo ratings yet

- Second Filter: R 1 2 F A C 1 2 10 HZ 0.756 100 10 F 2.105 KDocument1 pageSecond Filter: R 1 2 F A C 1 2 10 HZ 0.756 100 10 F 2.105 Klecuellarq85gmailcomNo ratings yet

- Second Filter: Figure 16-21. Second-Order Unity-Gain Sallen-Key Low-Pass FilterDocument1 pageSecond Filter: Figure 16-21. Second-Order Unity-Gain Sallen-Key Low-Pass Filterlecuellarq85gmailcomNo ratings yet

- C C 4b A: Example 16-2. Second-Order Unity-Gain Tschebyscheff Low-Pass FilterDocument1 pageC C 4b A: Example 16-2. Second-Order Unity-Gain Tschebyscheff Low-Pass Filterlecuellarq85gmailcomNo ratings yet

- Op Amps13 PDFDocument1 pageOp Amps13 PDFlecuellarq85gmailcomNo ratings yet

- Figure 16-15. General Sallen-Key Low-Pass Filter: A(s) A 1 C R R 1 A R C S R R C C SDocument1 pageFigure 16-15. General Sallen-Key Low-Pass Filter: A(s) A 1 C R R 1 A R C S R R C C Slecuellarq85gmailcomNo ratings yet

- C C 4b A: Example 16-2. Second-Order Unity-Gain Tschebyscheff Low-Pass FilterDocument1 pageC C 4b A: Example 16-2. Second-Order Unity-Gain Tschebyscheff Low-Pass Filterlecuellarq85gmailcomNo ratings yet

- RF Family of Products: Core Innovations For Differentiated RF SystemsDocument8 pagesRF Family of Products: Core Innovations For Differentiated RF SystemsFannush Shofi AkbarNo ratings yet

- MIG Welding Speed SelectionDocument1 pageMIG Welding Speed SelectionbudakgemukNo ratings yet

- Toshiba 2505 Service ManualDocument397 pagesToshiba 2505 Service Manualjannnu_sb50% (2)

- Applications of Inductors: Tuned Circuits, Sensors, Motors and MoreTITLEDocument8 pagesApplications of Inductors: Tuned Circuits, Sensors, Motors and MoreTITLEyousaf khanNo ratings yet

- RF Switches Using Phase Change Materials: Yonghyun Shim, Gwendolyn Hummel, and Mina Rais-ZadehDocument4 pagesRF Switches Using Phase Change Materials: Yonghyun Shim, Gwendolyn Hummel, and Mina Rais-ZadehkaurVRNo ratings yet

- LaserSaber Joule Ringer Matches Dons Adjusting DeviceDocument2 pagesLaserSaber Joule Ringer Matches Dons Adjusting DeviceTony GaryNo ratings yet

- Ppt. On Transformer WindingsDocument23 pagesPpt. On Transformer WindingsSandhya Rathore100% (2)

- Introduction to Generators, Protection Schemes, Relays and MaintenanceDocument44 pagesIntroduction to Generators, Protection Schemes, Relays and MaintenancerahulNrana100% (1)

- Electric Motor PresentationDocument19 pagesElectric Motor PresentationAzhar Mansuri0% (2)

- Name of Subdivision/IRCA: CAPITAL ESDDocument1 pageName of Subdivision/IRCA: CAPITAL ESDHIMANGSHU NATHNo ratings yet

- Bluetooth Headset Quick GuideDocument2 pagesBluetooth Headset Quick GuideAlex TiperNo ratings yet

- A Quantitative Comparison of Central Inverters and String Inverters in Utility Scale Solar Systems in North AmericaDocument11 pagesA Quantitative Comparison of Central Inverters and String Inverters in Utility Scale Solar Systems in North AmericaykuscuNo ratings yet

- ACP Specs PDFDocument6 pagesACP Specs PDFAbdElrahman AhmedNo ratings yet

- TrafficDocument7 pagesTrafficahmod202120No ratings yet

- PDFDocument19 pagesPDFWrittwikNo ratings yet

- Sir472Dp: Vishay SiliconixDocument13 pagesSir472Dp: Vishay SiliconixariezamhariNo ratings yet

- Fronius TPS 320i C Power Source Manual QuestionsDocument5 pagesFronius TPS 320i C Power Source Manual QuestionsJack MoenNo ratings yet

- 3.at Final Draw For P0089Document60 pages3.at Final Draw For P0089FILIN VLADIMIR100% (1)

- Eeg1Document3 pagesEeg1ronaldoa9No ratings yet

- MU320 Merging Unit: Analog and Digital, Fast and Accurate: Fully-Integrated Merging Unit For Process Bus ApplicationsDocument2 pagesMU320 Merging Unit: Analog and Digital, Fast and Accurate: Fully-Integrated Merging Unit For Process Bus ApplicationsMohamedNo ratings yet

- A Transko Company E-Brochure 2016Document7 pagesA Transko Company E-Brochure 2016shafNo ratings yet

- Haltech Dual Channel Wideband Instructions1Document2 pagesHaltech Dual Channel Wideband Instructions1Glenn-anthony Sending-State HortonNo ratings yet

- II Year Et Corrected FinalDocument518 pagesII Year Et Corrected Finalprasanth kumar 09No ratings yet

- Electronics Lab ManualDocument42 pagesElectronics Lab ManualShikhar DuttaNo ratings yet

- High-Efficiency Microwave BJT Power Amplifier Simulation: 24, Wright ofDocument4 pagesHigh-Efficiency Microwave BJT Power Amplifier Simulation: 24, Wright ofDania Largo JaimesNo ratings yet

- Ts Based All StandardsDocument12 pagesTs Based All Standardsanjes1No ratings yet

- Sistec Major Project Report Microcontroller Enabled Speaking System For Deaf and DumbDocument32 pagesSistec Major Project Report Microcontroller Enabled Speaking System For Deaf and Dumbukpandey2580% (5)

- Be Electrical 7 Sem PLC and Scada Application P (08) Dec 2016 PDFDocument3 pagesBe Electrical 7 Sem PLC and Scada Application P (08) Dec 2016 PDFParesh MahajanNo ratings yet

- Easergy P3 Protection Relays - P3U20Document3 pagesEasergy P3 Protection Relays - P3U20mardhiahNo ratings yet

- Model Over Current RelayDocument7 pagesModel Over Current RelayHayat AnsariNo ratings yet