Professional Documents

Culture Documents

Design of Staircase - 1 Data:: Safe in Deflection

Uploaded by

Uttam Raj SutraveOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Staircase - 1 Data:: Safe in Deflection

Uploaded by

Uttam Raj SutraveCopyright:

Available Formats

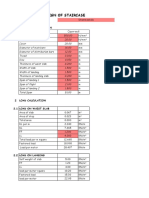

DESIGN OF STAIRCASE - 1

Data:

100 N/mm

2

Permissible Compressive Strength of Concrete (fck)=

Characteristic Strength of Steel (fy) = 415 N/mm2

Density of Concrete = 25 kN/m3

Riser R = 150 mm

Tread T = 300 mm

Clear length of the Staircase = 4.5 m

Length of the first Landing = 0m

Length of the second Landing = 2m

Width of the flight slab = 1.5 m

Width of the support = 0.23 m

Thickness of the Waist Slab = 0.175 m Safe in deflection

Loads

Dead Loads:

Waist slab section = sqrt(R2+T2)/T = 1.12 mm2

Load due to waist slab on slope per sq.m. area = 4.38 kN/m2

Load due to waist slab on plan per sq.m. area = 4.89 kN/m2

Load due to Step Section = 1.88 kN/m2

Load due to floor finish = 3.00 kN/m2

Handrail = 0.25 kN/m2

Dead Load per sq.m = 10.02 kN/m2

Live Load per sq.m = 4.0 kN/m2

Total Load = 14.02 kN/m2

Factored Load , W = 21.02 kN/m2

Width Of the Slab = 1.5 m

Total Factored Load for the Width Of the Slab = 31.54 kN/m

Loads on landing slab =

Load due to waist slab on plan per sq.m. area = 4.38 kN/m2

Load due to floor finish = 2.00 kN/m2

Handrail = 0.25 kN/m2

Live Load on landing = 4.0 kN/m2

Total Load = 10.63 kN/m2

Factored Load , W = 15.94 kN/m2

Total Factored Load for the Width Of the Slab = 24.00 kN/m2

31.54

24.00 24.00

A B

0.115 2.115 m

2.50 m

4.73 m

RA = 70.17kN RB = 62.2kN

Total load, W = 132.37 kN

Reaction at support B, RB = 62.20 kN

Reaction at support A, RA = 70.17 kN

Max. B.M. will occur at the section where shear force is minimum or zero.

Zero S.F. section from support B = 2.450 m

0.99

Max. B.M. = 47.96 kN.m

Required effective depth = 48 mm

Available effective depth = 149 mm

Mu/bd 2 = 1.44

Required percentage of steel, pt = 0.406 %

Area of steel required, Ast = 605 mm2

Diameter of the bar = 12 mm

Area of one bar, ast = 113 mm2

Spacing of the bars required = 187 mm

Spacing of the bars provided = 150 mm

Area of the steel provided = 754 mm2

% of steel provided = 0.506 %

Hence, Provide 12 mm Dia. Bars @ 150mm c/c.

Distribution Reinforcement Required = 0.12% of

gross C/S area = 210 mm2

Diameter of the bar = 8 mm

Area of one bar, ast = 50.27 mm2

Spacing of the bars = 239 mm

Spacing of the distribution bars = 20 mm

Area of the steel provided = 2513 mm2

% of steel provided = 1.12 %

Hence, Provide 8 mm Dia. Bars @ 20mm c/c.

Check for shear

Fac. Shear Force, Vu 70.17 kN

% of longitudinaltensile Steel, P 0.506 %

Shear strength of concrete, tc 0.54 N/mm2

Table 13 of IS-456-1978 (page 116)

Nominal Shear stress, tv = Vu / b * d 0.31 N/mm2

Safe in shear

Max. Shear stress tcmax

Table 14 of IS-456-1978 (page 116) = 6.3 N/mm2

Shear to be resisted by shear,

Vus= Vu - tc * b * d = 70 kN

No of legs = 2

Dia. of vertical stirrups = 8 mm

Area of stirrups ( Asv ) = 101 mm2

Check for Deflection

Length of effective span = 4.73 m

Actul l/d ratio (Provided) = 31.7 6.6278431

Type of support = 3

Basic l/d ratio = 26

1. Cantilever, 2. Simply Supported,

3. Continuous

Required % of tension reinforcement

Service stress, = 0.506 %

fs = 0.58*415*(Required steel/Provided

steel) = 193 N/mm2

Modification factor for tension reinforcement, 1/

[0.225+0.00322*fs+0.625 log10(pt) ] = 1.5

Allowable deflection after correction = 39.28

Safe in deflection

Design of landing Beam

Width Of the Landing Beam = 230 mm

Slab thicknesss = 175 mm

Depth of the Landing Beam without slab thicknes = 450 mm

Depth Of the Landing Beam = 625 mm

Effective Depth = 590 mm

Span of the Landing Beam = 3.00 m

Unfactored load on the landing beam = 44.12 kN/m

Consider 9" Thick Wall Load = 6.00 kN/m

Self Weight Of the Beam = 3.59 kN/m

Total Load On the Landing Beam = 53.72 kN/m

Maximum support facored moment = 48.35 kNm

Maximum span factored moment = 45.32 kNm

Reinf. At support

Mu/bd2 = 0.60 N/mm2

Required percentage of Steel = 0.169 %

Area Of Steel (pt*b*d/100) = 243 mm2

Provide Diameter Of the Bottom Bar = 20 mm

Area of each bottom bar = 314.16 mm2

Required no of bars = 0.77 Nos

Provided no of bars = 3 Nos

Reinf. At span

Mu/bd2 = 0.57

Required percentage of Steel = 0.158 %

Area Of Steel (pt*b*d/100) = 227 mm2

Provide Diameter Of the Bottom Bar = 20 mm

Area of each bottom bar = 314.16 mm2

No of span bars required = 0.72 Nos

Provided no of span bars = 3 Nos

Design for shear :

Fac. Shear Force ( Vu ) 120.86 kN

% of longitudinaltensile Steel ( P ) 0.200 %

Shear strength of concrete ( tc ) 0.35 N/mm2

Table 13 of IS-456-1978 (page 116)

Nominal Shear stress ( tv ) = Vu / b * d 0.89 N/mm2

Shear reinf. is required

Max. Shear stress tcmax

Table 14 of IS-456-1978 (page 116) = 6.3 N/mm2

Shear to be resisted by shear,

Vus= Vu - tc * b * d = 73 kN

No of legs = 2

Dia. of vertical stirrups = 10 mm

Area of stirrups ( Asv ) = 157 mm2

Check for max. spacing :

Max. allowble spacing is least of the following:

1. 300mm = 300 mm

2. 0.75 times the effective depth of beam = 443 mm

3. Spacing from min.shear reinforcement = 456 mm

Max. Allowble spacing of stirrups, Smax = 300 mm

Provided spacing of stirrups, S = 115.12 mm

Check for Deflection :

Max def = 5*w*l^4/384*E*I

E = 50000

I = 3936430833

Def = 0.28784825

Allowable del = l/325

= 9.23076923

safe

in deflection

33.55935

You might also like

- Faster and Cheaper - How Ride-Sourcing Fills A Gap in Low-Income Los Angeles NeighborhoodsDocument29 pagesFaster and Cheaper - How Ride-Sourcing Fills A Gap in Low-Income Los Angeles NeighborhoodsSam StecklowNo ratings yet

- Visualizing Geology 4th Edition Murck Test BankDocument29 pagesVisualizing Geology 4th Edition Murck Test Bankazuragwencr8ud100% (24)

- Open Well Staircase: 1. Design DataDocument7 pagesOpen Well Staircase: 1. Design DataEr Saroj Paudel100% (1)

- RoE - T9 & T10 Research v.2Document1 pageRoE - T9 & T10 Research v.2Susa Na100% (1)

- Suction Pile and FoundationDocument19 pagesSuction Pile and FoundationhaydarburedahNo ratings yet

- Staircase Isolated Tread TypeDocument9 pagesStaircase Isolated Tread TypeNishan GajurelNo ratings yet

- Staircase Isolated Tread TypeDocument9 pagesStaircase Isolated Tread TypeNishan GajurelNo ratings yet

- Combined Footing CheckDocument34 pagesCombined Footing ChecksudarshanNo ratings yet

- Staircase ManualDocument4 pagesStaircase ManualSakar ShresthaNo ratings yet

- RCD Course Work PDFDocument60 pagesRCD Course Work PDFSaciid LaafaNo ratings yet

- Stair Case Design: Say, 180 MM 164 MMDocument3 pagesStair Case Design: Say, 180 MM 164 MMShashankSinghNo ratings yet

- Calculation On Sizing of SlabDocument20 pagesCalculation On Sizing of SlabazhimsyammelNo ratings yet

- StructuresDocument4 pagesStructuresSada SanjayNo ratings yet

- Design of pile cap - PC2 (For 750x300 column) a Φ/5 a: cu 2 m y 2 mDocument8 pagesDesign of pile cap - PC2 (For 750x300 column) a Φ/5 a: cu 2 m y 2 mtheunknown076No ratings yet

- Design Data: Hostel Building Kaaf Uni Danniel Pascal StairDocument5 pagesDesign Data: Hostel Building Kaaf Uni Danniel Pascal StairDENCONo ratings yet

- Design Data: Design of Floor Slab ContinousDocument12 pagesDesign Data: Design of Floor Slab ContinousMohit VermaNo ratings yet

- Design ProjectDocument36 pagesDesign Projectveenabalu20No ratings yet

- 4.beam Design Singly and DoublyDocument10 pages4.beam Design Singly and DoublyReuben James BangaoilNo ratings yet

- Retaining WallDocument41 pagesRetaining Wallp_ignatiusNo ratings yet

- Slab Design FFDocument17 pagesSlab Design FFSivaAgathamudiNo ratings yet

- Calculation NoteDocument10 pagesCalculation NoteJay EvansNo ratings yet

- F1Document16 pagesF1engineerkranthi4055No ratings yet

- One Way Slab DesignDocument4 pagesOne Way Slab DesignMario FeghaliNo ratings yet

- Wind Load Calculation As Per IS 875 Part 3-2015 ProblemDocument9 pagesWind Load Calculation As Per IS 875 Part 3-2015 ProblemMahamadali DesaiNo ratings yet

- Structure Analysis&Design Report FinalDocument38 pagesStructure Analysis&Design Report FinalAbdulFatah El-falah100% (1)

- Cantilever SlabDocument5 pagesCantilever SlabMd Humayun Kabir100% (1)

- XXXXX Grid Slab - Admin BuildingDocument3 pagesXXXXX Grid Slab - Admin Buildingmrprabhu16No ratings yet

- Basement Wall DesignDocument2 pagesBasement Wall DesignArindam RoyNo ratings yet

- Analysis and Design of Shear WallsDocument24 pagesAnalysis and Design of Shear WallsRkkodi100% (3)

- Design Drawing Practice On Rectangular Combined Footing Numerical 2 PDFDocument8 pagesDesign Drawing Practice On Rectangular Combined Footing Numerical 2 PDFsm31No ratings yet

- Design ExamplesDocument12 pagesDesign ExamplesBrajesh Suman100% (1)

- Slab DesignDocument1 pageSlab DesignMadhu SudhanNo ratings yet

- Staircase Design - DharmashalaDocument4 pagesStaircase Design - DharmashalarahulNo ratings yet

- DG - Slab Design SDocument7 pagesDG - Slab Design Ssaaz adil100% (1)

- Design of Single-Pitched Roof Truss: Structural FormDocument10 pagesDesign of Single-Pitched Roof Truss: Structural FormRoshan KejariwalNo ratings yet

- Design of Lift Wall: Axial LoadDocument3 pagesDesign of Lift Wall: Axial LoadSavithri Murthy50% (2)

- S2 - Floor / Roof: Design of Two - Way Slab With Provision For Torsion at CornersDocument2 pagesS2 - Floor / Roof: Design of Two - Way Slab With Provision For Torsion at CornersMuhammed Sabah100% (1)

- Stair CaseDocument5 pagesStair CaseAnand3101No ratings yet

- 1.preliminary DESIGNDocument7 pages1.preliminary DESIGNSandip Paudel100% (1)

- Continuous BeamsDocument324 pagesContinuous BeamsKARTHIK SGNo ratings yet

- Input Data in Green Cells: FootingDocument3 pagesInput Data in Green Cells: FootingRenvil PedernalNo ratings yet

- UGWT DesignDocument2 pagesUGWT DesignZain Saeed100% (1)

- Wind LoadDocument6 pagesWind LoadRafaArdiSyahrezaNo ratings yet

- CACUALATION - (CORN Receiving) - Edit PDFDocument110 pagesCACUALATION - (CORN Receiving) - Edit PDFTrần TiếnNo ratings yet

- Design of Staircase Practical ExampleDocument24 pagesDesign of Staircase Practical ExamplePralhad KoreNo ratings yet

- Example 1 - Staircase Design PDFDocument2 pagesExample 1 - Staircase Design PDFHaziq Senin80% (5)

- L Footing Design ProgramDocument5 pagesL Footing Design ProgramTariku DessuNo ratings yet

- RC One Way Slab Design (ACI318-05)Document2 pagesRC One Way Slab Design (ACI318-05)emoriderNo ratings yet

- Footing DesignDocument4 pagesFooting DesignpnbastolaNo ratings yet

- Plinth Beams DesignDocument24 pagesPlinth Beams DesignRathinavel VenkateshwaranNo ratings yet

- Design of Simply Supported One Way SlabDocument15 pagesDesign of Simply Supported One Way SlabNikhil100% (2)

- Footing Design As Per BS 8110 PDFDocument1 pageFooting Design As Per BS 8110 PDFBobby A MathewNo ratings yet

- Stepped FootingDocument12 pagesStepped FootingV.m. RajanNo ratings yet

- Steel Column Axial LoadsDocument2 pagesSteel Column Axial LoadsGihan Chathuranga100% (1)

- Single Column FootingDocument6 pagesSingle Column Footingtopukuet100% (1)

- Case Study ppt11Document25 pagesCase Study ppt11WHATS APP STATUSNo ratings yet

- IAT-IV Question Paper With Solution of 18CV72 Design of RC and Steel Structural Elements Feb-2022-Sreelakshmi GopalakrishnanDocument29 pagesIAT-IV Question Paper With Solution of 18CV72 Design of RC and Steel Structural Elements Feb-2022-Sreelakshmi GopalakrishnanSrikanth ReddyNo ratings yet

- Example 5.1-BeamDocument4 pagesExample 5.1-BeamNur Alia NajwaNo ratings yet

- Isolated Footing Design: Foundation Type: IFDocument7 pagesIsolated Footing Design: Foundation Type: IFBhuwan JoshiNo ratings yet

- Footing Design According To BS8110 CodeDocument4 pagesFooting Design According To BS8110 CodeMohit VatsNo ratings yet

- Footing Design According To BS8110 CodeDocument4 pagesFooting Design According To BS8110 CodePre SheetNo ratings yet

- A (Isolated Footing)Document11 pagesA (Isolated Footing)innovationNo ratings yet

- Design of Square FootingDocument10 pagesDesign of Square Footingasif billalNo ratings yet

- RAFT DESIGN For Node No'sDocument73 pagesRAFT DESIGN For Node No'ssaiNo ratings yet

- Project EstimateDocument23 pagesProject EstimateUttam Raj SutraveNo ratings yet

- Updated GEO TECHNICAL LABORATORY FinalDocument177 pagesUpdated GEO TECHNICAL LABORATORY FinalUttam Raj SutraveNo ratings yet

- Box Culvert DesignDocument22 pagesBox Culvert DesignUttam Raj Sutrave100% (1)

- Concrete Lab ManualDocument146 pagesConcrete Lab ManualUttam Raj SutraveNo ratings yet

- Design of Bolted Gusset Base OF COLUMN (FOR HEAVELY LOADED COLUMS)Document5 pagesDesign of Bolted Gusset Base OF COLUMN (FOR HEAVELY LOADED COLUMS)Uttam Raj SutraveNo ratings yet

- Bracket ConnectionDocument4 pagesBracket ConnectionUttam Raj SutraveNo ratings yet

- Circular WaveguideDocument19 pagesCircular WaveguideLam DinhNo ratings yet

- VedicReport2 28 202412 53 08PMDocument55 pagesVedicReport2 28 202412 53 08PM처곧ᄉJimmyNo ratings yet

- Chap 6 MCQDocument3 pagesChap 6 MCQMahad SheikhNo ratings yet

- Constructivism in Instrumental Music EducationDocument12 pagesConstructivism in Instrumental Music Educationapi-416613415No ratings yet

- Persentasi Luwak CoffeeDocument36 pagesPersentasi Luwak CoffeeMukti LestariNo ratings yet

- Your Initial Task. Find Out What's in Me!Document6 pagesYour Initial Task. Find Out What's in Me!Earl MontecastroNo ratings yet

- Clutch ComponentsDocument19 pagesClutch ComponentsCecilia Gil60% (5)

- Speech Analysis Guidelines: The ContentDocument1 pageSpeech Analysis Guidelines: The ContentChristian MorenoNo ratings yet

- Defence10 BookDocument58 pagesDefence10 BookYash ChanneNo ratings yet

- Thesis Topics On Social EntrepreneurshipDocument6 pagesThesis Topics On Social EntrepreneurshipCollegePapersToBuySingapore100% (2)

- Syeilendra Pramuditya - Example of Motivation LetterDocument1 pageSyeilendra Pramuditya - Example of Motivation LetterSyeilendra PramudityaNo ratings yet

- Tomato BankDocument67 pagesTomato Bankkmusatheek musatheekNo ratings yet

- Definition, Classification and Diagnosis of Diabetes, Prediabetes and Metabolic SyndromeDocument6 pagesDefinition, Classification and Diagnosis of Diabetes, Prediabetes and Metabolic SyndromemandaNo ratings yet

- Input OutputcrwillDocument21 pagesInput OutputcrwillAbhishek SinghNo ratings yet

- The Lateral Trochanteric Wall Gotfried 2004 PDFDocument5 pagesThe Lateral Trochanteric Wall Gotfried 2004 PDFluis perezNo ratings yet

- TOS BiologyDocument2 pagesTOS BiologyBea Noreen Ungab100% (3)

- Adenosine Deaminase: Quantitative Determination of Adenosine Deaminase (ADA) in Serum and Plasma SamplesDocument1 pageAdenosine Deaminase: Quantitative Determination of Adenosine Deaminase (ADA) in Serum and Plasma Samplesmark.zac1990No ratings yet

- Anaerobic Fermentation of Substrate With High NitrDocument9 pagesAnaerobic Fermentation of Substrate With High NitrHanna SetyoNo ratings yet

- Aubrey Jaffer: Scheme Implementation Version 5f1Document149 pagesAubrey Jaffer: Scheme Implementation Version 5f1kevinmcguireNo ratings yet

- JD Pharmacy TechnologistDocument3 pagesJD Pharmacy Technologistpeter mulilaNo ratings yet

- List of RAs UpdatedDocument12 pagesList of RAs UpdatedThe SuperstarNo ratings yet

- Masoneilan 31000 Series Rotary Control ValvesDocument12 pagesMasoneilan 31000 Series Rotary Control ValvesJuan Manuel AcebedoNo ratings yet

- Exercises For Functional AnalysisDocument10 pagesExercises For Functional AnalysisEDU CIPANANo ratings yet

- 21 Day Fix Food ListDocument1 page21 Day Fix Food Listjavi martinezNo ratings yet

- Best Python TutorialDocument32 pagesBest Python Tutorialnord vpn1No ratings yet

- Tle q4 l5 Quiz Google FormsDocument5 pagesTle q4 l5 Quiz Google FormsEdilbert Bonifacio GayoNo ratings yet