Professional Documents

Culture Documents

CV of Amiya Kumar Das

Uploaded by

Rana BiswasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CV of Amiya Kumar Das

Uploaded by

Rana BiswasCopyright:

Available Formats

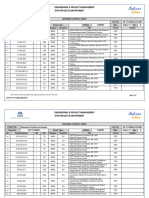

CURRICULUM VITAE

(AMIYA KUMAR DAS)

1. Proposed “Project Job Title” : Lead Designer-Process

2. Full Name of Staff Member : Mr. Amiya Kumar Das

3. Nationality : Indian

4. No. of Years of Experience : 5.5 years

5. Present Employer : IOT Design & Engineering Limited

6. Present Employment Title : Junior Manager-Process

7. Email Id : amiya.das@iotgroup.in

8. Education :

Sr. Name of Institution / Degree(s) or Diploma(s) obtained& Year of

No. University Specialization obtainment

1 University of Calcutta B.Sc.(Chemistry Hons) 2004

2 W.B.S.C.T.E. Post Diploma in Petrochemical Engg. 2007

3 Indian Institute of B.Tech in Chemical Engineering All semester

Chemical Engineers cleared.

Final result

awaited.

1. Membership in Professional :

Association

2. Other Trainings : Vocational Training at Haldia Petrochemical Ltd.

Haldia, West Bengal, India.

3. Countries of Work Experience : India

4. Employment Record :

From [Year] : 2011 To [Year] : Till date Total [Years] :< 1 Year

Employer Name IOT Design & Engineering Limited

Position Held Junior Manager-Process

From [Year] : 2007 To [Year] : 2011 Total [Years] : 4 Years

Employer Name Foster Wheeler India Private Limited

Position Held Designer-Process

5. Key Assignments / Task Data :

Sr. Brief Project Description & Duties / Responsibilities assumed in assignment

No.

Write Full Name of Proposed Staff Member Page 1 of 5

Name of Assignment or IOCL Paradip Refinery Project (EPC)

Project:

Year May 2009 to Dec 2010

Location Paradip, Orissa, India

Client Name IOCL

Main Project Features Alky-Isom, SRU & SARU

Positions held Overall Lead Process Designer in Alky-Isom, SRU & SARU unit

Activities Performed 1.Preparation of PFDs, P&IDs , MSDs & DPDTs

2. Preparing Line list, Equipment list, Valve list, Instrument list etc

1 from SPP&ID database.

3. Interfacing with Process, Piping & Instrumentation Team with other

work share offices also.

4. Ensuring all process deliverables are maintaining Quality in respect

with FW procedure/project procedure and facing discipline audit.

5. Involved in Checking of P&IDs

6. Leading, Guiding and solving the designer’s technical problems.

7. P&ID inconsistency checking.

8. Executing project procedures, specifications & implementation of

ISO.

Name of Assignment or IOCL Paradip Refinery Project (FEED)

Project:

Year Nov 2007 to Mar 2008

Location Paradip, Orissa, India

Client Name IOCL

2 Main Project Features Offsite & Utilities

Positions held Process Designer

Activities Performed 1.Designing PFD, MSD, DPTD using Microstation and P& ID using

SPPID

2.Preparing Line list.

3.P&ID inconsistency checking.

Name of Assignment or QPCC (QATAR PETROCHEMICAL COMPLEX PROJECT

Project:

Year April 2008 to Oct 2008

Location MESAIEED, QATAR

Client Name HONAM PETROCHEMICAL CORP.

3 Main Project Features Feed Project

Positions held Process Designer

Activities Performed 1.Designing PFD, MSD, DPTD using Microstation and P& ID using

SPPID

2. Preparing Line list.

3. P&ID inconsistency checking.

Name of Assignment or IN SALAH GAS SOUTHERN FIELDS PROJECT

Project

Year Oct 2008 to Mar 2009

Location Algeria

Client Name In Salah Gas

4 Main Project Features Revamp project

Positions held Lead Designer-Process

Activities Performed 1. Involved in checking of P&IDs and maintaining.

2. Guiding and solving the designer’s technical problems.

3.Designing PFD, MSD, DPDT & P&IDs using AutoCAD software

4. Executing project procedures, specifications & implementation of

Write Full Name of Proposed Staff Member Page 2 of 5

ISO.

Name of Assignment or SHELL U.K. OIL PRODUCTS LTD STANLOW

Project

Year Mar 2009 to April 2009

Location STANLOW

Client Name SHELL U.K LTD, STANLOW

5 Main Project Features Revamp project

Positions held Process Designer

Activities Performed 1. Designing PFD, MSD, DPTD using Microstation and P& ID using

SPPID

2. Preparing Line list.

3. P&ID inconsistency checking.

Name of Assignment or Karan Gas Processing Facilities

Project

Year Oct 2007 to Nov 2007

Location Saudi Arabia

Client Name Saudi Aramco

6 Main Project Features Feed Project

Positions held Process Designer

Activities Performed 1.Designing PFD, MSD, DPTD using Microstation and P& ID using

SPPID

2. Preparing Line list.

3. P&ID inconsistency checking.

Name of Assignment or CDU Preflash vessel installation to increase the CDU capacity

Project

Year 2011

Location Digboi Refinery

Client Name IOCL

Main Project Features Vessel design, Heat exchanger design, Crude pump, Flashed Crude

7 Pump design and crude line hydraulics.

Positions held Supporting Process Engineer

Activities Performed 1. Preparation of P&IDs.

2. Preparing Line list.

3. Preparation of Instrument process data sheets

4. Preparation of Equipment data sheets.

5. Participate at HAZOP study meeting.

Name of Assignment or Feasibility study and Design & Engineering for routing of Hydrogen

Project bullet’s PSV discharge to Flare Header.

Year 2011-2012

Location Digboi Refinery

Client Name IOCL

Main Project Features Checking of existing nearby flare headers’ adequacy and

identification of location of hook up point.Generation of detailed

8 specification of new PSV. Checking of adequacy of existing PSVs in

Hydrogen bullets for Flare Header (existing) back pressure.

HAZOP study of proposed modification.

Positions held Process Engineer

Activities Performed 1. Preparation of P&IDs.

2. Preparing Line list.

3. Preparation of Instrument process data sheets

4. Preparation of Feasibility Study Report.

Write Full Name of Proposed Staff Member Page 3 of 5

Name of Assignment or Study of Fire Water Network for Tank Farm area, Digboi Refinery,

Project Assam

Year 2012

Location Digboi Refinery

Client Name IOCL

Main Project Features Fire Water Network analysis

9

Positions held Suporting Engineer (Process)

Activities Performed 1. P&ID, PFD & line list.

2. Equipment list and data sheet.

3. Instrument list and data sheet.

4. C&E matrix.

Name of Assignment or Feasibility Study for Implementing MB Lal Committee

Project Recommendations in Various Tank Farms of Digboi Refinery

Year 2012

Location Digboi Refinery

Client Name IOCL

Main Project Features Feasibility Study

10

Positions held Suporting Engineer (Process)

Activities Performed 1. Preparation of TFMS scheme drawing & P&ID.

2. Preparation of Line List.

3. Instrument list

4. C&E matrix.

Name of Assignment or AUGMENTATION OF FIRE PROTECTION SYSTEM IN COMPLIANCE

Project WITH OISD 117 (LATEST EDITION) FOR NEW GRASSROOT TOPS AT

TIKRIKALAN (DELHI) AND JASIDIH (JHARKHAND)

Year 2012-13

Location TIKRIKALAN (DELHI) AND JASIDIH (JHARKHAND)

Client Name IOCL

Main Project Features Feasibility Study

Positions held Lead Engineer (Process)

Activities Performed 1. Collection of site data’s from Site visit

11 2. Preparation of FIR (First information report)

3. Preparation of GAP analysis report

4. Preparation of gap analysis report with MB Lal recommendation

5. Preparation of PFDs, P&IDs

6. Preparation of Line List, Instrument list, Equipment list.

7. Preparation of fire water and foam demand calculation, Instrument

air consumption

8. Preparation of Equipment datasheet

9. Preparation of Instrument datasheet.

6. Languages :

Write Full Name of Proposed Staff Member Page 4 of 5

Speak Read Write

English Good Good Good

Hindi Good Poor No

Bengali Good Good Good

Write Full Name of Proposed Staff Member Page 5 of 5

You might also like

- Aircraft Electrical Wiring Interconnect System (EWIS) Best PracticesDocument176 pagesAircraft Electrical Wiring Interconnect System (EWIS) Best Practicesnayapepe100% (5)

- Komatsu WB93R-2 engine repair manual sectionsDocument439 pagesKomatsu WB93R-2 engine repair manual sectionsBoyko Vasilev86% (7)

- Retail Outlet Inspection Report for M/S Raghavendra Filling StationDocument6 pagesRetail Outlet Inspection Report for M/S Raghavendra Filling StationSairam Prasad EeturiNo ratings yet

- Check Pipeline AlligmentDocument4 pagesCheck Pipeline AlligmentRana BiswasNo ratings yet

- CV For Static Equipment Design EngineerDocument8 pagesCV For Static Equipment Design Engineergenmotind1100% (3)

- Addendum No. 3 Request For Proposal No. 9118-15-5046 (October 1, 2015)Document3 pagesAddendum No. 3 Request For Proposal No. 9118-15-5046 (October 1, 2015)T.O. Nature & DevelopmentNo ratings yet

- (2015.10.02 Sub) Pls120064-Astsej-c-cat-ce-007 Rev B Anti-Corrosion PaintDocument7 pages(2015.10.02 Sub) Pls120064-Astsej-c-cat-ce-007 Rev B Anti-Corrosion PaintAnonymous UUw70xirblNo ratings yet

- PT. CG Power Systems Indonesia - Ref. ListDocument31 pagesPT. CG Power Systems Indonesia - Ref. Listbakrie46No ratings yet

- Materilal GI Pipes & FittingsDocument135 pagesMaterilal GI Pipes & FittingsVinodNo ratings yet

- Mock Up Sample Request For Backer RodDocument1 pageMock Up Sample Request For Backer RodiamsundarkNo ratings yet

- AA4Document19 pagesAA4Karthik P MuraliNo ratings yet

- Submittal Transmittal Sheet #: Project Name DB52-TH16-PQN-001 00 Submittal Title: Prequalification For ANTI TERMITEDocument1 pageSubmittal Transmittal Sheet #: Project Name DB52-TH16-PQN-001 00 Submittal Title: Prequalification For ANTI TERMITESasi KumarNo ratings yet

- K. Sivakumar's Resume for Power Plant Engineer RoleDocument4 pagesK. Sivakumar's Resume for Power Plant Engineer RoleSIVA0% (1)

- C2C BrochureDocument8 pagesC2C BrochureDarla ChavezNo ratings yet

- FEW Industrial Visit ReportDocument11 pagesFEW Industrial Visit ReportMathew JosephNo ratings yet

- 8.2.1. Monthly ReportDocument10 pages8.2.1. Monthly Reportkebarongan12No ratings yet

- WPR September 1Document101 pagesWPR September 1gulu padhanNo ratings yet

- Curriculum Vitae Piping DesignerDocument18 pagesCurriculum Vitae Piping DesignerRevankar B R ShetNo ratings yet

- Welding Procedure Specification (WPS)Document1 pageWelding Procedure Specification (WPS)Daniel ChewNo ratings yet

- Datasheets For Bucket Type StrainerDocument2 pagesDatasheets For Bucket Type StrainerbecpavanNo ratings yet

- VSA M&E DeliverablesDocument4 pagesVSA M&E Deliverablesmeeng2014No ratings yet

- Sulzer Mixpac Et. Al. v. Shanghai NSJ HardwareDocument5 pagesSulzer Mixpac Et. Al. v. Shanghai NSJ HardwarePriorSmartNo ratings yet

- Senior CAD Designer in TX Resume Daniel AndrzejewskiDocument3 pagesSenior CAD Designer in TX Resume Daniel AndrzejewskiDanielAndrzejewski0% (1)

- Check List JnNURMDocument36 pagesCheck List JnNURMshahqazwsxNo ratings yet

- Resume Piping Engineer Shadab KhanDocument3 pagesResume Piping Engineer Shadab Khanwasim92khanNo ratings yet

- Shrikant Shinde-1Document4 pagesShrikant Shinde-1Shrikant ShindeNo ratings yet

- ATIF Yasin CV Piping EngineerDocument12 pagesATIF Yasin CV Piping EngineeryasiriftikharNo ratings yet

- Mucg06m1tw - List of DocumentsDocument62 pagesMucg06m1tw - List of DocumentsKalai SelvanNo ratings yet

- FS PipingDocument317 pagesFS PipingOthman RejabNo ratings yet

- PDMS Designer PipingDocument4 pagesPDMS Designer PipingAlla VijayNo ratings yet

- IPS MBD21907 in 522 Datasheet of Emergency Relief Valve ADocument3 pagesIPS MBD21907 in 522 Datasheet of Emergency Relief Valve ANikhil KarkeraNo ratings yet

- SIAD Macchine Impianti S.p.A.: Page 1 of 4Document4 pagesSIAD Macchine Impianti S.p.A.: Page 1 of 4Fomaa ElsayedNo ratings yet

- 2093-FE-7903 Rev. CDocument34 pages2093-FE-7903 Rev. CAyush ChoudharyNo ratings yet

- ASTAVA BV Holland CatalogDocument28 pagesASTAVA BV Holland CatalogXavierNo ratings yet

- 21 13 00 Fire Fighting System, Sprinkler System and Fire ExtinguishersDocument42 pages21 13 00 Fire Fighting System, Sprinkler System and Fire ExtinguishersAdnan Ahmed KidwaiNo ratings yet

- Epcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitDocument7 pagesEpcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitKunalNo ratings yet

- CV Samir AhmedDocument4 pagesCV Samir AhmedSamir Ahmed100% (1)

- Boq r0 Reactor Gd1 and Gd2 190418Document52 pagesBoq r0 Reactor Gd1 and Gd2 190418UDayNo ratings yet

- Nyari Kerja Abroad MantapDocument5 pagesNyari Kerja Abroad Mantapandi dipayadnyaNo ratings yet

- Eil Spec For Architechture-6-75-0051 - Rev 0Document14 pagesEil Spec For Architechture-6-75-0051 - Rev 0innovativekarthiNo ratings yet

- Lokesh Naidu Resume PDFDocument4 pagesLokesh Naidu Resume PDFLokeshNaidu PudiNo ratings yet

- Sudeepmishra: Career ObjectiveDocument6 pagesSudeepmishra: Career Objectivesudeep9666No ratings yet

- Engineering & Project Management Site Projects DepartmentDocument7 pagesEngineering & Project Management Site Projects Departmentsmart_onyx17No ratings yet

- Sick Tanker Unloading PumpDocument3 pagesSick Tanker Unloading PumpSumantrra ChattopadhyayNo ratings yet

- Supplier Comments Response Sheet: Ain Tsila DevelopmentDocument22 pagesSupplier Comments Response Sheet: Ain Tsila DevelopmentZaidiNo ratings yet

- CP Control BoxDocument6 pagesCP Control BoxphuongNo ratings yet

- Junaid Mateen: Mechanical EngineerDocument2 pagesJunaid Mateen: Mechanical EngineerJunaid MateenNo ratings yet

- Arun Kumar S (Piping Design Engineer) - ResumeDocument3 pagesArun Kumar S (Piping Design Engineer) - ResumepavanNo ratings yet

- Guideline For Preparing IPDS - Instrument Process Data SheetDocument3 pagesGuideline For Preparing IPDS - Instrument Process Data Sheetbalaji krishnanNo ratings yet

- Project Punch List for JCS YAMAL LNGDocument1 pageProject Punch List for JCS YAMAL LNGAlfonNo ratings yet

- PMS Rev 0Document36 pagesPMS Rev 0rami ghorbelNo ratings yet

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsDocument6 pagesSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedNo ratings yet

- Sanjai Kumar Pandey: ResumeDocument4 pagesSanjai Kumar Pandey: ResumeHadfiNo ratings yet

- DcrerweDocument1 pageDcrerwesri9987No ratings yet

- Atirkfch-G Tat Tr4Ri: Standard Specification For Orifice Plates and FlangesDocument7 pagesAtirkfch-G Tat Tr4Ri: Standard Specification For Orifice Plates and FlangesBharat TrivediNo ratings yet

- Procedure For Preparation of Technical Bid AnalysisDocument5 pagesProcedure For Preparation of Technical Bid AnalysiskaandiNo ratings yet

- CR QapDocument2 pagesCR QapSimbu ArasanNo ratings yet

- Sample - Resume-IOCL FormatDocument5 pagesSample - Resume-IOCL FormatRajasekaran PrakasamNo ratings yet

- BIT Project EIL 91020Document41 pagesBIT Project EIL 91020Gourab KunduNo ratings yet

- Technical Documents 8787Document459 pagesTechnical Documents 8787Anonymous 3akQhQFJSL100% (1)

- PZ D CS Pi SP 015 02Document60 pagesPZ D CS Pi SP 015 02epbamdadNo ratings yet

- IOTDE CV Process Lead EngineerDocument6 pagesIOTDE CV Process Lead EngineerRana BiswasNo ratings yet

- Anuradha Sarkar: Thermal Power PlantsDocument7 pagesAnuradha Sarkar: Thermal Power PlantsRana BiswasNo ratings yet

- Online Realtime Chat1Document36 pagesOnline Realtime Chat1PRINCENo ratings yet

- To-Do ListDocument41 pagesTo-Do Listshahnwazkhanali04No ratings yet

- Anindita Pathak Nath CVDocument3 pagesAnindita Pathak Nath CVRana BiswasNo ratings yet

- Consultation_14Apr2024Document2 pagesConsultation_14Apr2024Rana BiswasNo ratings yet

- IL22388567200_Rana BiswasDocument1 pageIL22388567200_Rana BiswasRana BiswasNo ratings yet

- Receipt_01Mar2024_094127Document1 pageReceipt_01Mar2024_094127Rana BiswasNo ratings yet

- Static EquipmentDocument3 pagesStatic EquipmentRana BiswasNo ratings yet

- Bah Tour ExpDocument2 pagesBah Tour ExpRana BiswasNo ratings yet

- January 2019 February 2019: Mon Tue Wed Thu Fri Mon Tue Wed Thu FriDocument1 pageJanuary 2019 February 2019: Mon Tue Wed Thu Fri Mon Tue Wed Thu FriRana BiswasNo ratings yet

- Digital Charpy Impact Testing Machine As Per ASTM E23-Latest Edition-RejectedDocument1 pageDigital Charpy Impact Testing Machine As Per ASTM E23-Latest Edition-RejectedRana BiswasNo ratings yet

- Sr. No Name of Equipment StatusDocument2 pagesSr. No Name of Equipment StatusRana BiswasNo ratings yet

- Discr 180101285070 00MC 00177 20191016131923 PDFDocument1 pageDiscr 180101285070 00MC 00177 20191016131923 PDFRana BiswasNo ratings yet

- Sr. No Name of Equipment StatusDocument2 pagesSr. No Name of Equipment StatusRana BiswasNo ratings yet

- Artha Arathi AL: Mobile: E-MailDocument2 pagesArtha Arathi AL: Mobile: E-MailRana BiswasNo ratings yet

- Application Form Fellow F-7Document1 pageApplication Form Fellow F-7Rana BiswasNo ratings yet

- Dhruba CVDocument3 pagesDhruba CVRana BiswasNo ratings yet

- Electrical Engineer CVDocument3 pagesElectrical Engineer CVRana BiswasNo ratings yet

- Fellow - Application FormDocument8 pagesFellow - Application FormRajesh ChoudharyNo ratings yet

- Fellow - Application FormDocument8 pagesFellow - Application FormRajesh ChoudharyNo ratings yet

- Curriculum Vitaé: Academic QualificationsDocument4 pagesCurriculum Vitaé: Academic QualificationsRana BiswasNo ratings yet

- 1 Biswanath Palit: Bio-DataDocument3 pages1 Biswanath Palit: Bio-DataArindam DasNo ratings yet

- Piping Engineer: Anindya DasDocument3 pagesPiping Engineer: Anindya DasRana BiswasNo ratings yet

- Tax Point Date Description Tax Amount Net Amount: Sgst/UtgstDocument1 pageTax Point Date Description Tax Amount Net Amount: Sgst/UtgstRana BiswasNo ratings yet

- Current Royal Residences by Members of The Royal FamilyDocument19 pagesCurrent Royal Residences by Members of The Royal FamilyRana BiswasNo ratings yet

- Gmail - Your Zomato Order From Only Rolls - 03.08.19Document2 pagesGmail - Your Zomato Order From Only Rolls - 03.08.19Rana BiswasNo ratings yet

- Institution Engineers India membership contact detailsDocument1 pageInstitution Engineers India membership contact detailsRana BiswasNo ratings yet

- Ayan DuttaDocument1 pageAyan DuttaRana BiswasNo ratings yet

- Gmail - Your Zomato Order From Only Rolls - 03.08.19 PDFDocument2 pagesGmail - Your Zomato Order From Only Rolls - 03.08.19 PDFRana BiswasNo ratings yet

- Gmail - Your Zomato Order From Only Rolls - 03.08.19 PDFDocument2 pagesGmail - Your Zomato Order From Only Rolls - 03.08.19 PDFRana BiswasNo ratings yet

- Ola ride invoice for Rs. 66 from Kurla to Chedda Nagar MumbaiDocument3 pagesOla ride invoice for Rs. 66 from Kurla to Chedda Nagar MumbaiRana BiswasNo ratings yet

- Feltest Whitepaper - Correct Felt Permeability (ENG)Document6 pagesFeltest Whitepaper - Correct Felt Permeability (ENG)Engr. Waqar AliNo ratings yet

- ASME U & UM Stamp Certification ProcessDocument11 pagesASME U & UM Stamp Certification ProcessMd Anamul HoqueNo ratings yet

- OpenStage Provisioning Interface Developer's GuideDocument182 pagesOpenStage Provisioning Interface Developer's GuideEstêvão Samuel Procópio AmaralNo ratings yet

- C.B.S.E Study Material 2 (Unit-1)Document71 pagesC.B.S.E Study Material 2 (Unit-1)vikramkhatri4100% (2)

- Revision For First Term 9GCE 2010 11Document30 pagesRevision For First Term 9GCE 2010 11Anonymous 8VJhV1eI2yNo ratings yet

- PCN V19-001-484754120aDocument6 pagesPCN V19-001-484754120ajonatas Cassiano da silvaNo ratings yet

- CATALAGO ZITRON Rev 1Document16 pagesCATALAGO ZITRON Rev 1Vaibhav GuptaNo ratings yet

- SIPOCDocument7 pagesSIPOCFran JimenezNo ratings yet

- Adfl Corporate BrocheureDocument6 pagesAdfl Corporate Brocheurepranjal92pandeyNo ratings yet

- PIC Basic CourseDocument57 pagesPIC Basic Coursetermicas100% (3)

- Hydraulics Basic LevelDocument276 pagesHydraulics Basic LevelAsifa AslamNo ratings yet

- Thika Water and Sewerage Company Limited Tender Notice PDFDocument1 pageThika Water and Sewerage Company Limited Tender Notice PDFUsman ArifNo ratings yet

- Nikhil KulkarniDocument3 pagesNikhil KulkarniSumitNo ratings yet

- Predicting Bottomhole Assembly Performance: J.S. Williamson, A. LubinskiDocument13 pagesPredicting Bottomhole Assembly Performance: J.S. Williamson, A. Lubinskifaishal hafizhNo ratings yet

- Duratech 2009 Parts Manual SN Up To 0034 August 2010Document206 pagesDuratech 2009 Parts Manual SN Up To 0034 August 2010Ever RiveraNo ratings yet

- Item Description Unit QTY Rate Amount Egp. Egp. Division 2: Site Construction EarthworkDocument15 pagesItem Description Unit QTY Rate Amount Egp. Egp. Division 2: Site Construction EarthworkAmr M. AbdallahNo ratings yet

- Bombe 4Document154 pagesBombe 4Adith K PNo ratings yet

- Room Occupiency Tag in Revit Along With ScheduleDocument10 pagesRoom Occupiency Tag in Revit Along With ScheduleraviNo ratings yet

- Polymer IntroDocument15 pagesPolymer IntroYUG PRATAP SINGHNo ratings yet

- UPA Type Series BookletDocument122 pagesUPA Type Series BookletRicardo BarrosNo ratings yet

- General ISO Geometrical TolerancesDocument2 pagesGeneral ISO Geometrical TolerancesMaheshNo ratings yet

- Material TestingDocument7 pagesMaterial TestingkimsonNo ratings yet

- Inspection of Test Plan: Electrical EquipmentDocument7 pagesInspection of Test Plan: Electrical Equipmentzvlcar nainNo ratings yet

- B.tech. Civil Engineering Full Syllabus IndiaDocument118 pagesB.tech. Civil Engineering Full Syllabus IndiaAnubhav GargNo ratings yet

- Syntatic Analysis SampleDocument22 pagesSyntatic Analysis SampleSagarNo ratings yet

- FRP Technology by WeatherheadDocument20 pagesFRP Technology by WeatherheadSagarNo ratings yet

- Pool Fittings LeafletDocument20 pagesPool Fittings LeafletmohammudaphNo ratings yet