Professional Documents

Culture Documents

Inverter Drive The Efficient Heart of Air Conditioning Systems

Uploaded by

vishal vananiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inverter Drive The Efficient Heart of Air Conditioning Systems

Uploaded by

vishal vananiCopyright:

Available Formats

Inverter-

Technology

Inverter Drive

the efficient heart of air conditioning systems

Since the European introduction of the first Daikin VRV inverter drive systems provide capacity con-

inverter driven variable refrigerant volume (VRV) trol down to 0.8HP (2.5kW) operation before the

air conditioning system in 1989, “inverter drive” compressor ceases to operate. This type of control

has become widely accepted as the highly efficient is certainly adequate, since a demand of less than

“heart” of variable flow systems, offering many 0.8HP is not worth the running cost required to

energy saving and operating advantages. meet it. This control equates to around 11% mini-

mum operating capacity for large VRV systems and

Inverter advantages is seldom exceeded on alternative system set-ups.

The electronics and switching technology required

Room temperature [ °C ] to make up the inverter drive, have been developed

in accordance with EU Electromagnetic

Compatibility Directives (89/336/EEC) with which

compliance is required for CE Marking.

21 °C

Normal air con- An inverter

ditioning units minimises the

generate greater temperature The new Daikin VRV III air conditioning system can

temperature differences difference

Start-up period is about 30% shorter

achieve an efficiency (COP) of up to 3.98 in cooling

17 °C

Time

mode and 4.09 in heating mode in nominal condi-

Inverter air conditioning unit

tions with savings in operating power consumption

Normal air conditioning unit

to match (Relation between power input and cool-

ing/ heating capacity). Furthermore, 50% partial

Inverter technology load COP ratings as high as 5.9 can be realised

Inverter technology was originally conceived to under normal European operating conditions. These

provide close control of refrigerant flow and match values are achieved using the latest inverter tech-

the cooling load required at any time. nology in combination with DC reluctance motors.

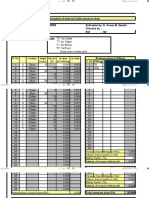

5 HP outdoor unit 8, 10, 12 HP outdoor unit 14, 16, 18 HP outdoor unit

100% 100% 100%

Compressor Capacity Control

Compressor Capacity Control

Compressor Capacity Control

N°1

280 Hz – 52 Hz

Inv.

N°1 + N°2 + N°3 Compressor

280 Hz – 52 Hz 280 Hz – 52 Hz Compr.

Inverter 35 Steps

20 Steps Compressor + N°2 Compressor N°3

29 Steps Compressor N°1 Inverter Control

100% Inv. 280 Hz – 52 Hz

Operation Compr. 20 Steps

Inverter N°2

Compressor 100% N°1 N°2 N°2

Operation Inverter Compressor Compressor N°1

Compressor

24% 14% 10%

Compressor 100% 100% Inv.

Operation Operation Compr.

Large Small Large Small Large Small

Load Load Load

You might also like

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- 1-4x HV Troubleshooting PDFDocument46 pages1-4x HV Troubleshooting PDFEmmanuel VirtudazoNo ratings yet

- Cooling and Heating Load CalculationsDocument51 pagesCooling and Heating Load CalculationsHaydery100% (1)

- What Is HIPOT Testing (Dielectric Strength Test) ?Document52 pagesWhat Is HIPOT Testing (Dielectric Strength Test) ?raza239100% (3)

- ECM Motors PDFDocument4 pagesECM Motors PDFNdia2007No ratings yet

- SCIENCE5 Summative TestDocument3 pagesSCIENCE5 Summative TestJulie Ann Gaca100% (1)

- Chiller PDFDocument20 pagesChiller PDFredaNo ratings yet

- Cat 330D FMDocument24 pagesCat 330D FMIvan100% (1)

- Installing Electrical Protective Devices For Distribution, Power, Lightning Protection and Grounding SystemsDocument23 pagesInstalling Electrical Protective Devices For Distribution, Power, Lightning Protection and Grounding SystemsYamut Si ako67% (6)

- List of cable nomenclature and ratingsDocument4 pagesList of cable nomenclature and ratingssmcsamindaNo ratings yet

- Enercon MonitorEnercon Monitoring Grid Connectioning Grid ConnectionDocument7 pagesEnercon MonitorEnercon Monitoring Grid Connectioning Grid ConnectionDeva Sravan Kumar SarmaNo ratings yet

- Operating Guide: VLT Midi Drive FC 280Document70 pagesOperating Guide: VLT Midi Drive FC 280Mr.K chNo ratings yet

- Turbine Inlet Air CoolingDocument4 pagesTurbine Inlet Air Coolingkrazylion100% (2)

- Technical Specifications: Duct Work and Outlets GeneralDocument16 pagesTechnical Specifications: Duct Work and Outlets GeneralNedunuri.Madhav MurthyNo ratings yet

- Caterpillar 330D FMDocument24 pagesCaterpillar 330D FMForomaquinasNo ratings yet

- Psikometric ChartDocument1 pagePsikometric Chartjohn_kadier651No ratings yet

- Causes of Transformer Failures and Diagnostic Methods - A Review PDFDocument15 pagesCauses of Transformer Failures and Diagnostic Methods - A Review PDFCerduardo Chanchisco Roga Rojas100% (1)

- VRV Reference: GuideDocument72 pagesVRV Reference: Guidekhamsone pengmanivongNo ratings yet

- High Performance Air Conditioning Energy EfficiencyDocument68 pagesHigh Performance Air Conditioning Energy EfficiencyPOLARIS ENGINEERING DEPARTMENTNo ratings yet

- Single-Stage VPM (VFD+PM) Screw Air Compressor - UCSDocument9 pagesSingle-Stage VPM (VFD+PM) Screw Air Compressor - UCSRUN GONo ratings yet

- Fresh Air Package UnitRTP BrochureDocument4 pagesFresh Air Package UnitRTP BrochurespsamcNo ratings yet

- HITEMA ENERGY SAVING SOLUTIONS WITH INTEGRATED COMPRESSED AIR & REFRIGERATION TECHDocument5 pagesHITEMA ENERGY SAVING SOLUTIONS WITH INTEGRATED COMPRESSED AIR & REFRIGERATION TECHm4xiNo ratings yet

- Integrated Advanced Digital Turbine Control For Steam TurbinesDocument4 pagesIntegrated Advanced Digital Turbine Control For Steam TurbinesJames IzquierdoNo ratings yet

- METUS - Getting Started With VRF - White PaperDocument11 pagesMETUS - Getting Started With VRF - White PaperEltonNo ratings yet

- Sliding Control Retrofit Power: Thermal PlantDocument6 pagesSliding Control Retrofit Power: Thermal PlantghostamirNo ratings yet

- Examples of Electric Drive Solutions and Applied TechnologiesDocument6 pagesExamples of Electric Drive Solutions and Applied TechnologiesPhan Thành MinhNo ratings yet

- Inverter InverterDocument2 pagesInverter InverterShouzab AbbasNo ratings yet

- Solutions Guide AirzoneDocument16 pagesSolutions Guide Airzoneljrojas2011No ratings yet

- Hydraulic Excavator: Engine Power Operating Weight Bucket CapacityDocument20 pagesHydraulic Excavator: Engine Power Operating Weight Bucket CapacityMauricio Ari AriNo ratings yet

- Analysis and Experimental Veri Cation of A Variable SpeedDocument11 pagesAnalysis and Experimental Veri Cation of A Variable SpeedHashfi HamdaniNo ratings yet

- E5810 0-12-08 Oil Air Coolers El Mi LQDocument11 pagesE5810 0-12-08 Oil Air Coolers El Mi LQPiero Fabrizzio Mendoza FuenteNo ratings yet

- Turbine Startup and Shutdown in Wind Farms FeaturiDocument11 pagesTurbine Startup and Shutdown in Wind Farms FeaturiArturo BareaNo ratings yet

- On Site Air Compressor Capacity TestDocument5 pagesOn Site Air Compressor Capacity TestvankayalasuryaNo ratings yet

- R22 SplitDocument2 pagesR22 Split姚小花No ratings yet

- 27 1 15 L07 L22 RS Brochure GBDocument8 pages27 1 15 L07 L22 RS Brochure GBjennlin.changNo ratings yet

- Chilled Water Air Conditioning: SeriesDocument15 pagesChilled Water Air Conditioning: SeriesTRAN DUYNo ratings yet

- Individual Room Control Applications IntroductionDocument12 pagesIndividual Room Control Applications IntroductionkkkhattabbbNo ratings yet

- Dry IG Mode Operation and AdvantagesDocument3 pagesDry IG Mode Operation and AdvantagesJym GensonNo ratings yet

- Laplace's TransformDocument16 pagesLaplace's TransformS AlvesNo ratings yet

- Shabaninia 2012Document9 pagesShabaninia 2012Bachir DjamateNo ratings yet

- Improved Energy Efficiency of Air Cooled ChillersDocument4 pagesImproved Energy Efficiency of Air Cooled ChillersKhozema GoodluckNo ratings yet

- Evolution of Air-cooled Turbine Generator DesignDocument7 pagesEvolution of Air-cooled Turbine Generator DesignasdfagNo ratings yet

- Danfoss FC102 HVAC DriveDocument40 pagesDanfoss FC102 HVAC DrivedesignselvaNo ratings yet

- Eke 1a PDFDocument93 pagesEke 1a PDFWilmer LeonNo ratings yet

- Catalog 2011Document84 pagesCatalog 2011Marlou RabinaNo ratings yet

- ErebaDocument12 pagesErebaHamo HamoNo ratings yet

- KP 206 2 enDocument8 pagesKP 206 2 enAmic BanatNo ratings yet

- Hks Lazar Kotly I Piece Na Pellet enDocument21 pagesHks Lazar Kotly I Piece Na Pellet enLaura-MariaDragomirNo ratings yet

- 2356 cptg007 En-Web PDFDocument24 pages2356 cptg007 En-Web PDF7esabat7033No ratings yet

- Danfoss Catalogue For VSDDocument52 pagesDanfoss Catalogue For VSDWee HuuNo ratings yet

- Drive Down Operating Costs,: With The Leader in HVAC EfficiencyDocument52 pagesDrive Down Operating Costs,: With The Leader in HVAC EfficiencydesignselvaNo ratings yet

- L23 L29 BrochureDocument8 pagesL23 L29 BrochuremaxNo ratings yet

- Acson modular chiller inverter seriesDocument20 pagesAcson modular chiller inverter serieskhairul nizamNo ratings yet

- ASCENDANT Health Care Brochure - SEMCO 2016-02Document16 pagesASCENDANT Health Care Brochure - SEMCO 2016-02JorgeNo ratings yet

- cp:19971881Document8 pagescp:19971881Xuan Man NguyenNo ratings yet

- Replace Pressure-Reducing Valves With Backpressure TurbogeneratorsDocument2 pagesReplace Pressure-Reducing Valves With Backpressure TurbogeneratorsEmerson RwkNo ratings yet

- Commissioning Commercial KitchensDocument3 pagesCommissioning Commercial KitchensMoh'd KhadNo ratings yet

- Trane Giải Nhiệt Gió CG-PRC048B-GB - 0121 - smDocument52 pagesTrane Giải Nhiệt Gió CG-PRC048B-GB - 0121 - smPhạm ĐứcNo ratings yet

- Engineers Newsletter: Keeping The "Free" in Free-CoolingDocument8 pagesEngineers Newsletter: Keeping The "Free" in Free-CoolingJoshuaNo ratings yet

- 48LCB 14 26 01PDDocument102 pages48LCB 14 26 01PDMohamed AmrNo ratings yet

- Energies 15 08026 v2Document33 pagesEnergies 15 08026 v2nissanroy5No ratings yet

- RTUA RTCA Designed To Perform Built To Last PDFDocument20 pagesRTUA RTCA Designed To Perform Built To Last PDFModussar IlyasNo ratings yet

- ITWGSE 3400 Rev-ADocument4 pagesITWGSE 3400 Rev-Agolf94No ratings yet

- Renner RSF OverviewDocument8 pagesRenner RSF OverviewVlad LiviuNo ratings yet

- CSD CSDX Series BrochureDocument11 pagesCSD CSDX Series BrochureJia TianNo ratings yet

- Optimal Vector Control ofDocument7 pagesOptimal Vector Control ofVinay KumarNo ratings yet

- Evaporation For Instant Coffee Plants Tcm11 54061Document1 pageEvaporation For Instant Coffee Plants Tcm11 54061Hung DoNo ratings yet

- Jurnal ReviewDocument42 pagesJurnal Reviewdiarfahreza89No ratings yet

- Adaptive Moving Sliding Mode Control For SISO Systems Application To An Electropneumatic SystemDocument5 pagesAdaptive Moving Sliding Mode Control For SISO Systems Application To An Electropneumatic SystemCesar VillamizarNo ratings yet

- 10-09 GreenBldg PPTDocument72 pages10-09 GreenBldg PPTherokaboss1987No ratings yet

- Avadh Club AHUVENTILATION SHEET 1 PDFDocument1 pageAvadh Club AHUVENTILATION SHEET 1 PDFvishal vananiNo ratings yet

- Pipe SizeDocument1 pagePipe Sizevishal vananiNo ratings yet

- Option 1Document1 pageOption 1vishal vananiNo ratings yet

- Munters High Temp Psych ChartDocument2 pagesMunters High Temp Psych ChartaniruddhaskNo ratings yet

- Swami Solar Electric Layout PDFDocument1 pageSwami Solar Electric Layout PDFvishal vananiNo ratings yet

- FCU BrochureDocument1 pageFCU Brochurevishal vananiNo ratings yet

- Exercises On Psychrometry (Solutions)Document4 pagesExercises On Psychrometry (Solutions)nirbhay pandeyNo ratings yet

- Ceiling Concealed DuctsDocument2 pagesCeiling Concealed Ductsvishal vananiNo ratings yet

- Advanced Air Curtain with Wing EC ControllerDocument8 pagesAdvanced Air Curtain with Wing EC Controllervishal vananiNo ratings yet

- Stair Case PressurizationDocument5 pagesStair Case Pressurizationvishal vananiNo ratings yet

- Static Pressure DropDocument3 pagesStatic Pressure Dropvishal vananiNo ratings yet

- Heat LoadDocument76 pagesHeat Loadvishal vananiNo ratings yet

- BS88 LV Fuse Links & Fuse Holders: TTM - 50-040-01 TIA - 50-001-01Document4 pagesBS88 LV Fuse Links & Fuse Holders: TTM - 50-040-01 TIA - 50-001-01skodgeNo ratings yet

- Methods of Installation and Current-Carrying Capacities Based On IEC 60364-5-52 Ed.3Document31 pagesMethods of Installation and Current-Carrying Capacities Based On IEC 60364-5-52 Ed.3Din TcmNo ratings yet

- PS5RV DatasheetDocument8 pagesPS5RV DatasheetJims Poma VilcahuamanNo ratings yet

- Rayan CarteDocument12 pagesRayan CarteRadhika RanaNo ratings yet

- Bslbattlfp OF Performance: TheheightDocument3 pagesBslbattlfp OF Performance: TheheightCamilo PérezNo ratings yet

- NTE6354 Thru NTE6365 Silicon Power Rectifier Diode 300 Amp, DO9Document3 pagesNTE6354 Thru NTE6365 Silicon Power Rectifier Diode 300 Amp, DO9felisiañoNo ratings yet

- 1.chapter 1 Overview Power eDocument26 pages1.chapter 1 Overview Power eFarah AzlinaNo ratings yet

- Ca HD4-R (En) H 1VCP000028-1602Document64 pagesCa HD4-R (En) H 1VCP000028-1602LEANDRONo ratings yet

- Protective Relaying & Power PlantsDocument36 pagesProtective Relaying & Power PlantsSayan AichNo ratings yet

- Schneider MiCOM P442 E0 Line User Manual ENUDocument6 pagesSchneider MiCOM P442 E0 Line User Manual ENURaúlEmirGutiérrezLópezNo ratings yet

- BD 25 A 20Document7 pagesBD 25 A 20ElectromateNo ratings yet

- Interruptor Magnum-Curvas PDFDocument110 pagesInterruptor Magnum-Curvas PDFantonio100% (1)

- 1VAP420002-TG - OEM IT Ref Guide - April2014 PDFDocument110 pages1VAP420002-TG - OEM IT Ref Guide - April2014 PDFflyzalNo ratings yet

- Extrait Doc Variateur GBDocument7 pagesExtrait Doc Variateur GBErick Fernando Chavez VargasNo ratings yet

- Svetlana EF86 High-Performance Audio PentodeDocument2 pagesSvetlana EF86 High-Performance Audio PentodeAntonio ZappuloNo ratings yet

- Electrical Machine DesignDocument9 pagesElectrical Machine DesignSandeep KumarkjNo ratings yet

- td2014p 000736 PDFDocument36 pagestd2014p 000736 PDFfoufou79No ratings yet

- ABB Brochure-Slip-Ring-1Document8 pagesABB Brochure-Slip-Ring-1Wael AbNo ratings yet

- GENKINGER englHBSEM1Document38 pagesGENKINGER englHBSEM1kashif AliNo ratings yet

- Sepam GamaDocument31 pagesSepam GamaHenry ArrvalNo ratings yet

- NSN Rectifier ManualDocument25 pagesNSN Rectifier ManualpetermamdouhraoufNo ratings yet

- Wiring Diagram IndexDocument36 pagesWiring Diagram IndexJose Luis AntonioNo ratings yet

- Afumex LSX: Product Datasheet & Applications GuideDocument8 pagesAfumex LSX: Product Datasheet & Applications GuideBhagoo HatheyNo ratings yet