Professional Documents

Culture Documents

Warning-Signs April 12

Uploaded by

Tyron Francis0 ratings0% found this document useful (0 votes)

26 views4 pagesby chrismar

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentby chrismar

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views4 pagesWarning-Signs April 12

Uploaded by

Tyron Francisby chrismar

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Triangular Contracted Weirs or V-Notch Weirs-are often used in water

supply, wastewater and sewage systems. They consist of a sharp edged

plate with a rectangular, triangular or v-notch profile for the water flow.

Contracted Weir or Trapezoidal Contracted Weirs-Is a commonly

used weir in many irrigation districts. The weir opening has a flat bottom

and sides that have a particular slope.

Cipolletti

Rectangular Contracted Weirs- A rectangular contracted weir has

rectangular opening where the sides are straight up and down.

A contracted weir means that the ditch leading up to the weir is wider than

the weir opening itself.

Ogee Weirs- is a common weir type whose cross-sectional profile

corresponds to the shape of the underside of a sharp-crested weir nappe.

Just as the shape or trajectory of the sharp-crested weir nappe changes

with flow rate, so does the ogee crest profile.

Broad-crested Weirs-is a flat-crested structure, where the water passes

over a crest that covers much or all the channel width.

Personal and General Laboratory Safety

1. Never eat, drink, or smoke while working in the laboratory.

2. Read labels carefully.

3. Do not use any equipment unless you are trained and approved as a user by your

instructor.

4. If you have long hair or loose clothes, make sure it is tied back and confined.

5. Keep the work area clear of all materials except those needed for your work. Coats

should be hung in the hall or placed in a locker. Extra books, purses, etc. should be kept

away from equipment that requires air flow or ventilation to prevent overheating.

6. Equipment failures – If a piece of equipment fails while being used, report it immediately

to your lab assistant or tutor. Never try to fix the problem yourself because you could

harm yourself and others.

7. Clean up your work area before leaving.

8. Wash hands before leaving the lab and before eating.

9. Never do unauthorized experiments.

10. Do not leave an on-going experiment unattended.

11. Maintain unobstructed access to all exits, fire extinguishers, electrical panels, emergency

showers, and eye washers.

12. Do not put unwanted materials inside the flume.

13. Do not lean on the acrylic glasses of the trainer.

14. Horse playing is not allowed within the trainer’s distance.

BEFORE THE LABORATORY EXPERIMENT

1. Start by familiarizing yourself with the laboratory equipment, particularly with the safety

conditions and procedures and learn how to stop the trainer in case of an emergency.

2. Prepare all the measuring devices to be used.

3. Check mechanical and electrical damages.

DURING THE LABORATORY EXPERIMENT

1. Fill the water tank with enough water. Stand by one or two pails of water in case the

there’s a shortage of water in the tank.

2. Check if the check valve is tightly fastened. And check if the valve is closed.

3. Switch on all the breaker in the control panel.

4. Plug the trainer in the outlet.

5. Ready the materials like the weirs

6. Press the Start/Stop button in the panel.

7. Write down the results.

AFTER THE LABORATORY EXPERIMENT

1. Press the stop button of the pump in the HMI.

2. Press the Start/Stop button the panel.

3. Switch off the all the circuit breaker in the control panel.

4. Drain the water in the storage tank by opening the valve in the tank.

5. Drain also the water in the inlet U shape tank by opening the valve in the top part of the

storage tank.

6. Drain the water inside the rectangular flume and discharge U shape tank by using

manually pump.

7. Disconnect the main plug of the trainer from the power outlet.

Hazards and Safety Precautions

This part of the chapter deals with safety procedures in operating flow measurement

trainer.

Electrical Hazards

1.) Improper Grounding

Prevention:

Electrical equipment must be properly grounded.

Grounding reduces the risk of being shocked.

2.) Inadequate Wiring

Prevention:

Used properly rated extension cords.

Make sure your power tools are being used with a properly rated extension

cord.

3.) Damage Insulation

Prevention:

Never use tools or extension cords with damaged insulation.

Never attempt to repair a damaged cord with tape.

Insulation prevents conductors from contacting each other or you.

4.) Overloaded Circuits

Prevention:

Never overload an outlet.

Use proper circuit breaker.

5.) Damaged tools and Equipment

Prevention:

Do not use and electric tools that are damaged.

You might also like

- EE Lab Manual for Mechanical Engineering StudentsDocument64 pagesEE Lab Manual for Mechanical Engineering Studentsbhavanimurugaramalin33% (3)

- Laboratory Practice Safety RulesDocument4 pagesLaboratory Practice Safety RulesGetahun Shanko KefeniNo ratings yet

- EM-I Lab Manual 28.10.08 LatestDocument82 pagesEM-I Lab Manual 28.10.08 Latestjoe2509100% (6)

- EMI Lab ManualDocument81 pagesEMI Lab Manualkiran_y2No ratings yet

- Ac12 20181203 PDFDocument12 pagesAc12 20181203 PDFGareth LloydNo ratings yet

- Bialetti Mokona CF40 - ULDocument68 pagesBialetti Mokona CF40 - ULallegro1100No ratings yet

- Air Station Safety GuideDocument304 pagesAir Station Safety GuideValerie Ilari MartiniNo ratings yet

- Lab 1_safety and precaution.asdDocument4 pagesLab 1_safety and precaution.asdak98faqNo ratings yet

- Lab SafetyDocument7 pagesLab Safetypknzdjr4ncNo ratings yet

- Manual de Un NebulizadosDocument14 pagesManual de Un NebulizadosPaulNo ratings yet

- EM-II Lab Manual 28.10.08 LatestDocument72 pagesEM-II Lab Manual 28.10.08 LatestPakala YedukondaluNo ratings yet

- Owner's Manual Bedienungsanleitung Mode d'emploi Manual de instrucciones Manual do Proprietário Manuale di istruzioni Руководство пользователяDocument20 pagesOwner's Manual Bedienungsanleitung Mode d'emploi Manual de instrucciones Manual do Proprietário Manuale di istruzioni Руководство пользователяYuri Peres FrançaNo ratings yet

- Electrical Machines Lab ManualDocument68 pagesElectrical Machines Lab Manualgopi_90550% (2)

- TM-127 Collet Tube PullerDocument18 pagesTM-127 Collet Tube PullerKaruNo ratings yet

- Instructions for use WASHING MACHINEDocument60 pagesInstructions for use WASHING MACHINETiberiu IonescuNo ratings yet

- Masina Za Ves - UputstvoDocument84 pagesMasina Za Ves - UputstvoHamza MavricNo ratings yet

- Washing machine manual: installation, use & troubleshootingDocument30 pagesWashing machine manual: installation, use & troubleshootingrohitpatil999No ratings yet

- Evaporative Cooler User ManualDocument12 pagesEvaporative Cooler User ManualFebin JosephNo ratings yet

- Drop Shape Humidifier ManualDocument12 pagesDrop Shape Humidifier ManualNitika13No ratings yet

- EWF 1674 FDW User Manual: en Washing MachineDocument24 pagesEWF 1674 FDW User Manual: en Washing MachineAnonymous QNZR7iVNo ratings yet

- Owner'S Manual Manuel Du Propriétaire Manual Del PropietarioDocument44 pagesOwner'S Manual Manuel Du Propriétaire Manual Del PropietarioDorvanNo ratings yet

- Manual LavavajillasDocument9 pagesManual LavavajillasEsteban de EchevarríaNo ratings yet

- Getting Started?: EasyDocument36 pagesGetting Started?: EasyThe secret TDMerNo ratings yet

- DeLonghi ManualDocument12 pagesDeLonghi ManualthomasdqtNo ratings yet

- Greenworks 21142 Power Head Manual EDocument24 pagesGreenworks 21142 Power Head Manual ETim EvansNo ratings yet

- LG Multi Type Air Conditioner Owner's ManualDocument28 pagesLG Multi Type Air Conditioner Owner's ManualACERGYNo ratings yet

- LG Multi Type Air Conditioner: Owner'S ManualDocument27 pagesLG Multi Type Air Conditioner: Owner'S ManualVardhan PatilNo ratings yet

- Electrical Safety EssentialsDocument28 pagesElectrical Safety EssentialsHariharan MuthukrishananNo ratings yet

- 9000 SeriesDocument48 pages9000 SeriesKarolína GalgonkováNo ratings yet

- Lab SafetyDocument3 pagesLab SafetyAshrafAtallaNo ratings yet

- Aquareef200 Instructions Lowres 000Document12 pagesAquareef200 Instructions Lowres 000thunderhossNo ratings yet

- Safety in SignallingDocument91 pagesSafety in SignallingVikas Srivastav100% (3)

- USER'S GUIDE: ESSENTIALS FOR YOUR NEW TVDocument82 pagesUSER'S GUIDE: ESSENTIALS FOR YOUR NEW TVAixy RiveraNo ratings yet

- Seiki Manual SE22HY01Document24 pagesSeiki Manual SE22HY01matwan29No ratings yet

- GB FR de Es PT TR PDFDocument72 pagesGB FR de Es PT TR PDFfaac88No ratings yet

- HLC 723G8 - OperatorsManual (B Thal) CDocument213 pagesHLC 723G8 - OperatorsManual (B Thal) CHw XuNo ratings yet

- Workshop Practice I ManualDocument31 pagesWorkshop Practice I ManualGetahun shankoNo ratings yet

- Samsung Frontier WasherDocument88 pagesSamsung Frontier Washerpetre333No ratings yet

- Manual - Electrolux Wash MachineDocument40 pagesManual - Electrolux Wash Machinemcthomaz01No ratings yet

- Denon HD2500Document30 pagesDenon HD2500a29057No ratings yet

- Rotating Equipment SafetyDocument34 pagesRotating Equipment SafetySuchismita Bhattacharya Bhaumik0% (1)

- Chipping HammerDocument4 pagesChipping HammerDwi Agung AriyonoNo ratings yet

- ESL 5201LO User Manual: en DishwasherDocument20 pagesESL 5201LO User Manual: en DishwasherMarius BaltariuNo ratings yet

- GISD - Maintenance Safety RulesDocument15 pagesGISD - Maintenance Safety RulesHarry Wart WartNo ratings yet

- Lab 4 Simulation - Group6 - DJJ40153Document10 pagesLab 4 Simulation - Group6 - DJJ40153Wani RizalNo ratings yet

- AEG Chillflex Aircon User ManualDocument92 pagesAEG Chillflex Aircon User ManualStef AnNo ratings yet

- HLC-723G8 OperatorsManual (STD) CDocument204 pagesHLC-723G8 OperatorsManual (STD) CHw XuNo ratings yet

- SOP SMB - 050.1 - Using A Rotory Evaporator DF NS 0614Document4 pagesSOP SMB - 050.1 - Using A Rotory Evaporator DF NS 0614Kimia AsikNo ratings yet

- ECE 1101 Lab ManualDocument45 pagesECE 1101 Lab Manualnbha0% (1)

- Air Conditioner: Owner'S ManualDocument21 pagesAir Conditioner: Owner'S Manualn505xNo ratings yet

- Ultimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsFrom EverandUltimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsRating: 3 out of 5 stars3/5 (8)

- Ultimate Guide: Plumbing, 4th Updated EditionFrom EverandUltimate Guide: Plumbing, 4th Updated EditionRating: 4 out of 5 stars4/5 (1)

- Ultimate Guide: Plumbing, Updated 5th EditionFrom EverandUltimate Guide: Plumbing, Updated 5th EditionRating: 4 out of 5 stars4/5 (3)

- Ultimate Guide: Wiring, 8th Updated EditionFrom EverandUltimate Guide: Wiring, 8th Updated EditionRating: 3.5 out of 5 stars3.5/5 (4)

- The Handy Homeowner's Repair Manual Comprehensive Guide to the Most Common DIY Home RepairsFrom EverandThe Handy Homeowner's Repair Manual Comprehensive Guide to the Most Common DIY Home RepairsNo ratings yet

- Advanced Plumbing Techniques: A Comprehensive Guide to Tackling Complex Projects for the DIY Enthusiast: Homeowner Plumbing Help, #3From EverandAdvanced Plumbing Techniques: A Comprehensive Guide to Tackling Complex Projects for the DIY Enthusiast: Homeowner Plumbing Help, #3No ratings yet

- CAD StandardsDocument21 pagesCAD StandardsYajaira Solórzano QuesadaNo ratings yet

- Sanitary Layout OkDocument26 pagesSanitary Layout OkTyron FrancisNo ratings yet

- Safety Lec 2,3,4 VR 2.0 PDFDocument96 pagesSafety Lec 2,3,4 VR 2.0 PDFTyron FrancisNo ratings yet

- Plate 6Document2 pagesPlate 6Tyron FrancisNo ratings yet

- RA 8495 - Mechanical Engineering LawDocument8 pagesRA 8495 - Mechanical Engineering LawSchuldich Schwarz100% (2)

- HVAC Duct Sizing GuideDocument91 pagesHVAC Duct Sizing GuidePrabir Bhowmik100% (1)

- Beer Management: Technological University of The Philippines - TaguigDocument5 pagesBeer Management: Technological University of The Philippines - TaguigTyron FrancisNo ratings yet

- Diwts Terms-Wps OfficeDocument1 pageDiwts Terms-Wps OfficeTyron FrancisNo ratings yet

- RA 8495 - Mechanical Engineering LawDocument8 pagesRA 8495 - Mechanical Engineering LawSchuldich Schwarz100% (2)

- Diwts Terms-Wps OfficeDocument1 pageDiwts Terms-Wps OfficeTyron FrancisNo ratings yet

- John DeweyDocument1 pageJohn DeweyTyron FrancisNo ratings yet

- Beer IngredientsDocument2 pagesBeer IngredientsTyron FrancisNo ratings yet

- Buoyancy Practice ProbleDocument3 pagesBuoyancy Practice ProbleTyron FrancisNo ratings yet

- Conveyor and Conveying System DocuDocument6 pagesConveyor and Conveying System DocuTyron FrancisNo ratings yet

- Types of TransformersDocument7 pagesTypes of TransformersTyron FrancisNo ratings yet

- Air - Envi - Hard - Copy - Docx Filename UTF-8''Air Envi HardDocument4 pagesAir - Envi - Hard - Copy - Docx Filename UTF-8''Air Envi HardTyron FrancisNo ratings yet

- William JamesDocument1 pageWilliam JamesTyron FrancisNo ratings yet

- Charles Sanders PeirceDocument1 pageCharles Sanders PeirceTyron FrancisNo ratings yet

- Project IdeasDocument1 pageProject Ideasc19138913iNo ratings yet

- ESSAR Welding Data SheetDocument2 pagesESSAR Welding Data SheetmanojkumarmurlidharaNo ratings yet

- User's Manual: EJX510A, EJX530A, EJX610A and EJX630A Absolute Pressure and Gauge Pressure TransmittersDocument51 pagesUser's Manual: EJX510A, EJX530A, EJX610A and EJX630A Absolute Pressure and Gauge Pressure TransmittersInstrumentation GCS GanaNo ratings yet

- ABB - Electrical Transmission and Distribution Reference Book PDFDocument851 pagesABB - Electrical Transmission and Distribution Reference Book PDFdavid1947No ratings yet

- KSCB It ReportDocument52 pagesKSCB It ReportShalu ShaluNo ratings yet

- REQUERIMIENTO UL498 - Del Certificado E2186Document6 pagesREQUERIMIENTO UL498 - Del Certificado E2186FRANCISCONo ratings yet

- ENG DS 1-1773870-7 Filter-Connector 0616Document74 pagesENG DS 1-1773870-7 Filter-Connector 0616VitaliyGNo ratings yet

- Full RF Signal Chains From 0Hz To 110GHzDocument4 pagesFull RF Signal Chains From 0Hz To 110GHzVanidevi ManiNo ratings yet

- Daka-r Manual 영문 Ver 1 161205Document45 pagesDaka-r Manual 영문 Ver 1 161205ngoctuyenkt1No ratings yet

- 08 0033 1b E HK Kap 11 DCDocument20 pages08 0033 1b E HK Kap 11 DCpakojidastavimNo ratings yet

- 938f PDFDocument2 pages938f PDFv_bladys100% (6)

- Is 2259 1963 PDFDocument23 pagesIs 2259 1963 PDFrohanmanimaniNo ratings yet

- Parachutist's Vertical Speed vs Time Graph ExplainedDocument15 pagesParachutist's Vertical Speed vs Time Graph ExplainedDewan Olin ChotepadaeNo ratings yet

- PHET Conductivity Simulation GuideDocument2 pagesPHET Conductivity Simulation GuidejuanNo ratings yet

- GIS Modules DE PDFDocument49 pagesGIS Modules DE PDFSrinivas K VamanamurthyNo ratings yet

- Planmeca: Power ConditionersDocument6 pagesPlanmeca: Power ConditionersAlexis A. Abreu A.No ratings yet

- Cty CP Prime Yên Bình - Vc5-ReportDocument11 pagesCty CP Prime Yên Bình - Vc5-ReportDu Khách Không GianNo ratings yet

- Chapter 2 Problems UpdatedDocument4 pagesChapter 2 Problems UpdatedDrGopikrishna PasamNo ratings yet

- Al Mezan Services LAB-131 - 14 - 07 - 20201 - SEDocument9 pagesAl Mezan Services LAB-131 - 14 - 07 - 20201 - SEHassan Ahmed KhanNo ratings yet

- BREAKDOWN COMPONENT FOR TERMINAL JAWA PHASE-1 PANELSDocument4 pagesBREAKDOWN COMPONENT FOR TERMINAL JAWA PHASE-1 PANELSsswahyudiNo ratings yet

- T7350 Installation InstructionsDocument12 pagesT7350 Installation InstructionsAmy ThompsonNo ratings yet

- AN91445 Antenna Design and RF Layout GuidelinesDocument60 pagesAN91445 Antenna Design and RF Layout GuidelinesaguiladeoroNo ratings yet

- GET-Electrical Test Paper PDFDocument10 pagesGET-Electrical Test Paper PDFatul sachanNo ratings yet

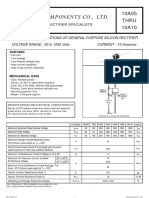

- DC Components Co., LTD.: 10A05 Thru 10A10Document3 pagesDC Components Co., LTD.: 10A05 Thru 10A10Faulhaber AdrianNo ratings yet

- MIL/MCT-2590 Charger For BB-X90/U BatteriesDocument1 pageMIL/MCT-2590 Charger For BB-X90/U Batteriesfalcom2No ratings yet

- Datasheet PDFDocument15 pagesDatasheet PDFViorel SorinNo ratings yet

- Samsung Ue40c7000 Ue46c7000 Ue55c7000 Ue40c8000 Ue46c8000 Ue55c8000 Ue65c8000 Ua40c7000 Ua46c7000 Ua55c7000 Ua40c8000 Ua46c8000 Ua55c8000 Ua65c8000 CH N79aDocument121 pagesSamsung Ue40c7000 Ue46c7000 Ue55c7000 Ue40c8000 Ue46c8000 Ue55c8000 Ue65c8000 Ua40c7000 Ua46c7000 Ua55c7000 Ua40c8000 Ua46c8000 Ua55c8000 Ua65c8000 CH N79aToni Martin SebéNo ratings yet

- User Manual: C440/XTOE Electronic Overload Relay, PROFIBUSDocument36 pagesUser Manual: C440/XTOE Electronic Overload Relay, PROFIBUSQR JcNo ratings yet

- 7000 SeriesDocument85 pages7000 SeriesBaltija MechanikasNo ratings yet

- Load Test On 3 o Squirrel Cage Induction MotorDocument4 pagesLoad Test On 3 o Squirrel Cage Induction MotoraruulvizhiyNo ratings yet