Professional Documents

Culture Documents

Datasheet Plastic Granules PDF

Datasheet Plastic Granules PDF

Uploaded by

Nileshkumar Thanvi0 ratings0% found this document useful (0 votes)

15 views1 pageOriginal Title

datasheet_plastic_granules.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views1 pageDatasheet Plastic Granules PDF

Datasheet Plastic Granules PDF

Uploaded by

Nileshkumar ThanviCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

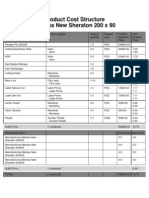

Plastic Granules

Plastic granules are produced from various resins in a polycondensation process, subse-

quently chopped up into smaller pieces and classified according to different grain sizes.

Applications

• Reusable abrasive • Paint-stripping

• Deburring • Micro-blasting

Blasting systems

• Pressure blast systems • Airless blast-cleaning equipment

• Injection blast cabinets

Typical physical properties Available sizes

Hardness approx. 3,5 – 4,0 mohs MESH Average grain size (mm)

Grain shape angular 12 / 16 1,20 – 1,70

Ignition temperature < 500 °C 16 / 20 0,80 – 1,20

Specific gravity approx. 1,5 g/cm3 20 / 30 0,60 – 0,80

Bulk density depending on granular size approx. 0,8 – 0,9 g/cm3 20 / 40 0,40 – 0,80

30 / 40 0,40 – 0,60

Typical chemical analysis 40 / 60 0,25 – 0,40

Plastics from: Urea, Melamine, Acrylic, 60 / 80 0,18 – 0,25

Polycarbonate resins Metric Average grain size (mm)

0,10 – 0,20

Packaging 0,15 – 0,25

25 kg bags on pallet up to 1 ton 0,25 – 0,50

1 ton loose in big bag 0,50 – 0,80

0,80 – 1,20

1,20 – 1,80

Other grain sizes can be produced if required.

www.kuhmichel.com Rev. 31.07.2009

You might also like

- SexualFu CompanionDocument31 pagesSexualFu CompanionfxfactorNo ratings yet

- Nodel Analysis MTE120Document15 pagesNodel Analysis MTE120Wee Khang100% (1)

- DIY Cockpit ControlsDocument58 pagesDIY Cockpit ControlsArie Maulana100% (1)

- COMPOSITEDocument164 pagesCOMPOSITEDrpriti DesaiNo ratings yet

- Bar Finishing: Processing StepsDocument23 pagesBar Finishing: Processing StepsKunwar Apoorva SinghNo ratings yet

- Blending of Aggregate For Bituminous Concrete (As Per Ms-2 Table 2.1)Document18 pagesBlending of Aggregate For Bituminous Concrete (As Per Ms-2 Table 2.1)Krunal Shah100% (1)

- Agricultural StructuresDocument6 pagesAgricultural StructuresRaymarck PatricioNo ratings yet

- Mix Design - m40 - Modified 28 Days CcsDocument23 pagesMix Design - m40 - Modified 28 Days CcsKuldeep Chakerwarti100% (2)

- Datasheet GarnetDocument1 pageDatasheet GarnetnnuekNo ratings yet

- Vent Volumes and Dust BurdensDocument2 pagesVent Volumes and Dust Burdenszane truesdaleNo ratings yet

- Mechanical OpeationDocument17 pagesMechanical Opeationsaurabhmeshram88No ratings yet

- B Wall DrawingDocument5 pagesB Wall DrawingJayanta MandalNo ratings yet

- AAG Tolerances GBDocument2 pagesAAG Tolerances GBJayantNo ratings yet

- Walnut Shell Grit: Kramer Industries, IncDocument1 pageWalnut Shell Grit: Kramer Industries, IncYashNo ratings yet

- The Importance of ParticleDocument44 pagesThe Importance of Particlejuan1040No ratings yet

- FUNDACIONESDocument1 pageFUNDACIONESCopy MasterNo ratings yet

- Typical Values of Soil Young's Modulus - Fill MaterialDocument1 pageTypical Values of Soil Young's Modulus - Fill MaterialhamidkarimpourNo ratings yet

- RuberGuide - 2017 ENGLISHDocument8 pagesRuberGuide - 2017 ENGLISHAndres Byke SepulvedaNo ratings yet

- ActionDocument1 pageActiondudi_ismail22No ratings yet

- Lecture 7B-Tut T8 Example Lanes Approach For COG OptimisationDocument24 pagesLecture 7B-Tut T8 Example Lanes Approach For COG OptimisationElijah MuntembaNo ratings yet

- 1.80 Mtrs Concrete Fence-Details1Document1 page1.80 Mtrs Concrete Fence-Details1Richard MonesNo ratings yet

- Plastic - MFG Process Comparisons-Other SourceDocument3 pagesPlastic - MFG Process Comparisons-Other Sourceswap dNo ratings yet

- Mesh Micron Sizes Chart Ebook From IsmDocument7 pagesMesh Micron Sizes Chart Ebook From IsmPratik JainNo ratings yet

- GraphDocument3 pagesGraphBrent GammadNo ratings yet

- GraphDocument3 pagesGraphBrent GammadNo ratings yet

- Semi-Logarithmic Grain Size PlotDocument3 pagesSemi-Logarithmic Grain Size PlotBrent GammadNo ratings yet

- Bag Filters: Synthetic Fine Filters F7Document2 pagesBag Filters: Synthetic Fine Filters F7mikael8118No ratings yet

- B4 Chapter4.Material Bendungan.Document12 pagesB4 Chapter4.Material Bendungan.Agustitus ArioNo ratings yet

- Iso 2768 MechanicalDocument1 pageIso 2768 MechanicalnrtmoorthiNo ratings yet

- پارتیکل سایزDocument1 pageپارتیکل سایزsaeid.mehregan.shNo ratings yet

- SBRSMDocument1 pageSBRSMVICTOR FQNo ratings yet

- JIS Kanto Loam Z8901 - Class 7 8 11 2015Document1 pageJIS Kanto Loam Z8901 - Class 7 8 11 2015Senthil Kumar GanesanNo ratings yet

- Bag Filters: Synthetic Fine Filters F6Document2 pagesBag Filters: Synthetic Fine Filters F6mikael8118No ratings yet

- Agricultural StructuresDocument6 pagesAgricultural StructuresRaymarck PatricioNo ratings yet

- Makanan & Minuman Item Harga (RM) Item Harga (RM)Document2 pagesMakanan & Minuman Item Harga (RM) Item Harga (RM)black shoesNo ratings yet

- Comminution: Dr. Fakhar Ud Din Assistant Professor Quaid-I-Azam University IslamabadDocument32 pagesComminution: Dr. Fakhar Ud Din Assistant Professor Quaid-I-Azam University Islamabadawais khanNo ratings yet

- Ti Pure How Ti02 Selection Improves Color Matching PerformanceDocument11 pagesTi Pure How Ti02 Selection Improves Color Matching Performancehai nguyenNo ratings yet

- Oferta Primavara 2020.bunDocument4 pagesOferta Primavara 2020.bundanivlad00No ratings yet

- Clastics Structure TextureDocument4 pagesClastics Structure TextureAHMED BAKRNo ratings yet

- WaterDocument22 pagesWaterUsama HaroonNo ratings yet

- Diametergrowth Lab5Document5 pagesDiametergrowth Lab5api-385650100No ratings yet

- Dimenzije I Tezine LimovaDocument2 pagesDimenzije I Tezine LimovaSinisa SimbaNo ratings yet

- Toleranties Rubberartikelen Algemeen PDFDocument2 pagesToleranties Rubberartikelen Algemeen PDFJason-chungNo ratings yet

- Toleranties Rubberartikelen AlgemeenDocument2 pagesToleranties Rubberartikelen AlgemeenJason-chung100% (1)

- 7466Document83 pages7466Abd RaNo ratings yet

- Vildon Filter Tfe 90Document2 pagesVildon Filter Tfe 90sitaNo ratings yet

- Das TDS - Ma PDSDocument2 pagesDas TDS - Ma PDSIMRAN KHANNo ratings yet

- 3.sieve Analysis in Fine AggregateDocument1 page3.sieve Analysis in Fine AggregateLakshithaGonapinuwalaWithanageNo ratings yet

- Kelompok 2 Lab. Beton LenturDocument21 pagesKelompok 2 Lab. Beton Lentur1A025D4 Jakon MuhsyahikhanalkahfyNo ratings yet

- Parameters For Different Materials-50watt SPDocument3 pagesParameters For Different Materials-50watt SPshavva achmadNo ratings yet

- Plastic Injection Molding Tolerance GuideDocument2 pagesPlastic Injection Molding Tolerance GuideRavindra ErabattiNo ratings yet

- Tolerances: Tolerances For Molded Parts - RubberDocument2 pagesTolerances: Tolerances For Molded Parts - Rubberandrefs7No ratings yet

- John Greene ResinDocument52 pagesJohn Greene ResinYesid Tapiero MartínezNo ratings yet

- 0-Sales - Invoice-Waghade Kirana ShopDocument1 page0-Sales - Invoice-Waghade Kirana ShopPankaj NimjeNo ratings yet

- Techno FashionDocument5 pagesTechno FashionMaria BurevskiNo ratings yet

- Cja YDocument18 pagesCja YC-jay PizarraNo ratings yet

- Unit 1 - Data StructuresDocument31 pagesUnit 1 - Data StructuresVarun KumarNo ratings yet

- DSMM - Assignment - Detailed Notes - 22 - 23Document4 pagesDSMM - Assignment - Detailed Notes - 22 - 23tanuNo ratings yet

- IFBI Solved Maths 7Document52 pagesIFBI Solved Maths 7Anurag BaraikNo ratings yet

- Review Jurnal - 3Document20 pagesReview Jurnal - 3eko hadiNo ratings yet

- Cat Elc (Extended Life Coolant) MdsDocument8 pagesCat Elc (Extended Life Coolant) Mdsharikrishnanpd3327No ratings yet

- Hatchet Objectives and Unit OutcomesDocument2 pagesHatchet Objectives and Unit Outcomesapi-241052507No ratings yet

- Debussy Nuages SCOREDocument8 pagesDebussy Nuages SCOREBetania LópezNo ratings yet

- Research On Multi Channel Marketing of EmbroideryDocument6 pagesResearch On Multi Channel Marketing of EmbroideryEditor IJTSRDNo ratings yet

- ListeningDocument2 pagesListeningnguyenna205okNo ratings yet

- Lesson 1 (Fundamentals of DBMS) PDFDocument30 pagesLesson 1 (Fundamentals of DBMS) PDFLingerfaith Mayor MoralesNo ratings yet

- Health Education & Behaviour Change CommunicationDocument50 pagesHealth Education & Behaviour Change CommunicationAarya MathewNo ratings yet

- View of Band and Loop A Case ReportDocument1 pageView of Band and Loop A Case Reportبسمة رياض عبد الستارNo ratings yet

- Sadiq ProjectDocument110 pagesSadiq ProjectSaqlain MustaqNo ratings yet

- User Guide Server Flex X240Document902 pagesUser Guide Server Flex X240Bruri S WahyudiNo ratings yet

- See The List Below Which Entails Textbooks by SubjectDocument5 pagesSee The List Below Which Entails Textbooks by SubjectVeer MaharajNo ratings yet

- Haykin Xue Neural Networks and Learning Machines 3ed Soln PDFDocument103 pagesHaykin Xue Neural Networks and Learning Machines 3ed Soln PDFExpedito Mello0% (1)

- 10-15-01 Baking Quality of Angel-Cake FlourDocument4 pages10-15-01 Baking Quality of Angel-Cake FlourMuhammad Farhan HidayatNo ratings yet

- Create A Scary Look-Through-The-Keyhole Illustration in Adobe Illustrator PDFDocument34 pagesCreate A Scary Look-Through-The-Keyhole Illustration in Adobe Illustrator PDFDave Supat TolentinoNo ratings yet

- HSIR14 Professional EthicsDocument7 pagesHSIR14 Professional EthicsAjeeth BNo ratings yet

- Earth Observation SatellitesDocument14 pagesEarth Observation SatellitesAkashkpNo ratings yet

- Dowf Rost: Engineering and Operating GuideDocument43 pagesDowf Rost: Engineering and Operating GuideninzauNo ratings yet

- Ap 7532 Data SheetDocument7 pagesAp 7532 Data SheetStephenNo ratings yet

- Pse Problems Group AssignmentDocument14 pagesPse Problems Group AssignmentSajid KhanNo ratings yet

- Imm 5645 eDocument2 pagesImm 5645 eArpon DebNo ratings yet

- G11 ABM Org and MGT Lesson 1 (Part 1)Document13 pagesG11 ABM Org and MGT Lesson 1 (Part 1)Leo SuingNo ratings yet