Professional Documents

Culture Documents

Kumar N S JULY2019 06

Uploaded by

KumardasNsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kumar N S JULY2019 06

Uploaded by

KumardasNsCopyright:

Available Formats

Kumara.N.S : kumardas25@gmail.com, kumardas_hrr@yahoo.com +91 9964110962 (Sr.

ENGINEER )

Scaling new heights of success with hard work & dedication and leaving a mark of excellence on each step to obtain a position

which allows me to utilize my knowledge and relevant experience in the field of Project management for the benefit of the

Organization.

Preferred areas: Manufacturing, OEM, Engineering Services, Design, Heavy Machinery Equipment’s/Industrial Products.

Information Security Management Business Continuity Management

Key Skills

poornaahwin@gmail.com Profile Summary

+91 97418888100

Product development

Please mention (Machine • Code

complete address with PIN A dynamic professional with over 7+ years of experience in the field of

Design), Component detailing, Product product design & development, Modeling & drafting, Engineering Change

change management, GD&T, welding, management.

Document & Data control. • Key expertise areas include N.P.D and Prototype, in the Heavy Machinery

Equipment’s-Blast hole rig M/C, Water well rig M/c, Mining, Mineral

CAD tools: Creo Parametric, Creo processing, Power crushers, Telescopic conveyors, Construction

view, Auto CAD, Solid works, Equipment’s.

Unigraphics. Autodesk inventor PDM: • Proposal preparation and getting approval from client

Windchill, pulse, intralink. • Responsible for maintaining Cycle time of part release from team members.

• Ensures designs are meeting the safety, quality, reliability, and cost goals.

Change Management as • Resource planning & organizing

Lead/Effective team member. • Design Conceptualizations.

• Preparation & discussion of Design Approval Prints with customers.

Relevant Offshore Exp.

• Conducting and participating in Design reviews & project meetings.

• Good knowledge and experience of PLM/ ERP system

Effective communications with clients,

• Design calculations-Hydraulics related.

Supplier & Inter departments for

various project related activities. An • Good experience on CREO.

innovative & creative professional • Part modeling, assembly, manufacturing drawings.

with strong planning, communication, • Preparing machine layout for customer approval.

analytical & negotiation skills • Release of Component drawings & Bill of Materials through SAP.

• Approval of supplier’s drawing and imported item drawings.

Hardworking, Owning Responsibility, • Identify bottlenecks in the designing and effectively troubleshoot the same.

Problem solving • Generation of Bill of Material using different ERP Systems.

• Monitoring team performance and report on metrics.

Good Technical skills, Meeting project • Providing guidance to the team based on management direction.

schedules. • Performing other miscellaneous project related assignments.

• Preparation of reports using Microsoft Power Point, Excel and Word doc.

ERP:Mfg-Pro,M3,SAP,DMS • Ability to work with domestic and international customer.

Team Management

Soft Skills Career Timeline

Therelek Engineer Don Bosco Tech L&T Technology

Pvt. Ltd, Bangalore Ltd, Bangalore Services Ltd, Chennai

Adaptable Motivational

Leader Chennai Chennai Chennai

Jan’2016 – Nov’2018-

Apr’2010 – Jan’2011 – Feb’2015 –

Nov’2018 Till date

Multitasking Dec’2010 Sep’2014 Dec’2015

abilities Communicator

Actualize Consulting Actualize Consulting

Eng, Bangalore Eng, Bangalore

Planner/

Problem Solving Organizer

Work Experience

Nov 2018 – Till date L&T Technology Services, Chennai.

Deputed to Vestas Wind Systems A/S , INDIA

Designation: Sr.Engineer

Projects Design Review & Change management

Client Vestas Wind Systems A/S

Responsibility Working as Module lead

Project Specialization Product development

Roles:

• Design and development of hydraulic systems and related components for wind turbine.

• Leading the team of 4 members.

• Building concepts for “cost cut out” of old variant and new assembly for new variant.

• Use of DFMpro-tool in the concept validation.

• Design feasibility in all the three Fs (Fit, Form and Function)

• Conducting Cross-Functional and 3D-Architect Reviews for the final concept approval.

• Negotiation on different proposals with clients

• Helping client to understand new processes & technologies

• Team handling, Delegate tasks and set deadlines, client interactions, Project estimations & Proposal making.

• Estimation of work involved, lead time and execution of task according to internal/onsite customer requirement.

Previous Experience

Jan’2016 – Nov 2018 Actualize Consulting Engineers Pvt Ltd, Bangalore

Deputed to TEREX India Research Center, Bangalore, INDIA

Designation: Team Lead-Mechanical

Projects NPD & Change management

Client Terex: Materials & Mineral processing System

Responsibility Worked as Team Lead

Project Specialization New Product development/ECM

Roles:

• Worked at TEREX India Research Center as Team Lead-Mechanical Deputed from Actualize.

• Key expertise areas include N.P.D and Prototype, 3D Modeling, Pro-Piping, Detailing, Assembly in the Heavy Earth Moving

equipment's-Mining, Mineral processing, Powerscreens, Power crushers, washing system, Telescopic conveyors.

• Knowledge of hydraulics and schematics reading skills.

• Involved in hydraulic power pack calculation.

• Involved in Pump, Motor, Bellhousing & coupling selection.

• Co-ordinate the day to day work planning, scheduling, monitoring of projects.

• Customer co-ordination and Drawing Quality check as per customer standard.

• Self-driven to meet the customer requirements like On-time delivery and Quality standards.

• Coordinate the review, presentation and release of design layouts, drawings, analysis and other documentation.

Feb’ 2015 – Dec 2015 Don Bosco Tech Ltd, Bangalore, India.

Designation: Automobile trainer

Roles:

• Worked as Automobile trainer under central govt project- NSQF.

• Troubleshooting engine and its related parts.

• Need to train the students from basic of automobile.

• Teaching Technical service issues & Conducting practical for automobile students

Jan’ 2011 – Spt 2014 Actualize Consulting Engineers Pvt Ltd, Bangalore India.

Designation: Senior Design Engineer

Roles:

• Capable of Handling of complicated assemblies, preparing BOM.

• Knowledge about selection of hydraulic hoses, fittings based on the size and creation of new hydraulic hoses and pipes.

• Creating parametric 3-D model & 2-D drawings as per the customer’s engineering STD.

• Concept development for new products and to improve existing products.

• Good knowledge on Rig machine (Drilling solutions- Blast hole & water well).

• Proficient in Creo Solid Modeling, Sheet metal, large Assembly, installations, weldments and Detailing

• Knowledge on configurators, Preparation of BOMs and performing other documentation activities.

• Structural design experience-chassis, tower, power pack base.

• Create and release engineering drawings & bill of materials

• Experience in working with global teams and knowledge of ECN/ECR.

• Basic Knowledge of GD&T-ASME Y14.5M.

Project 1: Design and development of Wind turbine: Hydraulic Power Unit

Team size-4

Job profile:

• Involved in Design and development of wind turbine components like hydraulic system.

• Follow-ups on supplier hydraulic tanks different variants and to make common for other turbines models.

• Conducting design reviews meeting with client and supplier implementing the changes as per the MOM to finalize

• Hydraulic modules with different configuration making them common interfaces.

• Design, 3D modeling of assemblies and sub-assemblies.

• Hose/pipe routing using creo piping module.

• Detailing of manufacturing parts.

Project 2: TCS-Telescopic conveyor system-140ft

Team size-6

Job profile:

• Worked as Team Lead-Mechanical involved in creation of concepts for Hydraulic power pack for conveyor system.

• Done hydraulic related calculations.

• Involved selection of pump, motor, filters, breathers, fittings, bellhousing, coupling and valves

• Design hydraulic tank Creation of hose installations,

• Hose/pipe routing using creo piping module.

• creation of supplier Specification sheets for sourcing department.

Project 3: Jaw crushers, cone crushers, Impact crusher, Inclined Screens and washing systems

Team size-15

Job profile:

• Worked as Team Lead involved in creation drawings for crushers, screeners and conveyor related components like Sheetmetal

(chute, hopper & feeder etc.), casting (fixed jaw, movable jaw) and assemblies of weldments, ladder handrail, walkways,

platform.

• Modifying existing design as per customer requirements like field issues, ECN.

• I was assigned with 6 team members to complete assigned tasks.

• Worked on weld reduction projects (weld-on to casting)

• Value Engineering through Design changes considering cost, functionality, Quality, safety and strength.

Project 4: DM75/DM30: Rotary blast hole drill rig - Large-range

Team size-10

Job profile:

• Worked as Sr. Design Engineer involved in creation of concepts for blast hole rig machine.

• Creation of weldments, ladder structural design respective handrail mounting brackets, FRP decking, double pump installations

and other related installations.

• Modified existing enclosure as per customer requirements.

• Worked on weld reduction projects (weld-on to Bolt on type, and metal decking to FRP Decking).

• Simplified tower rest design.

Project 5: DB40-water well Rig machine

Team size-20

Job profile:

• Worked as Sr.Design Engineer involved in prototype build.

• worked on creation Air module (Compressor) installation (discharge pipe, fittings selections), COC-Filter installation,

• Done Air intake filter installation and related mounting solutions.

• Receiver tank & piping, hose routing respective mounting brackets detailing releasing drawing for production.

• Done Air intake filter installation for Deck engine and PTO.

• Worked on power pack options Engine Installations,

• Worked on weight reduction project: Reduced hydraulic tank capacity

Project 6 : PV235 /PV310 Blast hole Rig Machine.

Team size-25

Job profile:

• Worked as Design Engineer involved in product improvement and change management.

• Involved in creation of complex weldment Assembly & drawings,

• Conceptual design and mounting solutions for hydraulic systems with drawings, selection of hoses and hose fittings, Suggesting

new route for both electrical cables and Hydraulic Hoses with drawings.

• Research on new products by referring standard components from catalogs and websites,

• Created cables and its harness assemblies running b/w control systems and Engine,

• Hose routing for Hydraulic systems. Hydraulic tank to valve rack ,Hydraulic Jack, tower raising Cyl,

• Design of Engine mounting brackets, pump drive brackets, Rig mainframe with various installations.

• Worked on structural projects like Tower with tubular structure, tower support.

• Installation of Fuel tank (options) hoses, rotary head installations. Radiator installation.

Project 7 : SDE-Power- crushers.

Team size-8

Job profile:

• Project involved conversion of 2D drawing to 3D models and drawings as per pre-defined customer standards.

• Worked as a team member involved in creation of sheet metal parts, casting & assembly weldments.

Project 8 : Dynapac-Road Construction Equipment’s.

Team size-10

Job profile:

• Worked as Team Member involved in creation of sheet metal weldment Assembly & drawings in Engine Installation Unit.

• Creation of hoses for hydraulic system for new models referring to the standard Hyd. Systems used in previous models using

Pro-piping module.

• Conceptual design for mounting cooling systems, Hydraulic Systems Etc. &

• creation of drawings for released parts, Creation of complex casting parts and its drawings.

Apr’ 2010 – Dec 2010 Therelek Engineers Pvt. Ltd, Bangalore India

Designation: Design Engineer

Roles:

• Generating detailed mechanical drawings & Preparation of Bill of Materials.

• Reveres Engineering, Involved in hand calculation of furnace.

• Preparing Layout Diagrams for mechanical Cost & Estimation of projects.

• Designing Piping layout & Civil Structures.

• Develop layouts and details of equipment for heat treat furnaces.

• Fabrication & Erection of heavy steel structure, coordination with vendors on continuous quality improvement.

Education

Year Examination Institution Major Field Board Performance

Overall

STJ Institute of Technology Ranibennur, Mechanical

2004-2009 B.E. V.T.U.

KARNATAKA, INDIA Engineering

Aggregate of 59.82%

PERSONAL PROFILE

Name: Mr. KUMARA.N. S

Father’s Name: Mr. SHIVANANDA.N. L

Date Of Birth: 10/07/1986

Marital Status: Married.

Nationality: INDIAN.

Languages: English, Kannada, Hindi

Hobbies: Photography, Listening To music, Travelling.

✓ Hardworking, Owning Responsibility, Problem solving,

✓ Good Technical skills, Meeting project schedules.

Personal Strengths: ✓ Strong team player with proven experience in crosses functional teams and

multitasking abilities.

✓ Willing to travel to the Customer site, as required.

Kumar,N,S

Permanent Address: Sri Renuka Nilaya,Opp Balaji Oil mill, A-Block Vidyanagar, Parasappa layout, HARIHAR,

577601, Karnataka, India

PASSPORT Expiry: 2027

You might also like

- CV For Project Manager - EngineerDocument4 pagesCV For Project Manager - EngineerShaikh IbrahimNo ratings yet

- Key Skills: Profile SummaryDocument5 pagesKey Skills: Profile SummaryKumardasNsNo ratings yet

- HVAC EngineerDocument2 pagesHVAC EngineerMohamed Ibrahim AhamedRasmiNo ratings yet

- Elluri Karthik 11yrs Value EngineeringDocument2 pagesElluri Karthik 11yrs Value EngineeringkarthikNo ratings yet

- Resume MD Zeeshan AshrafDocument3 pagesResume MD Zeeshan Ashraferzeeshan92No ratings yet

- Prabha ResumeDocument3 pagesPrabha Resumebharathgv65No ratings yet

- KARAN KHODE RESUME E4yearsDocument2 pagesKARAN KHODE RESUME E4yearswooden makersNo ratings yet

- Ambitious Engineer with 3.5 Years' ExperienceDocument2 pagesAmbitious Engineer with 3.5 Years' ExperienceMohamed Ibrahim AhamedRasmiNo ratings yet

- Application Engineer JDDocument2 pagesApplication Engineer JDJuhaya KojuaNo ratings yet

- Snehith Vadlakonda - SAP ABAPDocument12 pagesSnehith Vadlakonda - SAP ABAPSamir SahooNo ratings yet

- Curriculum Vitae (CV) : Wadah SalihDocument2 pagesCurriculum Vitae (CV) : Wadah SalihHR UAENo ratings yet

- Achieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivateDocument12 pagesAchieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivatestrganeshkumarNo ratings yet

- Ranjith Resume 1Document3 pagesRanjith Resume 1Shanmuga DharshiniNo ratings yet

- JIGAR S DESAI MES ResumeDocument2 pagesJIGAR S DESAI MES ResumeJigar DesaiNo ratings yet

- Donna - Jimenez Zeidan 2010Document6 pagesDonna - Jimenez Zeidan 2010donnajimenezzeidanNo ratings yet

- G.suresh B.e., M.b.a.Document5 pagesG.suresh B.e., M.b.a.shafeeq ahmedNo ratings yet

- Kumaravel Resume 14+ Lead Mechanical Designer - TLDocument3 pagesKumaravel Resume 14+ Lead Mechanical Designer - TLKumarNo ratings yet

- Aniket Sankpal ResumeDocument3 pagesAniket Sankpal ResumeAniket SankpalNo ratings yet

- Vigneshwaran.S: Areas of ExposureDocument2 pagesVigneshwaran.S: Areas of Exposuremamillapalli sri harshaNo ratings yet

- Project Management, Agile Consultant: Current Assignment Executive SummaryDocument1 pageProject Management, Agile Consultant: Current Assignment Executive SummaryvikieduNo ratings yet

- Profile Summary: Arjun BV Phone: +91-6362476588/9986489284Document5 pagesProfile Summary: Arjun BV Phone: +91-6362476588/9986489284PankajNo ratings yet

- SBD Bits & Iit JD 2022Document3 pagesSBD Bits & Iit JD 2022eue99332No ratings yet

- Career Objectives: Site Engineer &Document3 pagesCareer Objectives: Site Engineer &namshadNo ratings yet

- Resume - Gokul PDocument3 pagesResume - Gokul Pgokul.rock187No ratings yet

- Pammi CV 2019Document5 pagesPammi CV 2019Pammi SudhakarNo ratings yet

- Cover LetterDocument6 pagesCover LetterselvarajvijayakumarNo ratings yet

- Kkreasume 21Document2 pagesKkreasume 21wooden makersNo ratings yet

- Name: Sunil Peeroji Contact No.: 9866378849: Professional ProfileDocument3 pagesName: Sunil Peeroji Contact No.: 9866378849: Professional ProfileAnu RadhaNo ratings yet

- Best Resume For AllDocument12 pagesBest Resume For AllK KUMAR JENANo ratings yet

- ShivaRam ResumeDocument4 pagesShivaRam ResumeVishnu TejaNo ratings yet

- Sagar Dhumal-Mechanical Design EngineerDocument2 pagesSagar Dhumal-Mechanical Design Engineerchetan expertgsNo ratings yet

- Nirajkumar Mehta, PH.D.: Professional SummaryDocument2 pagesNirajkumar Mehta, PH.D.: Professional SummaryNirajkumar MehtaNo ratings yet

- Pratheepraj TDocument3 pagesPratheepraj TvenkyymdNo ratings yet

- Objective: Priya KarthickeyanDocument4 pagesObjective: Priya KarthickeyandeepvineetNo ratings yet

- Gunjan Dixit - : Business Analyst/ Project CoordinatorDocument7 pagesGunjan Dixit - : Business Analyst/ Project CoordinatorAditi GaurNo ratings yet

- Mukul Seth: Senior Manager, Engineering Rocket SoftwareDocument2 pagesMukul Seth: Senior Manager, Engineering Rocket SoftwareShreyas MishraNo ratings yet

- KM-2023 Engineering Manager Update 1686573682728 KeshavaMurthyDocument5 pagesKM-2023 Engineering Manager Update 1686573682728 KeshavaMurthyvikranthjNo ratings yet

- Contact: Sr. Product Design and Development EngineerDocument1 pageContact: Sr. Product Design and Development EngineerMohseen KarcheNo ratings yet

- Vaibhav CV GENDocument3 pagesVaibhav CV GENSarang BhongNo ratings yet

- Zeeshan Pathan Mechanical EngineerDocument4 pagesZeeshan Pathan Mechanical EngineerZeeshan PathanNo ratings yet

- Karan K. KhodeDocument2 pagesKaran K. Khodewooden makersNo ratings yet

- Anwesh YashrajDocument3 pagesAnwesh YashrajSangeeta TanejaNo ratings yet

- Imad, Amir: Colsdfsfsd Computing SkillsDocument9 pagesImad, Amir: Colsdfsfsd Computing Skillsamirimad100% (3)

- SP TemplateDocument9 pagesSP TemplateBorja mora méndezNo ratings yet

- Experienced Mechanical Engineer Seeking New ChallengesDocument3 pagesExperienced Mechanical Engineer Seeking New ChallengesbecknithNo ratings yet

- Resume - Hariharan - Business AnalystDocument2 pagesResume - Hariharan - Business Analystharish ragavNo ratings yet

- Oracle Consultant 0038Document8 pagesOracle Consultant 0038Cendien ConsultingNo ratings yet

- Vinay.S: Executive SummaryDocument5 pagesVinay.S: Executive Summaryfdhrh tryNo ratings yet

- Akhilesh Kumar Singh's Resume: Expert Oracle DeveloperDocument6 pagesAkhilesh Kumar Singh's Resume: Expert Oracle DeveloperNiharikaNicNo ratings yet

- Vishal Pawar - ResumeDocument4 pagesVishal Pawar - ResumeVishal PawarNo ratings yet

- RESUME SATYARTHGAUR 2023 TechMDocument14 pagesRESUME SATYARTHGAUR 2023 TechMsatyarthgaurNo ratings yet

- Syed Muzammil AliDocument1 pageSyed Muzammil AliSyed Muzammil AliNo ratings yet

- Amit Borkar: Profile SummaryDocument3 pagesAmit Borkar: Profile SummaryJeevan K G HosamaneNo ratings yet

- VenkateshBP TW ResumeDocument4 pagesVenkateshBP TW Resumevenesh bpNo ratings yet

- Latest CV of Rahul Saxena 2023Document1 pageLatest CV of Rahul Saxena 2023marycarter2684No ratings yet

- HImanshu ResumeDocument2 pagesHImanshu ResumeYashwanth NNo ratings yet

- Adarsh Gole - BADocument6 pagesAdarsh Gole - BAAnkit ButiyaNo ratings yet

- Neelalohit ChainiDocument8 pagesNeelalohit ChainiHARINo ratings yet

- Operation Manual For San 1400 TPP HDR IV CC BG 135TDocument155 pagesOperation Manual For San 1400 TPP HDR IV CC BG 135TKumardasNsNo ratings yet

- Received With Thanks ' 2,662.00 Through Payment Gateway Over The Internet FromDocument2 pagesReceived With Thanks ' 2,662.00 Through Payment Gateway Over The Internet FromKumardasNsNo ratings yet

- Karnataka Public School: Application FormDocument4 pagesKarnataka Public School: Application FormKumardasNsNo ratings yet

- Application of Hydraulic Based Transmission SystemDocument6 pagesApplication of Hydraulic Based Transmission SystemKumardasNsNo ratings yet

- AssistantDirectorVacancy 19082021Document17 pagesAssistantDirectorVacancy 19082021debasishNo ratings yet

- Materials RagaDocument9 pagesMaterials RagavenugopalsghNo ratings yet

- Bangalore Metro Rail Corporation Limited: WWW - Bmrc.co - InDocument7 pagesBangalore Metro Rail Corporation Limited: WWW - Bmrc.co - InKumardasNsNo ratings yet

- Provisional Certificate For COVID-19 Vaccination - 1 Dose: Beneficiary DetailsDocument1 pageProvisional Certificate For COVID-19 Vaccination - 1 Dose: Beneficiary DetailsKumardasNsNo ratings yet

- Aepmis Kvs IdDocument236 pagesAepmis Kvs IdMohindra Kaushal100% (1)

- Vil Receip9036943513 2021-06-18Document1 pageVil Receip9036943513 2021-06-18KumardasNsNo ratings yet

- Received With Thanks ' 2,662.00 Through Payment Gateway Over The Internet FromDocument2 pagesReceived With Thanks ' 2,662.00 Through Payment Gateway Over The Internet FromKumardasNsNo ratings yet

- Income Tax Calculator Fy 2021 22 v2Document15 pagesIncome Tax Calculator Fy 2021 22 v2KumardasNsNo ratings yet

- Important DatesDocument16 pagesImportant DatesPrabhu ShantaniNo ratings yet

- Nalikali 04aug20Document5 pagesNalikali 04aug20KumardasNsNo ratings yet

- Notif CAPFACs Exam 2021 Engl 150421Document15 pagesNotif CAPFACs Exam 2021 Engl 150421vivekNo ratings yet

- Loan Interest Payment Receipt: Har Pal Aapke Saath!Document2 pagesLoan Interest Payment Receipt: Har Pal Aapke Saath!KumardasNsNo ratings yet

- Sandeepani Rural Educational InstitutionDocument1 pageSandeepani Rural Educational InstitutionKumardasNsNo ratings yet

- SRF ID RTPCR 2238 7001 03608Document2 pagesSRF ID RTPCR 2238 7001 03608nitish mahatoNo ratings yet

- 02 Scientist-B MechEngg CWPRS Scru Eng RevDocument5 pages02 Scientist-B MechEngg CWPRS Scru Eng RevKumardasNsNo ratings yet

- DocumentviewsDocument5 pagesDocumentviewsnhhuhhNo ratings yet

- Vil Receipt 8095566364 2021-03-15Document1 pageVil Receipt 8095566364 2021-03-15KumardasNsNo ratings yet

- Application for NOC transferDocument2 pagesApplication for NOC transferKumardasNsNo ratings yet

- Form 30 (See Rule 55 (2) and (3) ) Application For Intimation and Transfer of Ownership of A Motor VehicleDocument2 pagesForm 30 (See Rule 55 (2) and (3) ) Application For Intimation and Transfer of Ownership of A Motor Vehiclenarasimha raoNo ratings yet

- Application for NOC transferDocument2 pagesApplication for NOC transferKumardasNsNo ratings yet

- Form 60Document2 pagesForm 60Rohit JainNo ratings yet

- Form 29Document1 pageForm 29jacobpulikodenNo ratings yet

- WABTEC - Mechanical EngineeringDocument2 pagesWABTEC - Mechanical EngineeringKumardasNsNo ratings yet

- CLCS Schme Circular and Guidline PDFDocument33 pagesCLCS Schme Circular and Guidline PDFap consultantNo ratings yet

- Dgéæãuàå Àävàäû Pàäläa Pà Áåt E Ásé: Àwæpá Àæpàlué ÁapàDocument27 pagesDgéæãuàå Àävàäû Pàäläa Pà Áåt E Ásé: Àwæpá Àæpàlué ÁapàKumardasNsNo ratings yet

- Online Advertisement 5may2021Document7 pagesOnline Advertisement 5may2021Md Mehbub SamratNo ratings yet

- Donald DeskeyDocument12 pagesDonald DeskeyDiksha GuptaNo ratings yet

- Week006 ModuleDocument9 pagesWeek006 ModuleKimberly FulledoNo ratings yet

- FDocument58 pagesFPricilia AlengNo ratings yet

- Unit 2 Architectural Styles and Case Studies BooksparDocument43 pagesUnit 2 Architectural Styles and Case Studies BooksparAnser PashaNo ratings yet

- Stress Analysis of Piping Systems and Pipelines-Harvard UniversityDocument542 pagesStress Analysis of Piping Systems and Pipelines-Harvard UniversityRjeb mohamed100% (2)

- Innovating Sarawak's Educational Landscape for 21st Century LearningDocument5 pagesInnovating Sarawak's Educational Landscape for 21st Century Learningbrenda nyapusNo ratings yet

- Universal Design HandbookDocument102 pagesUniversal Design Handbooktiatek75% (4)

- VLSI Low Power VLSI Design FundamentalsDocument324 pagesVLSI Low Power VLSI Design FundamentalsCorrisionbluryNo ratings yet

- Moore Machine VHDL CodeDocument2 pagesMoore Machine VHDL CodeKewl84No ratings yet

- Computer Engineering Thesis ExamplesDocument6 pagesComputer Engineering Thesis Examplesfc5f5qej100% (2)

- Mapping Artistic Research Towards DiagraDocument80 pagesMapping Artistic Research Towards DiagraAniella Ramírez MaglioneNo ratings yet

- Parametric Models of Facade Designs of High-Rise Residential BuildingsDocument8 pagesParametric Models of Facade Designs of High-Rise Residential BuildingsEn EvergreenNo ratings yet

- Ramakanth Layout Engineer 7yearsDocument3 pagesRamakanth Layout Engineer 7yearsRamnath KiniNo ratings yet

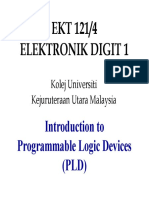

- EKT 121/4 Elektronik Digit 1: Introduction To Programmable Logic Devices (PLD)Document34 pagesEKT 121/4 Elektronik Digit 1: Introduction To Programmable Logic Devices (PLD)MasterArvinNo ratings yet

- Basic Elements of Transportation PlanningDocument3 pagesBasic Elements of Transportation PlanningnouriNo ratings yet

- Electrical Wiring Diagram Home Lift 6600Document21 pagesElectrical Wiring Diagram Home Lift 6600MACRO TECH LLCNo ratings yet

- Job Opportunities in Q1-2012 (NCG) - Novellus Vietnam LTDDocument3 pagesJob Opportunities in Q1-2012 (NCG) - Novellus Vietnam LTDNgô Hồng CôngNo ratings yet

- History of Design and Technological Developments in Different PeriodsDocument35 pagesHistory of Design and Technological Developments in Different PeriodsChuNo ratings yet

- Engineering Is Everywhere: David T. Bowker Purdue College of EngineeringDocument28 pagesEngineering Is Everywhere: David T. Bowker Purdue College of EngineeringSarita DudiNo ratings yet

- Architectural Theory: Charles Jencks: Modern Movements in ArchitectureDocument32 pagesArchitectural Theory: Charles Jencks: Modern Movements in ArchitectureBafreen BnavyNo ratings yet

- The 10 Steps in Engineering Design WorksheetDocument7 pagesThe 10 Steps in Engineering Design Worksheetapi-609159413No ratings yet

- EE Mid 2Document14 pagesEE Mid 2SifatNo ratings yet

- Art Cam Jewel Smith User GuideDocument160 pagesArt Cam Jewel Smith User GuideMX100100% (2)

- Edci545 Lesson PlanDocument11 pagesEdci545 Lesson Planapi-711528787No ratings yet

- VLSI Lab Manual Student Copy 21-22 04.10.21Document76 pagesVLSI Lab Manual Student Copy 21-22 04.10.21RanjithNo ratings yet

- Equipment & Piping Layout T.N. GopinathDocument88 pagesEquipment & Piping Layout T.N. Gopinathhirenkumar patelNo ratings yet

- LAB 3 IC DesignDocument6 pagesLAB 3 IC DesignShaifulIzuwanNo ratings yet

- WD D Assignment 2 BriefDocument3 pagesWD D Assignment 2 BriefNguyễn Khắc TàiNo ratings yet

- Introduction to Information Technology: Understanding Key Concepts Like Data, Information, and IT ProfessionalsDocument21 pagesIntroduction to Information Technology: Understanding Key Concepts Like Data, Information, and IT ProfessionalsFrank MosesNo ratings yet

- Policy Making CourseDocument67 pagesPolicy Making Coursemkubwimana100% (13)