Professional Documents

Culture Documents

Qualitex Lab Tests Materials

Uploaded by

Rajanikant Suryawanshi0 ratings0% found this document useful (0 votes)

38 views15 pagesThis document provides information about Qualitex Test House Pvt. Ltd., a material testing laboratory located in Pune, India. It lists the types of material testing services offered, including tests for concrete, steel, aggregates, cement, soil and more. It also provides details about the laboratory's accreditations, objectives, management, equipment and customer base. The goal of the laboratory is to provide reliable, professional material testing services to support the construction industry.

Original Description:

Original Title

Brochure Qualitex

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information about Qualitex Test House Pvt. Ltd., a material testing laboratory located in Pune, India. It lists the types of material testing services offered, including tests for concrete, steel, aggregates, cement, soil and more. It also provides details about the laboratory's accreditations, objectives, management, equipment and customer base. The goal of the laboratory is to provide reliable, professional material testing services to support the construction industry.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views15 pagesQualitex Lab Tests Materials

Uploaded by

Rajanikant SuryawanshiThis document provides information about Qualitex Test House Pvt. Ltd., a material testing laboratory located in Pune, India. It lists the types of material testing services offered, including tests for concrete, steel, aggregates, cement, soil and more. It also provides details about the laboratory's accreditations, objectives, management, equipment and customer base. The goal of the laboratory is to provide reliable, professional material testing services to support the construction industry.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 15

QUALITEX

TEST HOUSE PVT. LTD.

• Concrete Mix Designs

• Skid Resistance Test

• Mechanical Testing

• Roughness Testing MATERIAL TESTING

• Chemical Testing LABORATORY &

• Non - Nuclear Density

RESEARCH CENTER

• Non - Destructing Test

• Geo - Technical Investigation

• Steel Testing

You can count on our quality

ABOUT US

Qualitex Test House Pvt.Ltd is a professionally competent, reliable

& trustworthy organiza on based in Pune, engaged in tes ng of all

type of construc on materials since 2020. Laboratory

management system is under scope of accredita on of ISO

9001:2015 and its scope will be expand up ISO/IEC: 17025-2005

We are an independent laboratory with modern equipments and

expert staffs for deliver quality product to customer. We have the

objec ves of providing building material tes ng services to

Industry, Ins tu on, Government and other private agencies. The

laboratory is being run and managed by the technical and

experienced professionals having a wide experience in the various

areas of their specializa on. The laboratory employee’s well-

qualified staffs who are capable enough to test and supervise the

work and related quality func ons. The company has installed the

requisite equipments to meet the requirements.

MAIN OBJECT OF OUR ORGANISATION

v Customer Sa sfac on

v Long Term Rela onship with Customer

v Mo ve to Build Research Center

OUR ORGANISATION HEAD

Rajanikant Suryawanshi (Director)

Mr. Rajanikant Suryawanshi is an expert in construc on quality &

established the laboratory in the year 2020 under the name of

Qualitex Test House Pvt.Ltd.

He was completed his gradua on in Civil Engineer from Walchand

College of engineering, Sangli in year 2001 and started his carrier in

QAQC field from NAHI project “ Golden Quadrilateral “ project. He

had been worked in QAQC department in various Na onal, NH (PWD)

division, MSRDC and PWD project, and key project on NH4, NH7 and

Nagpur – Mumbai Expressway.

He is internal auditor of Quality management system ISO/IEC : 17025-

2005

MATERIAL TESTING FACILITY

▪ Steel :

▪ Wt /meter, UTS, 0.2% proof stress, % Elonga on, Bend & Rebend,

Chemical tests.

▪ Cement :

▪ Standard Consistency, Se ng Time (Ini al and Final), Soundness

(Le-chatlier method), Compressive Strength, Density, Fineness

Test (by Blain air), Chemical tests

▪ Aggregate (COURSE / Fine) :

▪ Sieve Analysis (Grada on), Bulk Density (Fine), Impact Value,

Crushing Value, Water Absorp on,

▪ Specific gravity (Coarse / Fine), Flakiness Index, Chemical tests

▪ Concrete :

▪ Cube : Compressive Strength of Cubes,

▪ Solid Block, AAC Block, CLC Block : Compressive strength, water

absorp on

▪ Paving block : Water absorp on, Compressive strength.

▪ Bricks : Compressive Strength, Water absorp on, Efflorescence

▪ Concrete core: Compressive strength

▪ Concrete beam: Flexural test Concrete mixed design: Conven onal method,

pumpable method, Accelerated method, Mortor design for plaster and brickwork,

flash brick mix design, Pavement Block Mix design

▪ Ceramic Tiles : Dimensional analysis, water absorp on, Modulus of rupture, crazing

resistance, chemical tests

▪ Structural steel :

▪ ensile test (with machining), weigh per meter, bend – rebend test

▪ Soil :

▪ Moisture content, Sp. Gravity, Grain size analysis, FSI, LL & PL, Classifica on of soil, FDT-

by sand replacement, core cu er method, MDD,OMC, Direct shear, tri- axial shear,

CBR(soaked & unsoak), Field CBR

▪ NDT tests :

▪ UPV method, rebound hammer, Half cell poten ometer test, Carbona on test

▪ Bitumen and modified bitumen tests :

▪ So ening point, penetra on test, Flash & fire point, Specific gravity, Duc lity test,

Elas c Recovery, Kinema c & Absolute viscosity

▪ Mas c Asphalt :

▪ Hardness number test, JMF of mas c asphalt

▪ Admixture Tests :

▪ PH, Density, Ash content, Chloride, Solid content

▪ Emulsion Test :

▪ % of Residue on 600 micron, Viscosity at 25 oC & Viscosity at 50oC, Residue by

evapora on, Miscibility in water

▪ GSB, WBM, WMM etc as per MORTH Sec on 400 :

▪ Tes ng of Material, JMF, Mix Grada on, CBR, Field density etc.

▪ Bituminous mixes (BM, DBM, SDBC, BC, Mas c Asphalt etc as per MORTH sec on

500): Tes ng of materials, Job mixed formula, Prepara on of Marshall specimen,

Density, stability & flow value tests, determina on of air voids, void filled with

Bitumen in the mix. Also core specimens are collected from pavement surfaces and

density, grada on & bitumen content are found out.

▪ Our Customers :-

▪ Public Work Department Projects.

▪ NHAI Project.

▪ KK Highway LLP

▪ V.M.Matere Infrastructure (India) Pvt.Ltd.

▪ DHD Infracon Pvt.Ltd

EQUIPMENTS PHOTOES

HUMIDIFIER HUMIDITY CHAMBER THERMOSTAND DLC COMPACTOR

ACCELERATED CURING TANK CONCRETE MIXER LE CHATELIER FLASK BLAINE AIR PERMEABILITY

SIEVE SHAKER TACK COAT PLATE HOT PLATE HYGROMETER

EQUIPMENTS PHOTOES

ACT TANK STRIPPING VALUE NCAT DUCTILITY TEST

ASPHALT DENSITY FLASH & FIRE LOSS ON HEAT THIN FILM OVEN

FLEXURAL TEST CTM MACHINE VISCOMETER ANDERSON PIPETTE

WATERBATH AIV MACHINE LAA MACHINE SOFTENING

KVALUE & FIELDCBR LAB CBR UTM MACHINE MARSH. STABILITY

COOLING BATH NON NUCLEAR DENSITY SKID RESISTANCE

FIFTH WHEEL BUMP INDICATOR

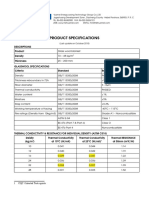

OUR SCOPE OF TESTING

Cement Fineness By Blaine’s Air IS 4031(Part 2) 100 m2/kg to 600 m2/kg

Permeability

Soundness by-Le-Chatelier IS 4031(Part 3) 0.5 mm to 20 mm

Soundness-Autoclave IS 4031(Part 3) 0.01 % to 1.5%

Consistency IS 4031(Part 4) 15 % to 40 %

Ini al Se ng Time IS 4031(Part 5) 10 minutes to 400 minutes

Final Se ng Time IS 4031 (Part 5) 100 minutes to 600 minutes

Compressive Strength IS 4031(Part 6) 2 N/mm2 to 90 N/mm2

Drying Shrinkage IS 4031(Part 10) 0.02 % to 2 %

Density/Specific Gravity IS 4031(Part 11) 1.5 g/cm3 to3.5 g/cm3

Fineness by Dry Sieving IS 4031(Part 1) 0.2 % to 30%

Pozzolana Fineness by Blaine’s Air IS 1727 100 m2/kg to 600 m2/kg

Permeability

Par cles retained on 45µ IS 1727 2 % to 50 %

IS Sieve

Lime Reac vity IS 1727 1 N/mm2 to 20 N/mm2

Compressive Strength IS 1727 50 % to 95 %

Soundness by Autoclave IS 1727 0.01 % to 1.5 %

Specific Gravity/Density IS 1727 1.0 g/cm3 to 3.2 g/cm3

Drying Shrinkage IS 4031(Part 10) 0.01 % to 2 %

Aggregates Crushing Value IS 2386 (Part 4) 1 % to 60%

Impact Value IS 2386 (Part 4) 1 % to 60 %

Abrasion Value IS 2386 (Part 4) 1 % to 70 %

OUR SCOPE OF TESTING

10% Fines value IS 2386 (Part 4) 1 kN to 500 kN

Sieve Analysis IS 2386 (Part 1) 100 mm to 0.150 mm

Specific Gravity IS 2386 (Part 3) 2 to 4

Water Absorp on IS 2386 (Part 3) 0.02 % to 5 %

Bulk Density IS 2386 (Part 3) 1.0 kg/l to 2.2 kg/l

Flakiness Index IS 2386 (Part 1) 1 % to 50 %

Elonga on Index IS 2386 (Part 1) 1 % to 50 %

Bulking of Fine Aggregate IS 2386(Part 3) 1.01 % to 11.1 %

Moisture Content KTRC/BM/SOP-09 0.1 % to 40 %

Issue No. 1

Dated 01.04.2018

Finesse Modulus KTRC/BM/SOP-26 0.8 to 6.0

Issue No. 1

Dated 01.04.2018

Silt content IS 2386 (Part 2) 0.05 % to 40 %

Material Finer than 75 µ/ IS 2386 (Part 1) 0.5 % to 6 %

Silt Content

Stone Polish Value IS 2386(Part 4) 20 to 120

Concrete Compressive Strength IS 516 1 N/mm2 to 84 N/mm2

Flexural/Transverse Strength IS 516 0.5 N/mm2 to 30 N/mm2

Permeability of Concrete IS 3085 1 m/sec to 50x10-12 m/sec

Water Absorp on IS 2185(Part 1) 0.1 % to 10%

Hollow & Solid Dimension IS 2185(Part 1) 80 mm to 800 mm

Concrete Block IS 2185(Part 2)

Water Absorp on IS 2185(Part 1) 0.1 % to 10 %

IS2185(Part 2)

Block Density IS 2185(Part 1) 1000 kg/m3 to 2000 kg/m3

IS 2185(Part 2)

OUR SCOPE OF TESTING

AAC Block Drying Shrinkage S 2185(Part 1) 0.01 % to 0.2 %

IS 2185(Part 2)

Moisture Movement IS 2185(Part 1) 0.01 % to 0.2 %

IS 2185(Part 2)

Compressive Strength IS 2185(Part 1) 2 N/mm2 to 30 N/mm2

IS 2185(Part 2)

Dimension IS 2185(Part 3) 80 mm to 800 mm

Block Density IS 2185(Part 3) 300 kg/m3 to 1100 kg/m3

IS 6441(Part 1)

Drying Shrinkage IS 2185(Part 3) 0.01 % to 0.2%

IS 6441(Part 2)

Compressive Strength IS 2185(Part 3) 1 N/mm2 to 20 N/mm2

IS 6441(Part 5)

Bricks Dimension & Dimensional IS 1077 20 mm to 5000 mm

Tolerance

Dimension IS 12894 20 mm to 5000 mm

-Pulverized Fuel Ash-Lime Bricks IS 1077 20 mm to 5000 mm

-Common Burnt Clay Building Bricks IS 13757 20 mm to 5000 mm

-Burnt Clay Fly Ash Building Bricks

Drying Shrinkage IS 4139 0.01 % to 1 %

Compressive Strength IS 3495(Part 1) 2 N/mm2 to 30 N/mm2

Water Absorp on IS 3495 (Part 2) 1 % to 30%

Efflorescence IS 3495 (Part 3) Qualita ve

Paver Block Visual Inspec on IS 15658 Qualita ve

Dimension, Area-Plan, Wearing Face IS 15658 40 mm to 500 mm

Thickness of wearing layer

Squareness, Length, Width

Water Absorp on IS 15658 0.1 % to 10 %

Compressive Strength IS 15658 20 N/mm2 to 100 N/mm2

Flexural Strength IS 15658 1 N/mm2to 15 N/mm2

OUR SCOPE OF TESTING

Freeze-Thaw Durability IS 15658 Qualita ve

Tensile Spli ng Strength IS 15658 1 N/mm2 to 30 N/mm2

Concrete Tiles Dimensions IS 1237 10 mm to 600 mm

IS 13801

IS 10646

IS 8968

Flatness IS 1237 0.1 mm to 1 mm

IS13801

IS 10646

IS 8968

Perpendicularity IS 1237 0.01% to 2 %

IS 13801

IS 10646

IS 8968

Straightness IS 1237 0.01% to 1.5 %

IS13801

IS 10646

IS 8968

Water Absorp on IS 1237 1% to 15 %

IS 13801

IS 10646

IS 8968

IS 1237

Wet Transverse Strength IS 13801 1 N/mm2 to 10 N/mm2

IS 10646

IS 8968

Natural Building Dimensions IS 1130 Upto 3000 mm

Stones

Hardness MOHS Scale 1 Mohs to 10 Mohs

Specific Gravity/Density IS 1122 1.0 to 4.0

IS 1124

Water Absorp on IS 1124 0.1 % to 10%

Compressive Strength IS 1121(Part 1) Upto 1500 kg/cm2

Point Load Strength IS 9143 5 kg/cm2 to 800 kg/cm2

Transverse Strength IS 1121(Part 2) 1 MPa to 35 Mpa

IS 13030

Moisture Content 0.01 % to 10 %

OUR SCOPE OF TESTING

Porosity IS 1124

Dry Density IS 13030

SOIL & ROCK

Grain Size Analysis

Soil IS 2720(Part 4)

Moisture content IS 2720(Part 2)

Specific Gravity IS 2720(Part 3)

Free Swell Index S 2720(Part 40)

Liquid Limit IS 2720(Part 5)

Plas c Limit IS 2720(Part 5)

Shrinkage Limit IS 2720(Part 6)

CBR Value IS 2720(Part 16)

Heavy compac on : Maximum IS 2720(Part 8)

Dry Density

Heavy Compac on : Op mum

Moisture Content

Light compac on: Maximum Dry IS 2720(Part 7)

Density

Light Compac on: Op mum

Moisture Content

UCS of soil IS 2720 (Part 10)

Density IS 2720 (Part 14)

High Strength Weight IS 1786s

IS 16651

Deformed KTRC/MECH/SOP/01

Steel Bar Issue No. 03

Date: 01.04.2018

Re-bend Test IS 1786

Pull out Test IS 16651

IS2770(Part 1)

SOIL AND ROCK

Clays and Soils PH IS 2720 (Part 26)

OUR SCOPE OF TESTING

SOIL AND ROCK Sulphate as So4 IS 2720 (Part 27) 0.005 % to 5 %

Clays and Soils Chloride as Cl IS 2720 (Part 27) 0.005 % to 5 %

Calcium Carbonate as CaCO3 IS 2720 (Part 23) 0.05 % to 80 %

Nitrogen as N IS 14684 0.002 % to 10 %

Organic Ma er IS 2720 (Part 22) 0.05 % to 2.5 %

Silica as SiO2 IS 2720 (Part 25) 0.1 % to 50 %

Ground And pH IS 3025 (Part 11) 1 to 13

Surface Water

Sulphate as So4 IS 3025 (Part 24) 5 mg/l to 2000 mg/l

Chloride IS 3025 (Part 32) 5 mg/l to 2000 mg/l

Suspended ma er IS 3025 (Part 17) 5 mg/l to 3000 mg/l

Organic ma er IS 3025 (Part 18) 5 mg/l to 1000 mg/l

Inorganic ma er/

Filterable Residue/ IS 3025 (Part 16) 5 mg/l to 2000 mg/l

Total Dissolved solids

Salts IS 3025 (Part 32) 5 mg/l to 2000 mg/l

Acidity as NaOH IS 3025 (Part 22) 0.2 ml to 5 ml

Alkalinity as H2SO4 IS 3025 (Part 23) 0.2 ml to 2 5 ml

Total Residue IS 3025 (Part 15) 5 mg/l to 10000 mg/l

(Total Solid-Dissolved Solids &

Suspended)

Total Hardness IS 3025 (Part 21) 2 mg/l to 10000 mg/l

Sulphites as So3 IS 3025 (Part 28) 5 mg/l to 500 mg/l

Bitumen & So ening Point IS 1205 30 °C to 80 °C

Bitumen Mix

Penetra on IS 1203 30 DIV. to 150 DIV.

Duc lity IS 1208 10 cm to 100 cm

Marshal Stability/Flow ASTM D1559 500 kg to 1800 kg

Bitumen Binder Content ASTM D2172 0.1 mm to 6.0mm

Bitumen & Bitu Solubility in Trichloroethylene IS 1216 1 % to 25%

minous Material

OUR SCOPE OF TESTING

Kinema c Viscosity IS 1206 (Part 3)

Mineral Ma er IS 1217

(Ash Content)

Loss on Hea ng IS 1212

Water Content IS 1211 0.01 % to 10 %

Specific Gravity IS 1202 0.7 to 2.0

Vola le ma er Content 0.1% to 75 %

IS 1220

Ma er Soluble in toluene IS 1215 0.1% to 30 %

Bitumen IS 8887

Emulsion Residue on 600 Micron Sieve 0.01% to 1.0 %

Viscosity by Saybolt Furol IS 3117 1 Saybolt to 500 Saybolt

Viscometer

Coagula on IS 8887 Qualita ve

Storage Stability 0.1 % to 10 %

Miscibility with water Qualita ve

Residue by Evapora on 0.05 % to 90 %

Water Content 0.05 % to 25 %

Par cle Charge Qualita ve

(Ca onic/Anionic)

Qualitex Test House Pvt. Ltd.

Gate No. 62, Sector No. 14, Boradewadi, Moshi - 412105 (MH) India.

83299 54636 | 95527 89113

info@qualitexhouse.in

www.qualitexhouse.in

Thank You......

You might also like

- TC-6174 Beacon Infralab India PVT LTDDocument15 pagesTC-6174 Beacon Infralab India PVT LTDankit hardahaNo ratings yet

- T 1169Document8 pagesT 1169ßålå ĮíNo ratings yet

- Annexure 2 Form 72 (Scope) Annexure IDocument4 pagesAnnexure 2 Form 72 (Scope) Annexure IVaghasiyaBipinNo ratings yet

- NAM Road Project Technical SpecificationDocument6 pagesNAM Road Project Technical SpecificationikreddyNo ratings yet

- Technical Note Tensar TRIAX TX160Document2 pagesTechnical Note Tensar TRIAX TX160Dicky WahyuNo ratings yet

- Form 72 Recommended Scope of Accreditation: (For Testing Laboratories)Document14 pagesForm 72 Recommended Scope of Accreditation: (For Testing Laboratories)Kushal SharmaNo ratings yet

- Material Testing As Per Is CodesDocument2 pagesMaterial Testing As Per Is Codesadityaratna gangji100% (1)

- Grdjev01i120050 PDFDocument6 pagesGrdjev01i120050 PDFRafael Obusan IINo ratings yet

- Stainless Steel 1.4401 Material Data SheetDocument3 pagesStainless Steel 1.4401 Material Data SheetLuis LoayzaNo ratings yet

- Stainless Steel 1.4404 Material Data SheetDocument3 pagesStainless Steel 1.4404 Material Data SheetDilipSinghNo ratings yet

- Stainless Steel 1.4404 316lDocument3 pagesStainless Steel 1.4404 316lDilipSinghNo ratings yet

- An Experimental Investigation On HPC Using Basalt Rock FiberDocument19 pagesAn Experimental Investigation On HPC Using Basalt Rock FiberIJRASETPublicationsNo ratings yet

- Ultrasonic Machining - WikipediaDocument23 pagesUltrasonic Machining - WikipediaChalla varun KumarNo ratings yet

- Construction & Quality Control of Flexible Pavement: Dr. N.K.S. Pundhir Senior Principal Scientist E-MailDocument84 pagesConstruction & Quality Control of Flexible Pavement: Dr. N.K.S. Pundhir Senior Principal Scientist E-MailMohd Ali100% (1)

- An Experimental Investigation On Steel Fiber Reinforced Concrete With Quarry Dust As A Partial Replacement of Fine AggregateDocument5 pagesAn Experimental Investigation On Steel Fiber Reinforced Concrete With Quarry Dust As A Partial Replacement of Fine AggregateIJRASETPublicationsNo ratings yet

- Peng Mat 2Document47 pagesPeng Mat 2Herry Eci MuhammadNo ratings yet

- Huamei Spec Sheets - 2018Document1 pageHuamei Spec Sheets - 2018Phan LongNo ratings yet

- Strip Seal Expansion JointDocument13 pagesStrip Seal Expansion JointsmithNo ratings yet

- Dense Bitumen Macadam (DBM) LayerDocument12 pagesDense Bitumen Macadam (DBM) LayerPathankot MandiNo ratings yet

- Influence of Deep Cryogenic TreatmentDocument14 pagesInfluence of Deep Cryogenic TreatmentBojan PodgornikNo ratings yet

- An Experimental Study On GFRC by Partial Replacement of Coarse Aggregate With Pumice Stone and Cement With Fly AshDocument9 pagesAn Experimental Study On GFRC by Partial Replacement of Coarse Aggregate With Pumice Stone and Cement With Fly Ashshivanand hippargaNo ratings yet

- Concrete Practice B&FDocument259 pagesConcrete Practice B&Fvijay100% (1)

- 1304..mix Design m25 Dalmia Cement... Mes JorhatDocument16 pages1304..mix Design m25 Dalmia Cement... Mes JorhatAbhishek KumarNo ratings yet

- Report 3523 M40 08 12 2019Document20 pagesReport 3523 M40 08 12 2019Imran KhanNo ratings yet

- Introduction to Properties and Applications of UHMWPEDocument3 pagesIntroduction to Properties and Applications of UHMWPEFatima NusserNo ratings yet

- 718 Stangard Egf (NV)Document5 pages718 Stangard Egf (NV)Sandeep gangulyNo ratings yet

- REACTIVE POWDER CONCRETE - DocxwDocument8 pagesREACTIVE POWDER CONCRETE - Docxwsalman kNo ratings yet

- Tribology Activities at DMRL: Defence Metallurgical Research Laboratory Hyderabad-500058, IndiaDocument17 pagesTribology Activities at DMRL: Defence Metallurgical Research Laboratory Hyderabad-500058, IndiaSwati Lalit ThakurNo ratings yet

- Concrete Technology (CE205) Concrete Technology Laboratory Report Academic Year (2021-2022)Document18 pagesConcrete Technology (CE205) Concrete Technology Laboratory Report Academic Year (2021-2022)Rahand KawaNo ratings yet

- Rilsan Fine Powders Physical PropertiesDocument2 pagesRilsan Fine Powders Physical Propertiesธนาชัย เต็งจิรธนาภาNo ratings yet

- Ceramite T: Bauxite and Silicon Carbide Based Trowellable RefractoryDocument2 pagesCeramite T: Bauxite and Silicon Carbide Based Trowellable RefractorySHRINIVASAN GTKNo ratings yet

- 1 4571 PDFDocument7 pages1 4571 PDFSiis IngenieriaNo ratings yet

- Maraging Steels For Aero Space ApplicationDocument33 pagesMaraging Steels For Aero Space ApplicationKalikota Prasad100% (1)

- SCC properties with bagasse ashDocument27 pagesSCC properties with bagasse ashHegdeVenugopalNo ratings yet

- Civil EngineerDocument26 pagesCivil Engineerchrreddy3No ratings yet

- Data Sheet Strenx 650 MCDocument3 pagesData Sheet Strenx 650 MCRoger BandeiraNo ratings yet

- Data Teknis Hive Honeycomb KoreaDocument70 pagesData Teknis Hive Honeycomb KoreailhamhanafyNo ratings yet

- Brochure TIMREX Graphites For Carbon Brushes and Carbon PartsDocument12 pagesBrochure TIMREX Graphites For Carbon Brushes and Carbon PartsvarundodhiaNo ratings yet

- M25 Mix Design 100 Recycled AggregateDocument9 pagesM25 Mix Design 100 Recycled AggregateRakesh ReddyNo ratings yet

- Department of Structural Engineering, Faculty of Engineering, M.B.M. Engineering College, Jai Narain Vyas University, JodhpurDocument10 pagesDepartment of Structural Engineering, Faculty of Engineering, M.B.M. Engineering College, Jai Narain Vyas University, JodhpurAjayvidyanand SharmaNo ratings yet

- TC-6616 Scope of Testing-Venus Testing and Research LaboratoryDocument19 pagesTC-6616 Scope of Testing-Venus Testing and Research Laboratoryankit hardahaNo ratings yet

- AAC LeichtBric 2020Document10 pagesAAC LeichtBric 2020Jared Josef GomezNo ratings yet

- 06 82 00 GRP LINING TO THE CONCRETE TANK OkDocument3 pages06 82 00 GRP LINING TO THE CONCRETE TANK OkshajbabyNo ratings yet

- 2205 Technical Data Sheet: Chemistry Mechanical PropertiesDocument6 pages2205 Technical Data Sheet: Chemistry Mechanical PropertiesJandri JacobNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- SSRG-IJCE - Thin White Topping RoadDocument5 pagesSSRG-IJCE - Thin White Topping RoadVinay RajNo ratings yet

- Dharmendra Kumar Roll No 7259363Document27 pagesDharmendra Kumar Roll No 7259363Neeraj MehtaNo ratings yet

- Finite Element Analysis On Friction Plate of A Wet Multiple Clutch by Using Various Friction MaterialsDocument8 pagesFinite Element Analysis On Friction Plate of A Wet Multiple Clutch by Using Various Friction MaterialsAnonymous kw8Yrp0R5rNo ratings yet

- Replacement of Fine Aggregate With Sawdust: Abishek Narayanan Hemnath. G, Sampaul K & Anne MaryDocument5 pagesReplacement of Fine Aggregate With Sawdust: Abishek Narayanan Hemnath. G, Sampaul K & Anne MaryramakrishnaNo ratings yet

- Rockboard 40Document2 pagesRockboard 40zaidg9876553No ratings yet

- Element Warren A2LA 0038 01 Mechanical PDFDocument21 pagesElement Warren A2LA 0038 01 Mechanical PDFAndre CasteloNo ratings yet

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- Bhavannarao@yahoo - Co.in: D.V .Bhavanna Rao Retired R&B Chief Engineer E-Mail: Phone: +919494440202Document192 pagesBhavannarao@yahoo - Co.in: D.V .Bhavanna Rao Retired R&B Chief Engineer E-Mail: Phone: +919494440202saibal deyNo ratings yet

- z3T - Dental Cobalt Chrome Alloy (EOS CC SP2)Document1 pagez3T - Dental Cobalt Chrome Alloy (EOS CC SP2)martinm3tNo ratings yet

- Material Product Data Sheet Polyester Powder: Quick FactsDocument3 pagesMaterial Product Data Sheet Polyester Powder: Quick FactsSaggam NarasimharajuNo ratings yet

- Concrete LabDocument97 pagesConcrete LabSiva NatNo ratings yet

- Electrode Booklet F Web 100Document1 pageElectrode Booklet F Web 100satnamNo ratings yet

- TDS RovalDocument4 pagesTDS RovalSyahril Fira86No ratings yet

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- BS 00812 114 1989 2011Document14 pagesBS 00812 114 1989 2011KEVIN100% (1)

- BS 00812 114 1989 2011Document14 pagesBS 00812 114 1989 2011KEVIN100% (1)

- EN 1317 Part 1Document23 pagesEN 1317 Part 1Rajanikant SuryawanshiNo ratings yet

- Disclosure To Promote The Right To InformationDocument20 pagesDisclosure To Promote The Right To InformationMythra VarunNo ratings yet

- Inflammatory Bowel DiseaseDocument27 pagesInflammatory Bowel DiseaseMihai VladescuNo ratings yet

- A Simple and Rapid Method For Colorimetric Determination of Histamine in Fish FleshDocument8 pagesA Simple and Rapid Method For Colorimetric Determination of Histamine in Fish Fleshmuratout3447No ratings yet

- ReptileDocument4 pagesReptileDratonius 101No ratings yet

- Overview of Systemic Constellation WorkDocument15 pagesOverview of Systemic Constellation WorkKaren Carnabucci100% (2)

- Long Test MILDocument3 pagesLong Test MILBern PabNo ratings yet

- Work Procedure For Temporary Fence GateDocument19 pagesWork Procedure For Temporary Fence GateAlbert OquindoNo ratings yet

- Optik 25Document6 pagesOptik 25z.umul9031No ratings yet

- Integrated Solutions For Oil & GasDocument52 pagesIntegrated Solutions For Oil & Gasmehrzad1373No ratings yet

- Robway SLI ManualDocument135 pagesRobway SLI ManualBatagor H. Isan100% (1)

- INDUSTRIAL TRAINING FOR UPSTREAM DOWNSTREAM PROCESS AND SERVICESDocument14 pagesINDUSTRIAL TRAINING FOR UPSTREAM DOWNSTREAM PROCESS AND SERVICESMshamil ShaamryNo ratings yet

- KalasarpaDosha RemedyDocument28 pagesKalasarpaDosha RemedyAnita Kadavergu100% (1)

- HM1 Bibliography Advancement QuestionsDocument11 pagesHM1 Bibliography Advancement QuestionsBrian ImberNo ratings yet

- STDs in Sangamon CountyDocument15 pagesSTDs in Sangamon CountyNewsTeam20No ratings yet

- New Flowers - FlowerMedDocument5 pagesNew Flowers - FlowerMedAndré CamargoNo ratings yet

- Intro To Psychology Crash Course Psychology 1Document3 pagesIntro To Psychology Crash Course Psychology 1Hahaha YeahNo ratings yet

- 3 Reliability and ValidityDocument16 pages3 Reliability and ValiditySyawal Anizam100% (1)

- Analiza PESTDocument16 pagesAnaliza PESTIoana Ciobanu100% (1)

- The Sinew (Tendino-Muscular) Meridians - Jade Institute ClassesDocument10 pagesThe Sinew (Tendino-Muscular) Meridians - Jade Institute ClassespanisajNo ratings yet

- Birth Control GuideDocument4 pagesBirth Control GuideNessaNo ratings yet

- EER WorksheetDocument3 pagesEER WorksheetMichael PoddubnyNo ratings yet

- The Importance of Earth Loop ImpedanceDocument4 pagesThe Importance of Earth Loop ImpedanceKarim Amer100% (1)

- PSC NKDocument44 pagesPSC NKDito Aprian100% (2)

- Environmental engineering guide for small boat basinsDocument40 pagesEnvironmental engineering guide for small boat basinsmote34No ratings yet

- SM SM830206-00Document134 pagesSM SM830206-00stiven lopezNo ratings yet

- 2021 Prosthetics Lower Limb Catalogue - enDocument524 pages2021 Prosthetics Lower Limb Catalogue - enBianca Denisse Arreola MascarenoNo ratings yet

- Math ProjectDocument18 pagesMath ProjectChar LotteNo ratings yet

- Standard Test Method For Hydrogen Sulfide and Mercaptan Sulfur in Natural Gas (Cadmium Sulfate Lodometric Titration Method) 'Document4 pagesStandard Test Method For Hydrogen Sulfide and Mercaptan Sulfur in Natural Gas (Cadmium Sulfate Lodometric Titration Method) 'Ray Emmanuelle CorsigaNo ratings yet

- Case Study 2 MNTDocument11 pagesCase Study 2 MNTapi-242547654No ratings yet

- Guide To The Cambodian Labour Law (En)Document73 pagesGuide To The Cambodian Labour Law (En)ហួត ភីរុណNo ratings yet

- Student Admission FormDocument2 pagesStudent Admission FormOmmsai co2011No ratings yet