Professional Documents

Culture Documents

Saint-Gobain Sekurit Automotive Glazing Production Processes

Uploaded by

Amir BakhshiyanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saint-Gobain Sekurit Automotive Glazing Production Processes

Uploaded by

Amir BakhshiyanCopyright:

Available Formats

AUTOMOTIVE GLASS MANUFACTURING DID YOU KNOW?

ZOOM ON

AT SAINT-GOBAIN SEKURIT

The water is filtered and reused in order to

reduce consumption as much as possible.

The glass scraps generated are partly

3 Forming 4 Lamination

recycled in the production of flat glass.

Laminated windshields Backlites, roofs and sidelites After washing and

The two sheets of glass are put The glass is heated and formed

5

drying, a cover of

on a skeleton (pairing) and then before being tempered. polymer interlayer is

heated in a furnace at 600°C. Tempering (rapid cooling of the inserted between the

Forming is done by gravity and glass by means of cold air) two sheets of glass Autoclaving

pressing if necessary. The glass is guarantees the mechanical in a clean The glass system

then cooled and separated. resistance of the glass as well room. is degassed at 140°C

as its fragmentation in case for a definitive adhesion

of breakage. of the glass and

the interlayer.

2

Printing

6

An enamel border

is printed on the glass,

as well as the logo

and the glazing typology. Final inspection

Different connectors are

soldered on the backlites.

All glass units are inspected

and packed in metal packaging.

G

NTIN

RI

1

P

ED DS

N AT HIEL

MI S

Cutting LA IND

W G

The glass is cut,

the edges are grinded NTIN

P RI S

and drilled. It is then washed

L ITE

and dried. CK

BA FS

ED O

E AT RO

H N D

A

DE

LITE

S

7

SI Pre-assembly of

added values

Various components

(rain&light sensors, profiles...)

are glued on the glazing according

to the customer's requirements.

You might also like

- Glass ManufacturingDocument23 pagesGlass ManufacturingPiyush VermaNo ratings yet

- Glass: A Delicate, Brittle But Tough MaterialDocument44 pagesGlass: A Delicate, Brittle But Tough MaterialAmlan Kar100% (1)

- GLASS AND GLAZING MATERIALS GUIDEDocument11 pagesGLASS AND GLAZING MATERIALS GUIDEBackupFilesNo ratings yet

- GlassDocument21 pagesGlassArif IzanyNo ratings yet

- MODULE 8 - Glass and Glass FractureDocument11 pagesMODULE 8 - Glass and Glass FractureCarlo CapunoNo ratings yet

- Lecture 09-10 - Division 08 - Division 09Document126 pagesLecture 09-10 - Division 08 - Division 09Via AnapiNo ratings yet

- ReportDocument32 pagesReportVipin Kumar SharmaNo ratings yet

- Forensic Analysis of GlassDocument16 pagesForensic Analysis of GlassDiogo Agostinho da CostaNo ratings yet

- Glass Manufacturing and PropertiesDocument4 pagesGlass Manufacturing and PropertiesBhavesh Dilip ChanchlaniNo ratings yet

- AWA As1288-2006 Glass GuideDocument96 pagesAWA As1288-2006 Glass GuideElias ChahineNo ratings yet

- Glassmaking Materials and ProcessesDocument30 pagesGlassmaking Materials and ProcessesJanice Melissa RayNo ratings yet

- GLASSDocument8 pagesGLASS1DC20AT033 Kaarthik N.No ratings yet

- BT1 - 5.0 Glass and GlazingDocument34 pagesBT1 - 5.0 Glass and GlazingCharles VernaldNo ratings yet

- GlassDocument17 pagesGlassDhaval JalalparaNo ratings yet

- GlassDocument14 pagesGlassJithendra Jagadish22No ratings yet

- Analysis of Glass - Glass EvidenceDocument40 pagesAnalysis of Glass - Glass EvidenceHihelloooNo ratings yet

- Report GlassDocument39 pagesReport GlassAlisha KhanNo ratings yet

- ABEGLASS Factory Catalogue Highlights Innovative Glass SolutionsDocument7 pagesABEGLASS Factory Catalogue Highlights Innovative Glass SolutionsDean Hadi WardanaNo ratings yet

- Introductiontopackagingdesign: DoublefunctionDocument5 pagesIntroductiontopackagingdesign: Doublefunctionquencylyn siarotNo ratings yet

- Part 2 GlassDocument13 pagesPart 2 GlassLenard UsonNo ratings yet

- 07Document25 pages07supriyo1970No ratings yet

- Ocus Technopolis glass structure case studyDocument3 pagesOcus Technopolis glass structure case studyShubhi KushwahaNo ratings yet

- Glass: Rachana Sansad-School of Interior Design F.Y.G.D. - 2019-2020Document6 pagesGlass: Rachana Sansad-School of Interior Design F.Y.G.D. - 2019-2020Neeraj GuptaNo ratings yet

- Lesson 06Document11 pagesLesson 06Lia CambangayNo ratings yet

- Glass WorkingDocument11 pagesGlass WorkingPedro Lumbreras100% (1)

- Building Materials - GlassDocument21 pagesBuilding Materials - GlassB.Shyamala0% (1)

- Glass As A Building MaterialDocument21 pagesGlass As A Building MaterialNikhil GoyalNo ratings yet

- Manufacturing Process Stages Melting Forming Cooling FinishingDocument6 pagesManufacturing Process Stages Melting Forming Cooling FinishingAida SuhanumNo ratings yet

- Types of Glass and Production TechniquesDocument76 pagesTypes of Glass and Production TechniquesJerome DacasinNo ratings yet

- A Bright Future For Glass-CeramicDocument10 pagesA Bright Future For Glass-CeramicNghia DuongNo ratings yet

- GlassDocument33 pagesGlassNeerajaNo ratings yet

- Saint Gobain Glass Protection PDFDocument20 pagesSaint Gobain Glass Protection PDFAnonymous t83HjAvXNo ratings yet

- Glass Fabrication Techniques and Properties for Architectural ApplicationsDocument6 pagesGlass Fabrication Techniques and Properties for Architectural ApplicationsJahnavi JayashankarNo ratings yet

- Ceramics Building Construction MaterialDocument7 pagesCeramics Building Construction MaterialAmina AbdiNo ratings yet

- Fun With Float GlassDocument17 pagesFun With Float GlassbahramrezaeiNo ratings yet

- Sun GuardDocument32 pagesSun GuardRachman SyamsudinNo ratings yet

- Building Glass UsesDocument21 pagesBuilding Glass UsesShreeya ShahNo ratings yet

- Glass FiberDocument21 pagesGlass FiberWasi Bangash100% (1)

- AWA AS1288 Glass GuideDocument96 pagesAWA AS1288 Glass GuideChristian Bar100% (2)

- Vitro-Td-138 Het GlassDocument8 pagesVitro-Td-138 Het GlassEdgar ValverdeNo ratings yet

- Glass - As A Building MaterialDocument26 pagesGlass - As A Building Materialghar n makaan promotersNo ratings yet

- Glass 2023 Part 1Document47 pagesGlass 2023 Part 1Shiv kumar ThakurNo ratings yet

- GlassDocument59 pagesGlassKhadija Kathawala90% (10)

- Material, Techniques AND Processess: Group - 1Document18 pagesMaterial, Techniques AND Processess: Group - 1Kavya SharmaNo ratings yet

- 5.2 Glass Regulations PDFDocument2 pages5.2 Glass Regulations PDFDanny WhiteNo ratings yet

- AWA AS1288 Glass GuideDocument96 pagesAWA AS1288 Glass GuideGayan WeerasekeraNo ratings yet

- Glass Types and Manufacturing ProcessDocument18 pagesGlass Types and Manufacturing ProcesszaraNo ratings yet

- Glass 2018 PDFDocument33 pagesGlass 2018 PDFTZShengNo ratings yet

- Ceramics NotesDocument57 pagesCeramics Noteseugin cebertNo ratings yet

- Material GlassDocument8 pagesMaterial GlassRanu AgarwalNo ratings yet

- MMBC Mod1 GlasssssDocument44 pagesMMBC Mod1 GlasssssNiveditha BalachandranNo ratings yet

- Unit V - Glass: Qualities & FeaturesDocument9 pagesUnit V - Glass: Qualities & FeaturesDeepthiNo ratings yet

- Glass:: Ce 6401/Cm/ Unit V - Modern MaterialsDocument24 pagesGlass:: Ce 6401/Cm/ Unit V - Modern Materialsyaro oruvanNo ratings yet

- Float Glass Manufacturing PlantDocument4 pagesFloat Glass Manufacturing PlantOgre MagiNo ratings yet

- Glass 1 ContinueDocument5 pagesGlass 1 ContinueFortiter FysproNo ratings yet

- 1 GlassDocument45 pages1 GlassIkhwan BudimanNo ratings yet

- Glass PDFDocument39 pagesGlass PDFHiren SavaliyaNo ratings yet

- Glass: Building MaterialsDocument25 pagesGlass: Building MaterialsSamhithaNo ratings yet

- Replace GlassDocument3 pagesReplace GlasstaxmacNo ratings yet

- ASME_RAM_1_2013_Reliability,_AvailabilityDocument24 pagesASME_RAM_1_2013_Reliability,_AvailabilityAmir BakhshiyanNo ratings yet

- 1-s2.0-S2352146519302790-mainDocument7 pages1-s2.0-S2352146519302790-mainAmir BakhshiyanNo ratings yet

- BS en 10293-2015Document24 pagesBS en 10293-2015Azima Zalfa AuliyakNo ratings yet

- Down FileDocument52 pagesDown FileMuhammet YildizNo ratings yet

- Air Brakes For TrainsDocument28 pagesAir Brakes For Trainsmakili8No ratings yet

- bds.en.13260.2010Document41 pagesbds.en.13260.2010Amir BakhshiyanNo ratings yet

- (Springer Series in Reliability Engineering) Adam Jabłoński, Marek Jabłoński - Digital Safety in Railway Transport―Aspects of Management and Technology-Springer (2022)Document153 pages(Springer Series in Reliability Engineering) Adam Jabłoński, Marek Jabłoński - Digital Safety in Railway Transport―Aspects of Management and Technology-Springer (2022)Amir BakhshiyanNo ratings yet

- BS en 12663-1-2010+a1-2014 - (2022-08-25 - 11-42-41 Am)Document44 pagesBS en 12663-1-2010+a1-2014 - (2022-08-25 - 11-42-41 Am)AEE Design MCF100% (1)

- HRN EN ISO 5817_2007Document40 pagesHRN EN ISO 5817_2007Amir BakhshiyanNo ratings yet

- FCS ManualDocument40 pagesFCS ManualAmir BakhshiyanNo ratings yet

- Gs-Hydro Hydraulic Piping Standard Handbook Revision 1Document200 pagesGs-Hydro Hydraulic Piping Standard Handbook Revision 1Haris StavrouNo ratings yet

- Festo-Proportional Hydraulics Basic LavelDocument126 pagesFesto-Proportional Hydraulics Basic Lavelapi-3808778100% (11)

- Saint-Gobain Sekurit Automotive Glazing Production ProcessesDocument1 pageSaint-Gobain Sekurit Automotive Glazing Production ProcessesAmir BakhshiyanNo ratings yet

- Astm D5907 13Document4 pagesAstm D5907 13Amir BakhshiyanNo ratings yet

- Cutting and Packing in Production and DistributionDocument255 pagesCutting and Packing in Production and DistributionAmir BakhshiyanNo ratings yet

- Annex A Financial Offer Form - Bills of Quantities For Base and Rubhal NakivaleDocument8 pagesAnnex A Financial Offer Form - Bills of Quantities For Base and Rubhal NakivaleEMINAT PRINCENo ratings yet

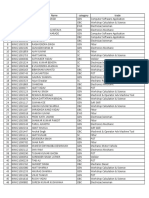

- SID List PantnagarDocument12 pagesSID List Pantnagarankitece01No ratings yet

- Single Flute Gundrills: BotekDocument40 pagesSingle Flute Gundrills: BotekDANIEL MANRIQUEZ FAVILANo ratings yet

- Chemistry For Engineering MaterialsDocument16 pagesChemistry For Engineering Materialsmyxyn.myguel.medinaNo ratings yet

- Specification For Precast Concrete WorksDocument39 pagesSpecification For Precast Concrete Worksm.nurhishammNo ratings yet

- JC Shortlisted For PraticalsDocument8 pagesJC Shortlisted For Praticalsvivek dongareNo ratings yet

- Lathe, Milling Machine, Computer Numerical Control (CNC) and RobotsDocument25 pagesLathe, Milling Machine, Computer Numerical Control (CNC) and RobotsLAKSH RAMASWAMYNo ratings yet

- Industeel wear resistant steel and mold steel pricesDocument2 pagesIndusteel wear resistant steel and mold steel pricesMustafa Mert SAMLINo ratings yet

- 2019 A Review On Resistance Spot Welding of Steel MaterialDocument13 pages2019 A Review On Resistance Spot Welding of Steel Materialguravshubham7777No ratings yet

- NDT Testing For Steel ConstructionDocument3 pagesNDT Testing For Steel Constructionfalcon arabNo ratings yet

- ADIP RefineryDocument2 pagesADIP RefineryVenkatesh Kumar RamanujamNo ratings yet

- F-Number Reference ChartDocument2 pagesF-Number Reference ChartRichard BennardoNo ratings yet

- Ball Screws Splines Cten PDFDocument186 pagesBall Screws Splines Cten PDFJulián GarcíaNo ratings yet

- GEV 2022 Company Presentation & Application - ENGDocument33 pagesGEV 2022 Company Presentation & Application - ENGSunil R HasabnisNo ratings yet

- Weld Defects EngineeringDocument29 pagesWeld Defects EngineeringAnatolie6No ratings yet

- Seminar: Subject: Transmission and Distribution Subject Code: Ee3401 Assignment - 2Document18 pagesSeminar: Subject: Transmission and Distribution Subject Code: Ee3401 Assignment - 2Ashwin srihariNo ratings yet

- Development of A Main Landing Gear Attachment Fitting Using Composite Material and Resin Transfer MouldingDocument19 pagesDevelopment of A Main Landing Gear Attachment Fitting Using Composite Material and Resin Transfer Mouldingmuhammad haidar razan hilmiNo ratings yet

- MSDS - ASMACO RTV GasketDocument2 pagesMSDS - ASMACO RTV GasketadminNo ratings yet

- Protan Mining Brochure - Ventilation DuctingDocument12 pagesProtan Mining Brochure - Ventilation DuctingTom HightNo ratings yet

- Introduction To WeavingDocument17 pagesIntroduction To WeavingJahaziNo ratings yet

- CISCRYL-DS50 (Duct Sealant)Document2 pagesCISCRYL-DS50 (Duct Sealant)ajeet soniNo ratings yet

- Filtech2022 Exhibitor ListDocument18 pagesFiltech2022 Exhibitor ListLoup ALPNo ratings yet

- SMA Jack Interface DrawingDocument1 pageSMA Jack Interface DrawingJose MatutesNo ratings yet

- Palm Karnel Shell Ash As A Partial Replacement For Cement in The Production of Paving BlocksDocument6 pagesPalm Karnel Shell Ash As A Partial Replacement For Cement in The Production of Paving BlocksFolorunsho AyomideNo ratings yet

- Report Project g03 - Motorcycle Clutch HubDocument4 pagesReport Project g03 - Motorcycle Clutch HubMUHAMMAD FARIZ ZAINUDDINNo ratings yet

- Competence Overview - New Candidates - BMSDocument19 pagesCompetence Overview - New Candidates - BMSJose DiazNo ratings yet

- Fosroc Product GuideDocument194 pagesFosroc Product GuideinbarajNo ratings yet

- Rest Pfas Appendix g2 31096 enDocument150 pagesRest Pfas Appendix g2 31096 endasfNo ratings yet

- Part 3 Chapter2Document33 pagesPart 3 Chapter2Mahmoud AlnaserNo ratings yet

- Mold Design Review Checklist: Part InformationDocument5 pagesMold Design Review Checklist: Part InformationAbdul BasitNo ratings yet