Professional Documents

Culture Documents

Tube Settler Calculation PDF

Tube Settler Calculation PDF

Uploaded by

STP VermifiltrationCopyright:

Available Formats

You might also like

- MBR Process Design Calculations-S.IDocument33 pagesMBR Process Design Calculations-S.ISindhuja Raghunathan67% (3)

- Tube Settler - CalculationDocument3 pagesTube Settler - CalculationJai Kumar88% (16)

- SBR Design CalculationsDocument26 pagesSBR Design Calculationsn_zeinoun78% (9)

- Process Calculations - 1 MLD - SBRDocument164 pagesProcess Calculations - 1 MLD - SBRRAJ100% (8)

- Lamella Clarifier Design 100CMDDocument7 pagesLamella Clarifier Design 100CMDHenry SP100% (3)

- Degasser Tower CalculationDocument1 pageDegasser Tower Calculationbalaji krishnan100% (2)

- Anoxic Tank Design & Aeration Requirement-Lanka Hospitals: Wastewater Characteristics Parameter Concentration (G/M)Document4 pagesAnoxic Tank Design & Aeration Requirement-Lanka Hospitals: Wastewater Characteristics Parameter Concentration (G/M)Vaish Kan100% (4)

- Spreadsheet For Activated Sludge ProcessDocument31 pagesSpreadsheet For Activated Sludge ProcessHemantk8731100% (8)

- STP Design 50KLDDocument3 pagesSTP Design 50KLDmurugaraj92% (13)

- Design Spreadsheet Calculation For SBR Sequential Biological ReactorDocument12 pagesDesign Spreadsheet Calculation For SBR Sequential Biological ReactorHenry SPNo ratings yet

- Sequencing Batch Reactor (SBR) Design Calculations - S.I. UnitsDocument37 pagesSequencing Batch Reactor (SBR) Design Calculations - S.I. UnitsOn Gnios Ingeniería60% (5)

- 50kld STP MBBRDocument15 pages50kld STP MBBRSanjay50% (4)

- Process Design For 1.70 IFAS STPDocument18 pagesProcess Design For 1.70 IFAS STPGenesis International0% (1)

- Clariflocculator DesignDocument8 pagesClariflocculator DesignsubratapapiyaNo ratings yet

- 20 KLD STP - Offer - MBBRDocument10 pages20 KLD STP - Offer - MBBRHarish Kumar MahavarNo ratings yet

- Dairy Etp CalculationsDocument7 pagesDairy Etp CalculationsSagar Apte100% (2)

- Design of Flash MixerDocument1 pageDesign of Flash Mixersumitanurag100% (3)

- MBBR 1.0 MLDDocument8 pagesMBBR 1.0 MLDkiran raghukiran100% (2)

- MBBR OM Manual-250Document42 pagesMBBR OM Manual-250senthil2002100% (3)

- Rapid Sand Filter Design Example PDFDocument2 pagesRapid Sand Filter Design Example PDFWONG TS95% (21)

- Kashmir Conflict: Dispute Between India and Pakistan Kashmir IssueDocument11 pagesKashmir Conflict: Dispute Between India and Pakistan Kashmir IssueAhmad CssNo ratings yet

- Enviraj MBBR CalculatorDocument3 pagesEnviraj MBBR Calculatorankur100% (2)

- Design 2 MLDDocument9 pagesDesign 2 MLDANIL KUMAR H CNo ratings yet

- Spreadsheets For Secondary Clarifier DesignDocument3 pagesSpreadsheets For Secondary Clarifier DesignNiong David100% (1)

- Example DAF Design Key Parameters CalculationDocument4 pagesExample DAF Design Key Parameters CalculationNoureddine MerahNo ratings yet

- MBR DesignDocument52 pagesMBR Designpragatheesk100% (2)

- Addendum Centrifugal Fans ZAvblue 00704309 en enDocument178 pagesAddendum Centrifugal Fans ZAvblue 00704309 en enalbsalves8645No ratings yet

- Tube Settler DesignDocument4 pagesTube Settler DesignKrishna Winx100% (1)

- Design of 100KLD STP Using MBBR TechnoloDocument9 pagesDesign of 100KLD STP Using MBBR TechnoloSTP VermifiltrationNo ratings yet

- ENVE 302 Environmental Engineering Unit Processes: Assist. Prof. Bilge Alpaslan KocamemiDocument48 pagesENVE 302 Environmental Engineering Unit Processes: Assist. Prof. Bilge Alpaslan KocamemiJestin Raj100% (1)

- Screen and SBR v1.0Document3 pagesScreen and SBR v1.0Richard Magadia Jr0% (1)

- SBR DesignDocument2 pagesSBR DesignHRK65100% (6)

- Hollow Fibre MBR - 30 MLDDocument8 pagesHollow Fibre MBR - 30 MLDakshay salviNo ratings yet

- SBR - 6 MLDDocument38 pagesSBR - 6 MLDsharan kommi100% (1)

- 40 KLD MBR QuoteDocument15 pages40 KLD MBR QuoteV Narasimha RajuNo ratings yet

- Supply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Document24 pagesSupply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Saif Ahmed Nabil100% (1)

- Conventional STP 400 KLDDocument15 pagesConventional STP 400 KLDK&K ConsultantsNo ratings yet

- STP Design (With MBBR)Document9 pagesSTP Design (With MBBR)Sagar Patel.100% (1)

- Air Requirement For SBR STPDocument2 pagesAir Requirement For SBR STPBS support100% (1)

- Design of Rapid Gravity Filter Design Criteria: (Rapid Sand Filter)Document4 pagesDesign of Rapid Gravity Filter Design Criteria: (Rapid Sand Filter)dpkNo ratings yet

- Design of WTP and STPDocument14 pagesDesign of WTP and STPVenu Ch100% (2)

- Sand Filter Vs Disc FilterDocument1 pageSand Filter Vs Disc FilterKailash ThapliyalNo ratings yet

- Design Calculation of 61kld STPDocument4 pagesDesign Calculation of 61kld STPAminur Rahman100% (2)

- Activated Sسمعيلثludge Calculation SheetDocument14 pagesActivated Sسمعيلثludge Calculation SheetYasser Fathy Aly100% (1)

- Clariflocculator CalculationsDocument4 pagesClariflocculator Calculationssanu80% (5)

- Clarifier Sizing SpreadsheetDocument1 pageClarifier Sizing Spreadsheetarvin4dNo ratings yet

- SBR Calculation - FullDocument8 pagesSBR Calculation - FullNguyễn Tiến NghĩaNo ratings yet

- Process Calculations 1 MLD SBRDocument168 pagesProcess Calculations 1 MLD SBRAngelo EndozoNo ratings yet

- Techno-Commercial Offer For 5 KLD ETP CUM 12 STP .Document10 pagesTechno-Commercial Offer For 5 KLD ETP CUM 12 STP .Anshika RaiNo ratings yet

- Design of UasbDocument2 pagesDesign of UasbEdward MagangaNo ratings yet

- STP Design CalculationDocument8 pagesSTP Design CalculationRajasekaran Gunasekaran0% (1)

- SBR Plant Design PDFDocument8 pagesSBR Plant Design PDFvishuNo ratings yet

- Design Basis Report - STP 90 KLDDocument11 pagesDesign Basis Report - STP 90 KLDvishu talapeNo ratings yet

- MBR Design SheetDocument9 pagesMBR Design SheetVenkatesh SivaramanNo ratings yet

- Symrpl 15 KLD STPDocument15 pagesSymrpl 15 KLD STPDnyaneshwar Dattatraya Phadatare100% (4)

- 20 KLD STP Upgreation PROPOSAL-GMCPLDocument7 pages20 KLD STP Upgreation PROPOSAL-GMCPLTech Monger100% (1)

- Annex 31 Tool Design Extended AerationDocument5 pagesAnnex 31 Tool Design Extended AerationAnonymous QiMB2lBCJLNo ratings yet

- Annex 31 Tool Design Extended AerationDocument5 pagesAnnex 31 Tool Design Extended AerationKalyca Nazhifa SalwaNo ratings yet

- Design of Slow Sand Filter FinalDocument11 pagesDesign of Slow Sand Filter FinalHemant SonawadekarNo ratings yet

- Civil FormulaDocument80 pagesCivil FormulaBharat SharmaNo ratings yet

- Annex 30 Tool - Design - Waste Stabilization PondsDocument8 pagesAnnex 30 Tool - Design - Waste Stabilization Pondsmurkeking100% (1)

- Silo CalcDocument3 pagesSilo CalcJai KumarNo ratings yet

- 28-Guidelines For Drinking-Water Quality, Vol. 1, Recommendations (3rd Edition) - WHO-9241546387-Wo PDFDocument541 pages28-Guidelines For Drinking-Water Quality, Vol. 1, Recommendations (3rd Edition) - WHO-9241546387-Wo PDFJai KumarNo ratings yet

- TAC Norms FP ManualDocument113 pagesTAC Norms FP ManualJai KumarNo ratings yet

- 8 Pavilion Case Study - NocheDocument18 pages8 Pavilion Case Study - NocheJerick NocheNo ratings yet

- Classical Topics, Innovative Approaches, New Concerns: I. ZygonDocument11 pagesClassical Topics, Innovative Approaches, New Concerns: I. ZygonJose Lozano GotorNo ratings yet

- General Chemistry: Dr. Rabih O. Al-Kaysi Ext: 47247 Email: Kaysir@ksau-Hs - Edu.saDocument34 pagesGeneral Chemistry: Dr. Rabih O. Al-Kaysi Ext: 47247 Email: Kaysir@ksau-Hs - Edu.saapi-19824406100% (1)

- The Student WebDocument191 pagesThe Student WebgansNo ratings yet

- Snake BiteDocument104 pagesSnake Bitenehanirmal0% (1)

- Soal Pas Big 8 2020-2021Document8 pagesSoal Pas Big 8 2020-2021Maratus SolikhahNo ratings yet

- Project Assignment DAMDocument2 pagesProject Assignment DAMPrimax DiagnosticsNo ratings yet

- 01MAT101121903-B: (2019 Scheme)Document3 pages01MAT101121903-B: (2019 Scheme)manjunath nNo ratings yet

- Week 2 Practicum ReflectionDocument2 pagesWeek 2 Practicum Reflectionapi-287584590No ratings yet

- AQA Physics P7 Radioactivity Past Paper QuestionsDocument23 pagesAQA Physics P7 Radioactivity Past Paper Questionsis7112No ratings yet

- Unix DumpsDocument21 pagesUnix DumpsGopakumar GopinathanNo ratings yet

- 29 Prepare, Load and Operate Ultrasonic Cleaner.Document13 pages29 Prepare, Load and Operate Ultrasonic Cleaner.dr_nkhan3415No ratings yet

- The Purchase Funnel: Definition & IntroductionDocument8 pagesThe Purchase Funnel: Definition & IntroductionDivya AhujaNo ratings yet

- Crystal Structure Notes: 1. Explain The Following Terms BrieflyDocument12 pagesCrystal Structure Notes: 1. Explain The Following Terms BrieflyNitesh ShahNo ratings yet

- J C Díaz-GuillénDocument14 pagesJ C Díaz-GuillénKArenNo ratings yet

- AIS Chapter 1 Question and Answer (Set E)Document3 pagesAIS Chapter 1 Question and Answer (Set E)John Carlos DoringoNo ratings yet

- Archaeology 101+Document5 pagesArchaeology 101+Trilogi IndonesiaNo ratings yet

- Cross Match TechniqueDocument5 pagesCross Match TechniqueANDREW MWITI100% (3)

- Hindu Catholic DialogueDocument1 pageHindu Catholic Dialoguemin4chuNo ratings yet

- Foundation of Digital GovermentDocument17 pagesFoundation of Digital Govermentizal005No ratings yet

- Chemistry For Dummies-71-82Document12 pagesChemistry For Dummies-71-82Rahmi maydayeniNo ratings yet

- Coastal Managemtn Holderness 2Document5 pagesCoastal Managemtn Holderness 2Grand OverallNo ratings yet

- Determination of The Aromatic Content and Polynuclear Aromatic Content of Diesel Fuels and Aviation Turbine Fuels by Supercritical Fluid ChromatographyDocument6 pagesDetermination of The Aromatic Content and Polynuclear Aromatic Content of Diesel Fuels and Aviation Turbine Fuels by Supercritical Fluid ChromatographyahmedNo ratings yet

- Biometric Authentication - Person Identification Using Iris RecognitionDocument5 pagesBiometric Authentication - Person Identification Using Iris RecognitionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Definition of LiberalizationDocument5 pagesDefinition of LiberalizationFiles DownloadNo ratings yet

- Protestant ReformationDocument5 pagesProtestant Reformationgreens rovaNo ratings yet

- Simple and Compound Sentences QuizDocument1 pageSimple and Compound Sentences Quizfrancis.mrs75% (8)

- Appendix ADocument3 pagesAppendix ANaeemo IraqiNo ratings yet

Tube Settler Calculation PDF

Tube Settler Calculation PDF

Uploaded by

STP VermifiltrationOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tube Settler Calculation PDF

Tube Settler Calculation PDF

Uploaded by

STP VermifiltrationCopyright:

Available Formats

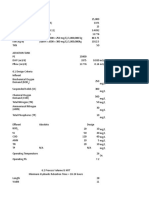

PROCESS DESIGN CALCULATIONS

FOR TUBE SETTLER IN WATER TREATMENT PLANT

5.0 (C) TUBE SETTLER

Raw water Flow = 100 Mld

Recycle Flow = 5 Mld

Design Flow = 100+5

= 105 Mld

Number of units provided = 4 nos.

So, Design flow per Tube Settler = 105/4

= 26.250 Mld

= 26250.000 m³/d

= 1093.750 m³/h

Shape of unit = Square

Length/ Breadth of Tube Settler provided = 11.40 m

Tube Pack Data:

Shape = Hexagonal - Chevron

Cross sectional area = 120 x 44 mm x mm

Hydraulic radius = 0.015 m

Settling area : 60° Slope = 11 m²/m³

Settling area : 55° Slope = 13 m²/m³

Vertical Space between Tubes = 0.044 m

Angle of inclination = 55 °

Select, Settling rate on the horizontal projected area of Tube Pack = 1.00 m³/m²/h

Apply the probability factor,as recommended by theTube Pack Vendor = 0.70

Revised Settling rate on the horizontal projected area of Tube Pack = 1* 0.7

= 0.70 m³/m²/h

Kinematic viscosity of water at 30°C = 0.00000080 m²/s

Design temperature of water = 20.00 °C

Kinematic viscosity of water at 20°C = 0.000001003 m²/s

Correction Factor for Settling rate, w.r.t. Kinematic viscosity = 0.0000008/0.000001003

= 0.798

Corrected Settling rate = 0.7*0.798

= 0.558 m³/m²/h

Selected Settling rate on the horizontal projected area of Tube Pack = 0.700 m³/m²/h

Selected vertical depth of Tube Pack = 1.000

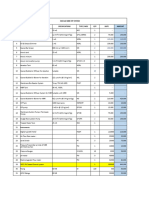

Plan area of the Tube Settler = 11.4*11.4

= 129.960 m²

Volume of Tube Pack provided = 129.96*1

= 129.960 m³

Loss of volume of Tube Pack, on account of inclination = 11.4*1 *(1/TAN55°)

= 7.982 m³

Effective volume of Tube Pack = 129.96-7.982

= 121.978 m³

Settling area of Tube Pack, corresponding to the inclination, = 121.978*13

based on the effective volume of Tube Pack = 1585.709 m²

Actual Settling rate on the horizontal projected area of Tube Pack = 1093.75 / 1585.709

0.690 m³/m²/h

< 0.70 m³/m²/h

Hence O.K.

Check for the performance of the Tube Settler:

Sedimentation takes place in the length following the transition length and it will retain all particles

with a settling velocity less than Vs.

Vs = V. k / { [sin θ + (Ls/d)cos θ ] }

Where,

Vs = Settling velocity, m³/m²/h

Ls = Settling length of Tube

d = depth of water in a Tube at right angle to the direction of flow, m

θ = angle of inclination of Tube Pack to the horizontal

k = a coefficient

= 1.33 for Hexagonal Tubes

Schiller formula to calculate transition length:

Lt = 0.0288 NR .D

Where,

Lt = Transition length

V = Average velocity of flow in the Tubes, m³/h.m²

= U / sin θ

U = Average upward velocity, m³/h.m²

= Surface loading rate of the Settling Tank

= Rate of flow / Tube entrance area

ν = Kinematic viscosity of water, m²/s = 0.00000086 m²/s

NR = Reynolds Number

Ls = L - Lt

Where,

L = Length of Tube

Ls = Settling length of Tube

Plan area of the Tube Settler = 11.4*11.4

= 129.96 m²

The tube entrance area is reduced due to the thickness of the tube pack and also due to the supporting

structure provided.

The support width of minimum 60 mm is recommended at a centre-to-centre distance of 1000 mm, in a

square grid.

No. of supporting angles, lengthwise @ 1m c-c spacing = (11.4/1)+1

= 12.40 nos.

Say = 13.00 nos.

No. of supporting angles, breadthwise @ 1m c-c spacing = (11.4/1)+1

= 12.40 nos.

Say = 13.00 nos.

Width of supporting angle of standard size, provided = 65.000 mm

= 0.065 m

Plan area lost by the supporting angles of width 65 mm = (11.4*13*0.065)+(11.4*13*0.065

-(13*13*0.065*0.065)

= 0.768 m²

Plan area lost by the thickness of the Tube Pack = 3.00 % of plan area

= 3%*129.96

= 3.899 m²

Total area of obstruction for flow through Tube Pack = 0.768+3.899

= 4.667 m²

Tube entrance area = 129.96-4.667

= 125.293 m²

Average upward velocity, U = 1093.75/125.293

= 8.730 m/h

Average velocity of flow in the Tubes, V = U / sin θ

= 8.73 / sin 55°

= 10.657 m/h

= 0.003 m/s

Hydraulic radius, R ( = CSA / Wetted perimeter) = 0.01500 m

Equivalent diameter, D ( = 4 R) = 4*0.015

= 0.060 m

Reynolds Number, NR = VR

ν

= 0.003*0.015/0.00000086

= 51.632

Transition length of Tube = 0.0288*NR*D

= 0.0288*51.632*0.06

= 0.089 m

Settling length of Tube, Ls = L - Lt

= 1-0.089

= 0.911 m

Relative settling length of tube = Ls/d = 0.911/0.044

= 20.700

Coefficient k for Hexagonal shaped Tubes = 1.33

Vs = V. k / { [sin θ + (Ls/d)cos θ ] }

= 10.657*1.33/((sin55°+20.7*cos55°))

= 1.117 m³/m²/h

> 0.690

Hence O.K.

Unit Size

Length / Breadth of Tube Settler provided = 11.40 m

Flow per Tube Settler = 1093.75 m³/h

= 0.3038 m³/s

Approx.liquid height above the top of the tube pack = 0.65 m

Vertical Height of Plates = 1.00 m

Horizontal velocity in the clarification shall be 0.02 to 0.03 m/s.

Horizontal Velocity in the clarification zone selected = 0.025 m/s

C/S area of clarification zone required below Tube Pack = 1093.75 / 3600 / 0.025

= 12.15 m²

Height of the Clarification zone required = 12.15 / 11.4

= 1.066 m

Depth of the sludge compression zone provided = 1.00 m

Space provided for sludge scrapper = 0.30 m

Side water depth of unit required = 0.65 + 1 + 1.066 + 1 + 0.3

= 4.016 m

SWD provided = 4.05 m

Hence O.K.

Provide V-Notch weir plates on the inner side of overflow launders.

Recommended weir loading for Tube Settler = 250 m³/m/d

Length of weir to be provided = 26250/250

= 105.000 m

No.of overflow launders to be provided = 105/(2*(11.4-(1/TAN 55°)

= 4.907

Say = 6.000 nos.

Approx.length of weir provided in each Tube Settler = 6*2*((11.4)-(1/TAN55°))

= 128.398 m

Discharge rate at design flow over the weir = 1093.75 / 128.398

= 8.52 m³/m/h

= 204.44 m³/m/d

< 250.00 m³/m/d

Hence O.K.

Design Hydraulic flow per Tube Settler = 30.000 Mld

= 30000.000 m³/d

Discharge rate at design Hydraulic flow over the weir = 30000 / 128.398

= 233.65 m³/m/d

Size: 4 Nos. Tube Settlers, each of 11.4 m x 11.4 m x 4.05 m SWD

You might also like

- MBR Process Design Calculations-S.IDocument33 pagesMBR Process Design Calculations-S.ISindhuja Raghunathan67% (3)

- Tube Settler - CalculationDocument3 pagesTube Settler - CalculationJai Kumar88% (16)

- SBR Design CalculationsDocument26 pagesSBR Design Calculationsn_zeinoun78% (9)

- Process Calculations - 1 MLD - SBRDocument164 pagesProcess Calculations - 1 MLD - SBRRAJ100% (8)

- Lamella Clarifier Design 100CMDDocument7 pagesLamella Clarifier Design 100CMDHenry SP100% (3)

- Degasser Tower CalculationDocument1 pageDegasser Tower Calculationbalaji krishnan100% (2)

- Anoxic Tank Design & Aeration Requirement-Lanka Hospitals: Wastewater Characteristics Parameter Concentration (G/M)Document4 pagesAnoxic Tank Design & Aeration Requirement-Lanka Hospitals: Wastewater Characteristics Parameter Concentration (G/M)Vaish Kan100% (4)

- Spreadsheet For Activated Sludge ProcessDocument31 pagesSpreadsheet For Activated Sludge ProcessHemantk8731100% (8)

- STP Design 50KLDDocument3 pagesSTP Design 50KLDmurugaraj92% (13)

- Design Spreadsheet Calculation For SBR Sequential Biological ReactorDocument12 pagesDesign Spreadsheet Calculation For SBR Sequential Biological ReactorHenry SPNo ratings yet

- Sequencing Batch Reactor (SBR) Design Calculations - S.I. UnitsDocument37 pagesSequencing Batch Reactor (SBR) Design Calculations - S.I. UnitsOn Gnios Ingeniería60% (5)

- 50kld STP MBBRDocument15 pages50kld STP MBBRSanjay50% (4)

- Process Design For 1.70 IFAS STPDocument18 pagesProcess Design For 1.70 IFAS STPGenesis International0% (1)

- Clariflocculator DesignDocument8 pagesClariflocculator DesignsubratapapiyaNo ratings yet

- 20 KLD STP - Offer - MBBRDocument10 pages20 KLD STP - Offer - MBBRHarish Kumar MahavarNo ratings yet

- Dairy Etp CalculationsDocument7 pagesDairy Etp CalculationsSagar Apte100% (2)

- Design of Flash MixerDocument1 pageDesign of Flash Mixersumitanurag100% (3)

- MBBR 1.0 MLDDocument8 pagesMBBR 1.0 MLDkiran raghukiran100% (2)

- MBBR OM Manual-250Document42 pagesMBBR OM Manual-250senthil2002100% (3)

- Rapid Sand Filter Design Example PDFDocument2 pagesRapid Sand Filter Design Example PDFWONG TS95% (21)

- Kashmir Conflict: Dispute Between India and Pakistan Kashmir IssueDocument11 pagesKashmir Conflict: Dispute Between India and Pakistan Kashmir IssueAhmad CssNo ratings yet

- Enviraj MBBR CalculatorDocument3 pagesEnviraj MBBR Calculatorankur100% (2)

- Design 2 MLDDocument9 pagesDesign 2 MLDANIL KUMAR H CNo ratings yet

- Spreadsheets For Secondary Clarifier DesignDocument3 pagesSpreadsheets For Secondary Clarifier DesignNiong David100% (1)

- Example DAF Design Key Parameters CalculationDocument4 pagesExample DAF Design Key Parameters CalculationNoureddine MerahNo ratings yet

- MBR DesignDocument52 pagesMBR Designpragatheesk100% (2)

- Addendum Centrifugal Fans ZAvblue 00704309 en enDocument178 pagesAddendum Centrifugal Fans ZAvblue 00704309 en enalbsalves8645No ratings yet

- Tube Settler DesignDocument4 pagesTube Settler DesignKrishna Winx100% (1)

- Design of 100KLD STP Using MBBR TechnoloDocument9 pagesDesign of 100KLD STP Using MBBR TechnoloSTP VermifiltrationNo ratings yet

- ENVE 302 Environmental Engineering Unit Processes: Assist. Prof. Bilge Alpaslan KocamemiDocument48 pagesENVE 302 Environmental Engineering Unit Processes: Assist. Prof. Bilge Alpaslan KocamemiJestin Raj100% (1)

- Screen and SBR v1.0Document3 pagesScreen and SBR v1.0Richard Magadia Jr0% (1)

- SBR DesignDocument2 pagesSBR DesignHRK65100% (6)

- Hollow Fibre MBR - 30 MLDDocument8 pagesHollow Fibre MBR - 30 MLDakshay salviNo ratings yet

- SBR - 6 MLDDocument38 pagesSBR - 6 MLDsharan kommi100% (1)

- 40 KLD MBR QuoteDocument15 pages40 KLD MBR QuoteV Narasimha RajuNo ratings yet

- Supply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Document24 pagesSupply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Saif Ahmed Nabil100% (1)

- Conventional STP 400 KLDDocument15 pagesConventional STP 400 KLDK&K ConsultantsNo ratings yet

- STP Design (With MBBR)Document9 pagesSTP Design (With MBBR)Sagar Patel.100% (1)

- Air Requirement For SBR STPDocument2 pagesAir Requirement For SBR STPBS support100% (1)

- Design of Rapid Gravity Filter Design Criteria: (Rapid Sand Filter)Document4 pagesDesign of Rapid Gravity Filter Design Criteria: (Rapid Sand Filter)dpkNo ratings yet

- Design of WTP and STPDocument14 pagesDesign of WTP and STPVenu Ch100% (2)

- Sand Filter Vs Disc FilterDocument1 pageSand Filter Vs Disc FilterKailash ThapliyalNo ratings yet

- Design Calculation of 61kld STPDocument4 pagesDesign Calculation of 61kld STPAminur Rahman100% (2)

- Activated Sسمعيلثludge Calculation SheetDocument14 pagesActivated Sسمعيلثludge Calculation SheetYasser Fathy Aly100% (1)

- Clariflocculator CalculationsDocument4 pagesClariflocculator Calculationssanu80% (5)

- Clarifier Sizing SpreadsheetDocument1 pageClarifier Sizing Spreadsheetarvin4dNo ratings yet

- SBR Calculation - FullDocument8 pagesSBR Calculation - FullNguyễn Tiến NghĩaNo ratings yet

- Process Calculations 1 MLD SBRDocument168 pagesProcess Calculations 1 MLD SBRAngelo EndozoNo ratings yet

- Techno-Commercial Offer For 5 KLD ETP CUM 12 STP .Document10 pagesTechno-Commercial Offer For 5 KLD ETP CUM 12 STP .Anshika RaiNo ratings yet

- Design of UasbDocument2 pagesDesign of UasbEdward MagangaNo ratings yet

- STP Design CalculationDocument8 pagesSTP Design CalculationRajasekaran Gunasekaran0% (1)

- SBR Plant Design PDFDocument8 pagesSBR Plant Design PDFvishuNo ratings yet

- Design Basis Report - STP 90 KLDDocument11 pagesDesign Basis Report - STP 90 KLDvishu talapeNo ratings yet

- MBR Design SheetDocument9 pagesMBR Design SheetVenkatesh SivaramanNo ratings yet

- Symrpl 15 KLD STPDocument15 pagesSymrpl 15 KLD STPDnyaneshwar Dattatraya Phadatare100% (4)

- 20 KLD STP Upgreation PROPOSAL-GMCPLDocument7 pages20 KLD STP Upgreation PROPOSAL-GMCPLTech Monger100% (1)

- Annex 31 Tool Design Extended AerationDocument5 pagesAnnex 31 Tool Design Extended AerationAnonymous QiMB2lBCJLNo ratings yet

- Annex 31 Tool Design Extended AerationDocument5 pagesAnnex 31 Tool Design Extended AerationKalyca Nazhifa SalwaNo ratings yet

- Design of Slow Sand Filter FinalDocument11 pagesDesign of Slow Sand Filter FinalHemant SonawadekarNo ratings yet

- Civil FormulaDocument80 pagesCivil FormulaBharat SharmaNo ratings yet

- Annex 30 Tool - Design - Waste Stabilization PondsDocument8 pagesAnnex 30 Tool - Design - Waste Stabilization Pondsmurkeking100% (1)

- Silo CalcDocument3 pagesSilo CalcJai KumarNo ratings yet

- 28-Guidelines For Drinking-Water Quality, Vol. 1, Recommendations (3rd Edition) - WHO-9241546387-Wo PDFDocument541 pages28-Guidelines For Drinking-Water Quality, Vol. 1, Recommendations (3rd Edition) - WHO-9241546387-Wo PDFJai KumarNo ratings yet

- TAC Norms FP ManualDocument113 pagesTAC Norms FP ManualJai KumarNo ratings yet

- 8 Pavilion Case Study - NocheDocument18 pages8 Pavilion Case Study - NocheJerick NocheNo ratings yet

- Classical Topics, Innovative Approaches, New Concerns: I. ZygonDocument11 pagesClassical Topics, Innovative Approaches, New Concerns: I. ZygonJose Lozano GotorNo ratings yet

- General Chemistry: Dr. Rabih O. Al-Kaysi Ext: 47247 Email: Kaysir@ksau-Hs - Edu.saDocument34 pagesGeneral Chemistry: Dr. Rabih O. Al-Kaysi Ext: 47247 Email: Kaysir@ksau-Hs - Edu.saapi-19824406100% (1)

- The Student WebDocument191 pagesThe Student WebgansNo ratings yet

- Snake BiteDocument104 pagesSnake Bitenehanirmal0% (1)

- Soal Pas Big 8 2020-2021Document8 pagesSoal Pas Big 8 2020-2021Maratus SolikhahNo ratings yet

- Project Assignment DAMDocument2 pagesProject Assignment DAMPrimax DiagnosticsNo ratings yet

- 01MAT101121903-B: (2019 Scheme)Document3 pages01MAT101121903-B: (2019 Scheme)manjunath nNo ratings yet

- Week 2 Practicum ReflectionDocument2 pagesWeek 2 Practicum Reflectionapi-287584590No ratings yet

- AQA Physics P7 Radioactivity Past Paper QuestionsDocument23 pagesAQA Physics P7 Radioactivity Past Paper Questionsis7112No ratings yet

- Unix DumpsDocument21 pagesUnix DumpsGopakumar GopinathanNo ratings yet

- 29 Prepare, Load and Operate Ultrasonic Cleaner.Document13 pages29 Prepare, Load and Operate Ultrasonic Cleaner.dr_nkhan3415No ratings yet

- The Purchase Funnel: Definition & IntroductionDocument8 pagesThe Purchase Funnel: Definition & IntroductionDivya AhujaNo ratings yet

- Crystal Structure Notes: 1. Explain The Following Terms BrieflyDocument12 pagesCrystal Structure Notes: 1. Explain The Following Terms BrieflyNitesh ShahNo ratings yet

- J C Díaz-GuillénDocument14 pagesJ C Díaz-GuillénKArenNo ratings yet

- AIS Chapter 1 Question and Answer (Set E)Document3 pagesAIS Chapter 1 Question and Answer (Set E)John Carlos DoringoNo ratings yet

- Archaeology 101+Document5 pagesArchaeology 101+Trilogi IndonesiaNo ratings yet

- Cross Match TechniqueDocument5 pagesCross Match TechniqueANDREW MWITI100% (3)

- Hindu Catholic DialogueDocument1 pageHindu Catholic Dialoguemin4chuNo ratings yet

- Foundation of Digital GovermentDocument17 pagesFoundation of Digital Govermentizal005No ratings yet

- Chemistry For Dummies-71-82Document12 pagesChemistry For Dummies-71-82Rahmi maydayeniNo ratings yet

- Coastal Managemtn Holderness 2Document5 pagesCoastal Managemtn Holderness 2Grand OverallNo ratings yet

- Determination of The Aromatic Content and Polynuclear Aromatic Content of Diesel Fuels and Aviation Turbine Fuels by Supercritical Fluid ChromatographyDocument6 pagesDetermination of The Aromatic Content and Polynuclear Aromatic Content of Diesel Fuels and Aviation Turbine Fuels by Supercritical Fluid ChromatographyahmedNo ratings yet

- Biometric Authentication - Person Identification Using Iris RecognitionDocument5 pagesBiometric Authentication - Person Identification Using Iris RecognitionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Definition of LiberalizationDocument5 pagesDefinition of LiberalizationFiles DownloadNo ratings yet

- Protestant ReformationDocument5 pagesProtestant Reformationgreens rovaNo ratings yet

- Simple and Compound Sentences QuizDocument1 pageSimple and Compound Sentences Quizfrancis.mrs75% (8)

- Appendix ADocument3 pagesAppendix ANaeemo IraqiNo ratings yet