0% found this document useful (0 votes)

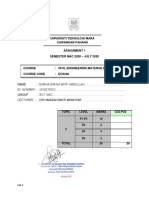

121 views5 pagesM30 Concrete Mix Design Report

1) The document provides the mix design and material specifications for M30 grade concrete.

2) The mix proportion is 1 part cement to 1.785 parts fine aggregate to 3.240 parts coarse aggregate by weight.

3) Testing was done to determine the compressive strength of concrete cubes at 3 days, which was found to be 154.07 kg/cm2, meeting the target strength.

Uploaded by

KA25 ConsultantCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

121 views5 pagesM30 Concrete Mix Design Report

1) The document provides the mix design and material specifications for M30 grade concrete.

2) The mix proportion is 1 part cement to 1.785 parts fine aggregate to 3.240 parts coarse aggregate by weight.

3) Testing was done to determine the compressive strength of concrete cubes at 3 days, which was found to be 154.07 kg/cm2, meeting the target strength.

Uploaded by

KA25 ConsultantCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd