Professional Documents

Culture Documents

Plastic - MFG Process Comparisons-Other Source

Uploaded by

swap d0 ratings0% found this document useful (0 votes)

4 views3 pagesThe document compares several plastic manufacturing processes: injection molding, thermoforming, blow molding, rotational molding, polymer extrusion, and compression molding. It outlines key properties of each process including the types of shapes produced, material and part size limits, achievable tolerances and surface finishes, production rates and costs, advantages and disadvantages, and common applications.

Original Description:

Original Title

Plastic_Mfg Process Comparisons-other source

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document compares several plastic manufacturing processes: injection molding, thermoforming, blow molding, rotational molding, polymer extrusion, and compression molding. It outlines key properties of each process including the types of shapes produced, material and part size limits, achievable tolerances and surface finishes, production rates and costs, advantages and disadvantages, and common applications.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views3 pagesPlastic - MFG Process Comparisons-Other Source

Uploaded by

swap dThe document compares several plastic manufacturing processes: injection molding, thermoforming, blow molding, rotational molding, polymer extrusion, and compression molding. It outlines key properties of each process including the types of shapes produced, material and part size limits, achievable tolerances and surface finishes, production rates and costs, advantages and disadvantages, and common applications.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 3

Property Name

Injection Molding Thermoforming Blow Molding

Thin-walled: Cylindrical,

Thin-walled: Cubic, Thin- Thin-walled: Cylindrical, Thin- Thin-walled: Cylindrical,

Shapes

walled: Complex walled: Cubic, Thin-walled: Thin-walled: Cubic,

(Flat) Complex Thin-walled: Complex

Part size Envelope: 0.01 in³ - 80 ft³

Weight: 0.5 oz - 55 lb Area: 0.04 in² - 300 ft² Envelope: Up to 105 ft³

Thermoplastics

Materials

(Composites, Elastomer,

Thermosets) Thermoplastics Thermoplastics

Surface finish 16-Apr 60 - 120

- Ra (μin) (1 - 32) (16 - 120) 250 - 500

± 0.008 ± 0.04 ± 0.04

Tolerance (in.)

(± 0.002) (± 0.008) (± 0.01)

Max wall 0.03 - 0.25 0.015 - 0.15 0.015 - 0.125

thickness (0.015 - 0.5) (0.002 - 0.25) (0.01 - 0.24)

10000 - 1000000 10 - 1000 100000 - 1000000

Quantity

(1000 - 1000000) (1 - 100000) (1000 - 1000000)

Months

Lead time

(Weeks) Days Days

Can form complex shapes

and fine details, Excellent Can form complex

Advantages surrface finish, Good shapes with uniform

dimensional accuracy, wall thickness, High

High production rate, Low Can produce very large production rate, Low

labor cost, Scrap can be parts, High production rate, labor cost, Little scrap

recycled Low cost generated

Limited to hollow, thin

walled parts with low

Disadvantages degree of asymmetry,

Poor control of wall

Limited to thin walled Limited shape complexity, thickness, Poor surface

parts, High tooling and Limited to thin walled parts, finish, Few material

equipment cost, Long Scrap cannot be recycled, options, High tooling

lead time possible Trimming is required and equipment cost

Applications Housings, containers, Packaging, open containers, Bottles, containers,

caps, fittings panels, cups, signs ducting

Rotational Molding Polymer Extrusion Compression Molding

Flat, Thin-walled:

Thin-walled: Cylindrical, Cylindrical, Thin-walled:

Thin-walled: Cubic, Thin- Cubic, Solid: Cylindrical, Flat, Thin-walled: Cylindrical, Thin-walled:

walled: Complex Solid: Cubic Cubic, Thin-walled: Complex

Area: 0.005 in² - 16 ft²

Envelope: Upto 670 ft³ Diameter: 0.04 - 6.0 in Weight: 0.2 oz - 35 lb

Thermoplastics Thermosets

Thermoplastics (Elastomer, Thermosets) (Composites, Elastomer, Thermoplastics)

16 - 63

Jun-60 (8 - 75) Jun-60

± 0.04 ± 0.04 ± 0.04

(± 0.016) (± 0.01) (± 0.006)

0.1 - 0.25 0.016 - 6.0 0.06 - 0.5

(0.02 - 0.50) (0.0008 - 6.0) (0.03 - 0.8)

100 - 1000 1000 - 200000

(1 - 8000) 10000 - 1000000 (100 - 200000)

Weeks

Days Weeks (Days)

Can produce large parts

with uniform wall Good surface finish, High

thickness, Low tooling production rate, Low labor

and equipment cost, Little cost, Little scrap

scrap generated generated Low labor cost, Little scrap generated

Limited to hollow, thin Limited to uniform cross

walled parts, Cannot form sections, High equipment Limited shape complexity, Few material

fine details, Low cost, Long lead time options, High tooling cost, Long lead time

production rate possible possible

Storage containers

(tanks, vessels, bins), Rods, bars, tubing, sheet,

housings cable, frames Housings, panels, dishes

You might also like

- The Accuracy Under VDG - Merkblatt P690: Length Tolerances (In MM)Document2 pagesThe Accuracy Under VDG - Merkblatt P690: Length Tolerances (In MM)MichaelNo ratings yet

- Material Schedule FormatDocument104 pagesMaterial Schedule FormatJibril Tauheed83% (6)

- Getting Started with Handplanes: How to Choose, Set Up, and Use Planes for Fantastic ResultsFrom EverandGetting Started with Handplanes: How to Choose, Set Up, and Use Planes for Fantastic ResultsRating: 1 out of 5 stars1/5 (1)

- Chapter 4 - Determination of Particle Size of Soils - Astm D422-63 (1990)Document10 pagesChapter 4 - Determination of Particle Size of Soils - Astm D422-63 (1990)Yena Cabalu100% (1)

- Sand & AggregateDocument75 pagesSand & AggregateCBIT CIVIL A1No ratings yet

- Fundamentals of Hydraulic MotorsDocument8 pagesFundamentals of Hydraulic Motorsswap dNo ratings yet

- Particle Characterization: 06 August 2021 10:24Document32 pagesParticle Characterization: 06 August 2021 10:24TUSHIT JHANo ratings yet

- Estimate of StaircaseDocument56 pagesEstimate of StaircaseNikhil67% (3)

- Plastic RecyclingDocument7 pagesPlastic RecyclingGeroldo 'Rollie' L. Querijero0% (1)

- Snap Fit Design ManualDocument24 pagesSnap Fit Design Manualswap dNo ratings yet

- Cabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsFrom EverandCabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsRating: 5 out of 5 stars5/5 (2)

- Estimate of FootingDocument42 pagesEstimate of FootingNikhilNo ratings yet

- Plastic Industry ReportDocument50 pagesPlastic Industry ReportBrownson Succex Junior100% (2)

- The Green Way To BuildDocument4 pagesThe Green Way To BuildnfahmiNo ratings yet

- This Supply Is Composed of Two PartsDocument92 pagesThis Supply Is Composed of Two PartsShyammurugesanNo ratings yet

- Clutch HandbookDocument199 pagesClutch Handbookswap d100% (1)

- Wall PannelsDocument5 pagesWall PannelsGaurav MallaNo ratings yet

- Sound Absorption DataDocument4 pagesSound Absorption DataJeofrey Awingan CodiamatNo ratings yet

- Synthetic PolymersDocument45 pagesSynthetic PolymersIboniks Beponpiks DabondatskiNo ratings yet

- Die CastingDocument43 pagesDie CastingSree Raj83% (12)

- Property Name: Die Casting Centrifugal Casting Investment CastingDocument11 pagesProperty Name: Die Casting Centrifugal Casting Investment CastingjohnblackburnNo ratings yet

- BCE - H2SO4 Tower InternalsDocument3 pagesBCE - H2SO4 Tower InternalsDũng LêNo ratings yet

- Comminution: Dr. Fakhar Ud Din Assistant Professor Quaid-I-Azam University IslamabadDocument32 pagesComminution: Dr. Fakhar Ud Din Assistant Professor Quaid-I-Azam University Islamabadawais khanNo ratings yet

- Tables and Calcs For Sound Absorption CoefficientDocument4 pagesTables and Calcs For Sound Absorption CoefficientSeverina MallariNo ratings yet

- Notes&LectureDocument25 pagesNotes&LectureEl LlacunaNo ratings yet

- TICO Pipe SupportsDocument8 pagesTICO Pipe SupportsEjeantengNo ratings yet

- Material Wall Thickness 7-17-19 FDocument1 pageMaterial Wall Thickness 7-17-19 Fsaurav0000999No ratings yet

- Specs - ABSDocument3 pagesSpecs - ABSBurak KececiNo ratings yet

- Data Teknis Alcoflux KoreaDocument40 pagesData Teknis Alcoflux KoreaDebby saputraNo ratings yet

- Material Schedule FormatDocument104 pagesMaterial Schedule FormatRana ImtiazNo ratings yet

- 2 CE201 Aggregate v5Document27 pages2 CE201 Aggregate v5Adnan ChowdhuryNo ratings yet

- Notes 03Document79 pagesNotes 03jeffmugacha6No ratings yet

- TemperedDocument5 pagesTemperedPutri Desty AmeliaNo ratings yet

- AAC LeichtBric 2020Document10 pagesAAC LeichtBric 2020Jared Josef GomezNo ratings yet

- Aggregates: Nilanjan MitraDocument10 pagesAggregates: Nilanjan MitrassriramiitNo ratings yet

- Unit 3.2 Basic Soil Properties-ISCDocument20 pagesUnit 3.2 Basic Soil Properties-ISCjsyadav.nithNo ratings yet

- Day OneDocument141 pagesDay OneChina AlemayehouNo ratings yet

- ROCKWOOL SLAB CompressedDocument2 pagesROCKWOOL SLAB CompressedGhulam HussainNo ratings yet

- Molycop - Tech Sheet Small Size Balls 003 MCAU - SMLTS1.3 - 290519 PDFDocument3 pagesMolycop - Tech Sheet Small Size Balls 003 MCAU - SMLTS1.3 - 290519 PDFreza razaviNo ratings yet

- Boism PanelDocument24 pagesBoism PanelhipreyashNo ratings yet

- Soil Descriptions - Figure 1 and 2 Revised ISSMFE - Rev. Oct, 2012Document2 pagesSoil Descriptions - Figure 1 and 2 Revised ISSMFE - Rev. Oct, 2012Terobau111No ratings yet

- 01 Gravity TheoryDocument7 pages01 Gravity Theorymuttu swamyNo ratings yet

- MArket Survey GRP 10Document9 pagesMArket Survey GRP 10shraddhaNo ratings yet

- CEMC Module 1Document52 pagesCEMC Module 1Biswajit SamalNo ratings yet

- Item Quantity Our Specifications Sample Image YOUR SPECIFICATIONS (Kindly Indicate) Make and Model Unit Price (Kes) Total Price (Kes)Document2 pagesItem Quantity Our Specifications Sample Image YOUR SPECIFICATIONS (Kindly Indicate) Make and Model Unit Price (Kes) Total Price (Kes)Karti CloudNo ratings yet

- Tissue Preparation For TEM: Sectioning & StainingDocument25 pagesTissue Preparation For TEM: Sectioning & StainingBhaskar GangulyNo ratings yet

- Datasheet GarnetDocument1 pageDatasheet GarnetnnuekNo ratings yet

- Pigments TiO2Document43 pagesPigments TiO2dougNo ratings yet

- GeM Bidding 2906890Document19 pagesGeM Bidding 2906890Hussain ShaikhNo ratings yet

- Brochure QualitexDocument15 pagesBrochure QualitexRajanikant SuryawanshiNo ratings yet

- Rotational MoldingDocument2 pagesRotational MoldingSri NavinNo ratings yet

- Acoustic BasicsDocument14 pagesAcoustic BasicsgirishtiwaskarNo ratings yet

- Qatar Steel - Metal DeckDocument4 pagesQatar Steel - Metal DeckkarthickNo ratings yet

- Essar Steel Rockstar 400Document2 pagesEssar Steel Rockstar 400HimanshuNarayanSinghNo ratings yet

- Herjay R. Sulapas Building Utilities 3 BS Architecture 3 Activity 4 - Feb. 11, 2020Document4 pagesHerjay R. Sulapas Building Utilities 3 BS Architecture 3 Activity 4 - Feb. 11, 2020Herjay Racho SulapasNo ratings yet

- Nyloflex ACE Nyloflex ACE Digital: Sets The Standard in High Quality Flexo PrintingDocument2 pagesNyloflex ACE Nyloflex ACE Digital: Sets The Standard in High Quality Flexo PrintingIoan-Alexandru CsinádyNo ratings yet

- Process Comparison Chart: SLA SLS PJP Cast Urethanes MJP CJPDocument1 pageProcess Comparison Chart: SLA SLS PJP Cast Urethanes MJP CJPnagmech07No ratings yet

- MO - Module 1 t0 3Document90 pagesMO - Module 1 t0 3AABID SHAIKNo ratings yet

- Mo Modules PDFDocument146 pagesMo Modules PDFAABID SHAIKNo ratings yet

- Clean Room Panel - BRDDocument9 pagesClean Room Panel - BRDjaykhor9328No ratings yet

- 1-Designing and Proportioning Normal Concrete MixturesDocument50 pages1-Designing and Proportioning Normal Concrete MixturesMa ThiNo ratings yet

- Ceramic Honeycomb Filter With High Temperature Resistant Porous Ceramic FilterDocument4 pagesCeramic Honeycomb Filter With High Temperature Resistant Porous Ceramic Filtersaraz_01No ratings yet

- BlockDocument4 pagesBlockThangcha KhongsaiNo ratings yet

- JPSBS0006Document2 pagesJPSBS0006manikandanNo ratings yet

- Aggregates: CE 201 Engineering MaterialsDocument17 pagesAggregates: CE 201 Engineering MaterialsMahadi HasanNo ratings yet

- Design GuidelinesDocument21 pagesDesign Guidelinesswap dNo ratings yet

- By Me - Welding1Document21 pagesBy Me - Welding1swap dNo ratings yet

- Weld Symbols On Module Particulate FilterDocument6 pagesWeld Symbols On Module Particulate Filterswap dNo ratings yet

- By Me-WeldingDocument13 pagesBy Me-Weldingswap dNo ratings yet

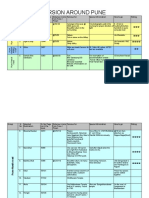

- One Day Excursion Around PuneDocument5 pagesOne Day Excursion Around Puneswap dNo ratings yet

- Dealing With A Difficult BossDocument16 pagesDealing With A Difficult Bossswap dNo ratings yet

- BY ME-TorsionDocument14 pagesBY ME-Torsionswap dNo ratings yet

- Rename: Startpart - Sleeve - DRW and Startpart - Sleeve - Flat - DRW FromDocument9 pagesRename: Startpart - Sleeve - DRW and Startpart - Sleeve - Flat - DRW Fromswap dNo ratings yet

- CMM (Co-Ordinate Measuring Machine)Document7 pagesCMM (Co-Ordinate Measuring Machine)swap dNo ratings yet

- Missing and Isometric Views PPT V1 by KirankumarDocument93 pagesMissing and Isometric Views PPT V1 by Kirankumarswap dNo ratings yet

- Design Guidelines: Obust and Ptimized Esigns ContinuedDocument3 pagesDesign Guidelines: Obust and Ptimized Esigns Continuedswap dNo ratings yet

- Expanding The Limits of SPCDocument23 pagesExpanding The Limits of SPCswap dNo ratings yet

- Equalizing Datum TargetsDocument3 pagesEqualizing Datum Targetsswap dNo ratings yet

- ToleranceDocument26 pagesToleranceswap dNo ratings yet

- DIMENSIONINGDocument26 pagesDIMENSIONINGswap dNo ratings yet

- Theory of Dimensioning: Vijay SrinivasanDocument34 pagesTheory of Dimensioning: Vijay Srinivasanswap dNo ratings yet

- Common Terms and Definitions: Basic DimensionDocument9 pagesCommon Terms and Definitions: Basic Dimensionswap dNo ratings yet

- Dimensioning: We Value Our RelationshipsDocument41 pagesDimensioning: We Value Our Relationshipsswap dNo ratings yet

- DIMENSIONINGDocument26 pagesDIMENSIONINGswap dNo ratings yet

- References: of Assemblies of Rigid Parts. IN: Proceedings of The 1999 IEEE InternationalDocument19 pagesReferences: of Assemblies of Rigid Parts. IN: Proceedings of The 1999 IEEE Internationalswap dNo ratings yet

- Saint-Gobain Sekurit Automotive Glazing Production ProcessesDocument1 pageSaint-Gobain Sekurit Automotive Glazing Production ProcessesAmir BakhshiyanNo ratings yet

- Acousitc Glazing Based On Different PVB Interlayers - Bernd KollDocument5 pagesAcousitc Glazing Based On Different PVB Interlayers - Bernd KollKrzysztof HarasimowiczNo ratings yet

- Aging IadaDocument60 pagesAging IadaJunaidah MohdnoorNo ratings yet

- IdentificationDocument6 pagesIdentificationbhaleshNo ratings yet

- Blow Molding 1Document21 pagesBlow Molding 1prashant_cool_4_u100% (1)

- Elastomer CompareDocument1 pageElastomer ComparetedfdfeNo ratings yet

- MaskaraDocument23 pagesMaskaraRaagul SureshNo ratings yet

- Blow MoldingDocument17 pagesBlow MoldingNilanjana MishraNo ratings yet

- Bullet Proof GlassDocument8 pagesBullet Proof GlassMurad HossenNo ratings yet

- Stock ShapesDocument12 pagesStock ShapesandhikabpNo ratings yet

- MT Casting Part 1Document115 pagesMT Casting Part 1Ahad RazzNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationNileshNo ratings yet

- Lecture 1: Introduction To Composite Materials Lecture 1: Introduction To Composite MaterialsDocument75 pagesLecture 1: Introduction To Composite Materials Lecture 1: Introduction To Composite MaterialsUtsho DasNo ratings yet

- Quality Conrol Test For Plastic ContainersDocument27 pagesQuality Conrol Test For Plastic ContainersNitin KashyapNo ratings yet

- Standard Seal ProfilesDocument3 pagesStandard Seal ProfilesSunny SonawaneNo ratings yet

- Plastics Materials: Properties and ApplicationsDocument7 pagesPlastics Materials: Properties and ApplicationsArnold SigeyNo ratings yet

- Casting DetailsDocument8 pagesCasting DetailsudayraochNo ratings yet

- Pom Delrin 500alDocument5 pagesPom Delrin 500alcountzeroaslNo ratings yet

- BUEFA®-Spezial+products GBDocument5 pagesBUEFA®-Spezial+products GBsearun327No ratings yet

- Public RegisterDocument344 pagesPublic RegisterNuriman JaafarNo ratings yet

- Round Sight Red GlassesDocument1 pageRound Sight Red GlassesjegadishNo ratings yet

- Asia polymer-EV302Document1 pageAsia polymer-EV302ShahryarNo ratings yet

- Chlorine Dioxide Material CompatibilityDocument3 pagesChlorine Dioxide Material CompatibilityMuhammad UmairNo ratings yet

- Marine Plastic DebrisDocument8 pagesMarine Plastic DebrisRAVIKA TA'AWWANA SANDRANo ratings yet

- PVC TrunkingDocument10 pagesPVC TrunkingmartinNo ratings yet

- Bahan Sintetik Dalam Industri: Synthetic Materials in IndustryDocument11 pagesBahan Sintetik Dalam Industri: Synthetic Materials in IndustrySunSuriaNo ratings yet